Sugar block finishing conveying device

A conveying device and technology of sugar cubes, applied in the field of sugar cube sorting and conveying devices, can solve the problems of reverse placement of sugar cubes, troublesome packaging process, low efficiency, etc., and achieve the effect of simple structure, reasonable design, and not easy to miss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

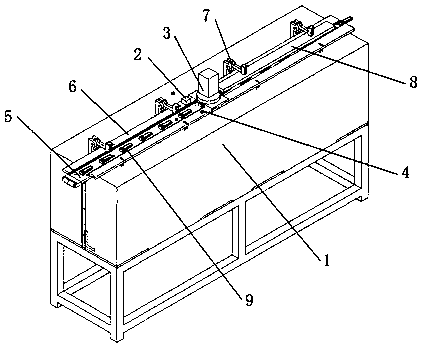

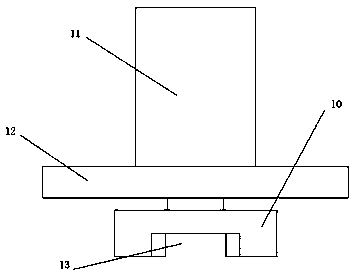

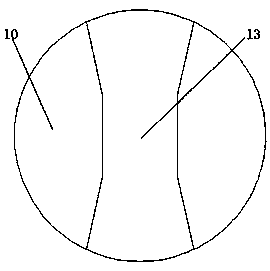

[0023] like Figure 1-3 Shown, a kind of candy arrangement conveying device, it comprises conveying device, described conveying device comprises conveyor belt 5, and candy 9 is conveyed by conveyor belt 5, and it also comprises industrial visual camera 2 and selection device 3, industrial visual camera 2, The selection device 3 is sequentially arranged on the conveying device along the conveying direction of the conveyor belt. The conveying device is also provided with a trigger switch 4, which corresponds to the industrial vision camera 2. The trigger switch 4 detects the sugar cube 9, and the trigger switch 4 is connected to the industrial vision camera. 2. The industrial vision camera 2 is connected to the selection device 3; the selection device 3 includes a sugar-turning plate 10 and a servo motor 11, the sugar-turning plate 10 is rotatably mounted on the conveying device through a fixed bracket 12, and the sugar-turning plate 10 is located on the side of the conveying dev...

Embodiment 2

[0025] like Figure 1-3 As shown, in the technology of embodiment 1, the further described trigger switch 4 is a contact switch, the contact switch is connected to the lever, and the lever extends to the top of the conveyor belt 5, the candy 9 moves with the conveyor belt 5, and the candy 9 tops Move the lever, the lever acts to close the contact switch, and the contact switch gives a signal to the industrial vision camera 2.

[0026] When the present invention is used, the candies 9 are evenly placed on the conveyor belt 5 of the conveying device, and move together with the conveyor belt 5, the candies 9 pass the trigger switch 4 in turn, the previous candy triggers the trigger switch 4, and the trigger switch 4 sets the industrial vision A signal from the camera 2, the industrial vision camera 2 takes pictures and calculates the positional relationship of the candy, and the previous candy moves into the opening slot 13 of the sugar turning plate, and the industrial vision ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com