Dedusting purification device for cutting machine

A technology of purification device and cutting machine, which is used in combination devices, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as affecting environmental safety, unsatisfactory protection effect, and inability to fundamentally protect the health of workers, and achieves a high level of improvement. The effect of purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

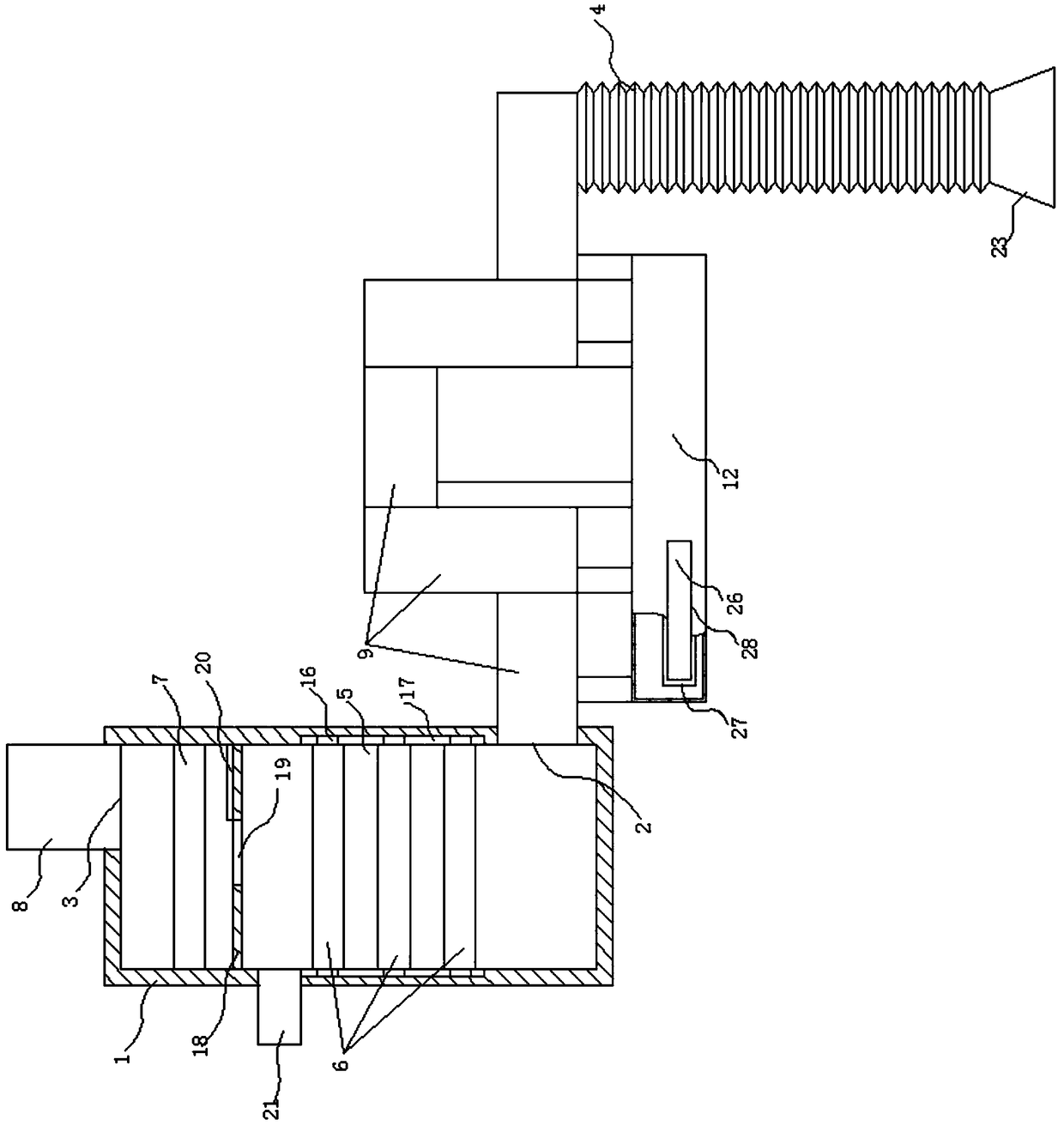

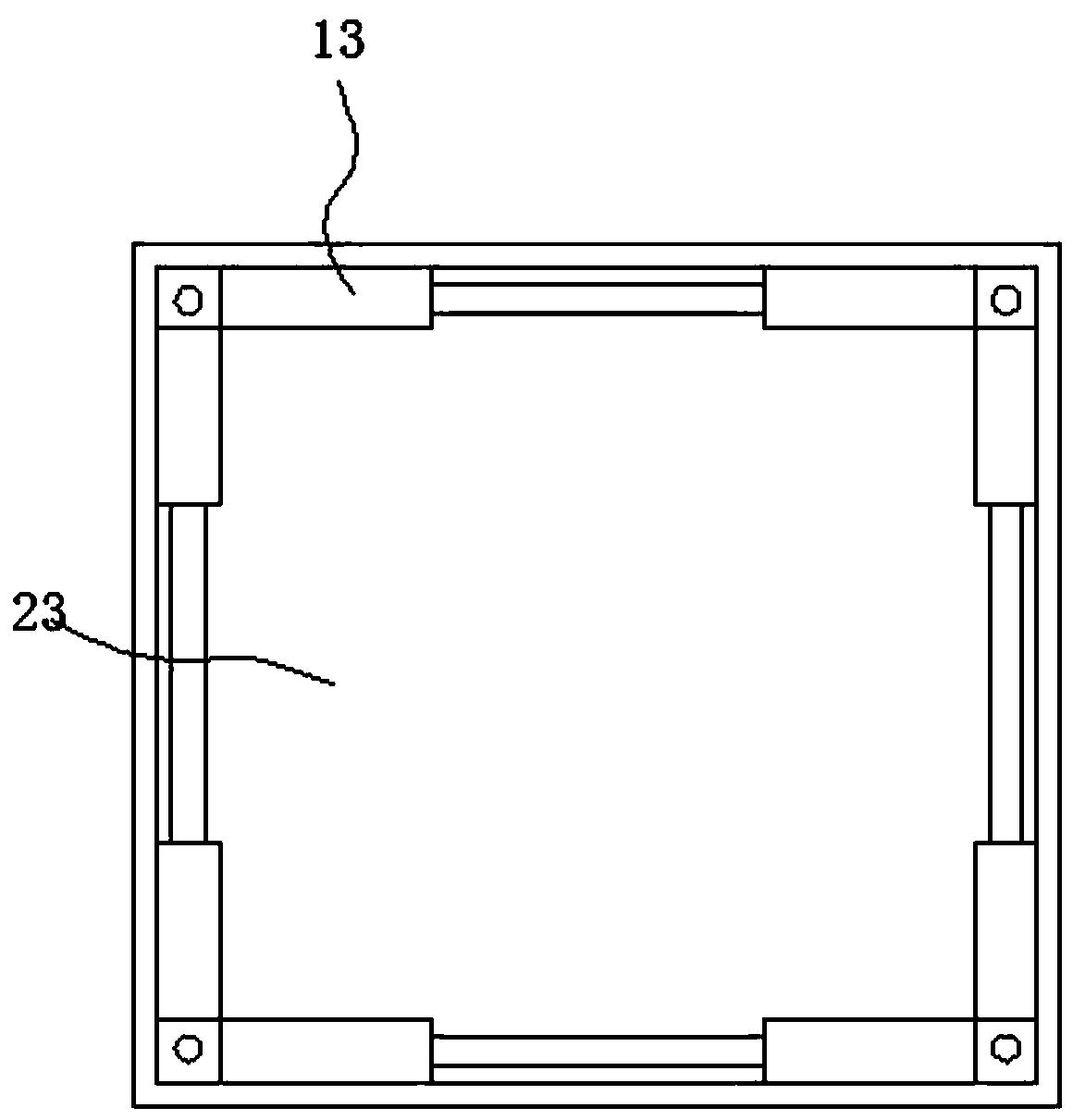

