Propulsion integrated rubber plastic ball production clamp device

A fixture device and plastic ball technology, applied in the field of rubber and plastics, can solve the problems of solidified production mode, inability to achieve multi-purpose, lack of diversity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

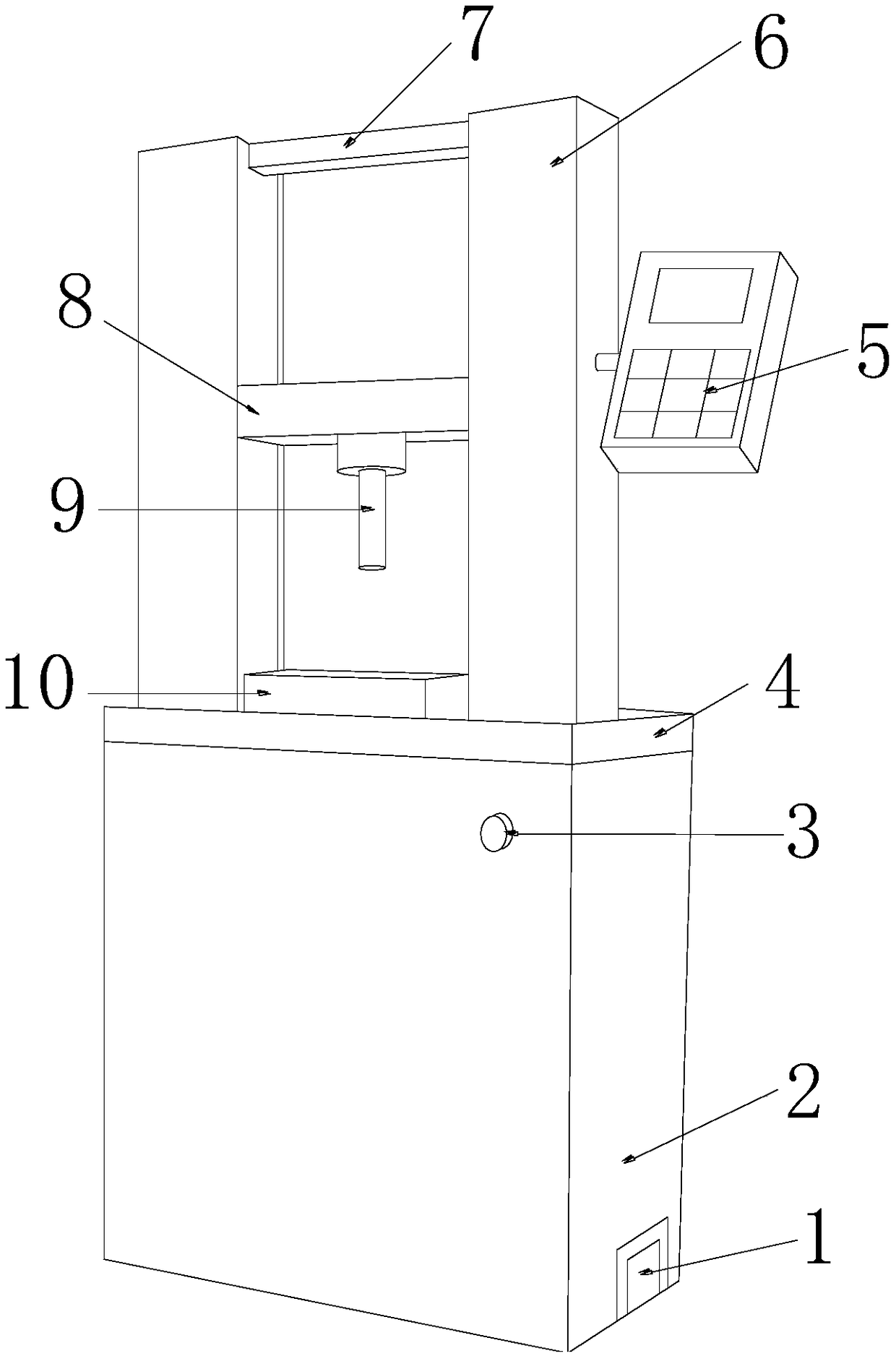

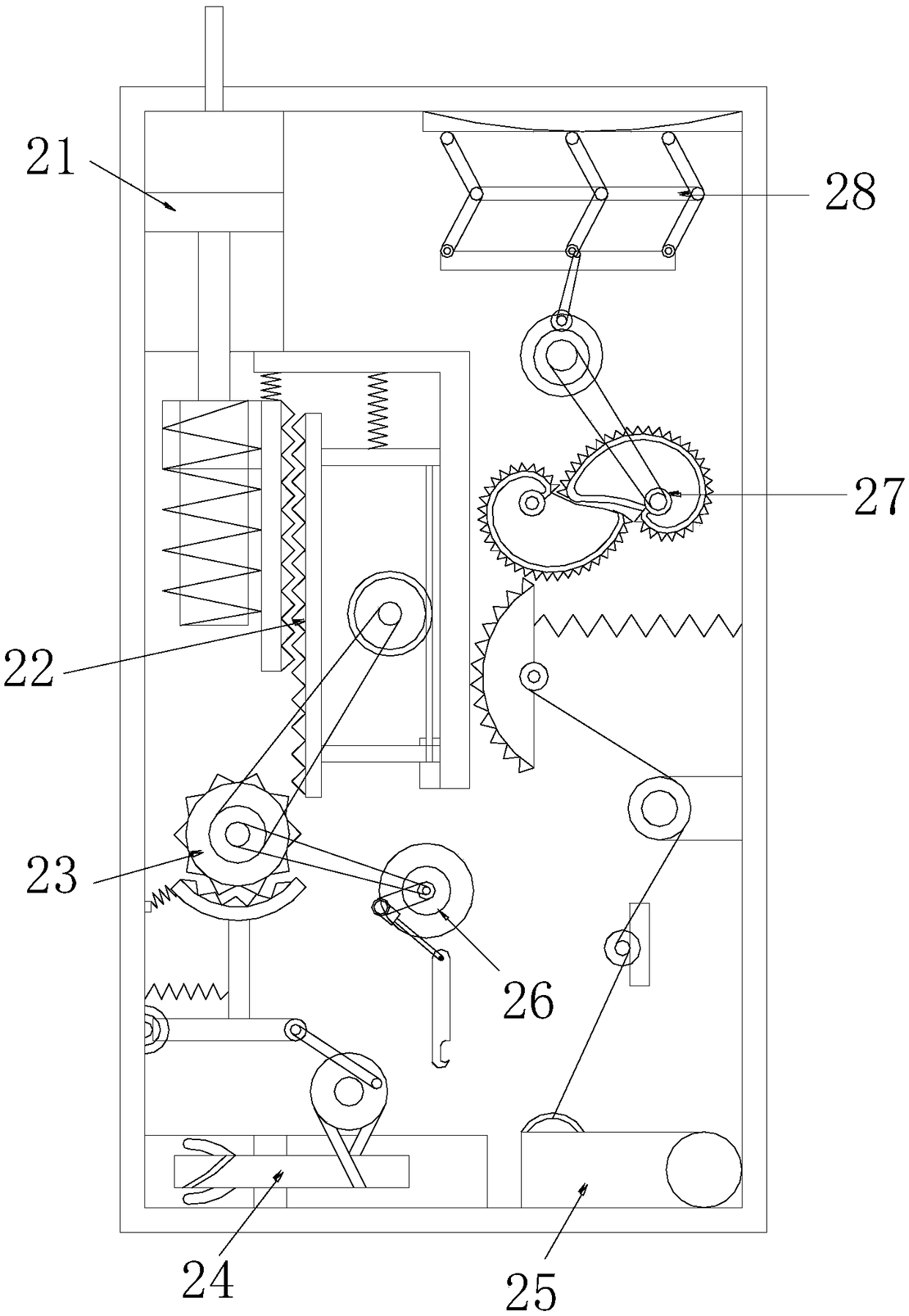

