A multi-connected concrete impermeability test block demoulding device

A demoulding device and concrete technology, which can be applied to unloading devices, manufacturing tools, etc., can solve the problems that the device cannot be efficiently realized, and achieve the effects of improving demoulding efficiency, extending the lever arm, and facilitating storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described with reference to the accompanying drawings.

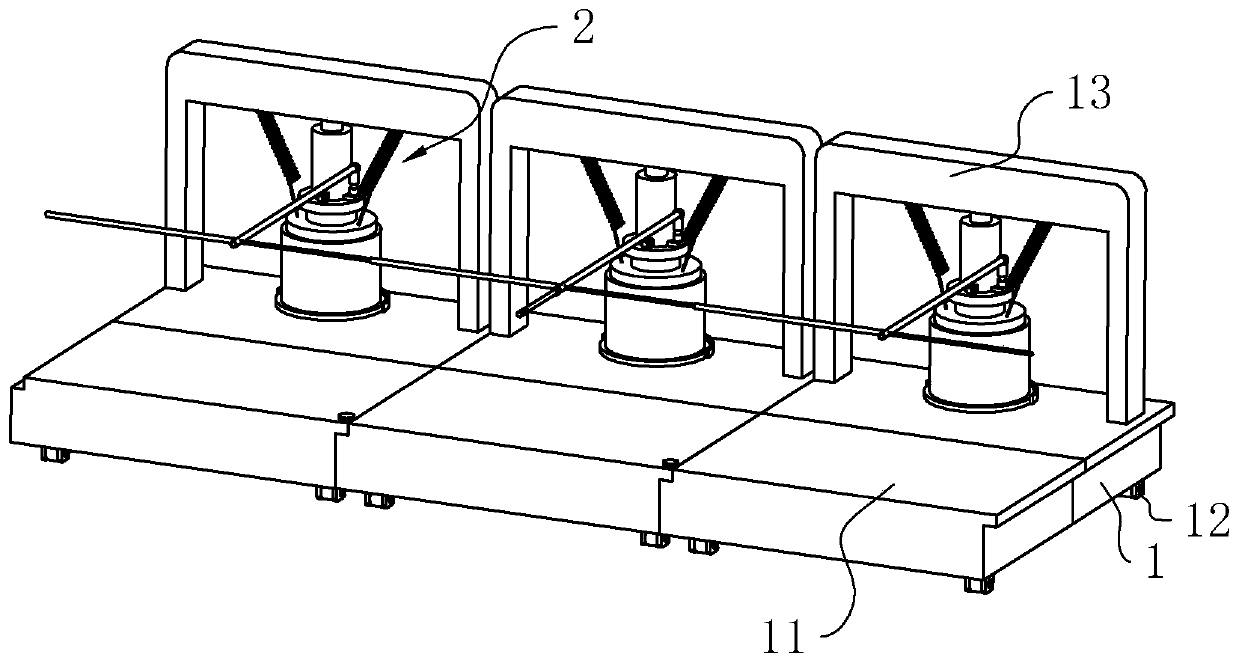

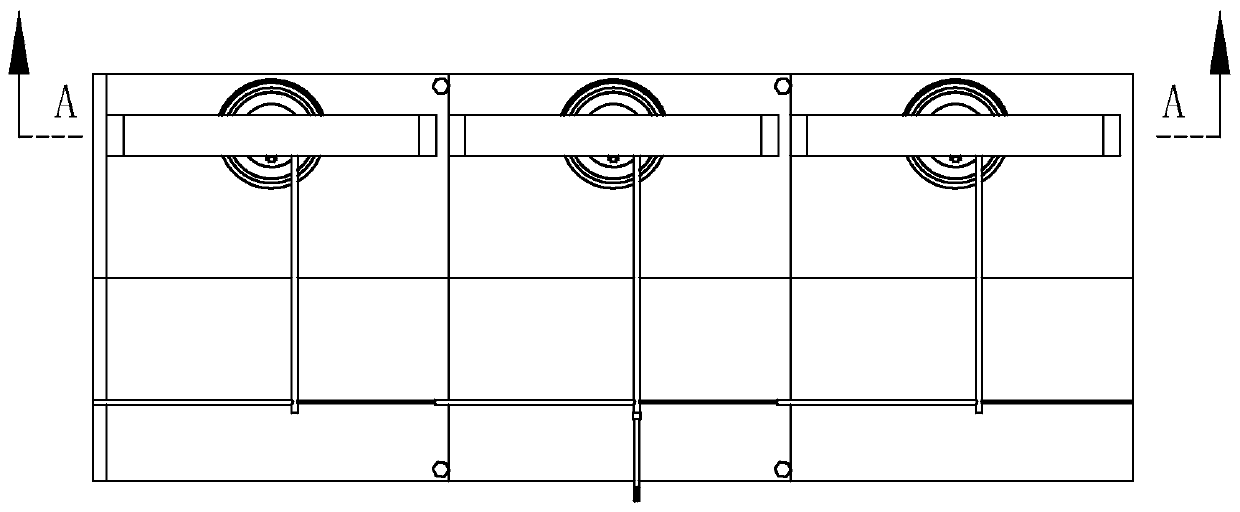

[0041] A multi-connected concrete impermeability test block demoulding device, refer to figure 1 , including a base, the base includes several unit bases 1 spliced with each other, and the several unit bases 1 are sequentially connected by bolts along a straight line. Rollers 12 are all installed under each unit seat 1 . A door-shaped frame 13 is fixed on each unit seat 1 and a stripping assembly 2 is installed in each frame 13 .

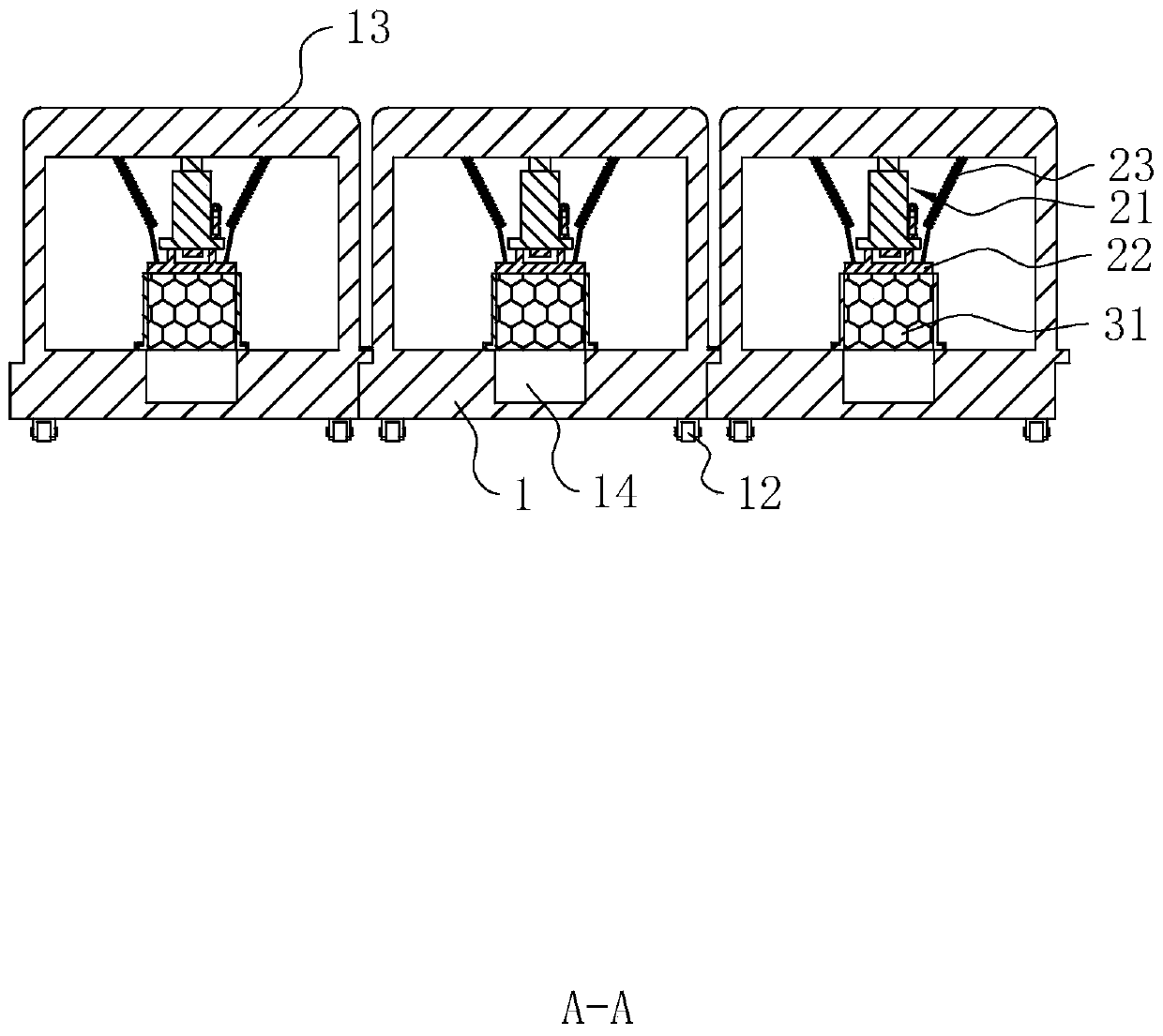

[0042] refer to Figure 4 and Figure 5 , each unit seat 1 is provided with a demoulding hole 14 corresponding to the stripping assembly 2, the aperture of the demoulding hole 14 will be greater than the outer diameter of the concrete test block 31, and less than the outer diameter of the test mold 3 (refer to image 3 ).

[0043] refer to Figure 4 The stripping assembly 2 includes a hydraulic jack 21 fixed in the frame 13, a top plate 22 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com