Solder joint structure, solder joint method and solder joint auxiliary tool

A bonding structure and bonding method technology, applied in the field of solder bonding aids, can solve the problem of low productivity and high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

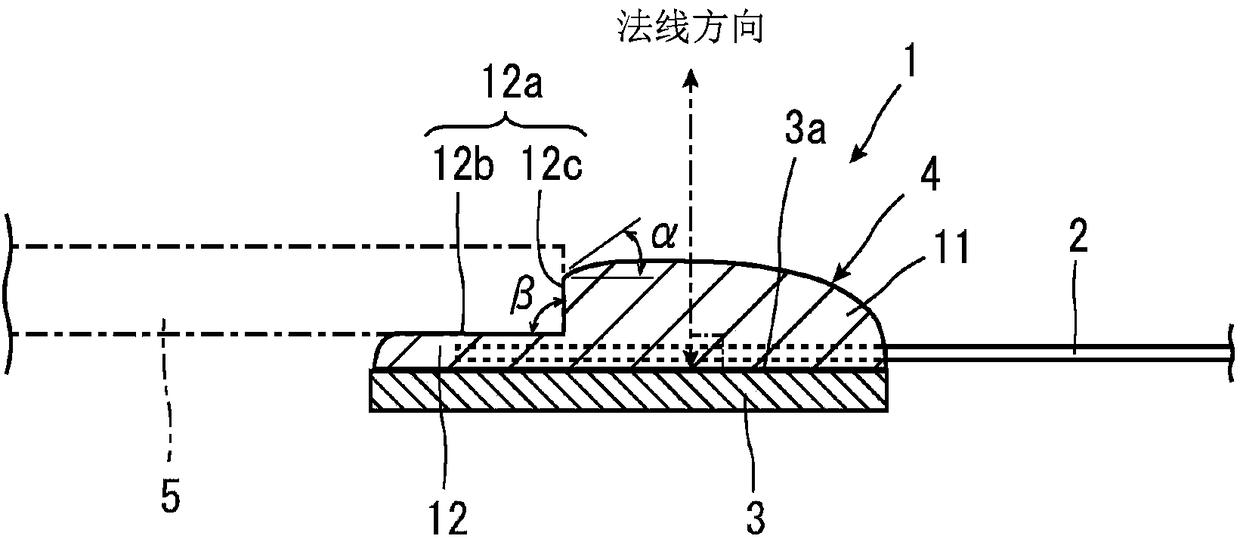

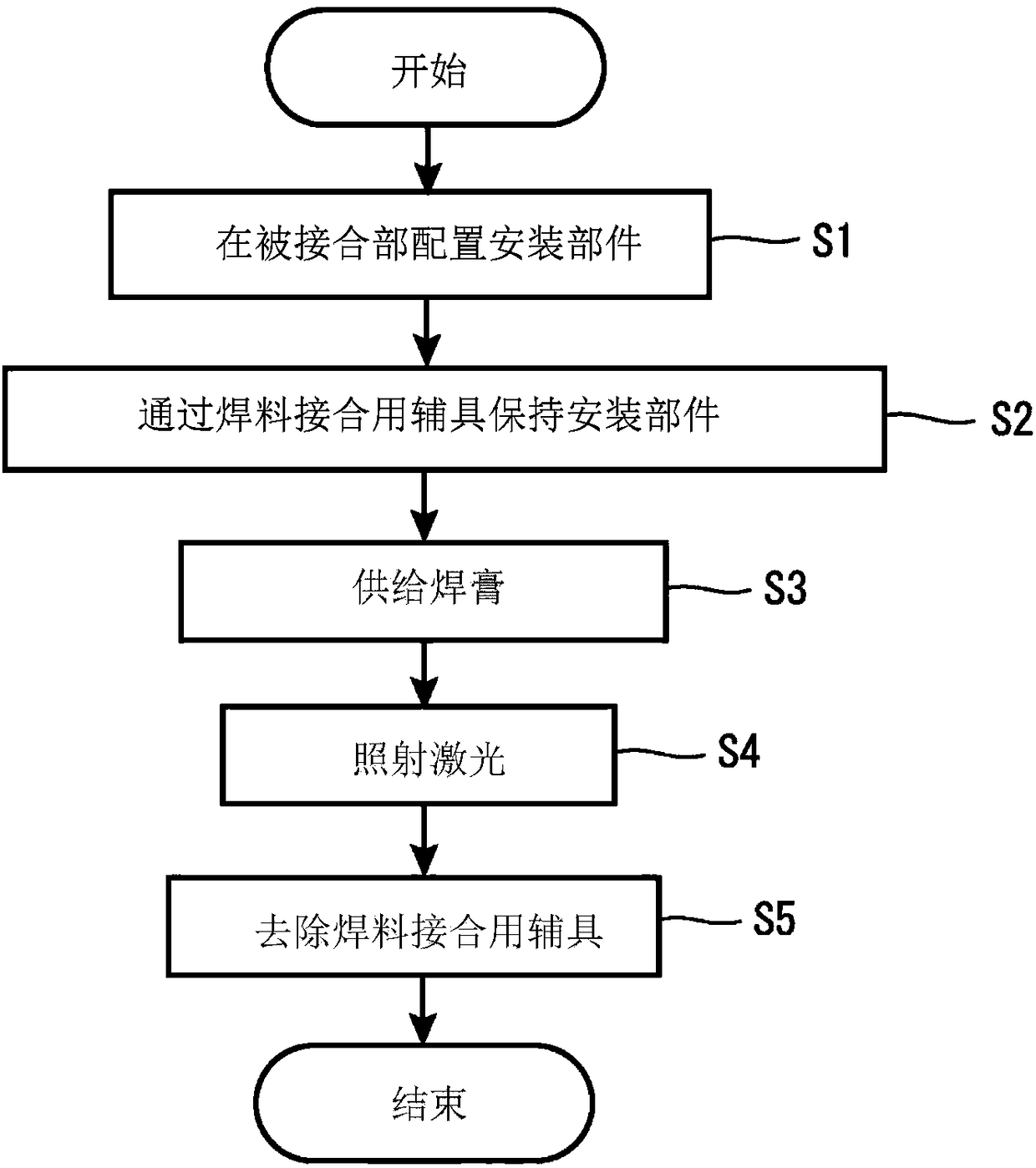

[0019] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, the same code|symbol is attached|subjected to the same or corresponding part in a figure, and the description is not repeated. In addition, the dimensions of the components in the drawings do not represent the dimensions of the actual components, the dimensional ratios of the components, and the like.

