Bridge plug

A bridge plug and body technology, applied in the field of oilfield development tools, can solve problems such as unhanging, delamination failure of bridge plugs, failure of slips sitting and hanging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

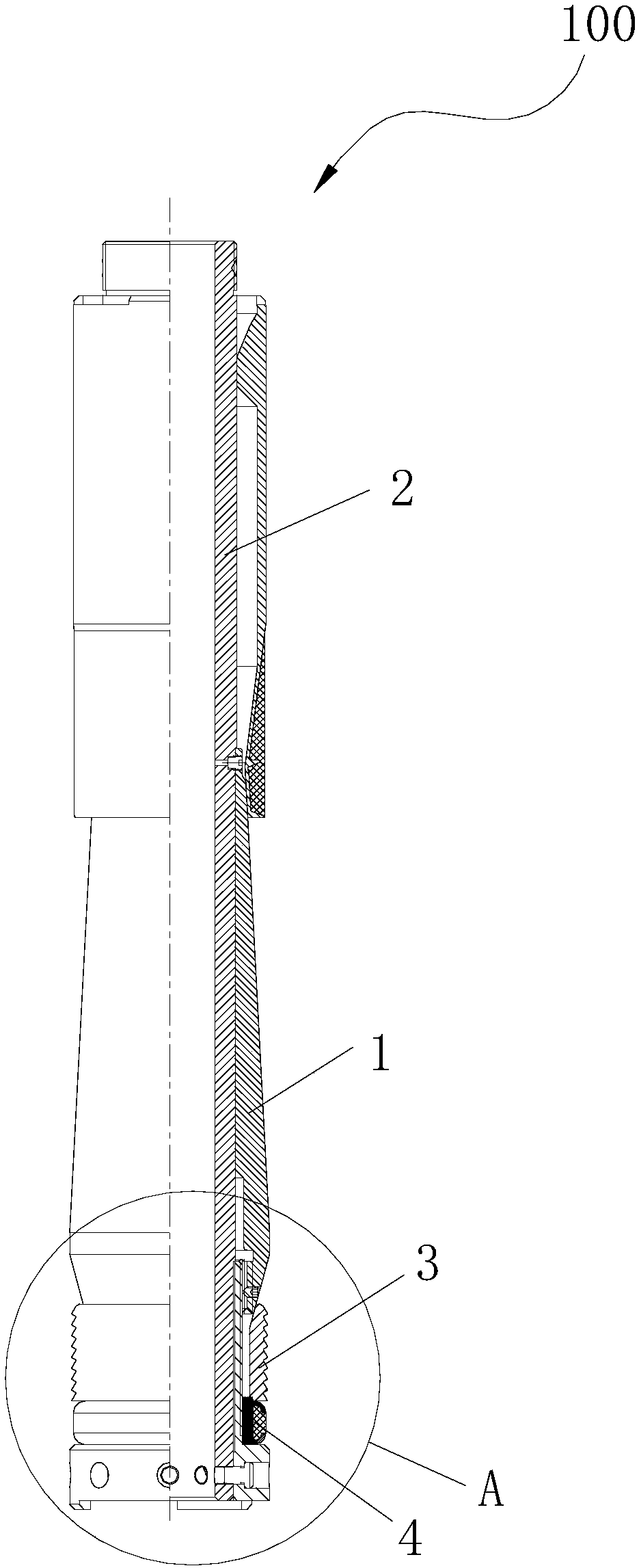

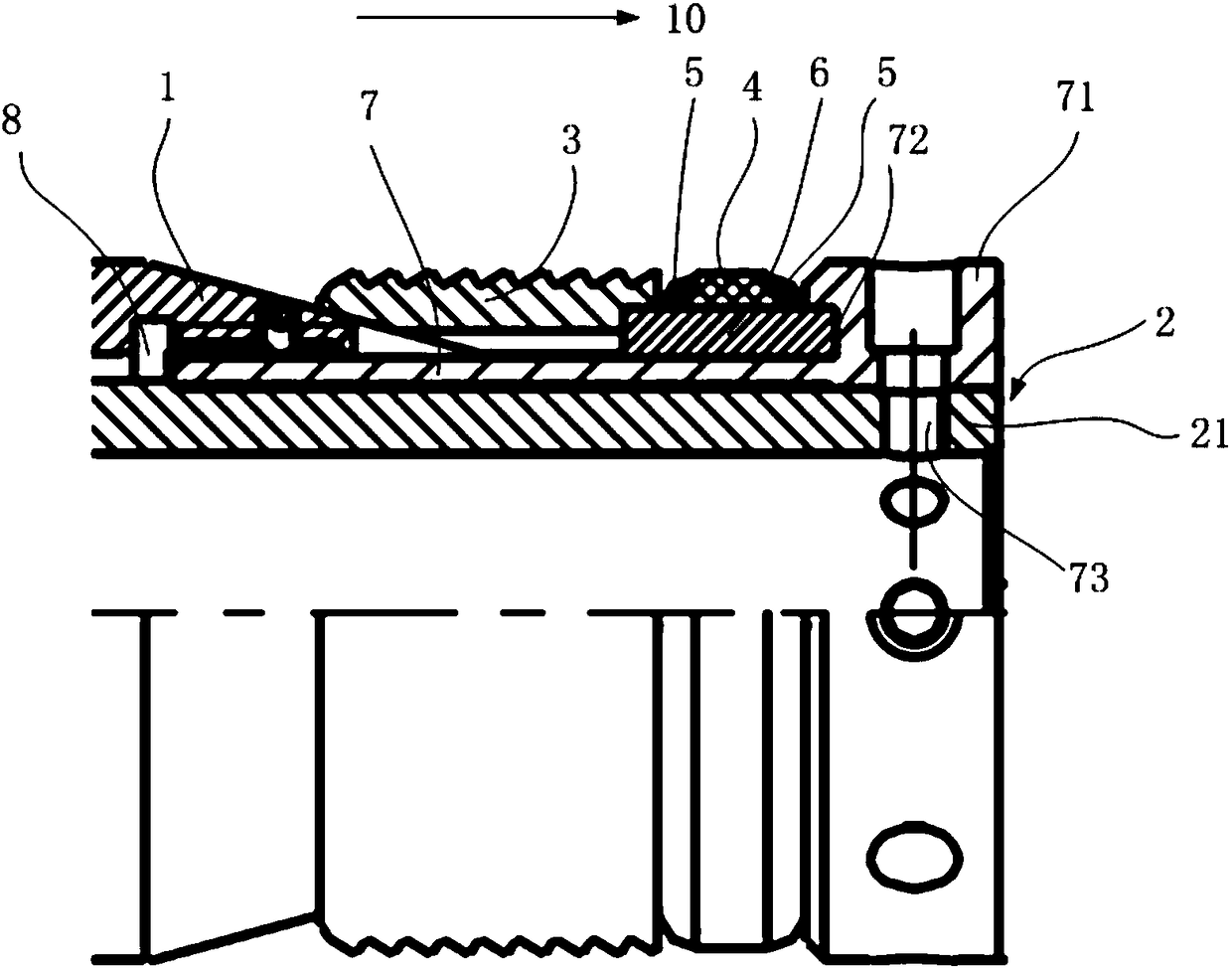

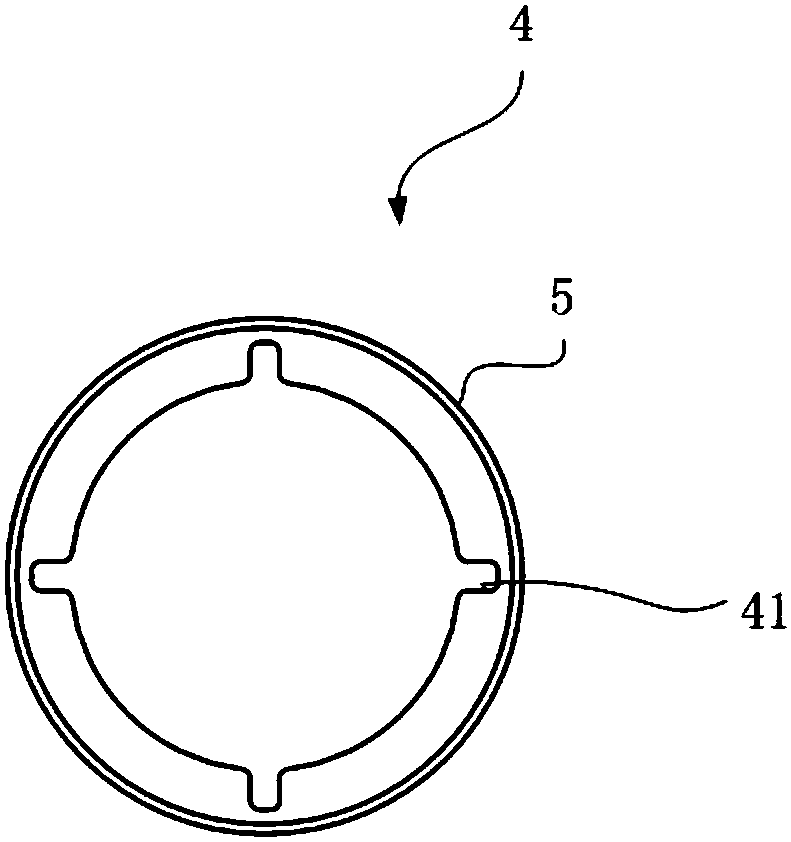

[0022] figure 1 A bridge plug 100 according to the invention is schematically shown. Such as figure 1 As shown, the bridge plug 100 at least includes a bridge plug body 2 , a slip 3 sleeved on the bridge plug body 2 , a slip driver 1 upstream of the slip 3 , and an elastic body 4 downstream of the slip 3 . The slip driving part 1 and the elastic part 4 are respectively in contact with corresponding ends of the slips 3 . The slip driver 1 is also connected to the bridge plug body 2 through an elastic anti-retraction mechanism 8 . Under the condition of being subjected to a force toward the downstream, the slip driving member 1 can move toward the downstream along the bridge plug body 2 and push the slip 3 radially outward and toward the downstream over the anti-retraction mechanism 8, so that the slip 3 Radial expansion (thus enabling sitting) and pushes against the elas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com