Mine water deep well recharge method

A mine water and deep well technology, applied in mining equipment, earthwork drilling, mining equipment, etc., can solve the problems of excessive detection of heavy metals in wastewater, failure to meet discharge standards, and impact on the surrounding environment, achieving long-term safety and environmental protection, reducing treatment costs, The effect of protecting the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

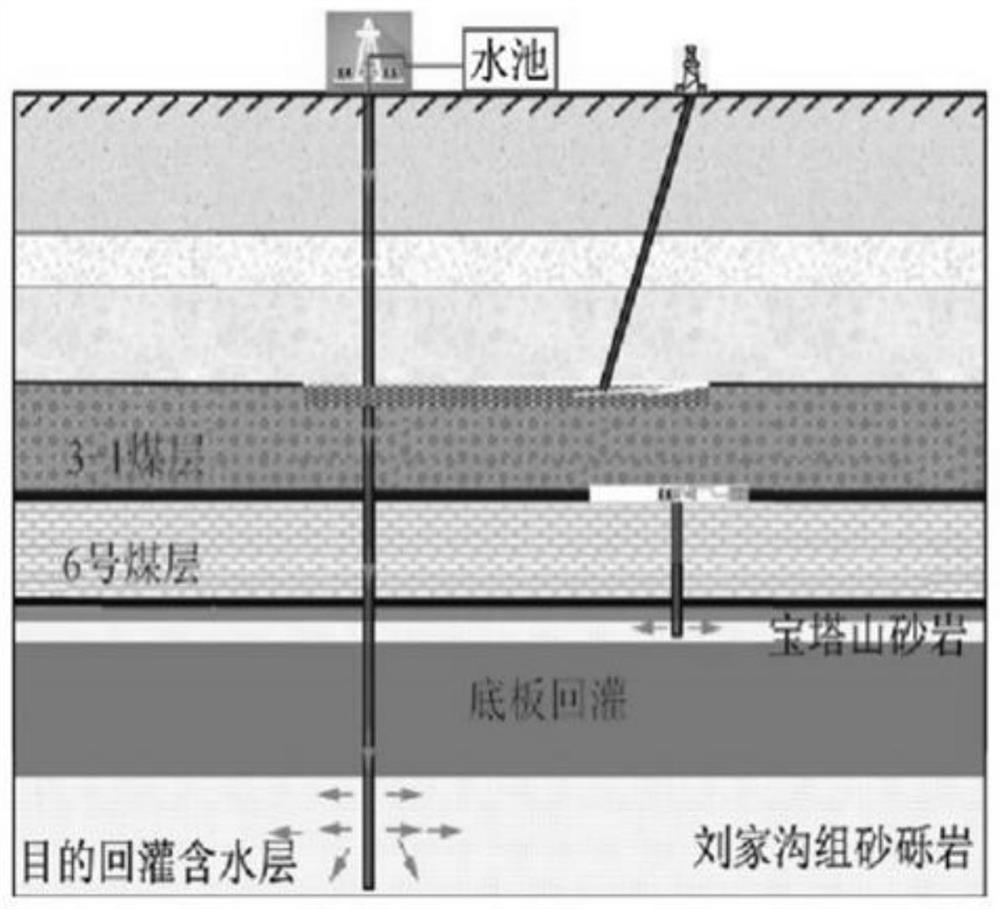

[0023] For the first specific implementation, please refer to Figure 1-3 , The present invention provides a technical scheme: a method for recharging a deep well in a mine, comprising: step 1: determining the target layer for recharging; step 2: predicting the amount of water injection; step 3: selecting the location of the recharging well; step 4: finalizing the design Pore layer and depth; Step 5: Design the well structure; Step 6: Carry out the water injection test of the recharge well to determine the recharge capacity of the target layer;

[0024] In this implementation, the recharge target layer determined in step 1 has low minimum principal stress and low fracture pressure, and the lithology of the recharge target layer is pure, the porosity and permeability conditions of the coarse sandstone section are the best, and the recharge target layer is cored The fractures are relatively developed and have a larger thickness, which is conducive to the expansion and extensio...

specific Embodiment approach 2

[0025] Specific embodiment 2, this embodiment is a further limitation of specific embodiment 1. The recharge target layer in the present invention needs to have the following characteristics: a. Low minimum principal stress and fracture pressure; b. Low density, high depth and shallow lateral difference; c. The lithology is pure, and the porosity and permeability conditions of the coarse sandstone section are the best; d. Coring fractures are relatively thicker than the developed section and e.

