Chip and dust removal device of processing machine tool

A technology of dust removal device and processing machine tool, which is applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of cumbersome transfer processing, large dust removal load, affecting the production efficiency and quality of processing machine tools, etc., so as to improve by-products and recover value, reduce energy consumption and cost, ensure continuous operation and process quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

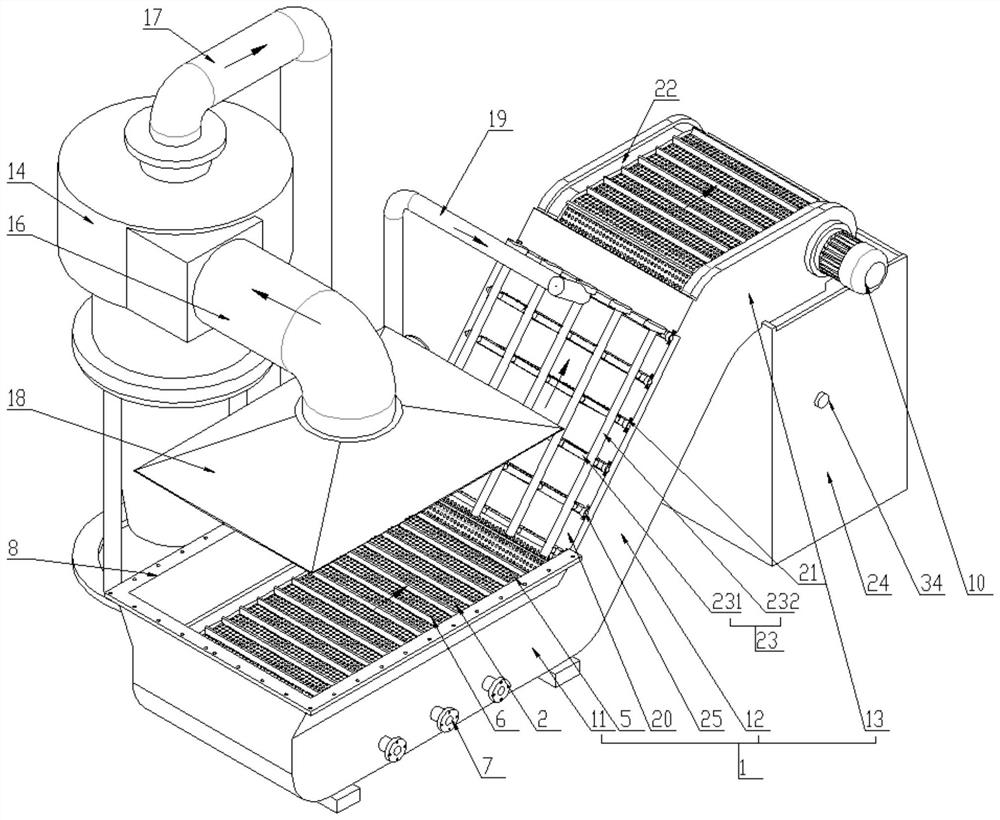

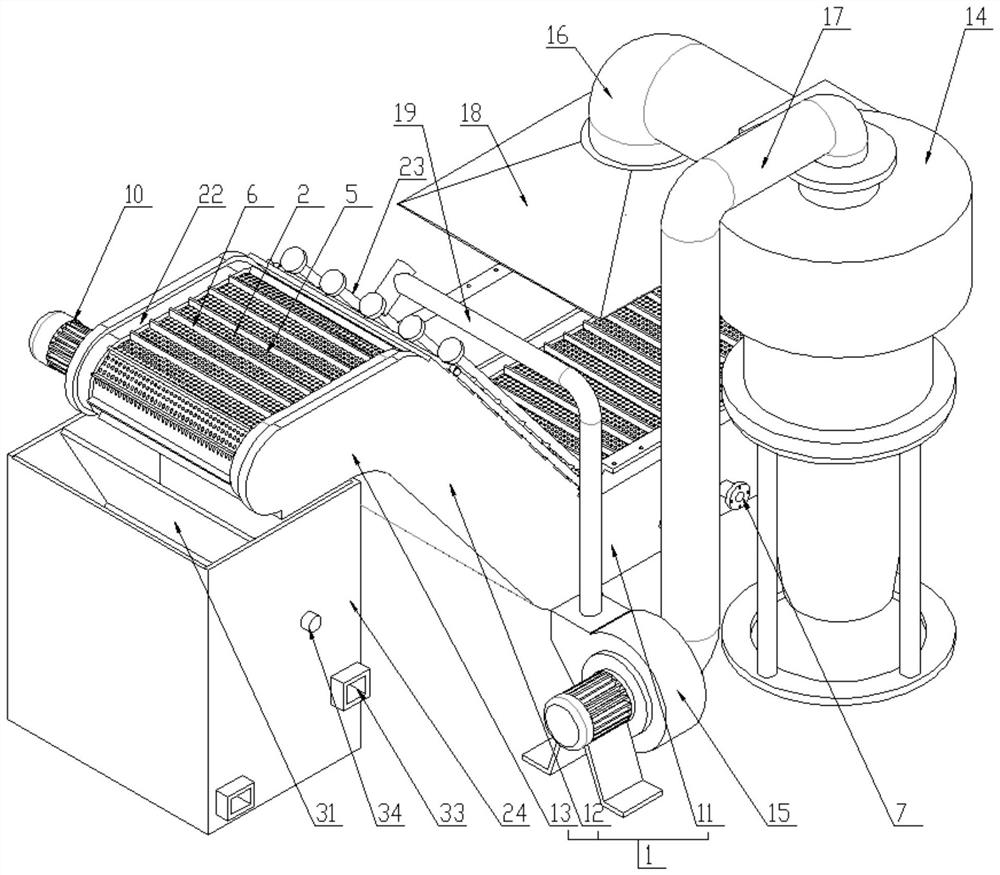

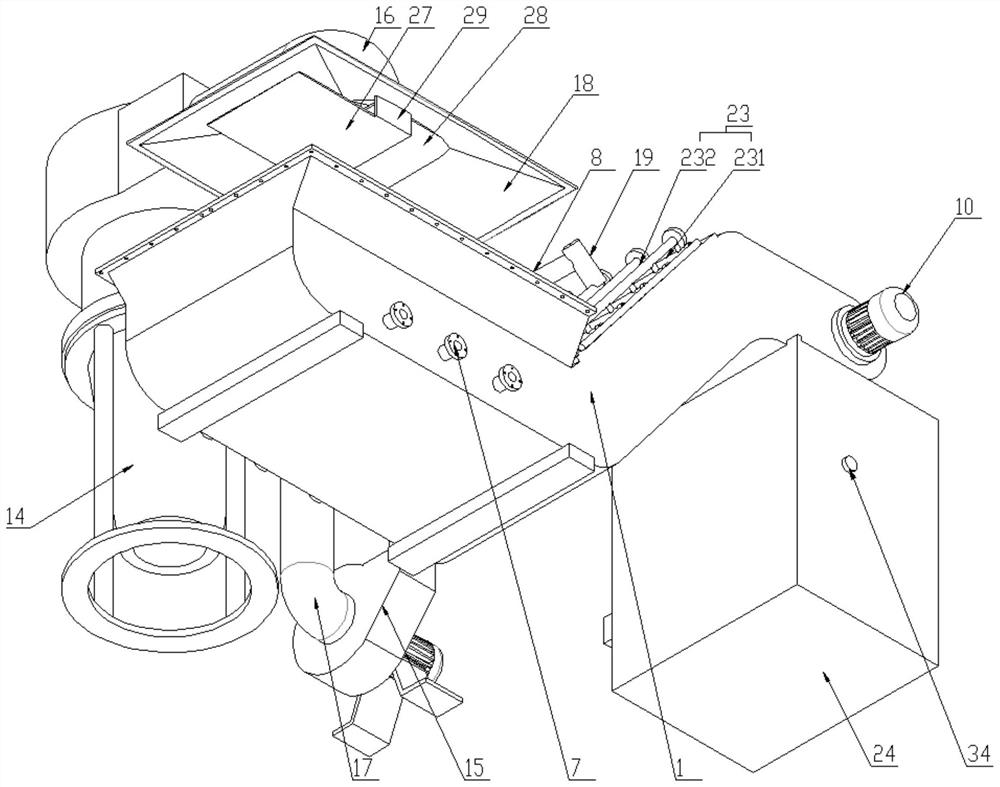

[0020] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] A chip removal and dust removal device for a processing machine tool, comprising a frame 1, wherein the frame 1 includes a water tank 11 with an open top, a lifting frame 12 and a transfer frame 13 connected in one structure, and the frame 1 is provided with a The conveyor belt 2 that rotates between the water tank 11, the lifting frame 12 and the transfer frame 13, the two ends of the conveyor belt 2 are provided with synchronously rotating driving rollers 3 and driven rollers 4, and the conveyor belt 2 is provided with a number of rollers distributed in an array. The permeable holes 5 and several belt plates 6 arranged at intervals, the side of the water tank 11 is provided with at least one water outlet 7;

[0022] The top of the water tank 11 is provided with an outwardly expanded opening flange 8, and the conveyor belt 2 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com