Automatic detection device of wrapping tape laminated belt

An automatic detection device and technology of wrapping tape, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of ensuring the straightening effect of the wrapping tape, avoid uneven wrapping, facilitate inspection, and increase the contact effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

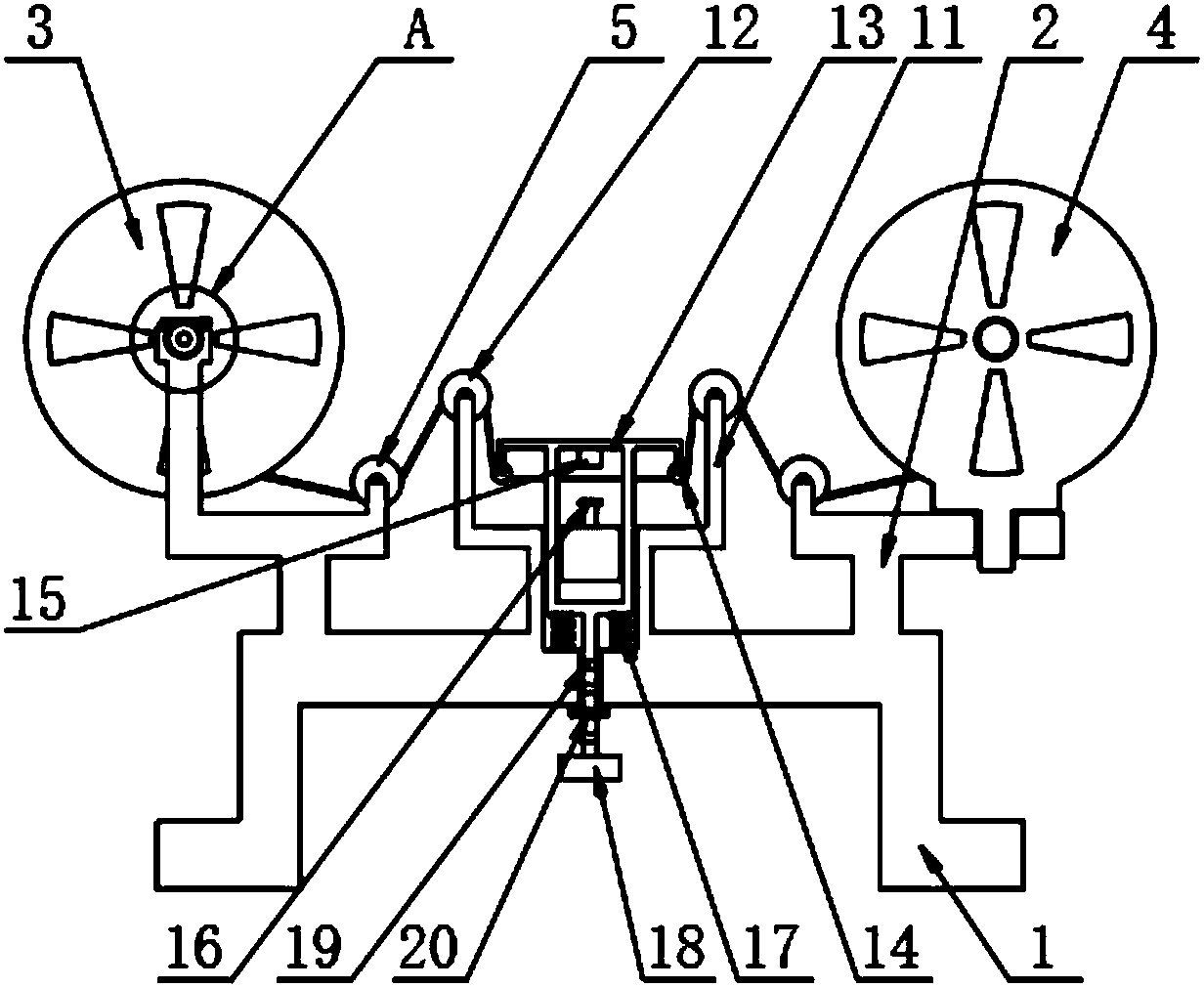

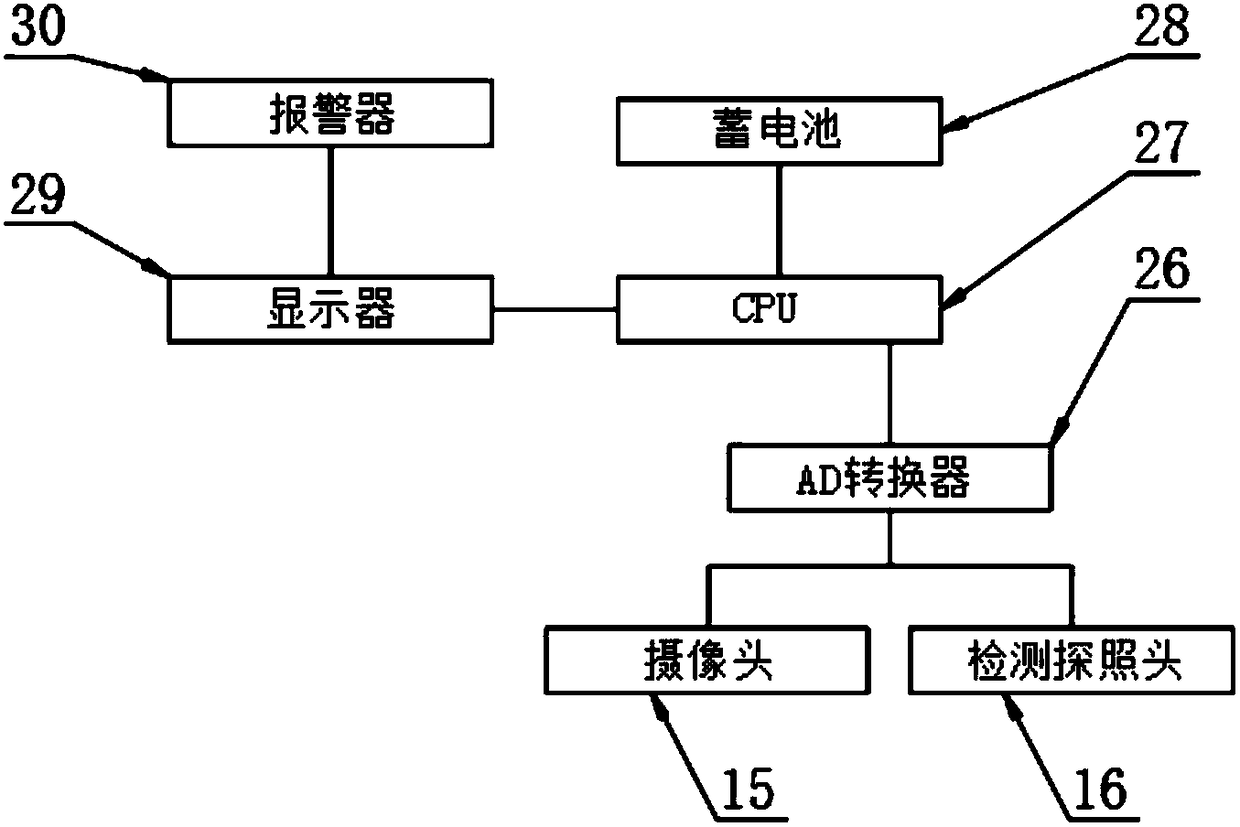

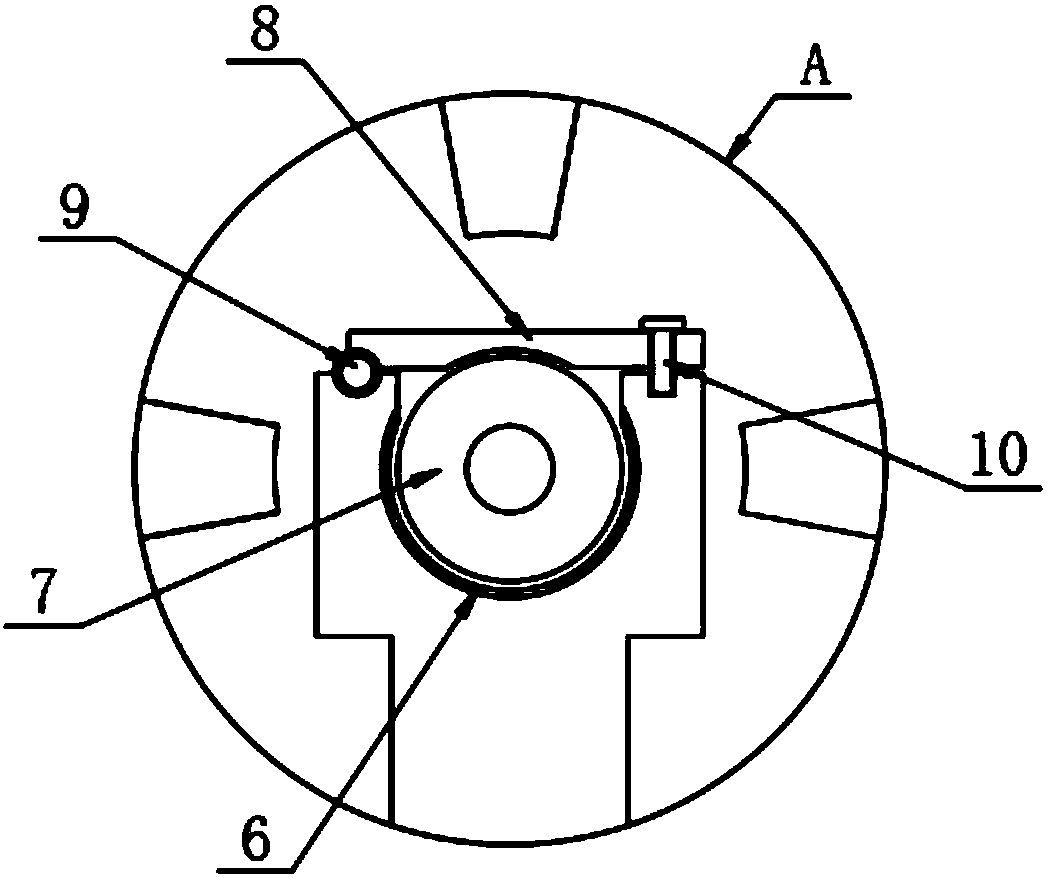

[0025] The present invention provides such Figure 1-4 A wrapping tape stacking automatic detection device shown includes a bracket 1, a frame block 2 is provided on both sides of the top of the frame block 1, and a tape reel 3 is provided on one side of the top of the frame block 2. The other side of the top of the block 2 is provided with a tape take-up