Spherical butterfly valve

A butterfly valve and spherical technology, applied in the field of spherical butterfly valves, can solve the problems of affecting medium parameters, local uneven thickness of the valve body wall, reduced valve flow capacity, etc. The effect of improving the flow capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

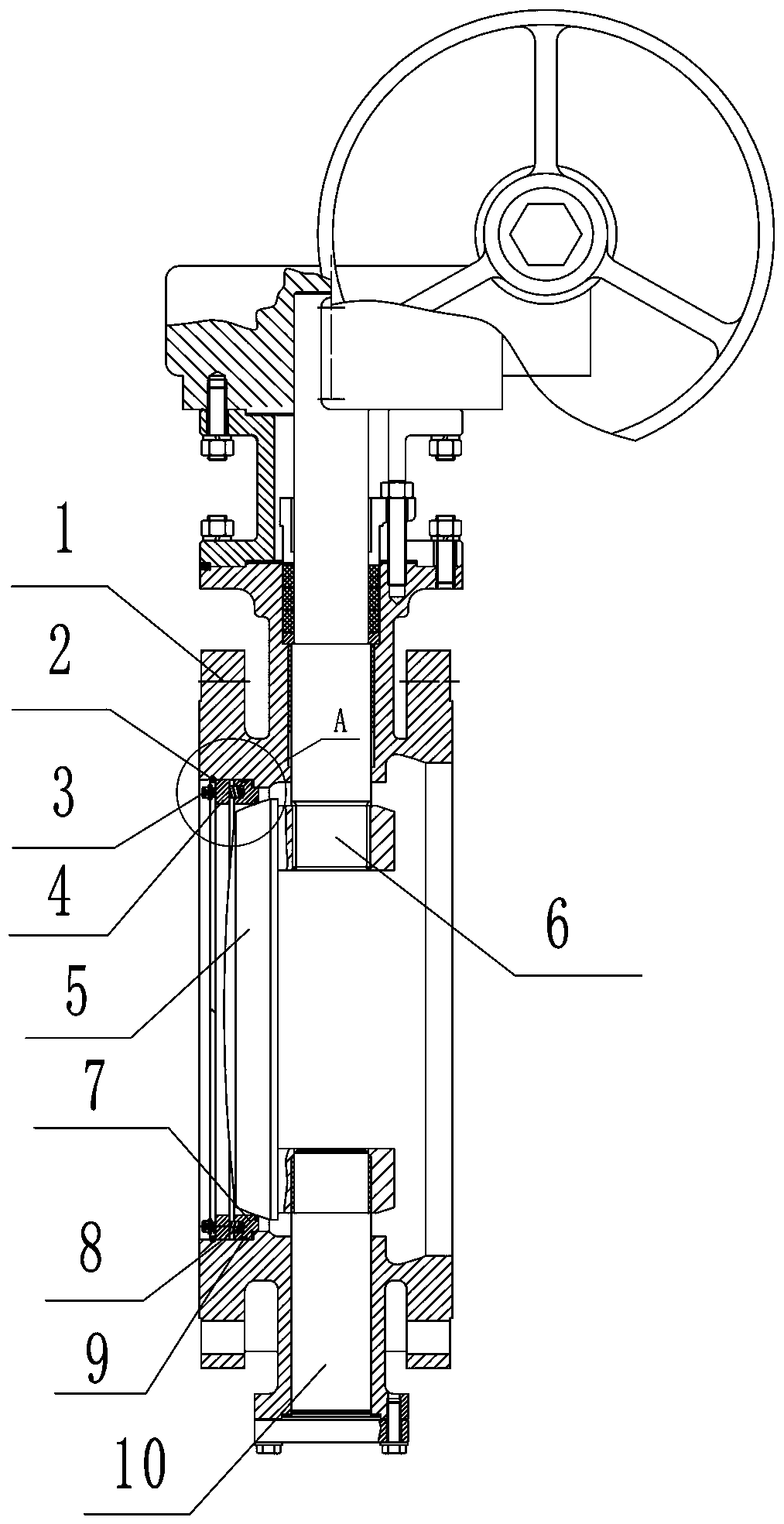

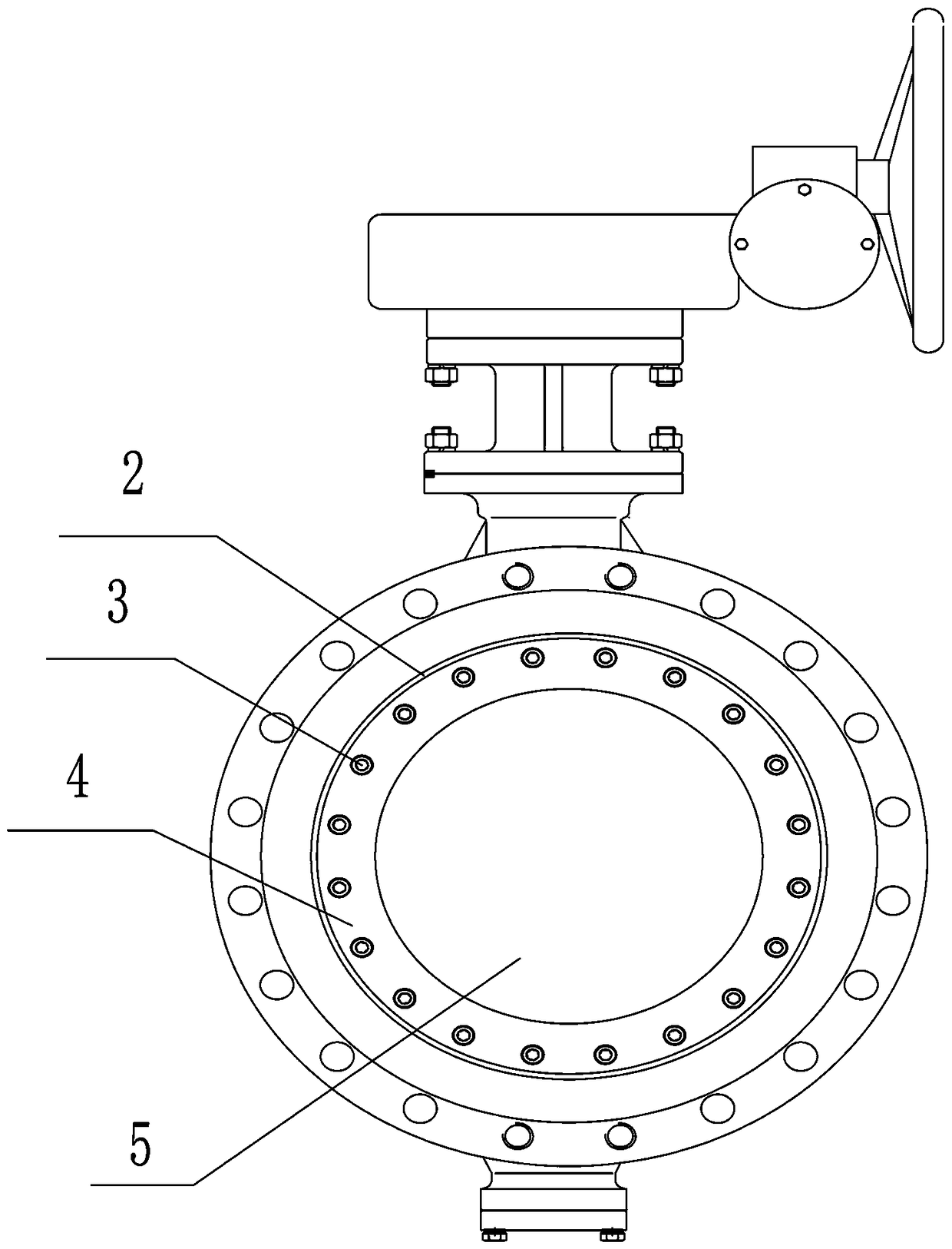

[0023] This embodiment provides a spherical butterfly valve, such as figure 1 , figure 2 and image 3 As shown, it includes a driving device, a valve body 1, a valve shaft, a valve seat 7 and a valve plate 5. The valve body 1 is provided with a cavity for accommodating the valve plate 5, and the valve plate 5 is movably arranged in the cavity. In the chamber, the valve shaft is eccentrically connected to the valve plate 5, and the driving device drives the valve plate 5 to rotate through the valve shaft.

