Negative pressure antiskid tray

A kind of tray, anti-slip technology, applied in the field of life, can solve the problems of insufficient anti-slip, dirty customer's clothes, trouble, etc., and achieve the effect of good adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

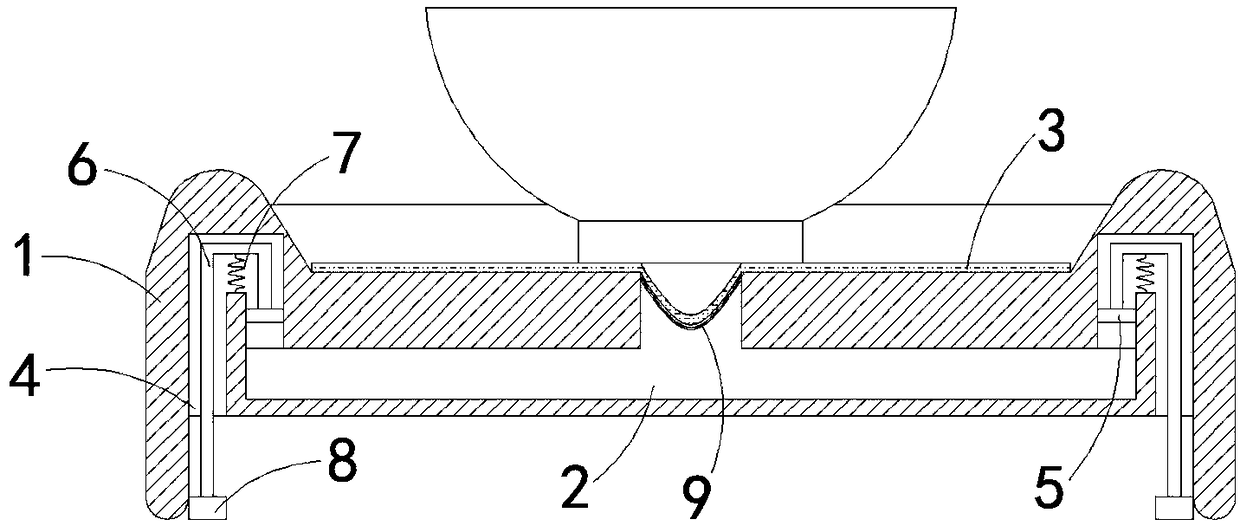

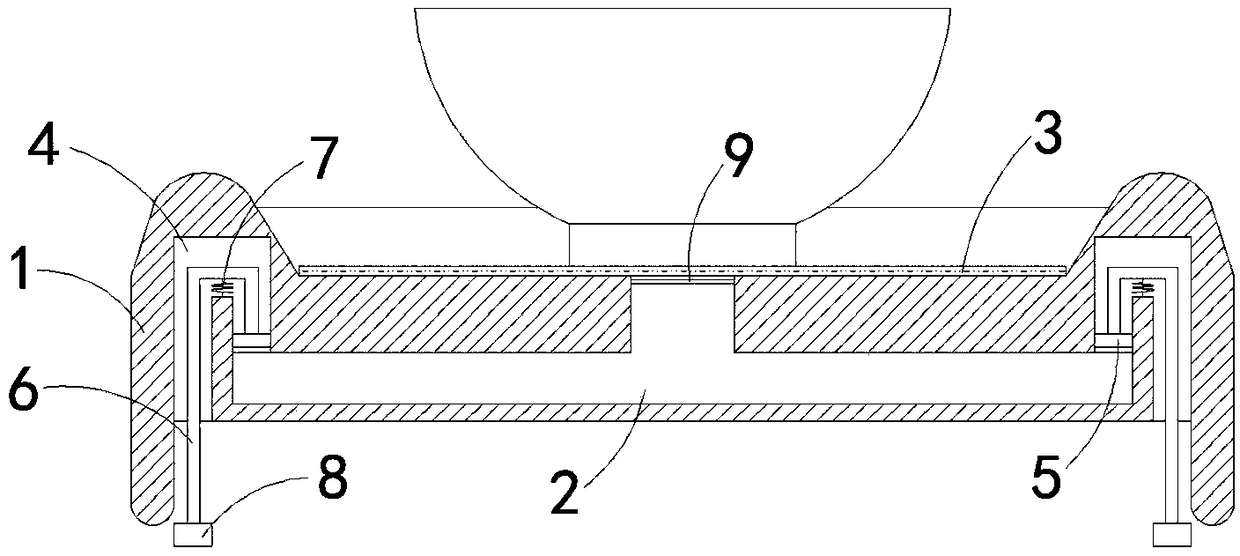

[0019] like Figure 1-2 As shown, a negative pressure non-slip tray includes a tray body 1, and a cavity 2 is provided in the tray body 1. It should be noted that the cavity 2 is sealed with sealing oil, because the sensitivity of the sealing oil to ambient temperature is low , so when the ambient temperature changes, its volume is relatively stable, and the first opening is fixedly connected with an anti-seepage film 9. Specifically, the anti-seepage film 9 is made of HDPE anti-seepage film to prevent the sealing oil from leaking out. The cavity 2 is Inverted T-shaped setting, the upper end of the cavity 2 is provided with a first opening that communicates with the outside world. It is worth mentioning that the size of the first opening should ensure sufficient suction under the premise that the size of the first opening is smaller than the area of the bottom of the vessel. The tray body 1 The upper end is fixedly connected with a sealing film 3 covering the first opening. ...

