A high-temperature superconducting shimming system applied to magnetic resonance equipment

A magnetic resonance equipment and high-temperature superconducting technology, which is applied in the manufacture/processing of superconducting devices, superconducting magnets/coils, superconducting devices, etc., can solve the inaccurate control process, the influence of turning off the magnetic field, and the insufficient on-off speed and other problems, to achieve the effect of obvious advantages, fast on-off speed, and small heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

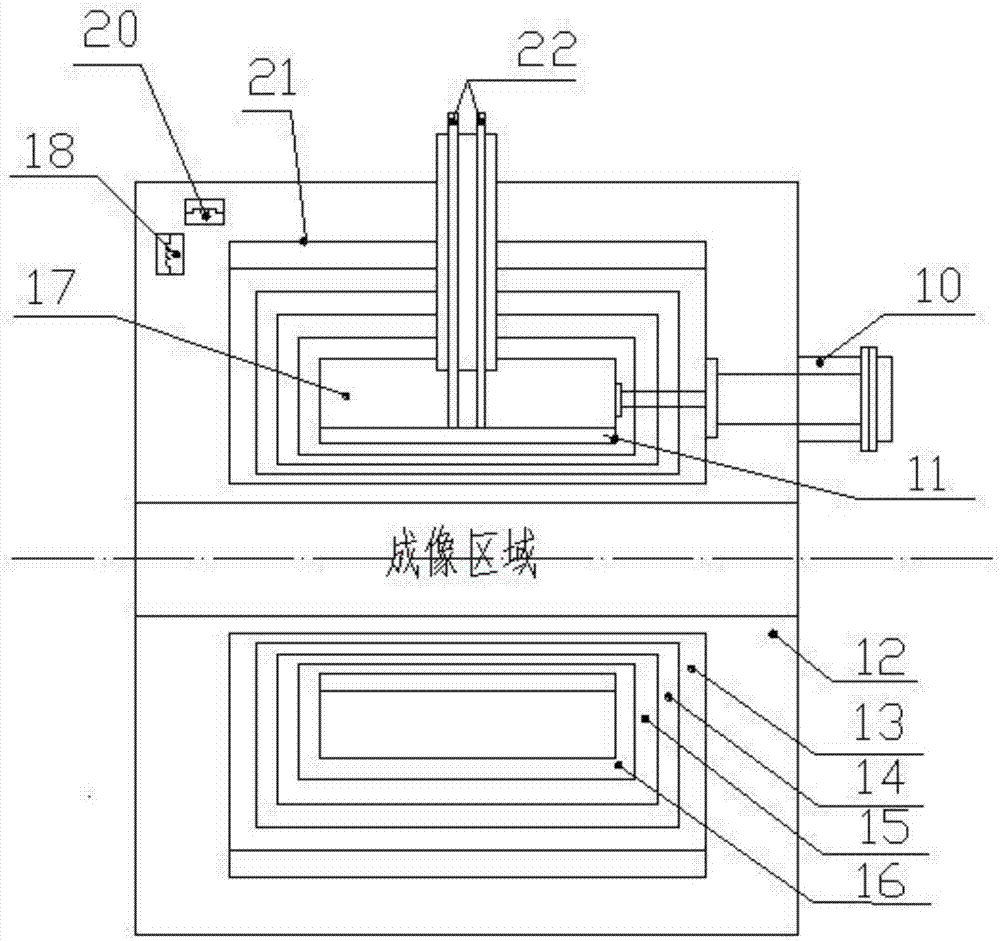

[0032] Such as figure 2 As shown, the magnetic resonance equipment is composed of a refrigerator 10, a superconducting main coil area 11, a system shell 12, a 70K cold screen 13, a 40K cold screen 14, a 20K cold screen 15, a 10K cold screen 16, a 4.2K cold screen 17, a high temperature Composed of a superconducting shimming area 21 and a cold source drainage groove 22;

[0033] In this embodiment, the cryostat is a multi-screen heat insulation structure combining multi-layer radiation protection screen and steam cooling screen. screen, thereby improving the thermal insulation effect. The cryostats are 4.2K cold screen 17, 10K cold screen 16, 20K cold screen 15, 40K cold screen 14, and 70K cold screen 13 from inside to outside.

[0034]The refrigerating machine 10 is used for cooling the cold screen of the cryostat, and is set as two-stage refrigeration, cooling the 4.2K cold screen 17 and the 70K13 cold screen respectively. The first-stage refrigeration is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com