Effective aluminum profile cutting machine

A technology of aluminum profiles and cutting machines, which is applied in the direction of metal sawing equipment, sawing machine accessories, metal processing equipment, etc., and can solve the problems of small cutting thickness, affecting the appearance, and not being able to withstand high temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

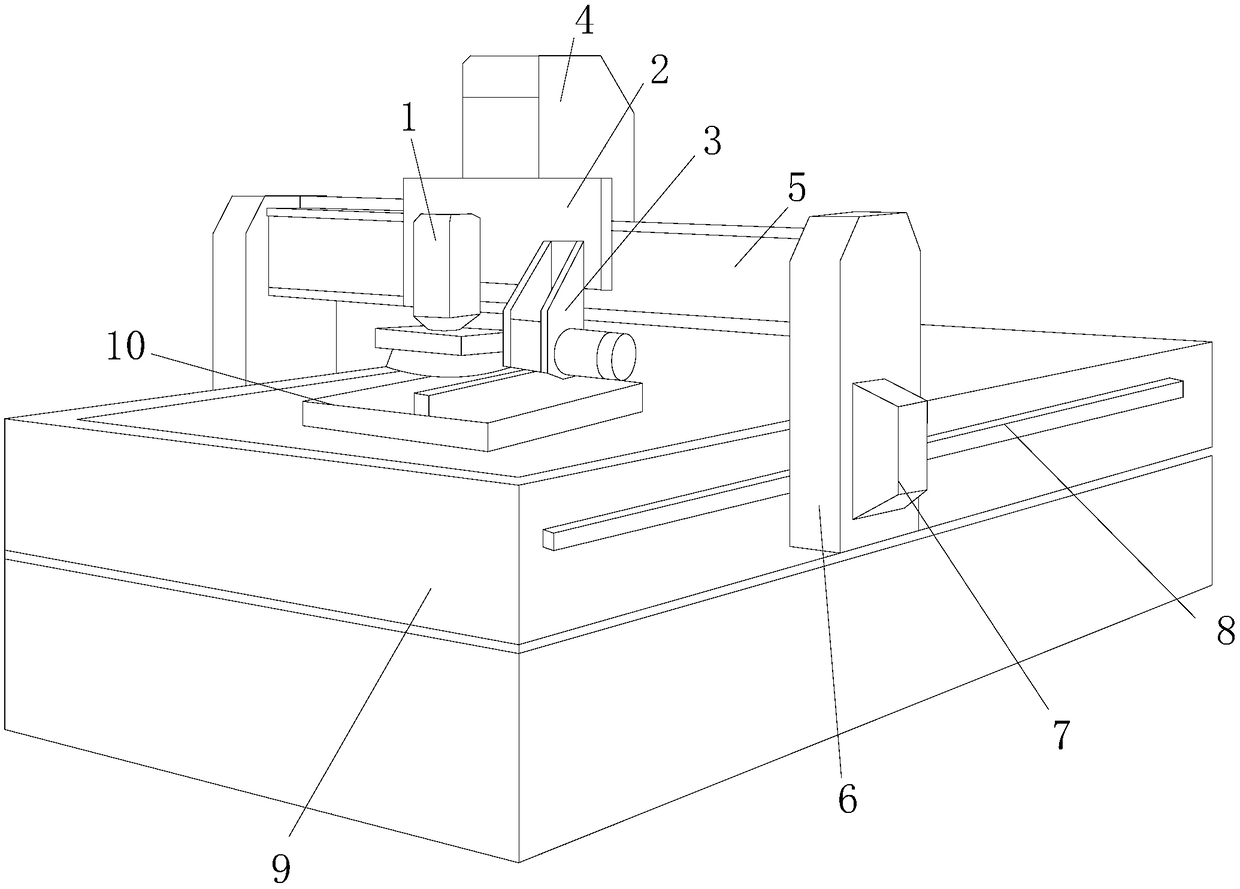

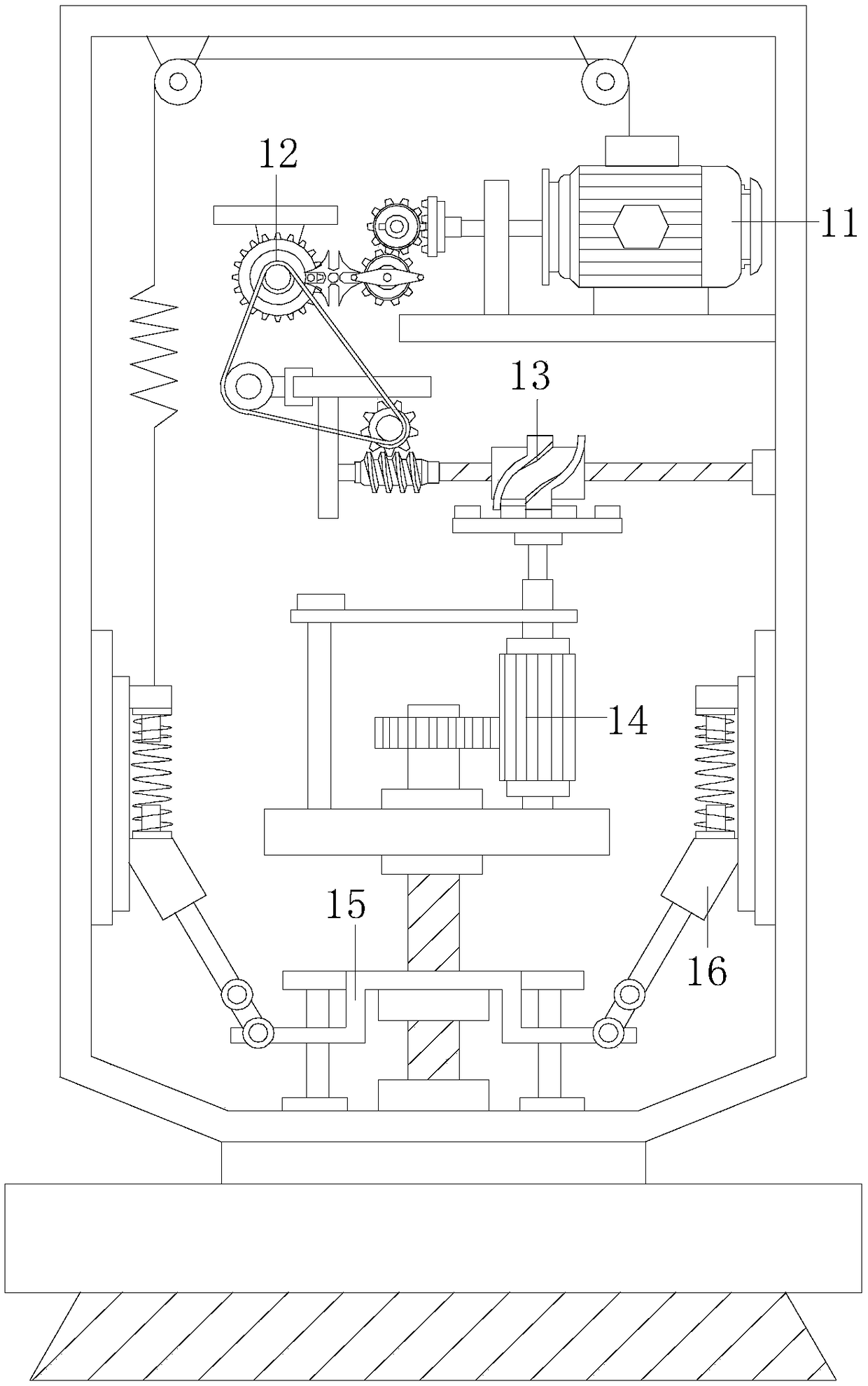

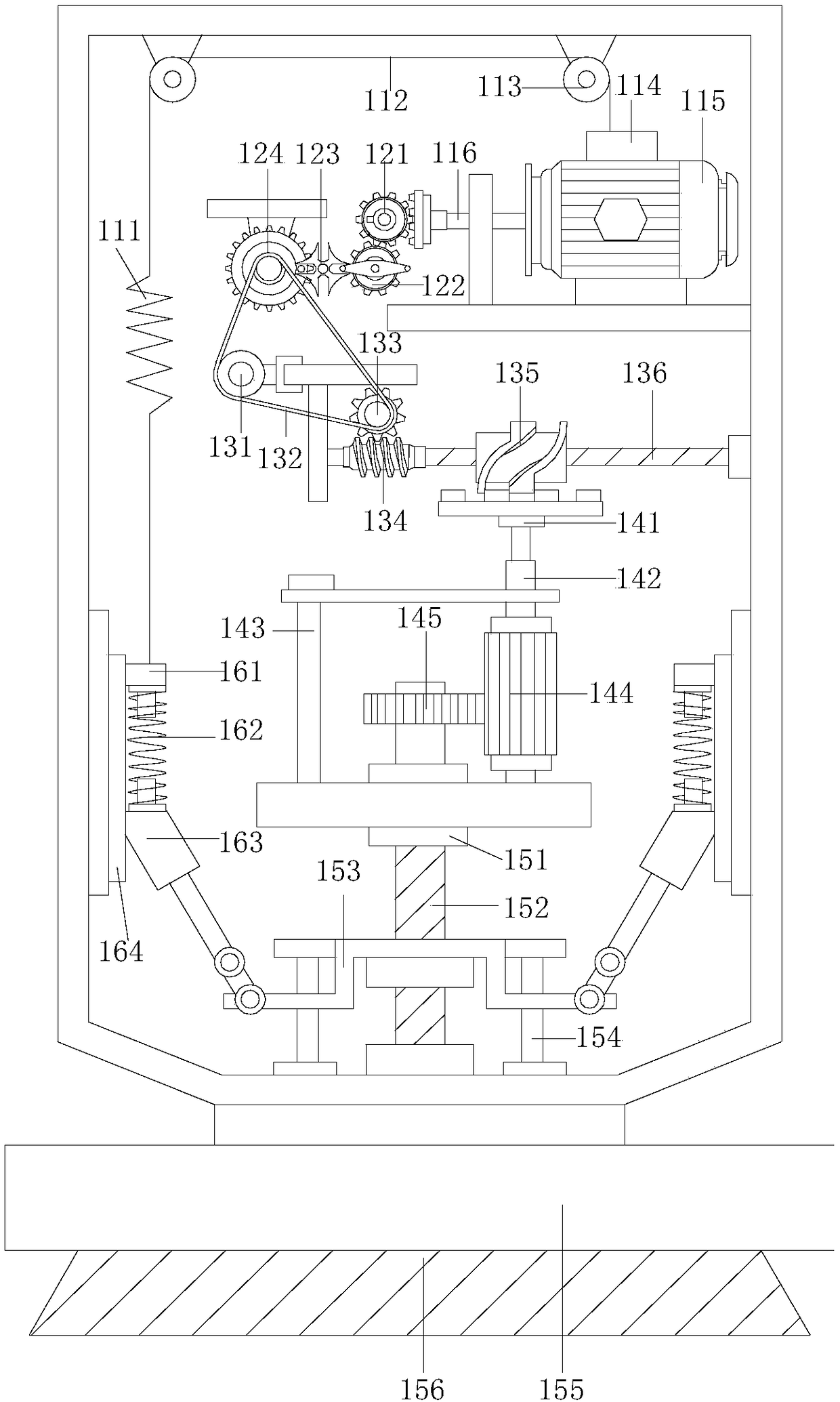

[0020] Such as Figure 1-Figure 4As shown, the present invention provides a high-efficiency aluminum profile cutting machine, the structure of which includes: a quick cleaning device 1, a fixed plate 2, a cutting motor 3, a left and right moving frame 4, a beam 5, a column 6, a driver 7, a rail 8, and a body 9. The chuck 10 is fixed. The quick cleaning device 1 is welded and installed on the front end of the fixed plate 2 and is parallel to the cutting motor 3. The fixed plate 2 is fixed on the front surface wall of the left and right moving frame 4 by bolts. The left and right moving frame 4 is vertically fixed on the top of the crossbeam 5 and is flexibly connected. The column 6 is provided with two left and right sides installed on the crossbeam 5. The rail 8 is welded and fixed on the left and right sides of the body 9. The fixed Chuck 10 is horizontally fixed on the top of body 9, and cooperates with the fast cleaning device 1 on the top in clearance, and described driver...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap