Elastic-film-type tire burst and side turning preventing tire structure

A technology of elastic film and run-flat tires, applied in tire measurement, tire parts, transportation and packaging, etc., can solve the problems of high manufacturing cost, complex structure, rubber waste, etc., and achieve low cost, high reliability and simple device structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

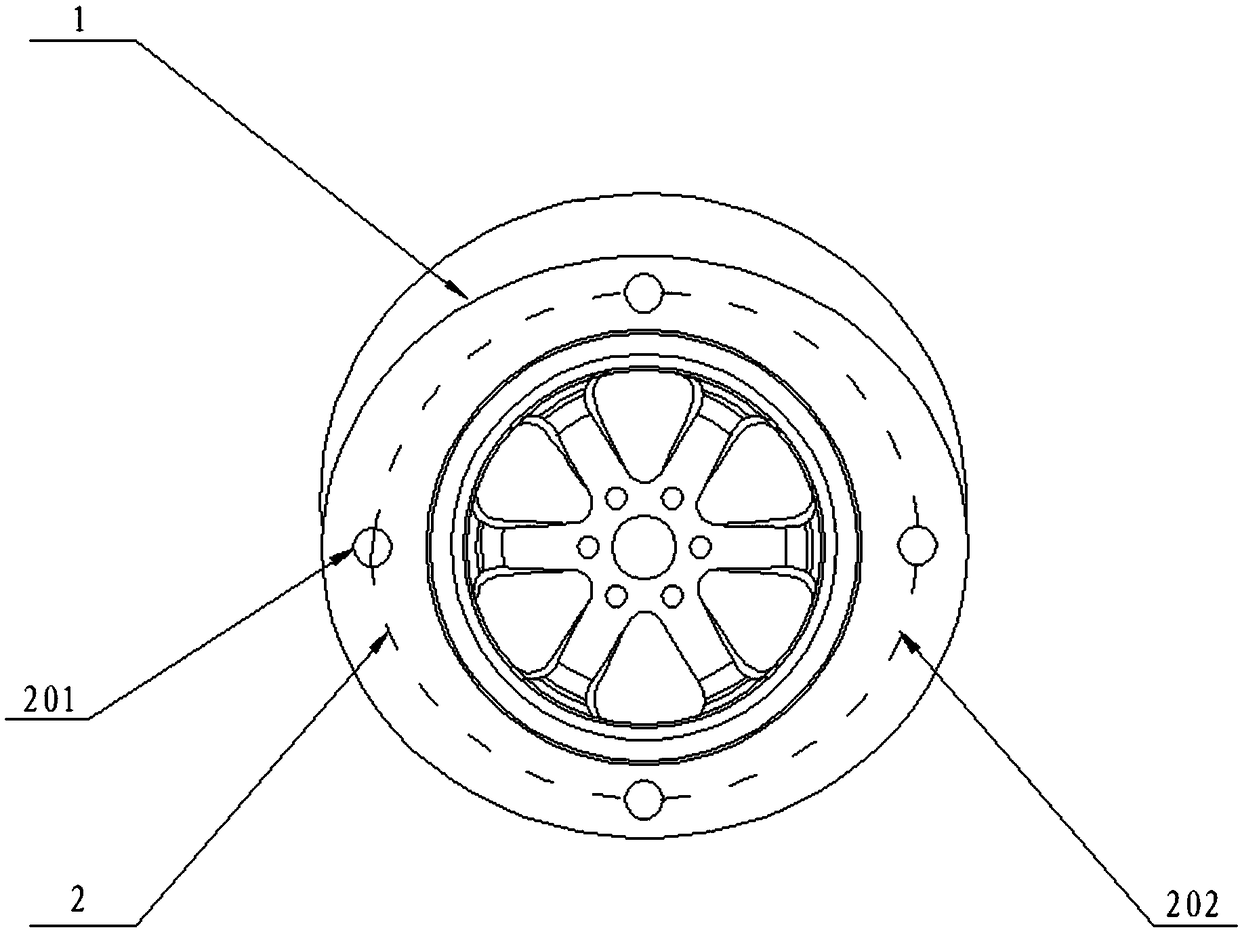

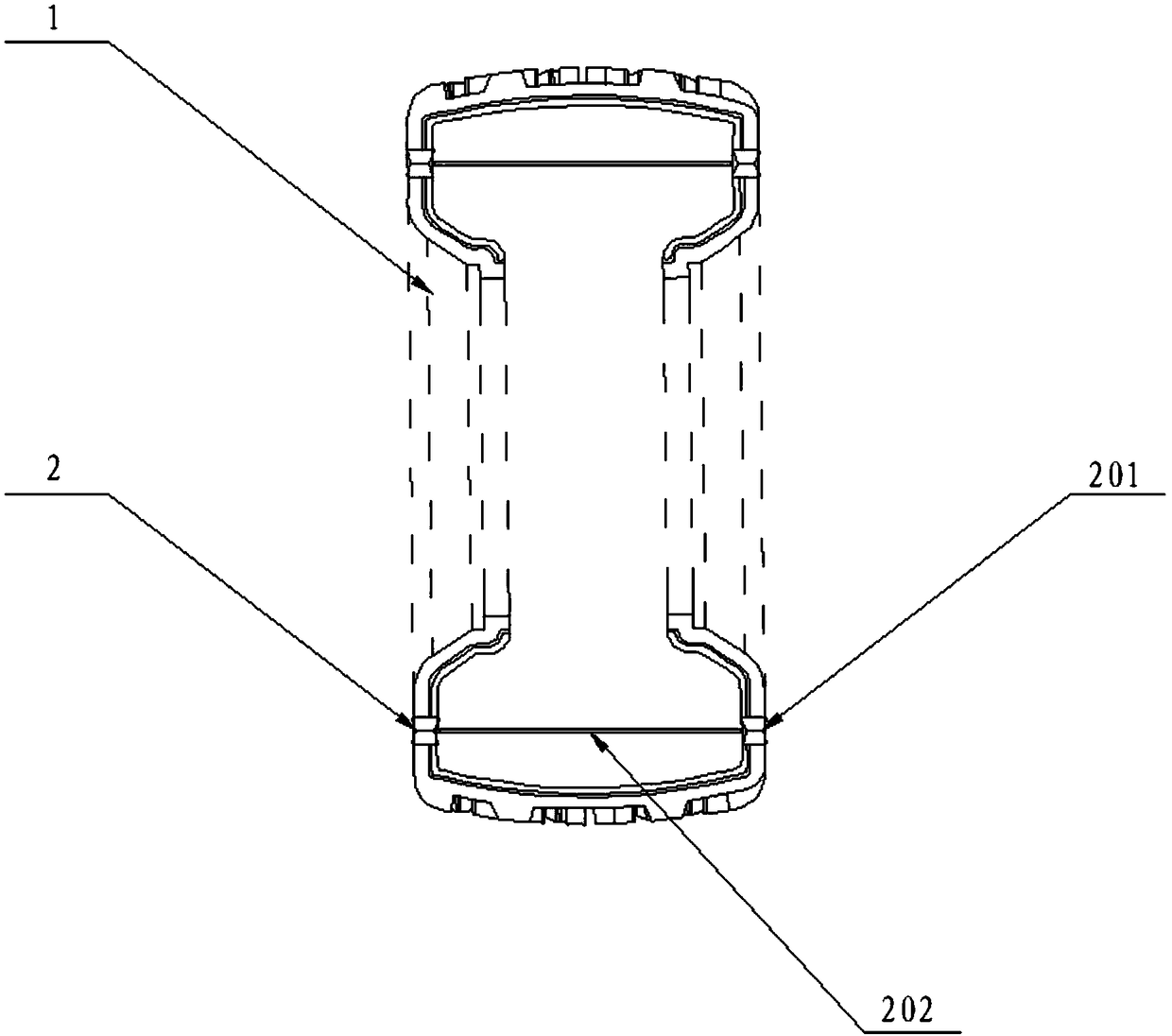