[0026] In this implementation, the estimated water injection amount in step 2 can be estimated according to the formula V=πR2Hφ, and V is the volume of the injected medium, m3; R is the radius of the treatment layer, R=500m (3a); H is the thickness of the treatment layer, H= 69m (69m in the section with better infiltration conditions), Φ is the porosity of the treated layer, which is taken as 7.49%.

specific Embodiment approach 4

[0027] Specific embodiment four, this embodiment is a further limitation of specific embodiment one, the linear regression method of the estimated water injection amount in the present invention:

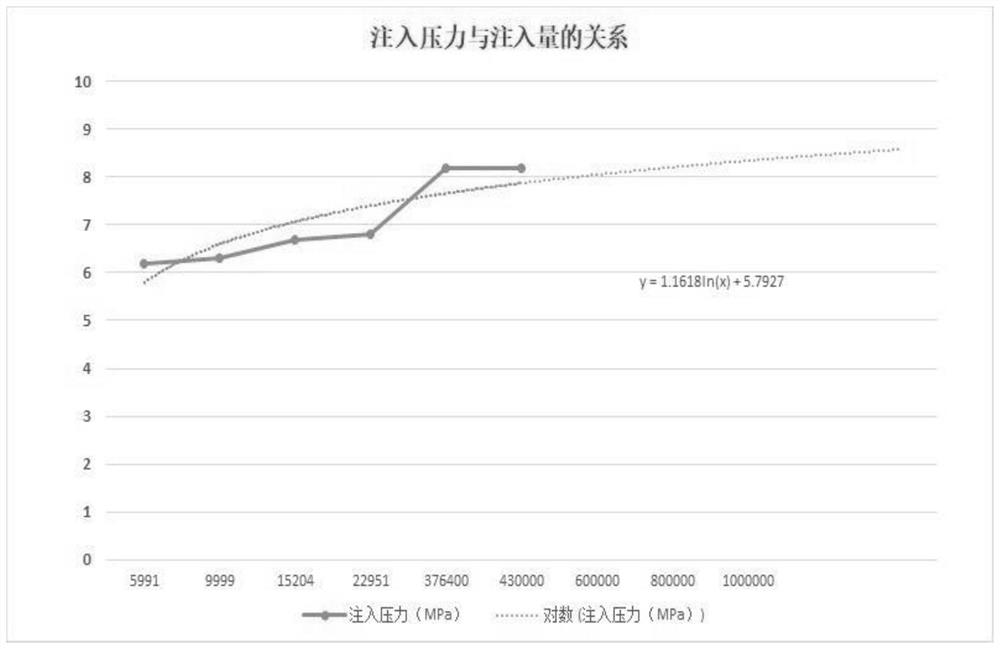

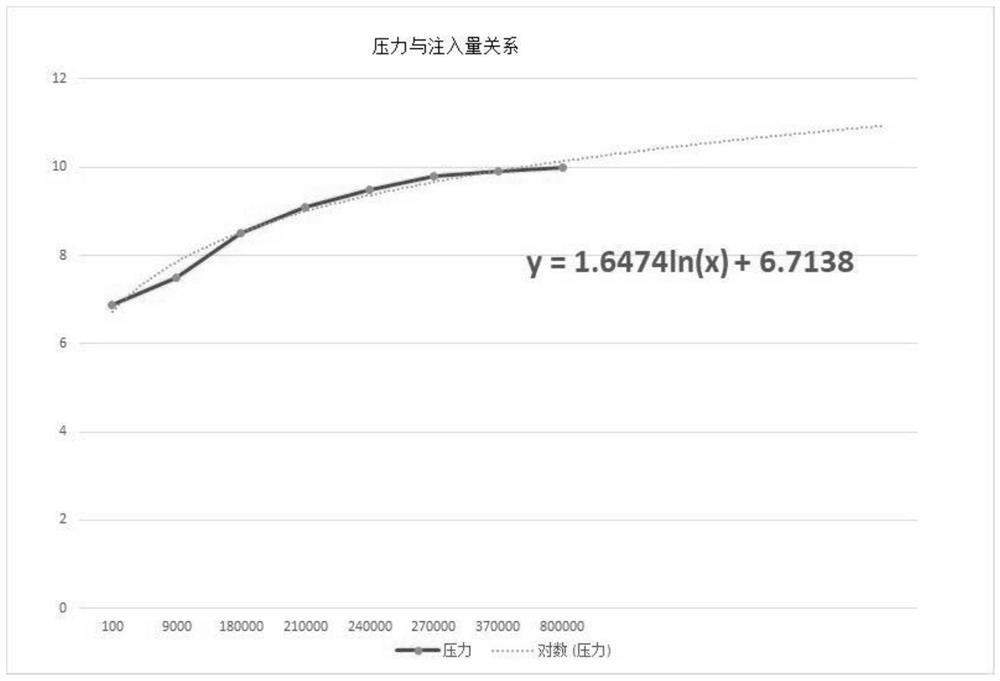

[0028] According to the logarithmic regression model established according to the water pressure test data of Well MC-1 in Mudu Chaideng Mine and Well NL-1 in Nalinhe No. 2 Well, when the water injection volume of Well MC-1 reaches 1 million m3, the corresponding water injection pressure is 8.3MPa; 1 When the water injection volume reaches 800,000 m3, the water injection pressure is 10.2MPa; the relationship between injection pressure and injection volume can be seen in detail figure 1 and figure 2 shown.

[0029] In this implementation, in step 3, the drilling trajectory at the position of the recharge well needs to maintain a certain safety distance from the underground roadway and the chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com