Temperature-control probe support and air conditioner

A technology of a temperature control probe and a support part, which is applied in the field of air-conditioning equipment, can solve the problem that the temperature control probe bracket cannot be installed and removed in a stable and fixed state at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

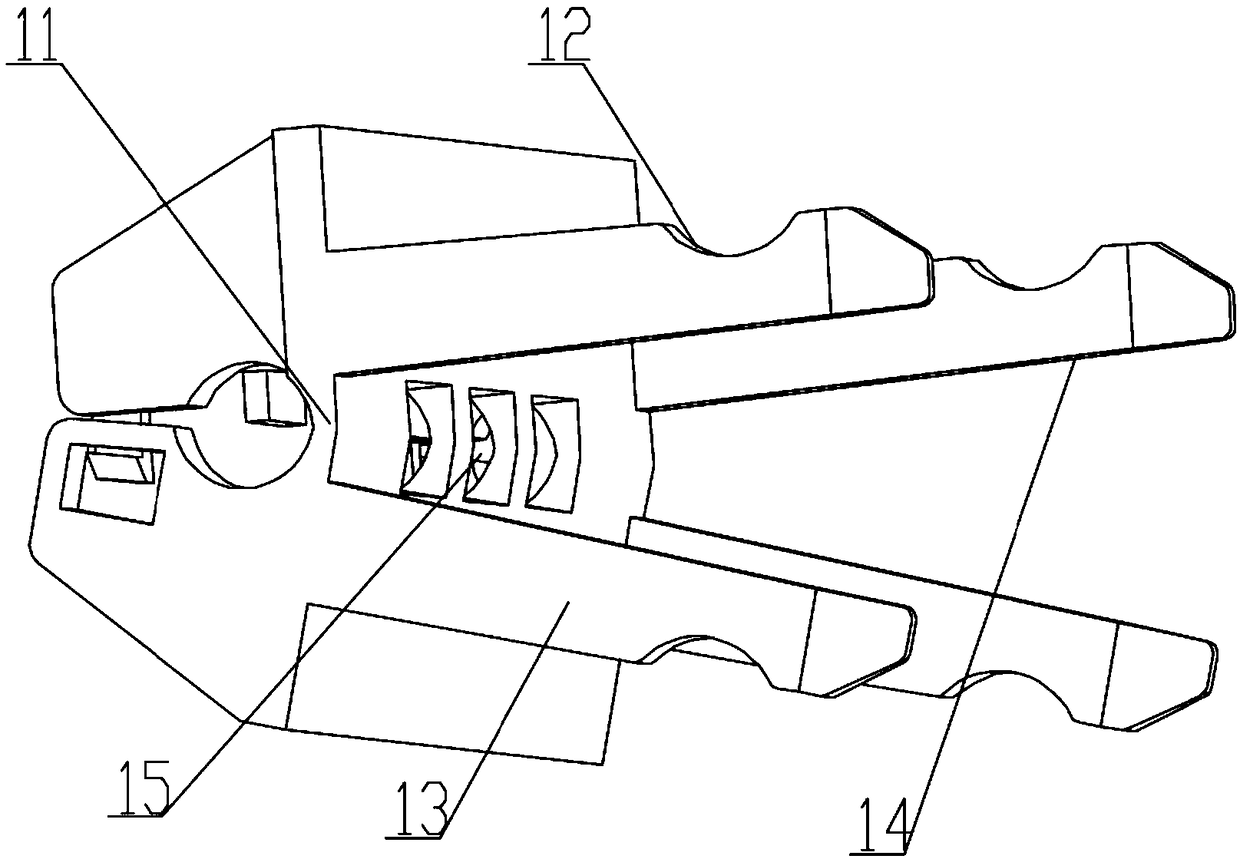

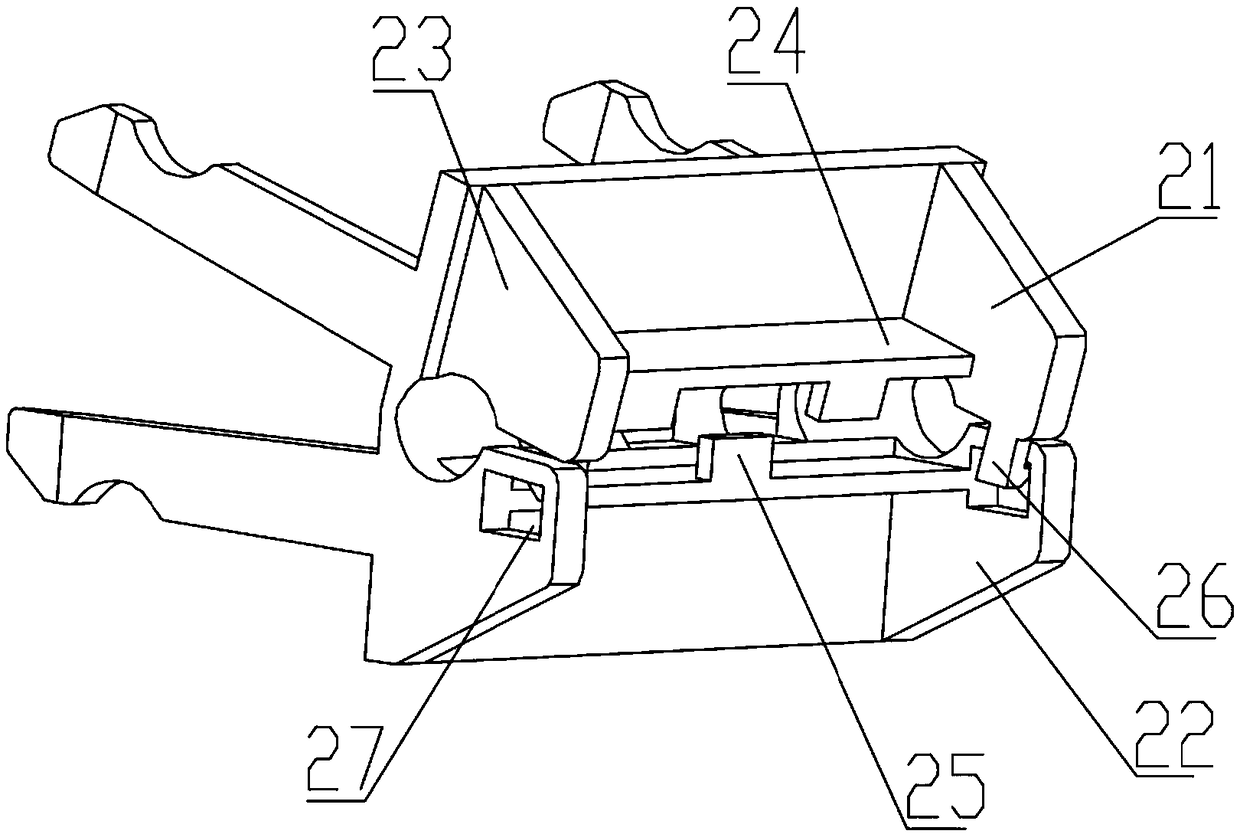

[0045] The temperature control probe bracket includes a clamping assembly 1 and a mounting assembly, the mounting assembly includes a positioning part 2 and a mounting part 3, the positioning part 2 is connected to the clamping assembly 1, and the clamping assembly 1 includes The deformation part 11 and the clamping part 12, the deformation of the deformation part 11 causes the movement of the clamping part 12 to realize the fixing of the clamping assembly 1 and the finned heat exchanger; the positioning part 2 ensures The deformation state of the deformation part 11 ensures the stable connection between the clamping part 12 and the finned heat exchanger; the mounting part 3 is arranged on the clamping assembly 1, and the mounting part 3 is used for For placing the temperature control probe.

[0046] After the temperature control probe is installed on the temperature control probe bracket, the user applies an external force to the clamping assembly 1 to cause mechanical moveme...

Embodiment 2

[0049] like figure 1 and figure 2 as shown, figure 1 It is the front view of the three-dimensional structure of the temperature control probe bracket described in this embodiment, figure 2 It is a rear view of the three-dimensional structure of the temperature control probe bracket described in this embodiment.

[0050] The clamping assembly 1 includes a pair of symmetrically arranged jaw bodies 13, the jaw bodies 13 are connected by the deformation portion 11, and the jaw bodies 13 are each provided with a support portion 14, and the support portion 14 is provided with There is the clamping portion 12, and in this embodiment, the clamping portion 12 is configured as an arc-shaped clamping groove.

[0051] The engaging portion 12 is provided on the symmetrically arranged claw bodies 13 , and the elastic deformation of the deformation portion 11 causes the distance between the engaging portions 12 on the two claw bodies 13 The size changes, and when the clamping parts 12 ...

Embodiment 3

[0066] like Figure 7 and Figure 8 , Figure 7 It is a perspective view of the active state of the temperature control probe bracket in this embodiment; Figure 8 It is a perspective view of the temperature control probe bracket in a fixed state in this embodiment.

