Glass transport rack

A technology for placing racks and glass, which is applied in the direction of transportation and packaging, conveyor objects, furnaces, etc. It can solve the problems of affecting glass transportation efficiency, glass surface wear, and complicated operation, so as to improve the scope of application, prevent surface wear, and simple operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

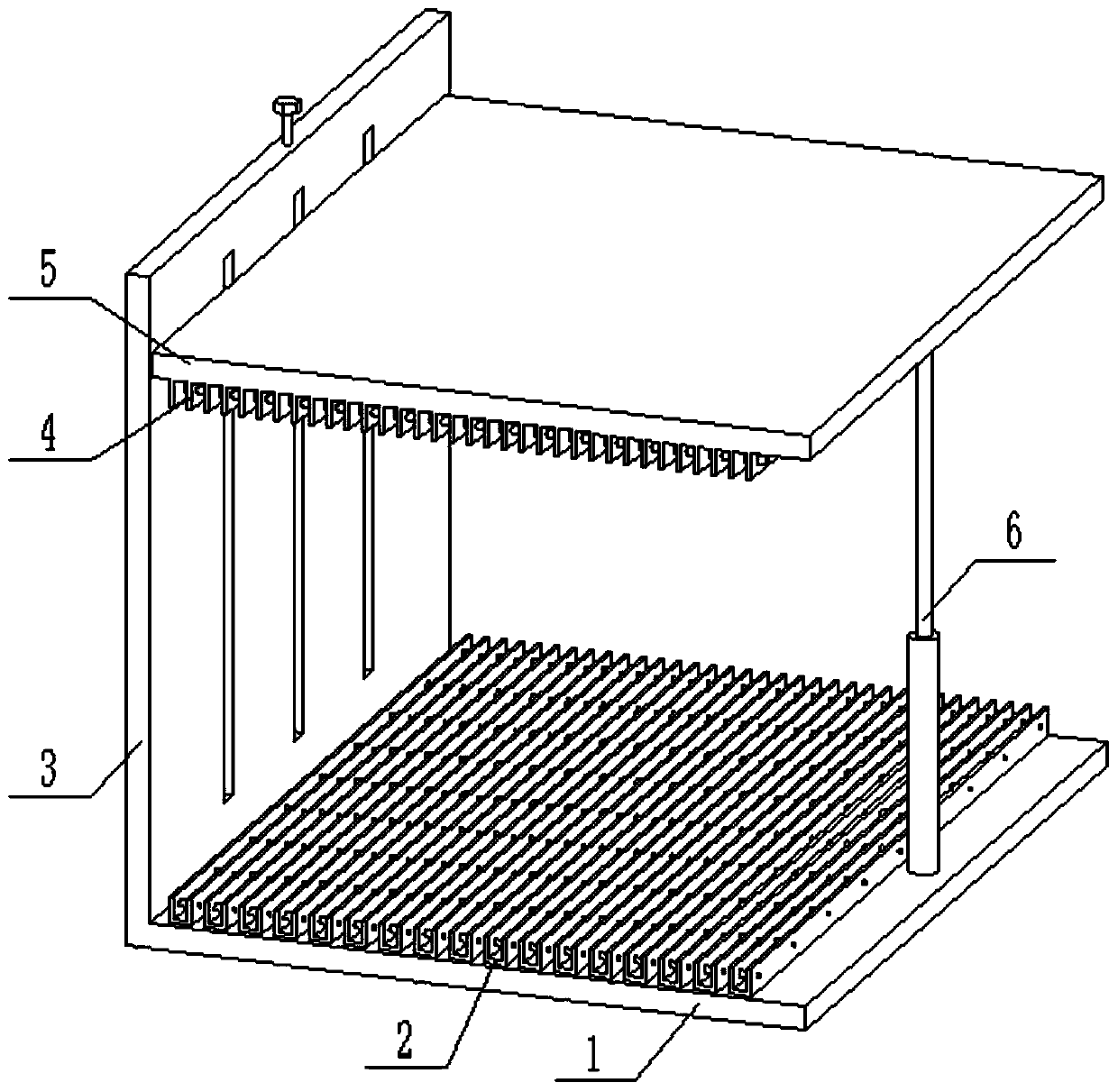

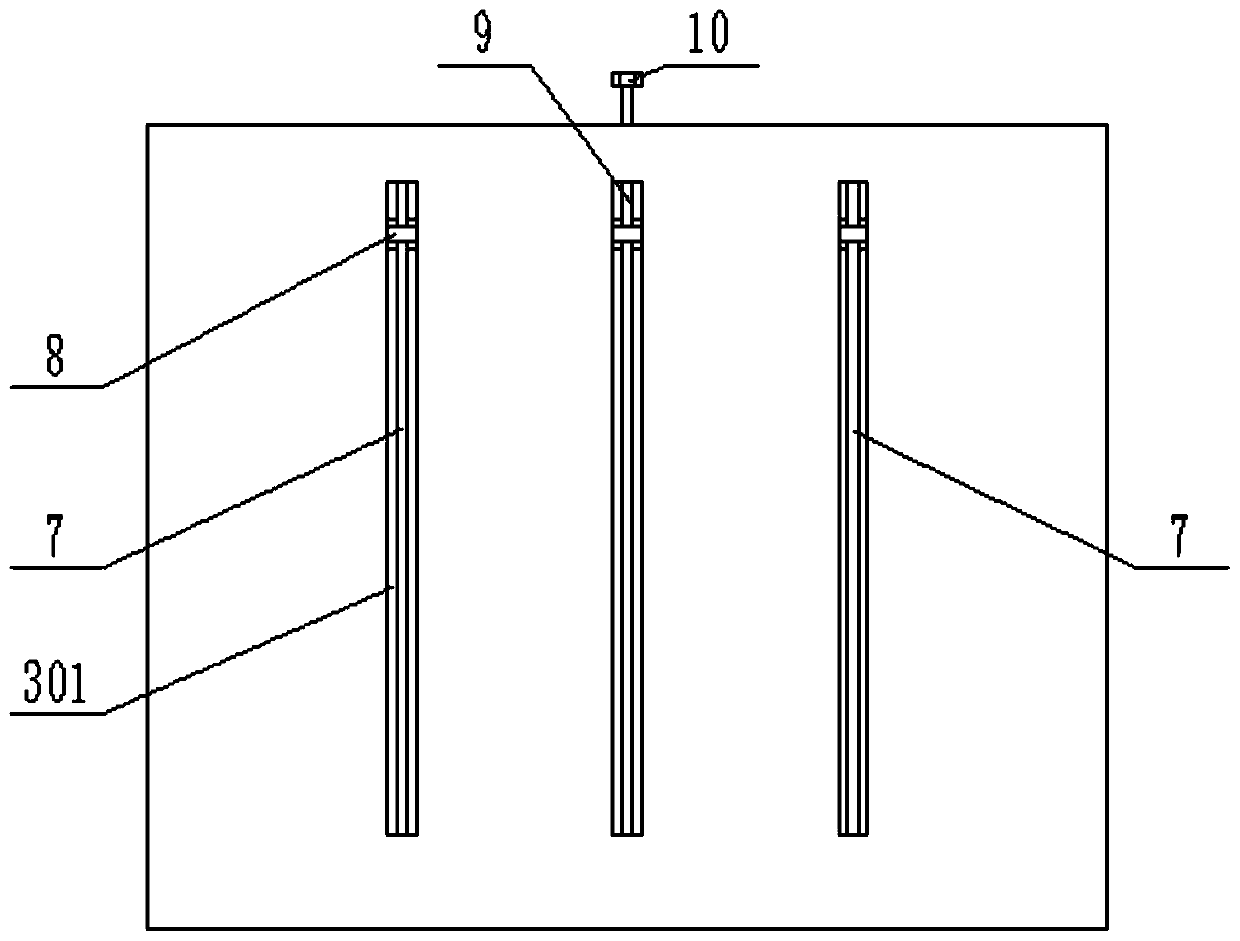

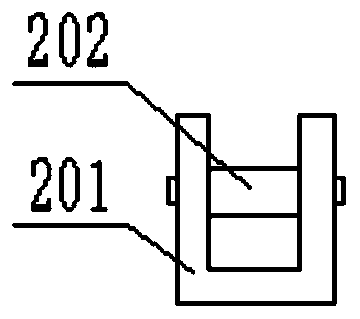

[0031] The first embodiment: see Figure 1-Figure 5 As shown, the present invention provides a shelf for glass transportation, including a fixed base plate 1, a support vertical plate 3 is installed on one side of the fixed base plate 1, and an adjustable support column 6 is installed on the other side of the fixed base plate 1, and the upper end of the fixed base plate 1 is uniform A guiding mechanism 2 is provided; three height-adjusting grooves 301 are provided through the surface of the supporting vertical plate 3, and a height-adjusting screw 9 is installed inside one of the height-adjusting grooves 301, and a guide shaft 7 is installed inside the other two height-adjusting grooves 301, and the guide shaft 7 is located on both sides of the height-adjusting screw 9; the lifting block 8 is installed on the height-adjusting screw 9 and the guide shaft 7, and the lifting plate 5 is installed on the end of the lifting block 8, and the lifting plate 5 is parallel to the fixed ba...

no. 2 approach

[0043] The second embodiment: a shelf for glass transportation, including a fixed bottom plate 1, characterized in that: a support vertical plate 3 is installed on one side of the fixed bottom plate 1, and an adjustable support column 6 is installed on the other side of the fixed bottom plate 1 , the upper end of the fixed bottom plate 1 is evenly provided with a guide mechanism 2; the surface of the support vertical plate 3 is provided with three height adjustment grooves 301, one of which is equipped with a height adjustment screw 9 inside the height adjustment groove 301, and the other two The guide shaft 7 is installed inside the height adjustment groove 301, and the guide shaft 7 is located at both sides of the height adjustment screw 9; the lift block 8 is installed on the height adjustment screw 9 and the guide shaft 7, wherein the height adjustment screw The front of the lifting block 8 on the bar 9 is provided with a threaded hole, the lifting block 8 on the guide shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com