Fastening and production technology thereof

A production process and fastener technology, applied in the field of fasteners and their production processes, can solve problems such as inability to apply to pipes of various brands and sizes, increase equipment installation time, and inability to adjust the size of fasteners. The effect of reducing equipment installation engineering time, novel and simple structure, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

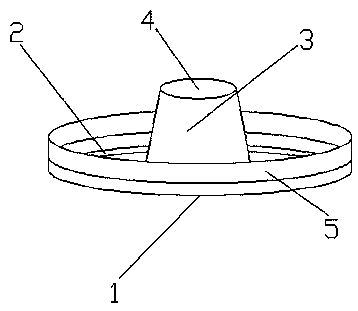

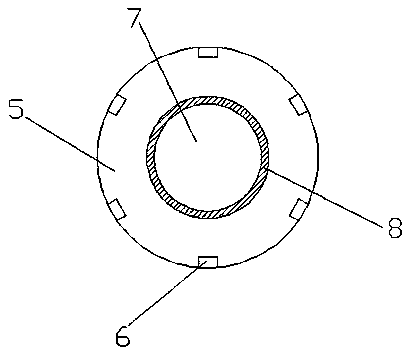

[0022] see Figure 1-2 , the present invention provides a technical solution: a fastener and its production process, including a chassis 1, the chassis 1 is provided with a fitting groove 2, a post 3, a fixing hole 4, a cover plate 5, a buckle 6, The post hole 7 and the sealing plate 8, the fitting groove 2 is located inside the chassis 1, the post 3 is fixedly connected to the middle of the chassis 1, and the fixing hole 4 is located at the post 3 Above, the cover plate 5 is fixedly connected above the chassis 1, the buckle 6 is fixedly connected to the periphery of the cover plate 5, and the post hole 7 is located in the middle of the cover plate 5, The sealing plate 8 is fixedly connected to the periphery of the post hole 7 .

[0023] The depth of the fitting groove 2 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com