Support device for early removal template

A supporting device and a technology for early demolition of formwork, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problem of affecting the adjustment accuracy of the height of the column, not being able to adapt to the height of the floor, and affecting Adjust the support strength of the column and other issues to achieve the effect of reasonable design layout, convenient assembly and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

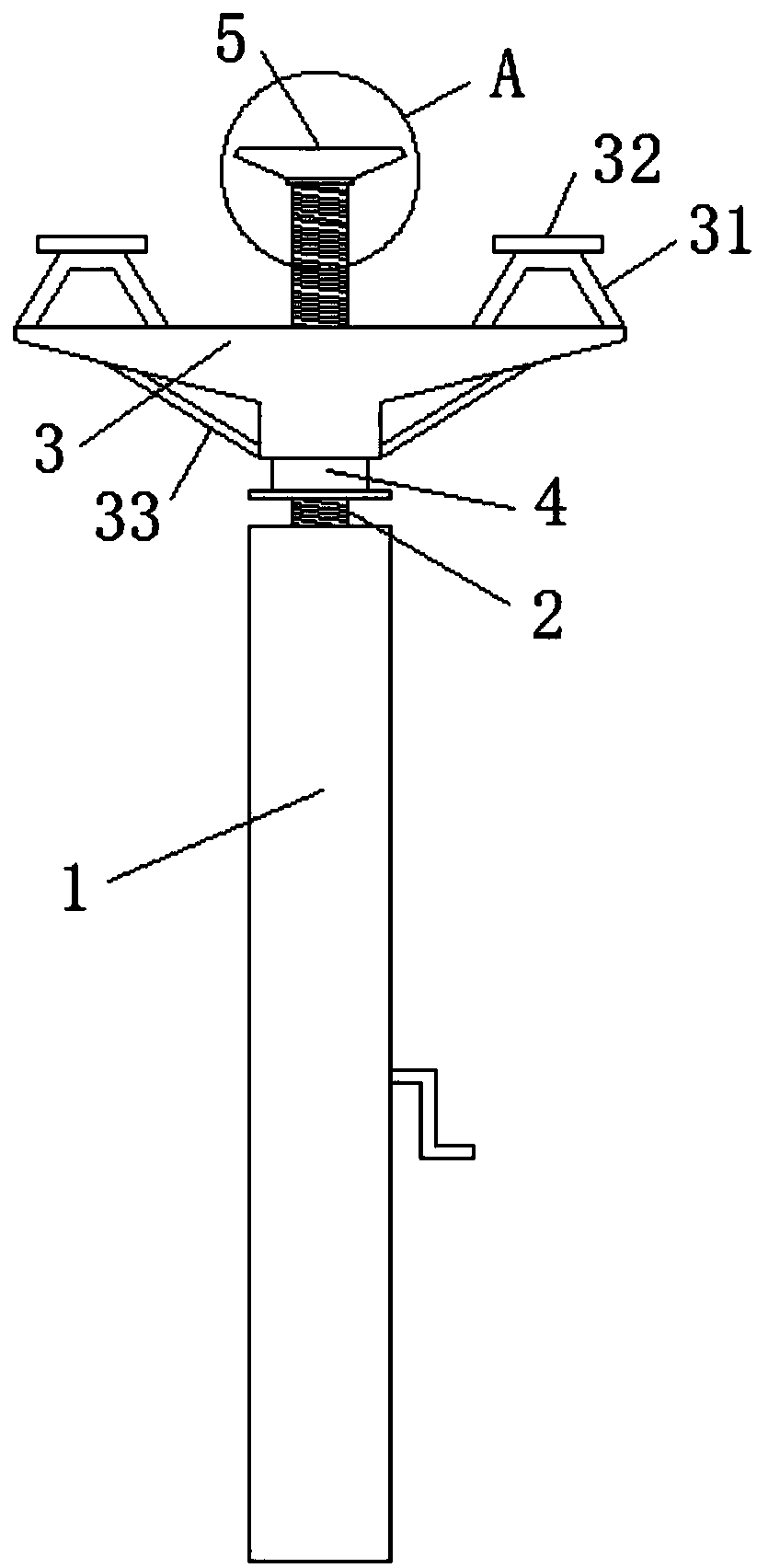

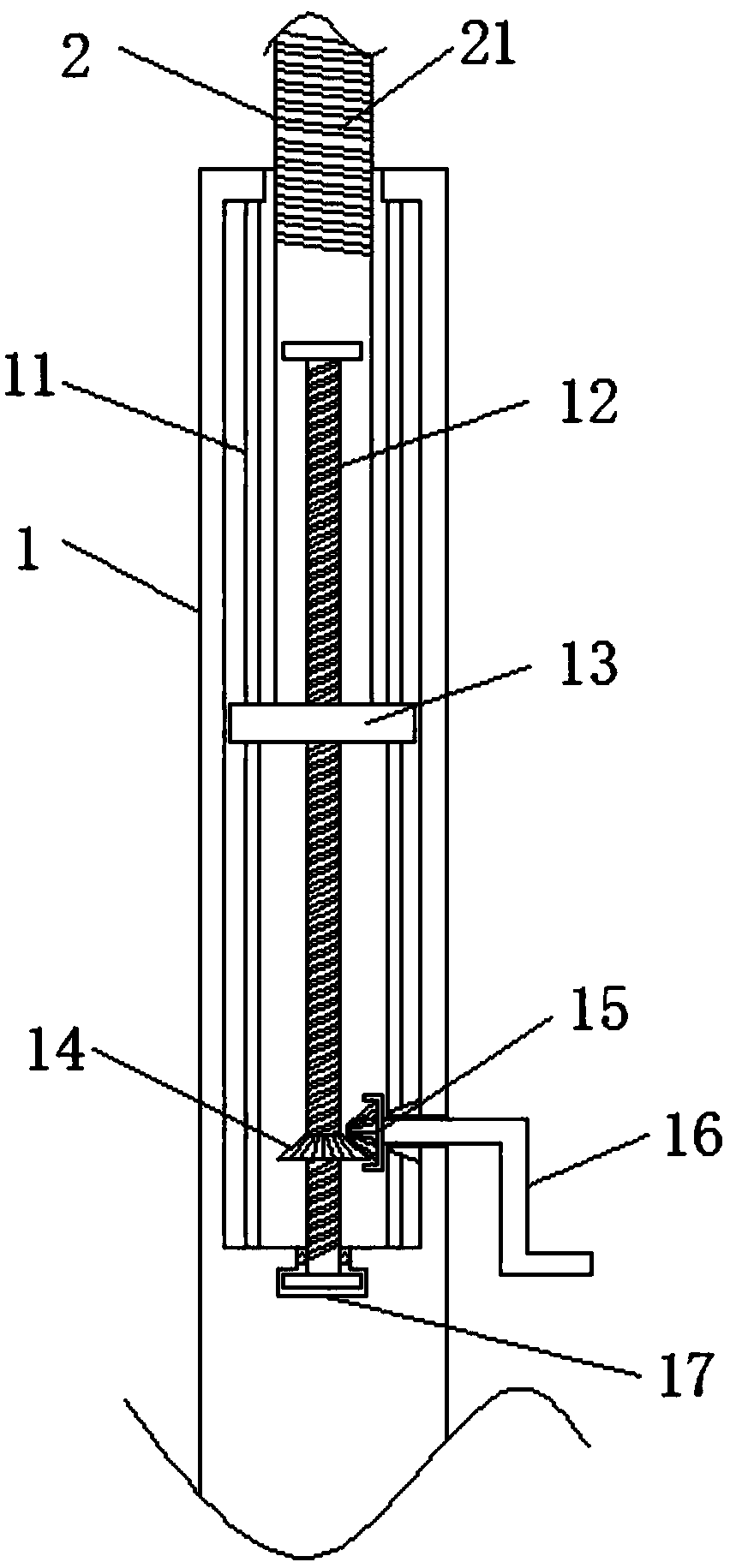

[0032] refer to Figure 1-5 , a support device for dismantling formwork, comprising a support column 1,