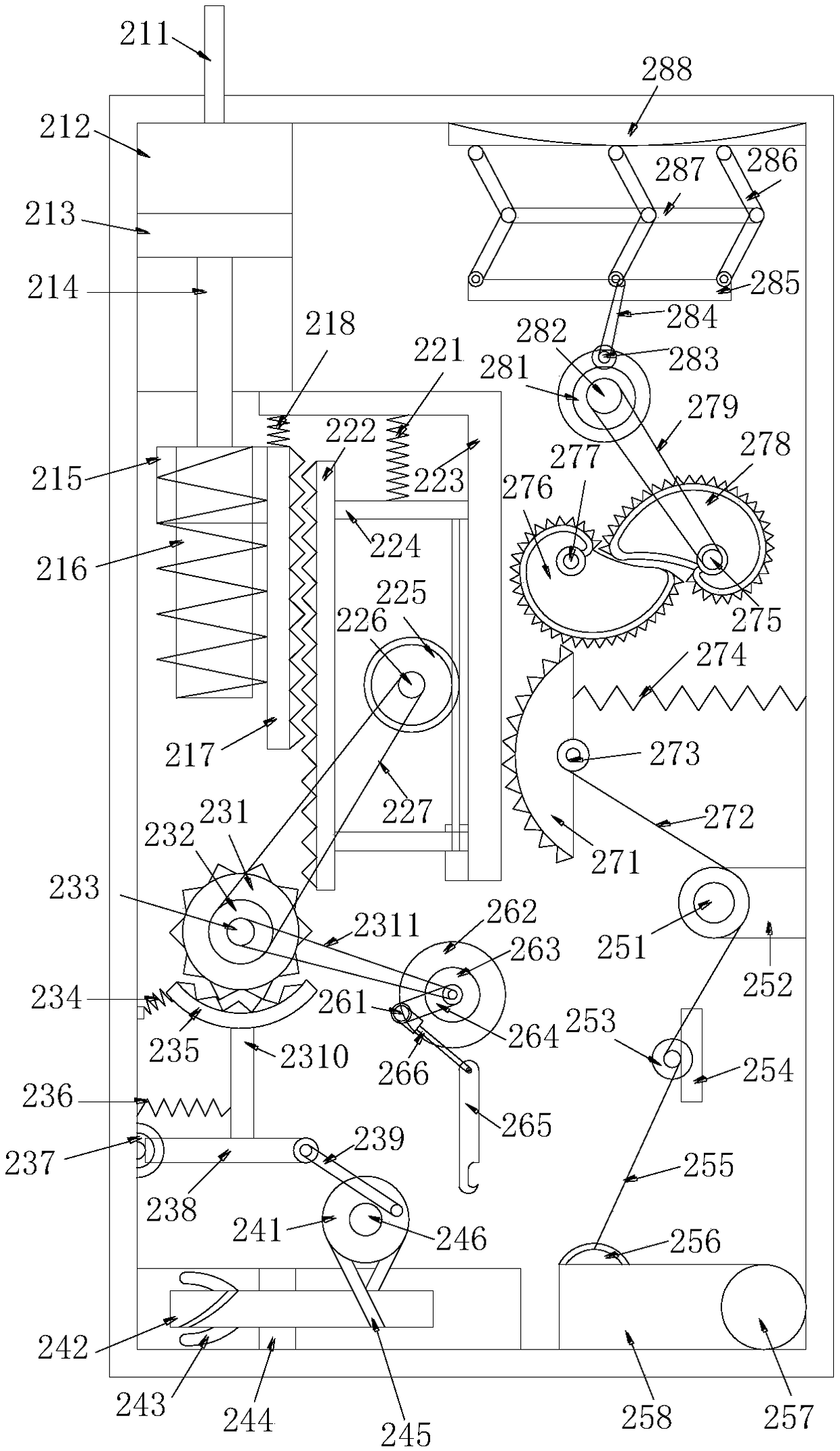

[0025] see Figure 1-Figure 4 , the present invention provides a push-in integrated rubber and plastic ball production jig device: its structure includes a power connection seat 1, a width adjustment device 2, a start switch 3, a connecting sleeve 4, a controller 5, a track column 6, a connecting rod 7, a push Seat 8, shaping mold 9, splint 10, the electric socket 1 is inlaid below the right end of the width adjustment device 2, the start switch 3 is screwed to the right end of the surface of the width adjustment device 2, and the connecting sleeve 4 is nested Above the width adjustment device 2, two track posts 6 are provided and vertically fixed above the connecting sleeve 4, the controller 5 is vertically fixed on the right side of the right en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com