Cross knot-type winding fancy eddy current sensor and coil winding method thereof

An eddy current sensor, cross-junction technology, applied in coil manufacturing, inductance/transformer/magnet manufacturing, coils, etc., can solve the problems of lack of stress and strain eddy current sensors, etc., to achieve convenient installation and positioning, reduce complexity, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

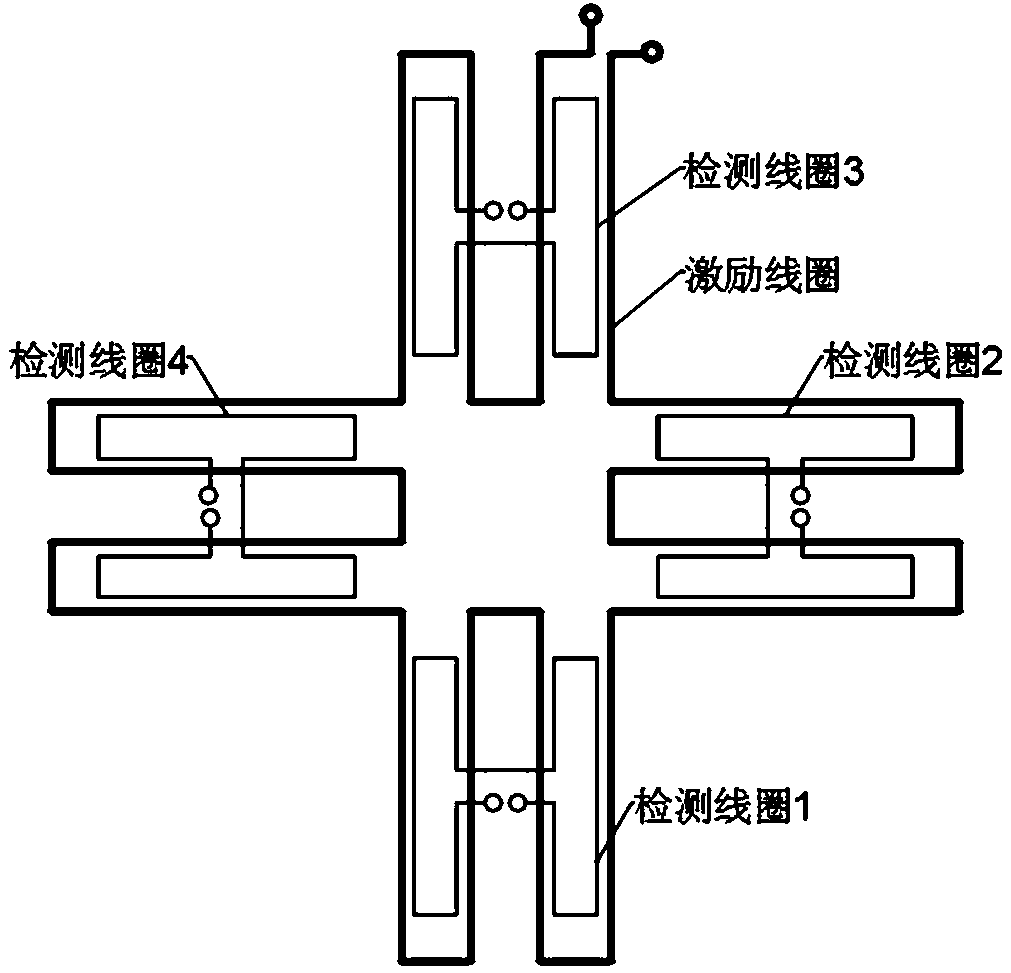

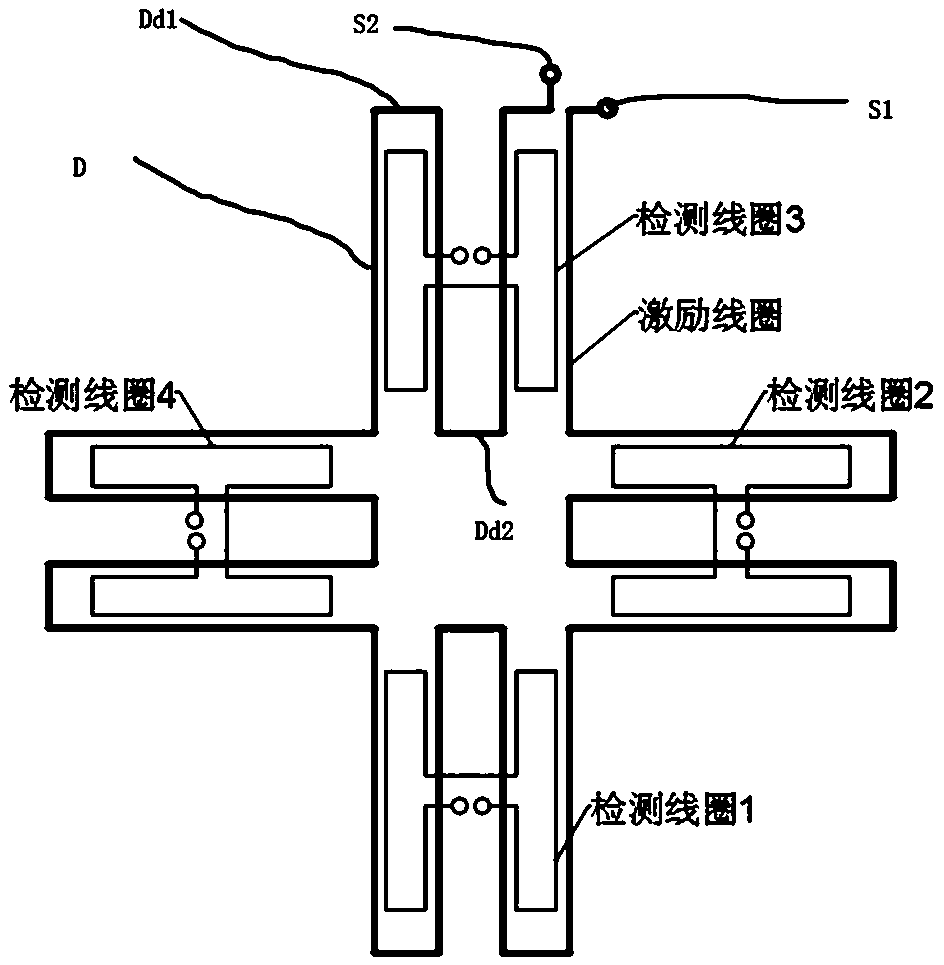

[0032] The invention provides a cross-junction meander fancy eddy current sensor for detecting stress and strain. The eddy current sensor includes a printed circuit board and a coil group on the printed circuit board. The printed circuit board can choose a flat printed circuit board or a flexible printed circuit board.

[0033] The coil set includes an excitation coil and a detection coil, and an alternating current is connected to the excitation coil to induce an eddy current on the structure under test.

[0034] Specifically, the coil set includes:

[0035] The excitation coil wound in the shape of a "ten" with wires is used. The "ten" shape has four convex parts, and each convex part includes a meandering line. The meandering line is composed of at least one meandering unit. When the meandering fold line at the top includes at le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com