[0020] In addition, in the following description, the direction (normal direction) perpendicular|vertical to the surface 3a of the to-be-joined part 3 is called "up-down direction." And, the direction parallel to the surface 3 a of the joined portion 3 is referred to as "lateral direction".

[0021] (solder joint structure)

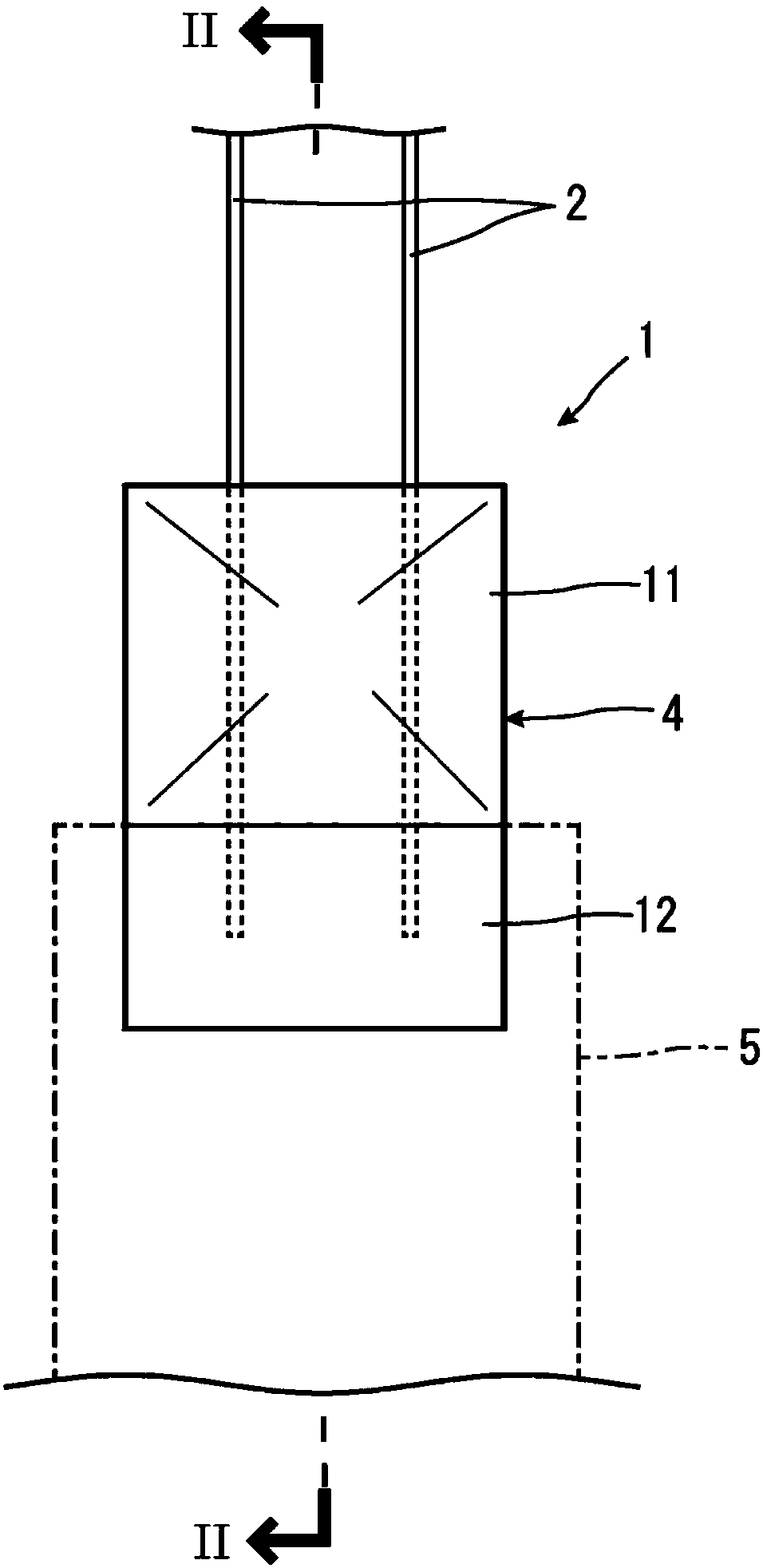

[0022] figure 1 It is a plan view schematically showing the solder joint structure 1 according to the embodiment of the present invention. figure 2 yes figure 1 The II-II line sectional view in. The solder joint structure...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap