Conveying and discharging groove rail for mold standard parts

A standard parts and conveying trough technology, applied in the field of mold standard parts processing equipment, can solve the problems of low work efficiency, high labor intensity of staff, large workload of manual blanking and stacking, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

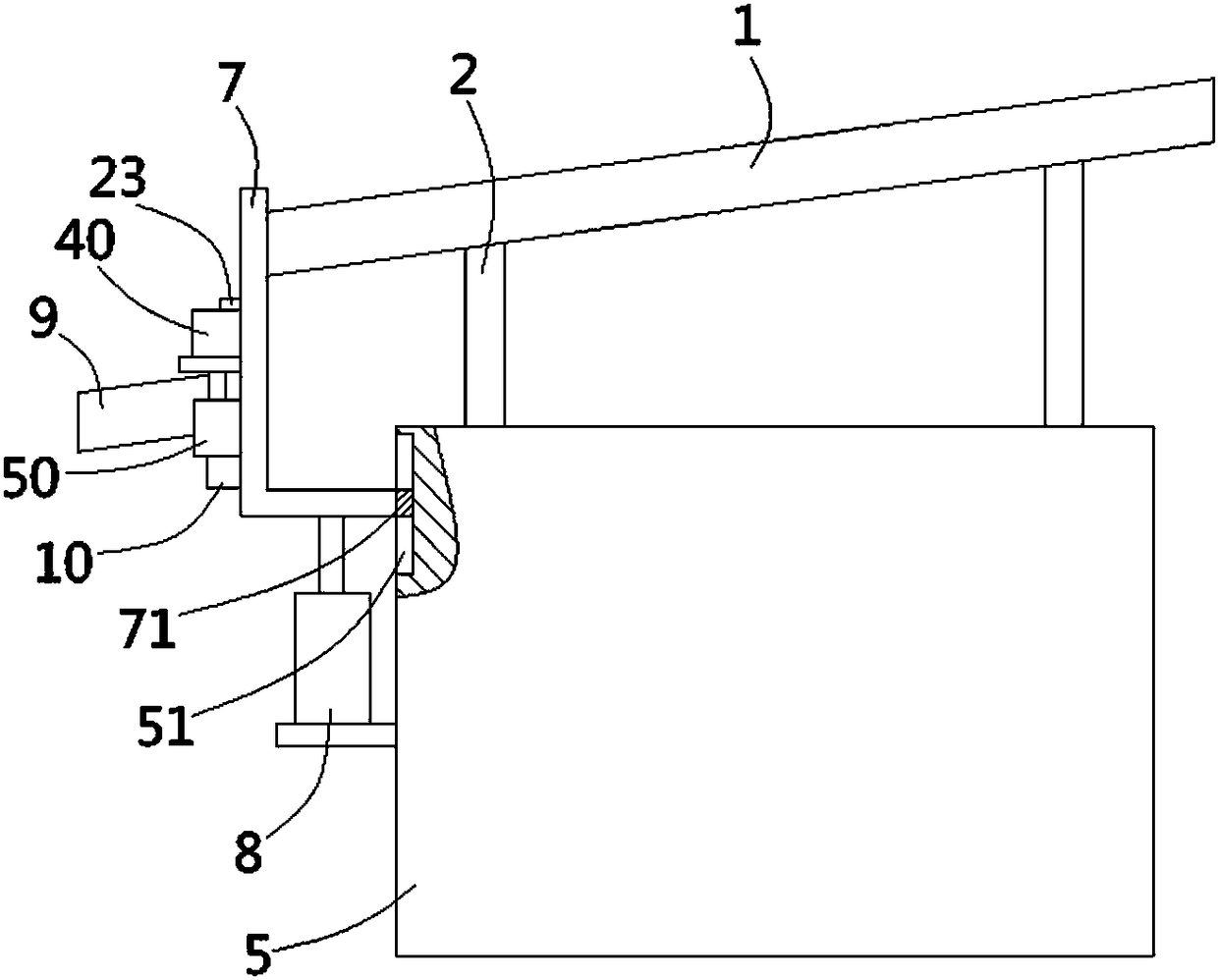

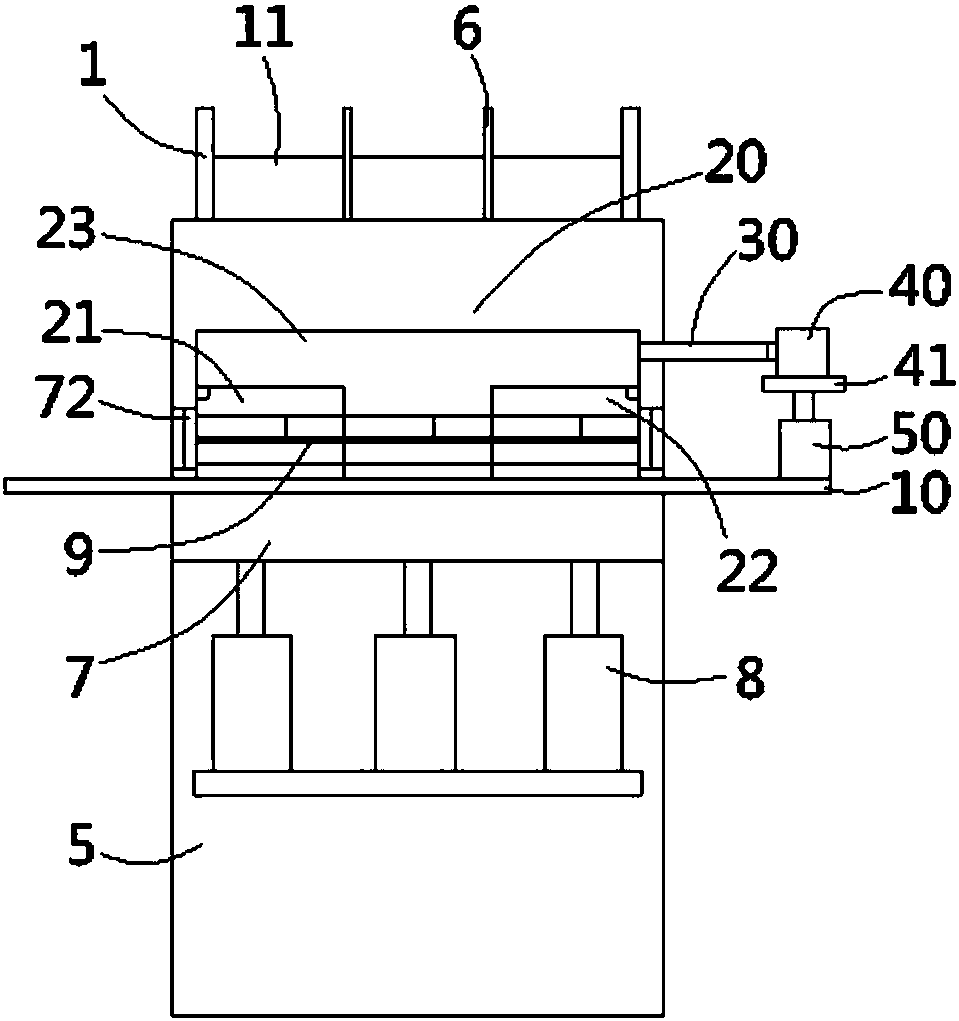

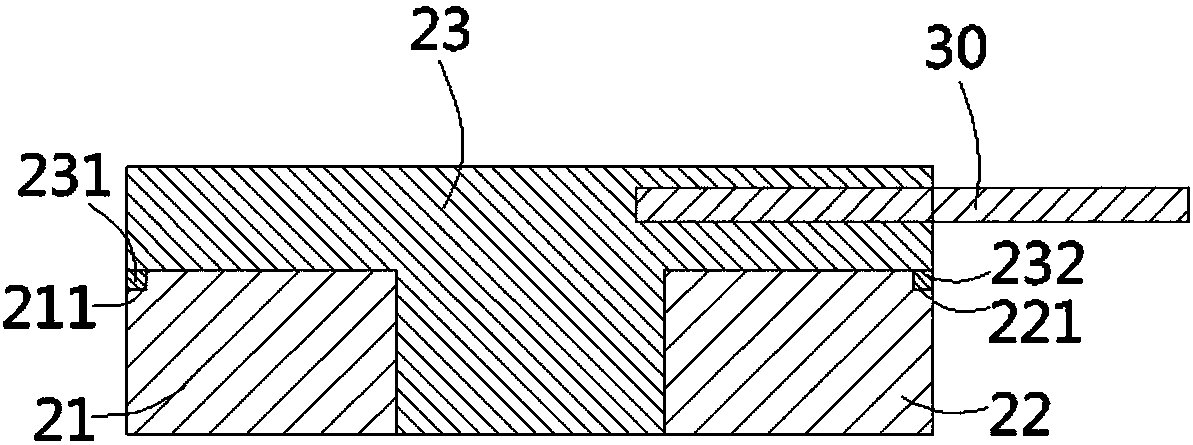

[0022] See figure 1 , figure 2 , Figure 5 , The conveying and unloading trough rail of a standard mold part of the present invention includes an inclined lifting channel 1, a plurality of pillars 2 are fixed on the lower end of the lifting channel 1, and the lower end of the pillar 2 is fixed at On the supporting plate 3, the lower end surface of the supporting plate 3 is pressed against a number of pressure sensors 4, the pressure sensors 4 are fixed on the bracket 5, there are multiple pressure sensors 4, and the pressure sensors 4 are uniformly distributed in an array On the supporting plate 3, the pressure sensor 3 is embedded on the upper end surface of the bracket 5, the supporting plate 3 is pressed aga...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap