Triangular surrounding excitation type eddy current transducer and coil winding method thereof

An eddy current sensor, excitation coil technology, applied in the direction of transformer/inductor coil/winding/connection, inductance/transformer/magnet manufacturing, instruments, etc., can solve the problem of lack of eddy current sensor, lack of metal structure stress and strain, etc., to reduce Complexity, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

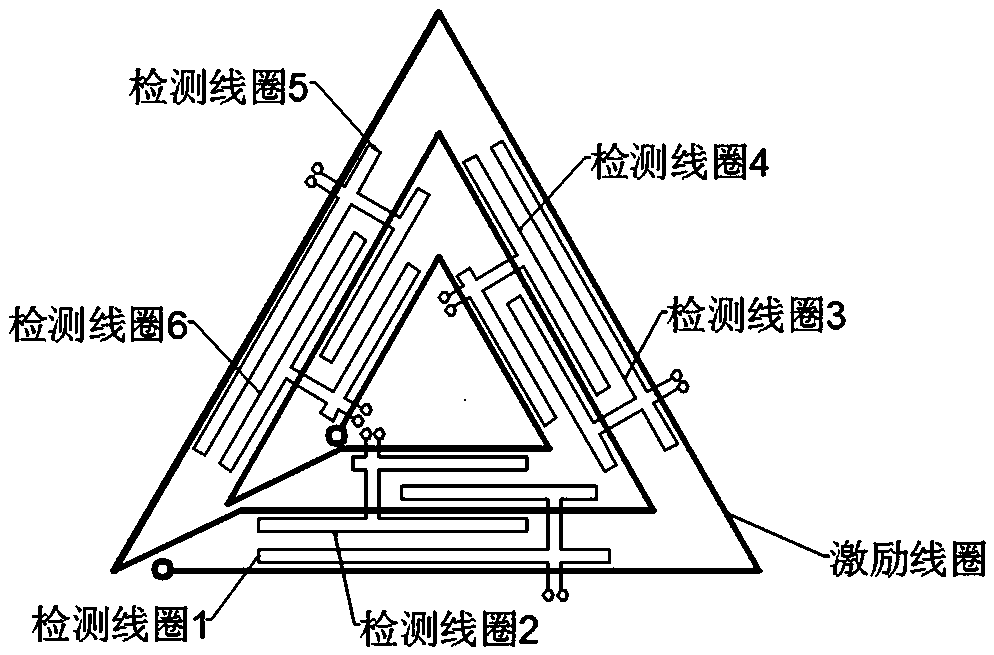

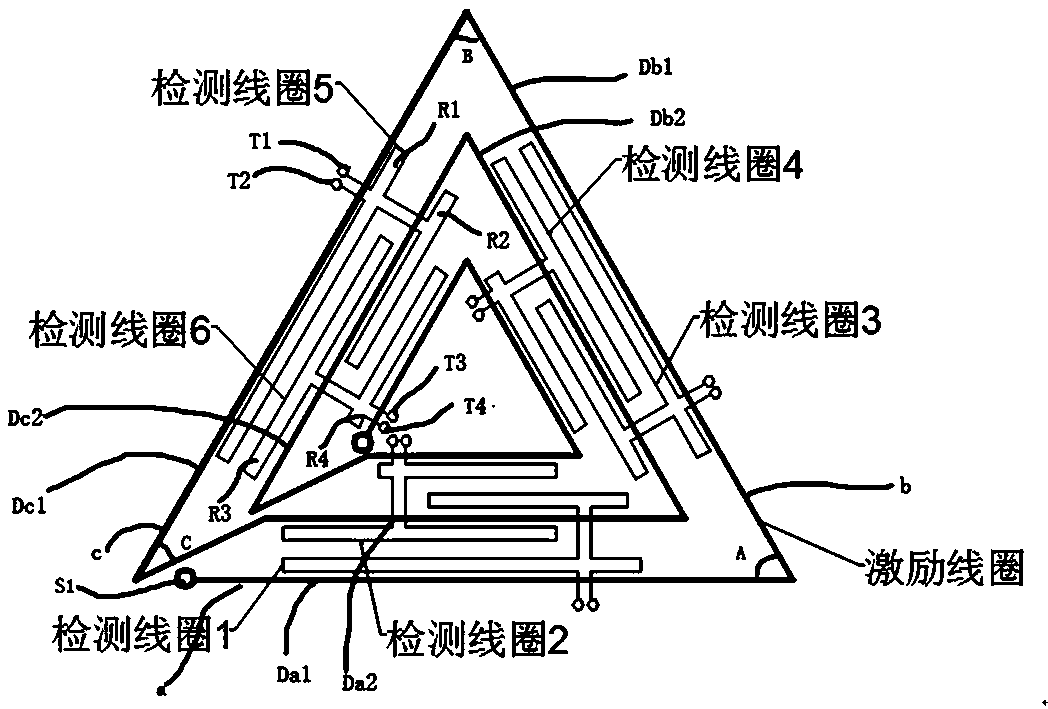

[0034] The invention provides a triangular surround excitation type eddy current sensor for detecting stress and strain. The eddy current sensor includes a printed circuit board and a coil group on the printed circuit board. The printed circuit board can be a flat printed circuit board or a flexible printed circuit board.

[0035] The coil group includes an excitation coil and a detection coil. When an alternating current is inserted into the excitation coil, eddy currents will be induced on the structure under test.

[0036] Specifically, the coil set includes:

[0037] (1) Triangular surround type excitation coils wound by wires. The excitation coils can be isosceles triangles or equilateral triangles, preferably equilateral triangles. The excitation coils can be arranged in multiple circles from outside to inside or from inside to outside. Triangular ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com