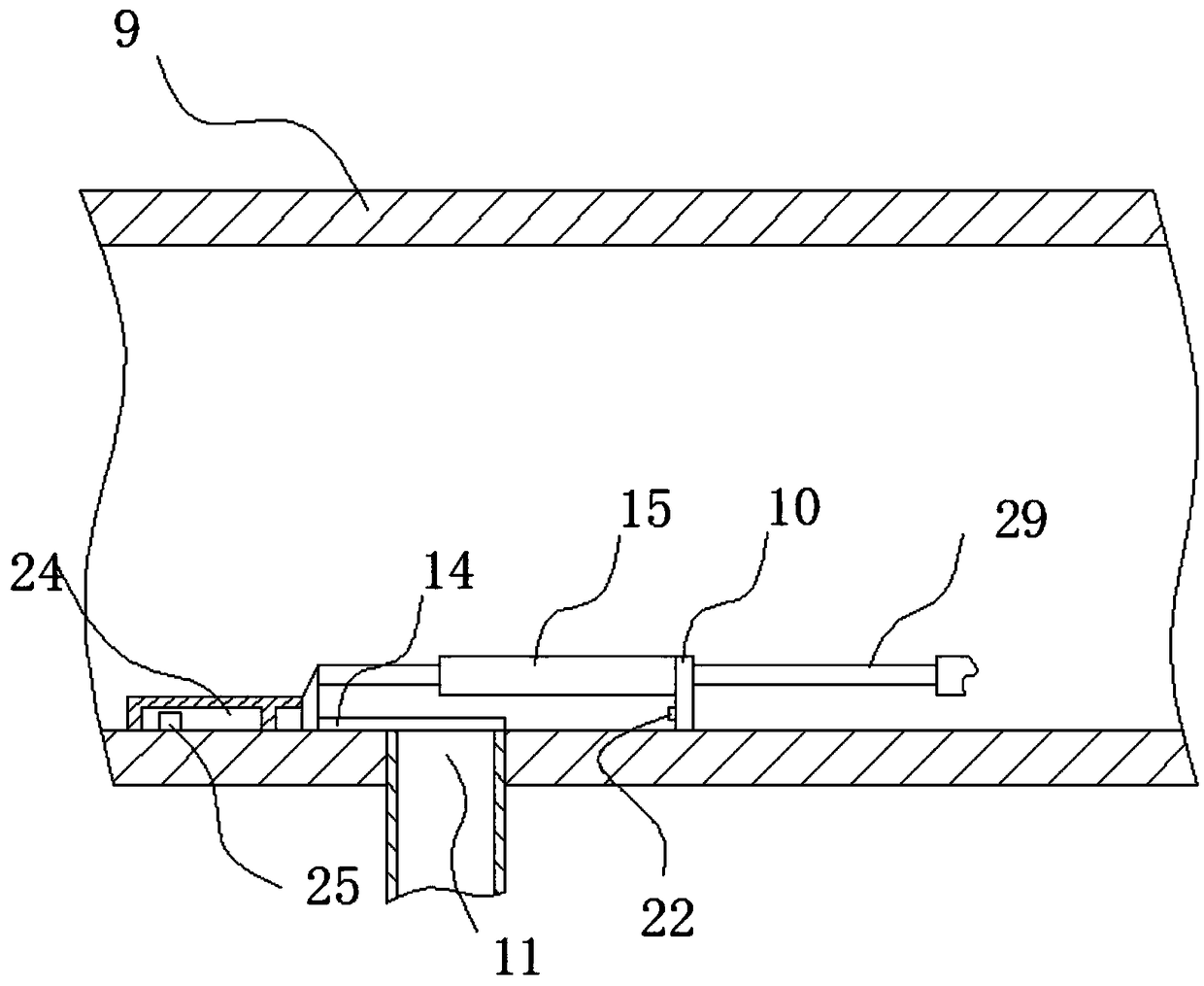

[0017] Such as Figure 1 to Figure 3 As shown, a dust removal and purification device for a cutting machine includes a housing 1, the housing 1 is provided with an air inlet 2 and an air outlet 3, the air inlet 2 is connected to a telescopic tube 4, and the telescopic tube 4 The air inlet is provided with an air inlet size adjustment device, and the housing 1 is provided with a dust removal chamber 5 between the air inlet 2 and the air outlet 3, and the dust removal chamber 5 is provided with a The coarse filter element 6 of the air outlet 2 and the fine filter element 7 adjacent to the air outlet, the air outlet 3 is equipped with an induced draft fan 8, an air duct device is arranged between the air inlet 2 and the telescopic tube 4, and the air duct The device includes a plurality of air ducts 9 perpendicular to each other. A scraper 10 is provided on the horizontal plane of the air duct 9. A dust removal port 11 is provided on the horizontal plane of each of the air ducts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com