Gravure printing process and printing equipment for paper packaging box

A technology of printing equipment and box gravure, which is applied in the direction of gravure rotary printing machine, printing, printing machine, etc., can solve the problem of short residence time of cardboard, achieve the effect of improving drying effect, easy contact, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

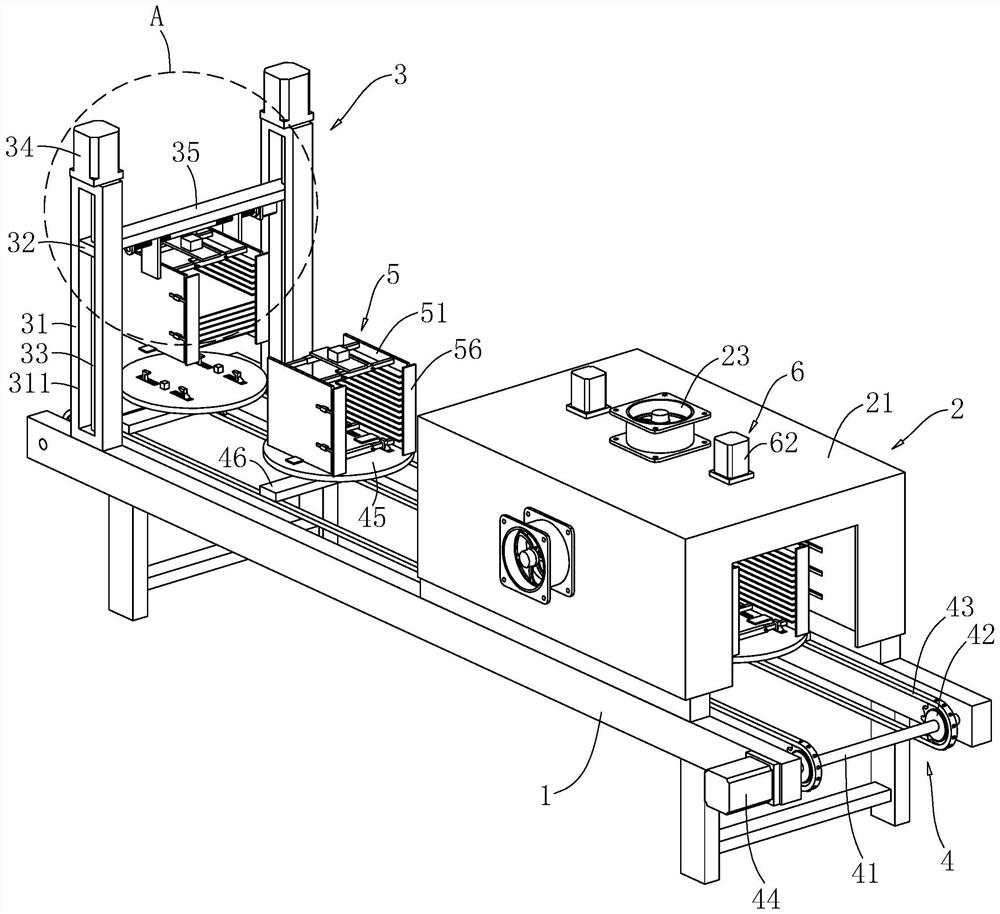

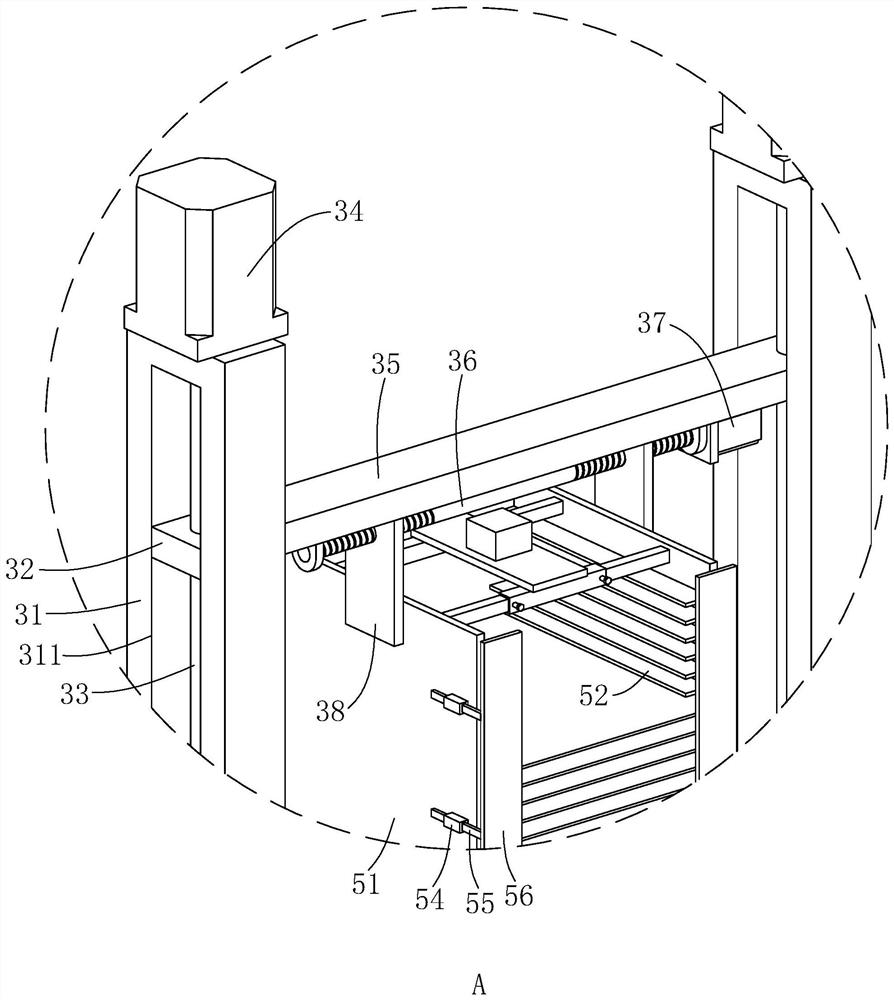

[0039] The following is attached Figure 1-6 The application is described in further detail.

[0040] The embodiment of the present application discloses a gravure printing process for a paper packaging box.

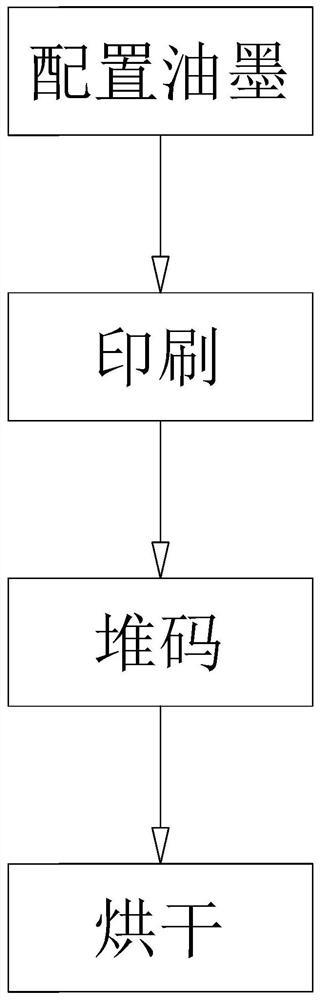

[0041] refer to figure 1 , the printing process includes the following steps:

[0042] S1: Configure the ink, the operator mixes the ink, mixes patterns of different colors to meet the printing of different patterns, and adds the adjusted ink to the corresponding printing machine;

[0043] S2: Printing, the cardboard is fed into the printing machine, and the cardboard is printed sequentially through the printing machine, so that different patterns appear on the cardboard;

[0044] S3: Stacking, stacking the printed cardboards, and keeping a certain gap between two adjacent straight boards, so as to reduce the mutual friction between the cardboards, resulting in blurred printing patterns;

[0045] S4: Drying. After the cardboard stacking is completed, the cardboard is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com