Advanced drainage and precipitation system and method for sandstone aquifer and construction method

A water layer and sandstone technology, which is applied in the field of water prevention and control in coal mines, can solve the problems of shaft wall cracking, poor stability of shaft wall deformation and deformation of inclined shafts, and achieve rapid and safe excavation and overcome repeated water and sand inrush effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] A new mine in Yuheng mining area, Shaanxi, with a designed production capacity of 10Mt / a and a service life of 95 years. The topsoil is 26.5m thick, and the Cretaceous strata are as thick as 668.5m. Among them, the average thickness of the Luohe Formation is 371.3m. It has the characteristics of large thickness, medium-strong water richness, high water pressure, poor-medium permeability and extremely heterogeneous. The main inclined shaft was originally constructed using the freezing method, but after the first exposure of the sandstone of the Luohe Formation, a water and sand inrush accident occurred (water volume 78m 3 / h), which brings great difficulties and security threats to mine construction.

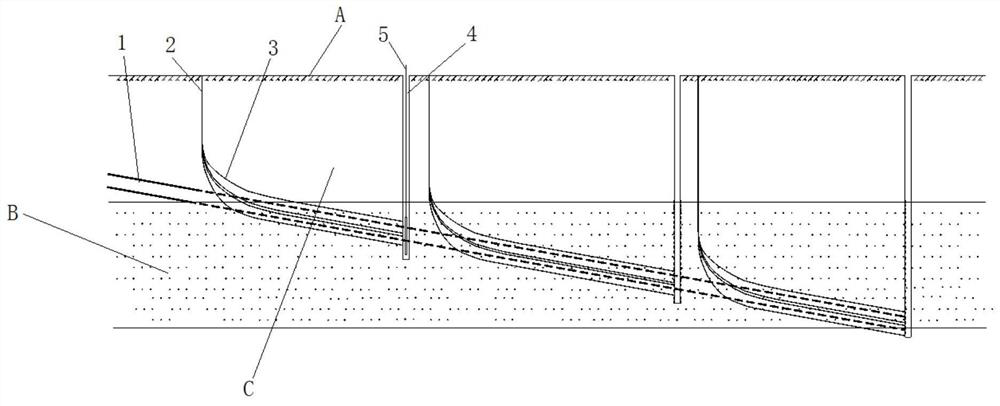

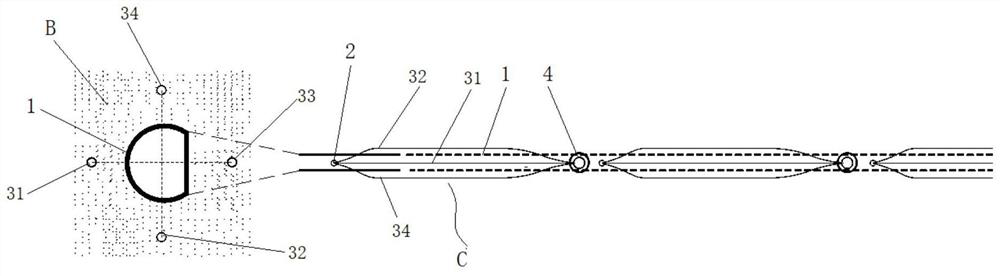

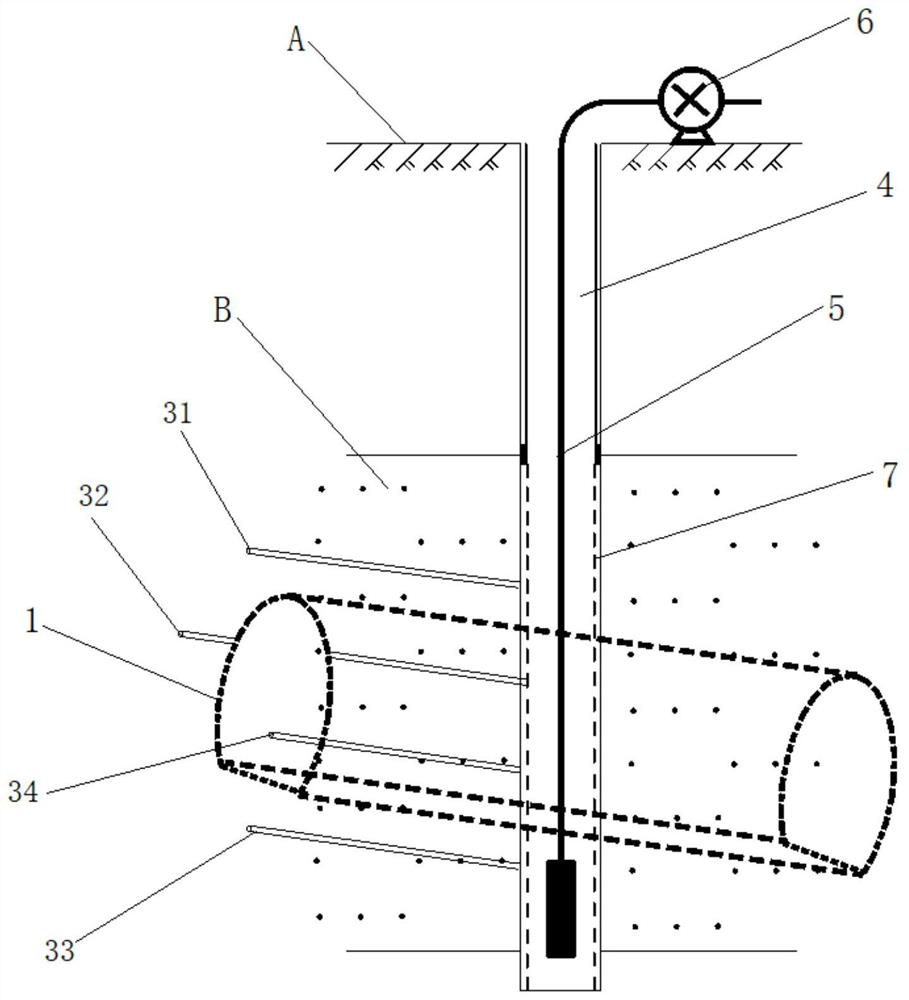

[0096] Adopt the present invention to carry out construction (referring to figure 1 , figure 2 and image 3 ), an advanced dewatering method for long-distance inclined wells passing through the thick sandstone aquifer, the steps are as follows:

[0097] Step 1): Deter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com