[0033] Also includes

[0034] Stabilize the lifting mechanism, strengthen the support mechanism and the jacking mechanism;

[0035] The stable lifting mechanism arranged inside the support column 1 includes a directional slide bar 11 and a lifting screw 12, wherein the directional slide bar 11 is located on both sides of the lifting screw 12, and a lifting horizontal plate 13 is connected between the directional slide bar 11 and the lifting screw 12 , the bottom of the lifting screw 12 is provided with a driven gear 14, the bottom of one side of the support column 1 is rotated with an adjusting handle 16, and one end of the adjusting handle 16 is equipped with a driving gear 15 that drives the driven gear 14 to rotate;

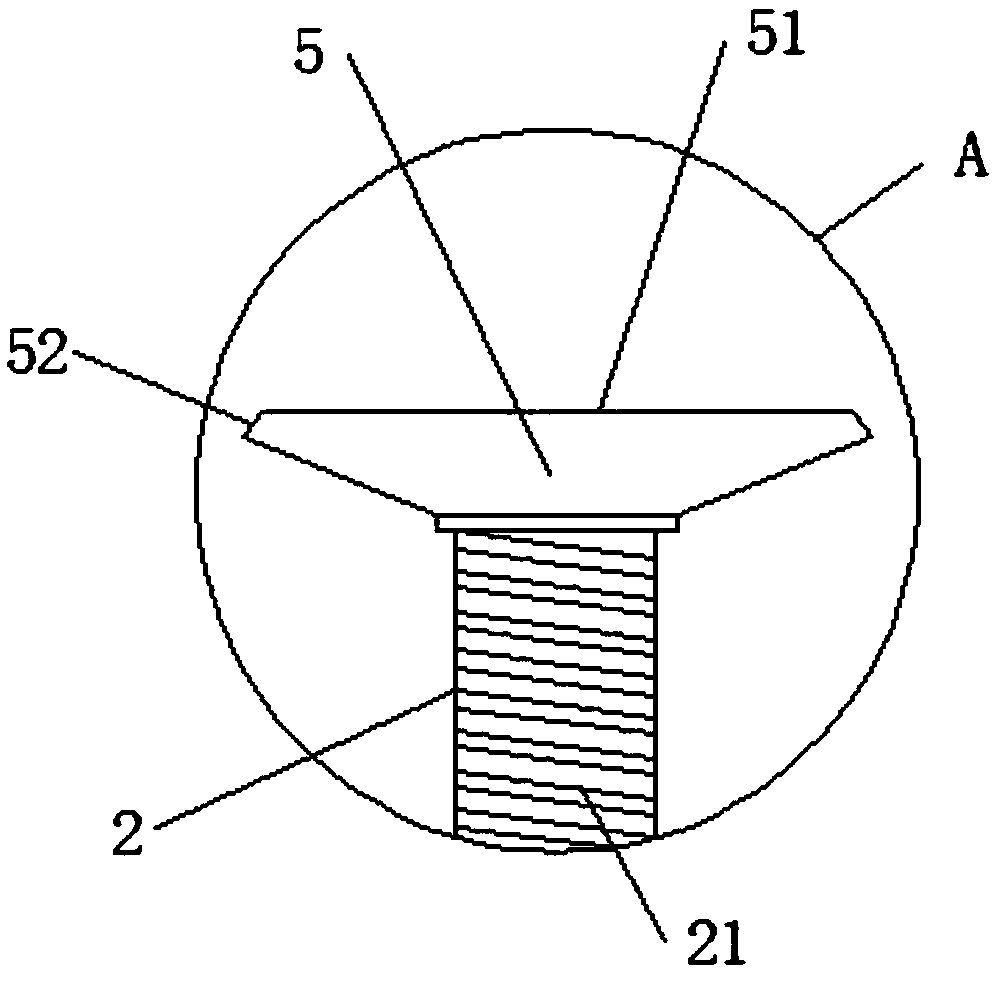

[0036] The reinforced support mechanism includes a stable strut 2 at the top of the support column 1 and an early dismantling bracket 3 sleeved on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com