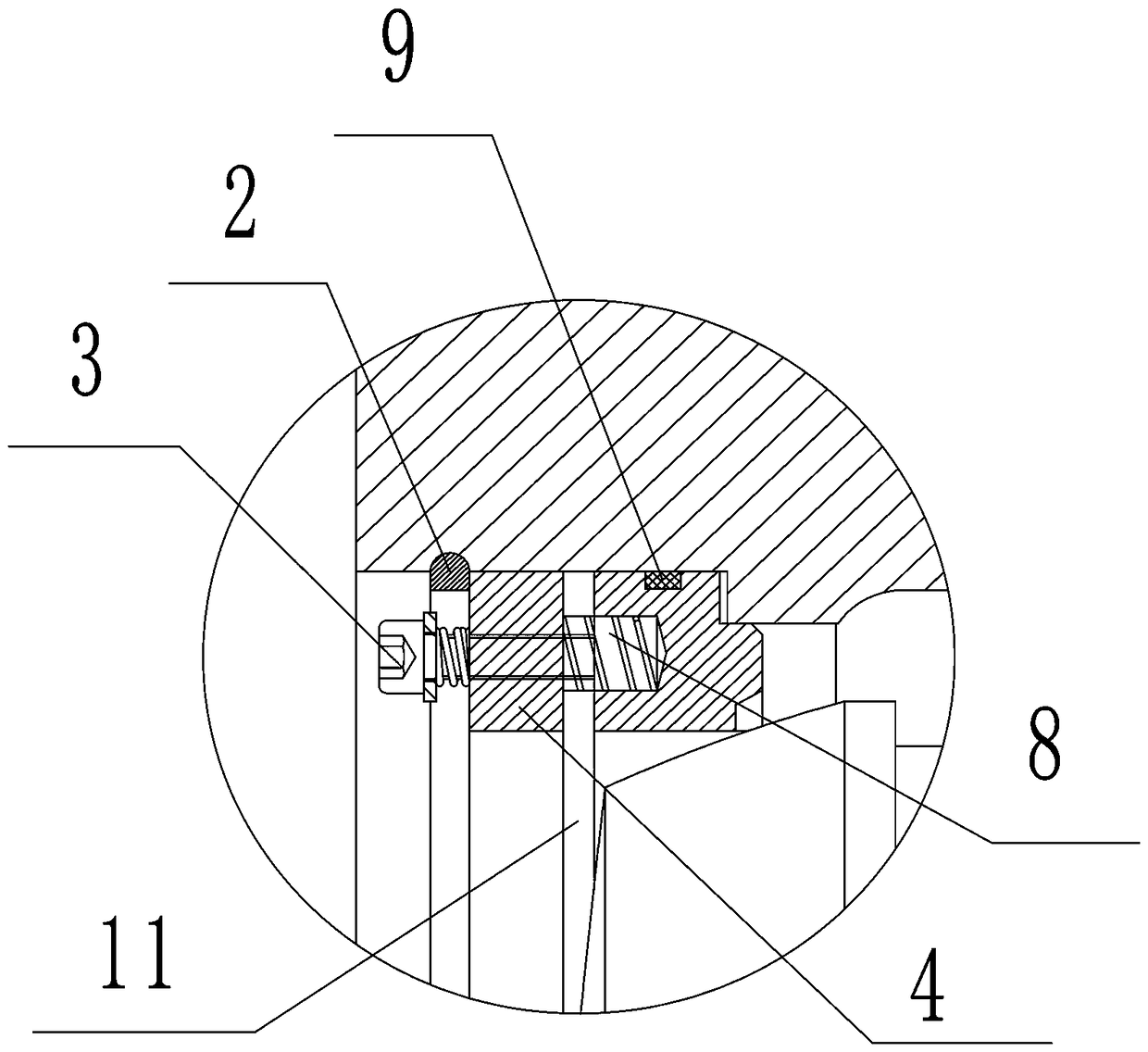

[0024] Specifically, the valve seat 7 is provided with a sealing ring 9, and the valve seat 7 is sealed on the inner wall of the cavity through the sealing ring 9, and the valve plate 5 and the valve seat 7 form a dynamic sealing pair. .

[0025] A valve seat retainer 4 for pressing the valve seat 7 and a valve seat retainer 2 for restricting the valve seat retainer 4 are also arranged on the inner wall of the cavity. The outer edge of the valve seat retainer ring 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com