Production method for light-transmitting marble tiles

A marble and ceramic tile technology, applied in the field of preparation of light-transmitting marble tiles, can solve the problem that light-transmitting materials cannot express the pure natural beauty of natural stone well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

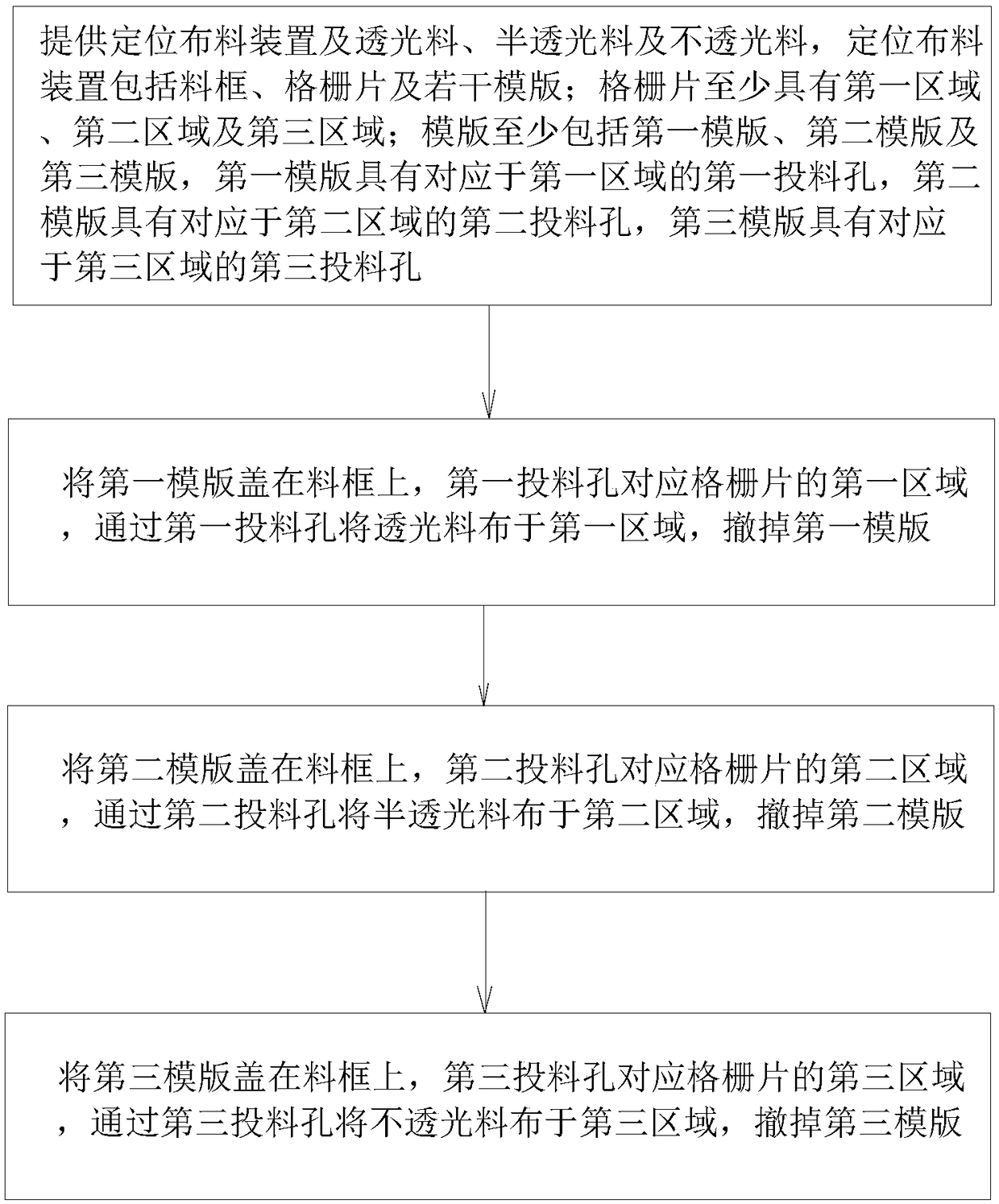

[0031] Please refer to figure 1 , is the preparation method of the translucent marble tile of the embodiment of the present invention, comprises the following steps:

[0032] 1. According to the selected light-transmitting stone material, scan and obtain the design drawing, and design and position the distributing device 100 and the silk screen group for glaze printing according to the above design drawing.