reel 4, and one side of the tape release reel 3 and the tape take-up reel 4 is provided with a first reversing roller 5, and between the tape release reel 3 and the frame block 2 is a A rubber ring 6, a rotary rod 7 is provided on the outside of the tape release reel 3, a pressure plate 8 is provided on the top of the rotary rod 7, a bearing 9 is provided at one end of the pressure plate 8, and a fastening screw 10 is provided at the other end of the pressure plate 8 , the inside of the first reversing roller 5 is provided with a fixed frame 11, the top of the fixed frame 11 is provided with a second reversing roller 12, the ...

Embodiment 2

[0030] The tape release reel 3 is placed correspondingly to the rubber ring 6, one end of the pressing plate 8 is fixedly connected with the bearing 9, the other end of the pressing plate 8 is connected with the frame block 2 through the fastening screw 10, and the pressing plate 8 is fixed by the fastening screw 10. Fasten on the top of the frame block 2, and then make the tape reel 3 stable.

[0031] The bottom of the take-up reel 4 is provided with a protruding rod, and the protruding rod is matched with the frame block 2. A wrapping tape is arranged between the unwinding reel 3 and the take-up reel 4, and the first reversing roller 5 , the second redirection roller 12 and the third redirection roller 14 are all attached to the surface of the wrapping belt, and the effect of the first redirection roller 5, the second redirection roller 12 and the third redirection roller 14 is used to wrap around Tighten the straps to prevent the wrapping straps from coming off.

[0032] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com