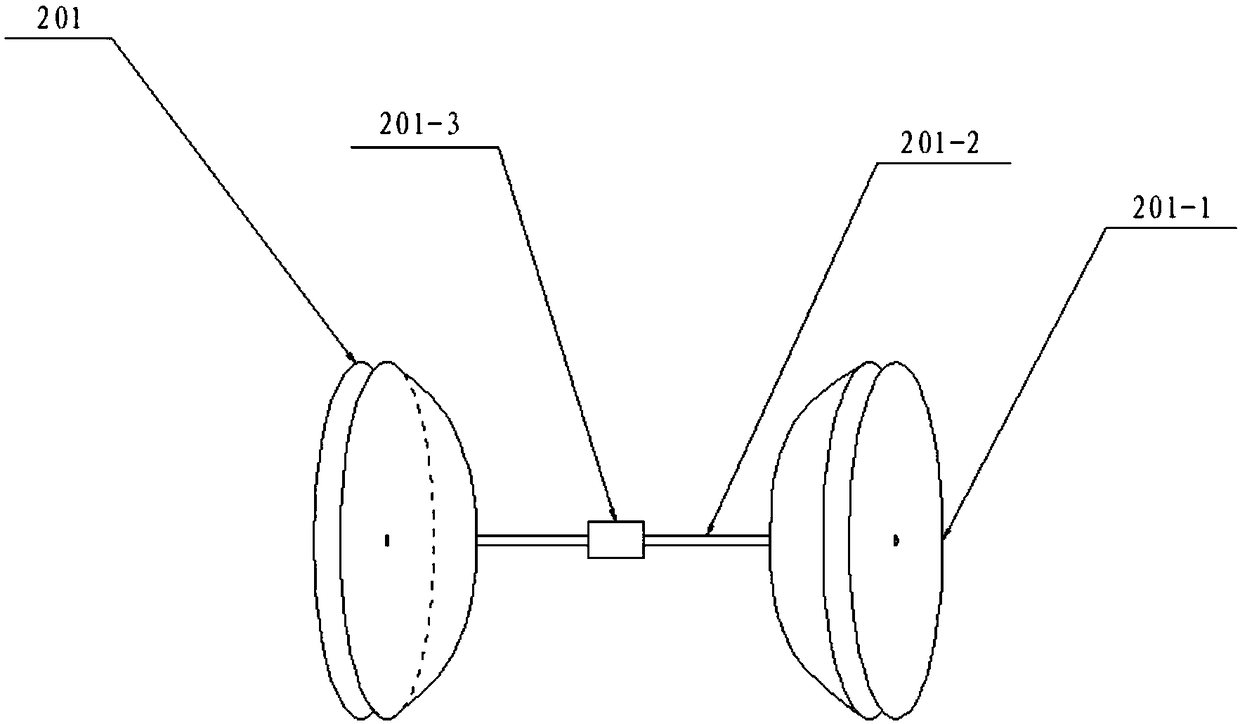

[0030] refer to Figure 1-5 As shown, an elastic film type run-flat tire rollover tire structure includes a tire body 1 and an anti-rollover structure 2, the anti-rollover structure 2 is arranged inside the tire body 1, and the anti-rollover structure 2 includes a weak The link structure 201 and the elastic film 202, the weak link structures 201 are respectively arranged on the corresponding positions of the side walls of the tire body 1 to form a group, and the weak link structures 201 and the weak link structures 201 are connected by the elastic film 202 , the weak link structure 201 includes a connecting block 201-1, a connecting rod 201-2 and a weak link 201-3, the connecting block 201-1 includes two pieces corresponding to the work, and the connection between the two connecting blocks 201-1 The connecting rod 201-2 is connected to the weak link 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com