Embodiment 2

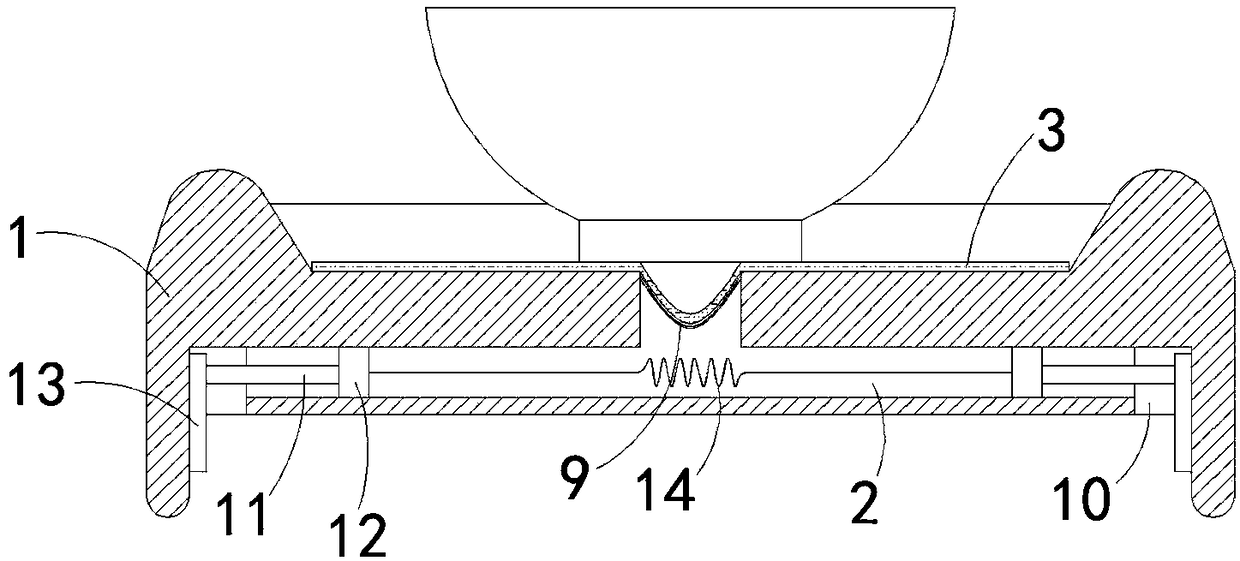

[0023] like image 3 As shown, a negative pressure non-slip tray includes a tray body 1, a cavity 2 is provided in the tray body 1, and the cavity 2 is arranged in an inverted T shape. The upper end of the cavity 2 is provided with a first opening communicating with the outside world. The upper end of the body 1 is fixedly connected with a sealing film 3 covering the first opening. Second openings are provided on both sides of the cavity 2, and a control mechanism is provided in the second opening. It should be noted that the control mechanism includes a Groove 10 on both sides and opening downwards, the side wall of the groove 10 is connected with the cavity 2, the second connecting rod 11 is horizontally arranged in the groove 10, and the second connecting rod 11 is located at one end of the cavity 2 A second sealing plug 12 that matches the cavity 2 is fixedly connected, and one end of the second connecting rod 11 located in the groove 10 is fixedly connected with a pull pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com