Stacking structure for vibration bodies

A vibrating body and stacking technology, which is applied in the field of stacking structures, can solve the problems of unfavorable workers' on-site work, large space occupation, and uneven workshop, so as to improve the working environment of the workshop and facilitate the work of on-site workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

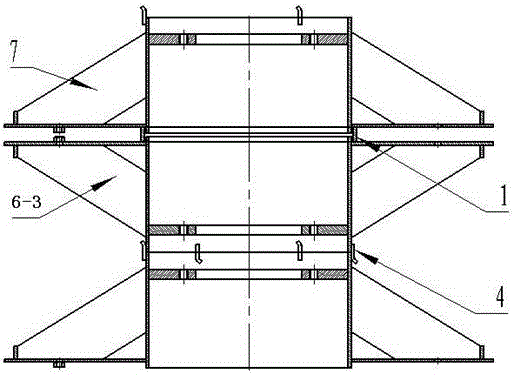

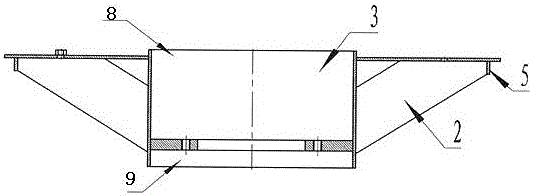

[0013] This technical solution makes the vibrating body 3 stacked up and down. In the further embodiment, the vibrating body is a vibrating body. The upper part of the vibrating body 3 is large and the lower part is small in a bowl shape. The reinforcing ring 5 is set, and the middle cylinder is 10-20 mm higher than the upper and lower planes, so that the two ends of the cylinders of the upper part 8 and the lower part 9 form a ring, and a positioning ring 1 is arranged on the upper part of the vibrating body, and the positioning ring 1 is higher than The upper ring is 30-50mm, and the periphery of the cylinder at the bottom of the vibrating body 3 is welded with positioning claws 4. At least 3 of the positioning claws 4 are evenly distributed. No offset occurs, so the vibrating body is positioned through the positioning ring 1 and the positioning claw 4. When stacking, the vibrating body 6-3 and another vibrating body 7 are stacked up and down and supported by the supporting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com