Cargo transfer auxiliary device for automatic storage retrieval

A technology for auxiliary devices and goods, applied in the directions of transportation and packaging, packaging, rigid containers, etc., can solve the problems of easy dumping of goods, inconvenient measurement, and high use limitations, so as to reduce the phenomenon of dumping, reduce use limitations, and improve The effect of using reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

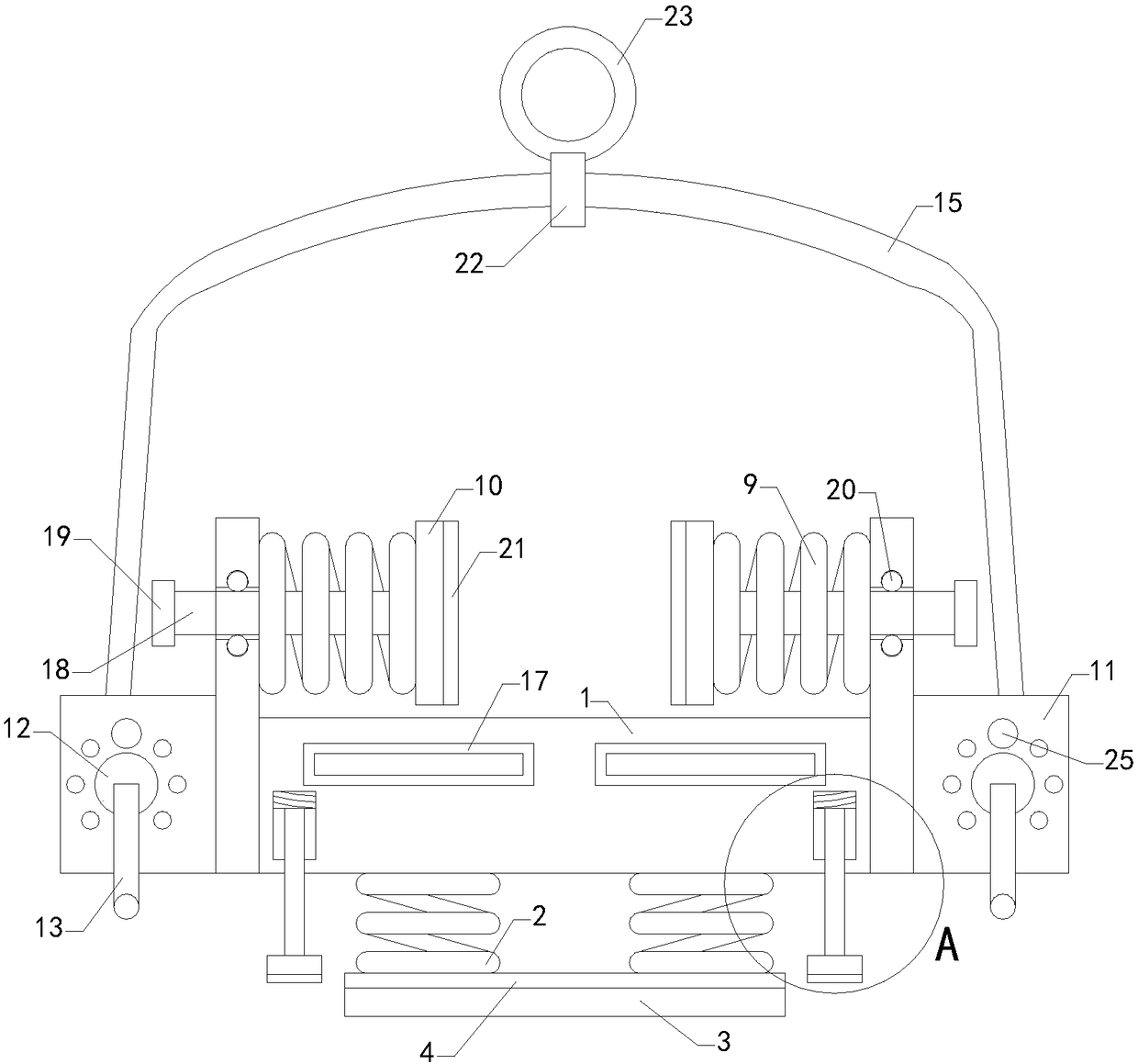

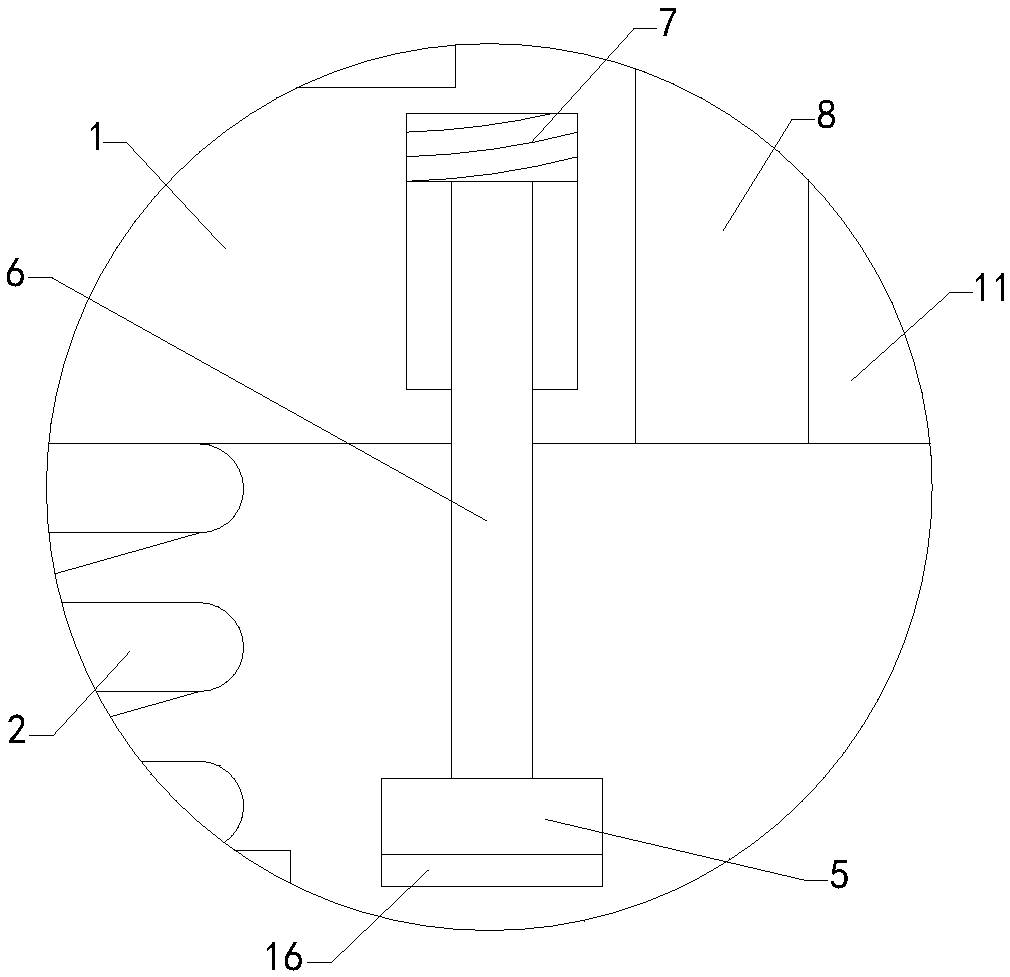

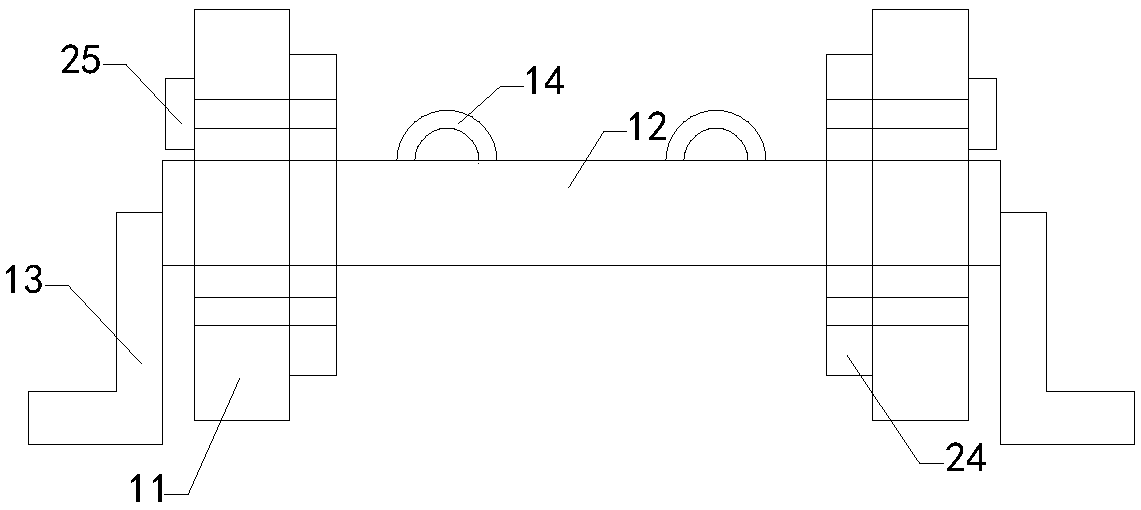

[0019] Such as Figure 1 to Figure 3 As shown, a cargo transfer auxiliary device for automatic storage and retrieval of the present invention includes a pallet 1, a group of jacks are longitudinally arranged in the upper left area and the upper right area of the pallet; it also includes a group of support springs 2, a bottom plate 3, A weight sensor 4, a set of bases 5, a set of support columns 6 and a set of circular support plates 7, the weight sensor is installed on the top of the bottom plate, and the top and bottom ends of a set of support springs are respectively connected to the bottom of the tray and the left half area and right of the weight sensor. Semi-area c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com