[0067] In this embodiment, the temperature control probe bracket includes a box body 4, the installation part 3 and the positioning part 2 are arranged on the box body 4, and the box body 4 includes a cover plate 41 and a bottom plate 42, The cover plate 41 and the bottom plate 42 are movably connected, and the cover plate 41 and the bottom plate 42 can freely rotate around the connecting position to realize the closing and closing between the cover plate 41 and the bottom plate 42 Open.

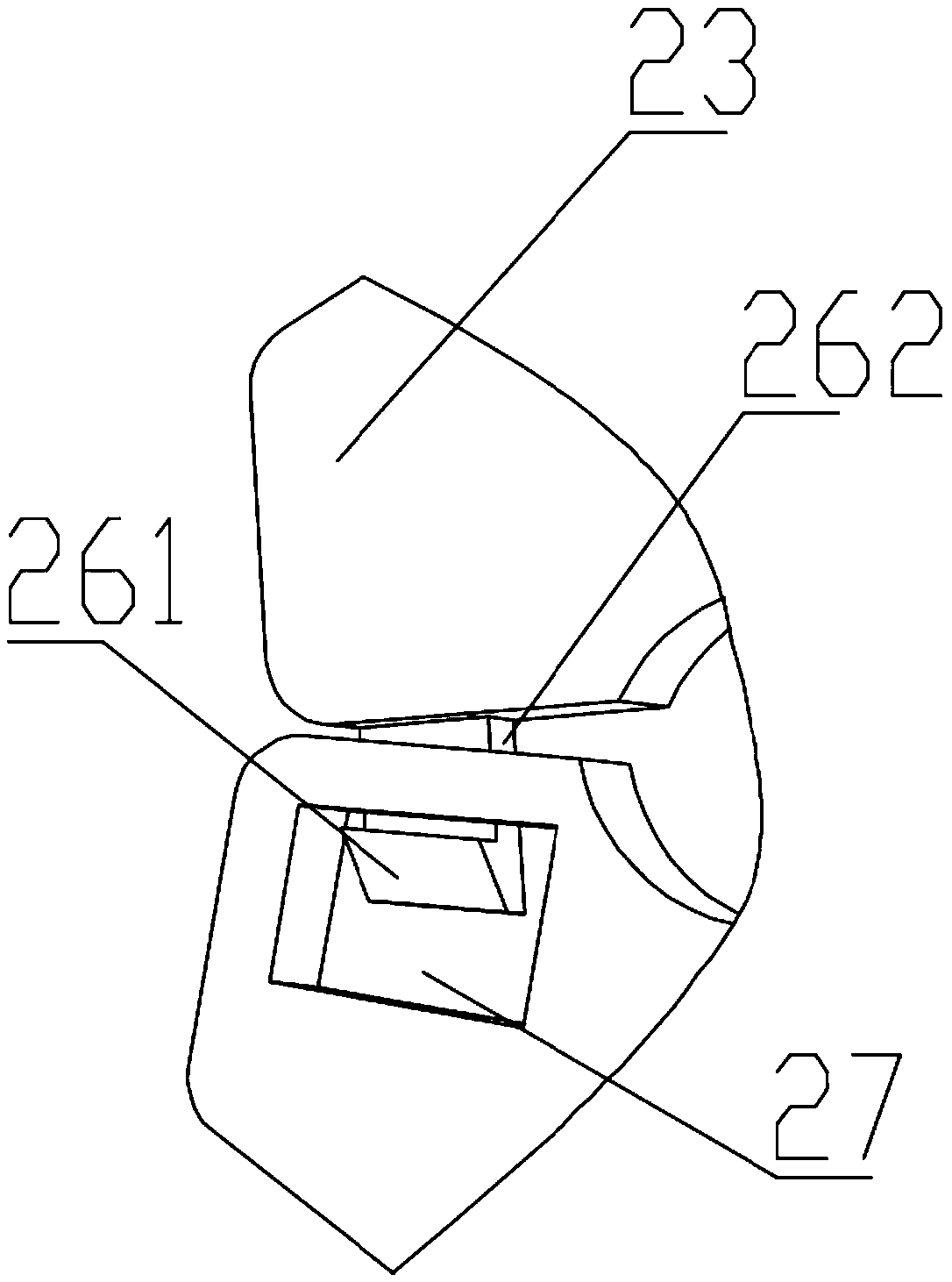

[0068] The locking block 26 and the locking slot 27 of the positioning portion 2 are respectively arranged on the cover plate 41 and the bottom plate 42 , and the locking block 26 and the locking slot 27 are correspondingly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com