[0033] 2. Provide positioning fabric device 100 and light-transmitting, semi-transparent and opaque materials.

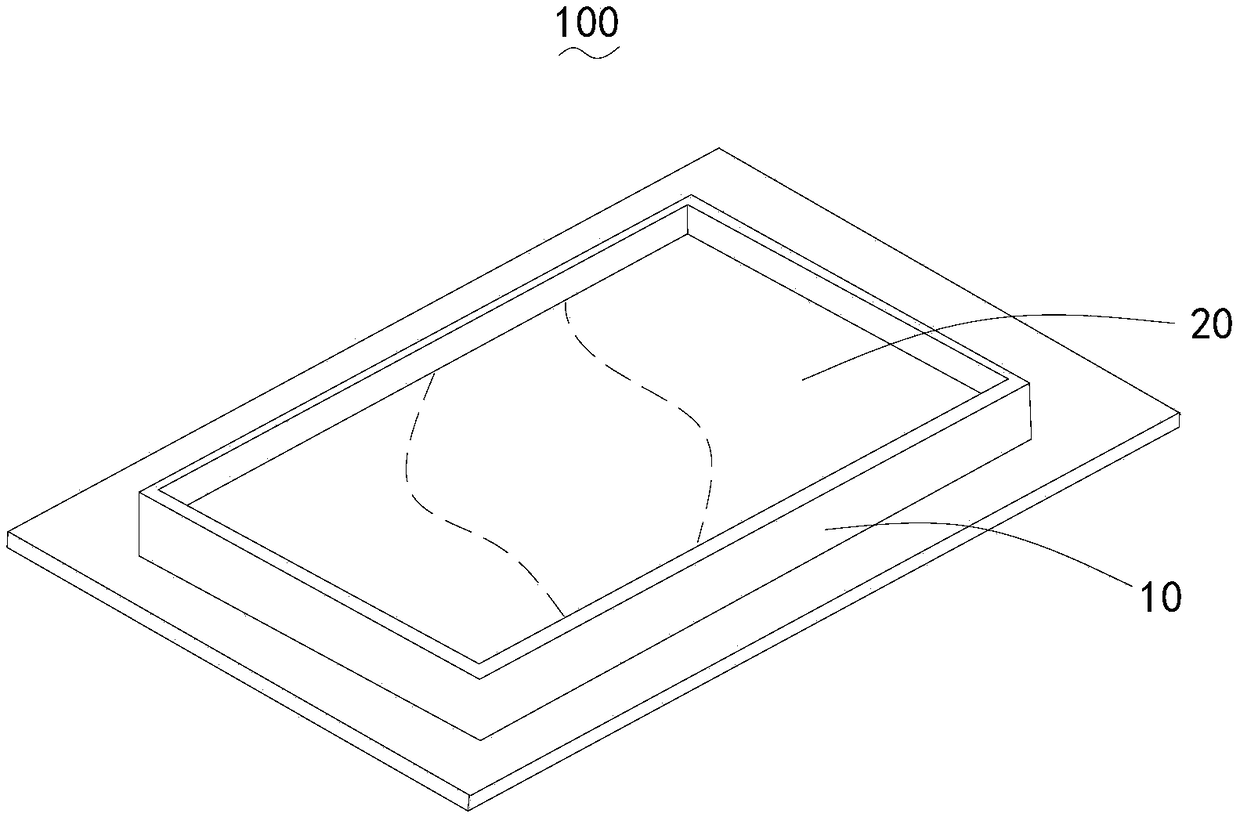

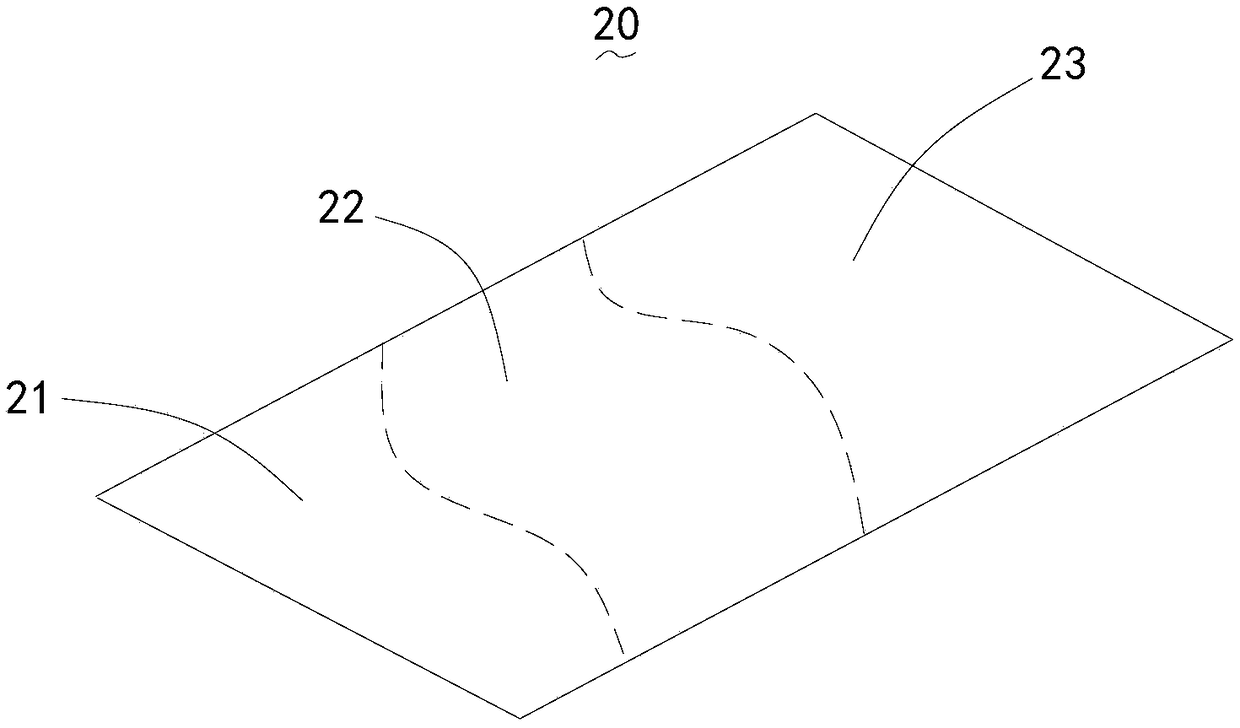

[0034] Please refer to Figure 2 to Figure 4 , the positioning distribution device 100 includes a material frame 10, a grid sheet 20 and a plurality of templates 30, the grid sheet 20 is located in the material frame 10, and the edge of the grid sheet 20 is connected to the material frame 10; the grid sheet 20 has at least a first area 21. The second area 22 and the third area 23, the first area 21 is used to cast light-transmitting material, the second area ...

Embodiment 2

[0059] Please refer to Figure 5 , the difference between this embodiment and the first embodiment is: the first area 21 is connected to the second area 22 , and the second area 22 is connected to the third area 23 .

[0060] In the positioning distribution device 100 described in this embodiment, the grid sheet 20 further includes a fourth area 24, and the fourth area 24 is used for casting light-transmitting, semi-transparent or opaque materials. In this way, the area of the grid sheet is more, so that the light-transmitting, semi-transparent and opaque effects on the formed tiles are combined more, and more various tile effects are displayed. The fourth area 24 can be in contact with the first area 21 , the second area 22 and / or the third area 23 , which is selected according to the setting of the light-transmitting area. The first template 31, the second template 32 or the third template 33 are provided with the fourth feeding hole corresponding to the fourth area 24, t...

Embodiment 3

[0062] The difference between this embodiment and the first embodiment is that: the first area 21 is connected to the second area 22 , and the second area 22 is connected to the third area 23 .

[0063] The positioning and distributing device 100 described in this embodiment further includes a fourth template, and a fifth feeding hole corresponding to the fourth area 24 is opened on the fourth template. After the third stencil 33 is removed, the fourth stencil is covered on the material frame 10 , and the transparent material, semi-transparent material or opaque material is arranged in the fourth region 24 through the fifth feeding hole. In this embodiment, the fourth area 24 is connected to the third area 23, and the fourth area 24 injects the transparent material through the fifth feeding hole.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com