Guardrail with compound functions of vibration reduction and disaster prevention

A composite function, guardrail technology, applied in the direction of roads, road safety devices, roads, etc., can solve problems such as damage, continuous car accidents, other vehicles damage their own structures, etc., to achieve the effect of reducing damage, reducing vehicle speed, and reducing mechanical damage losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

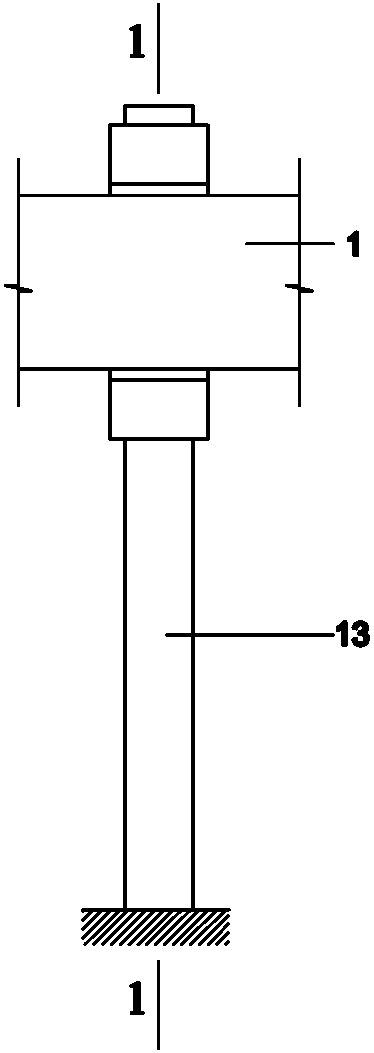

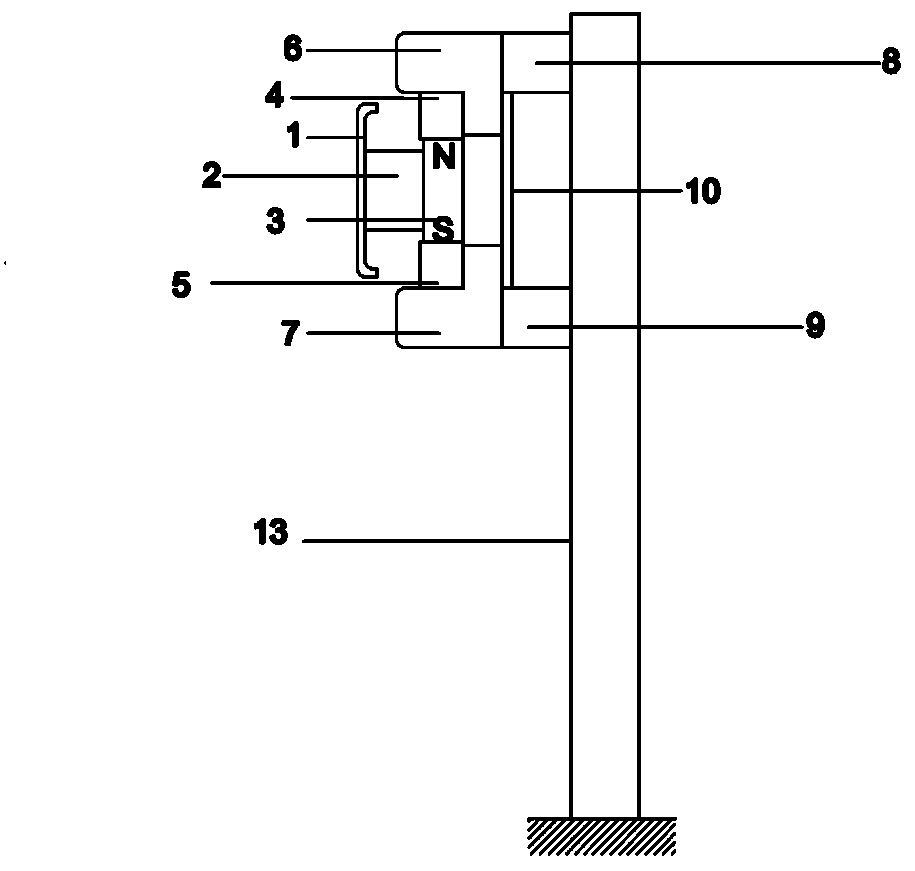

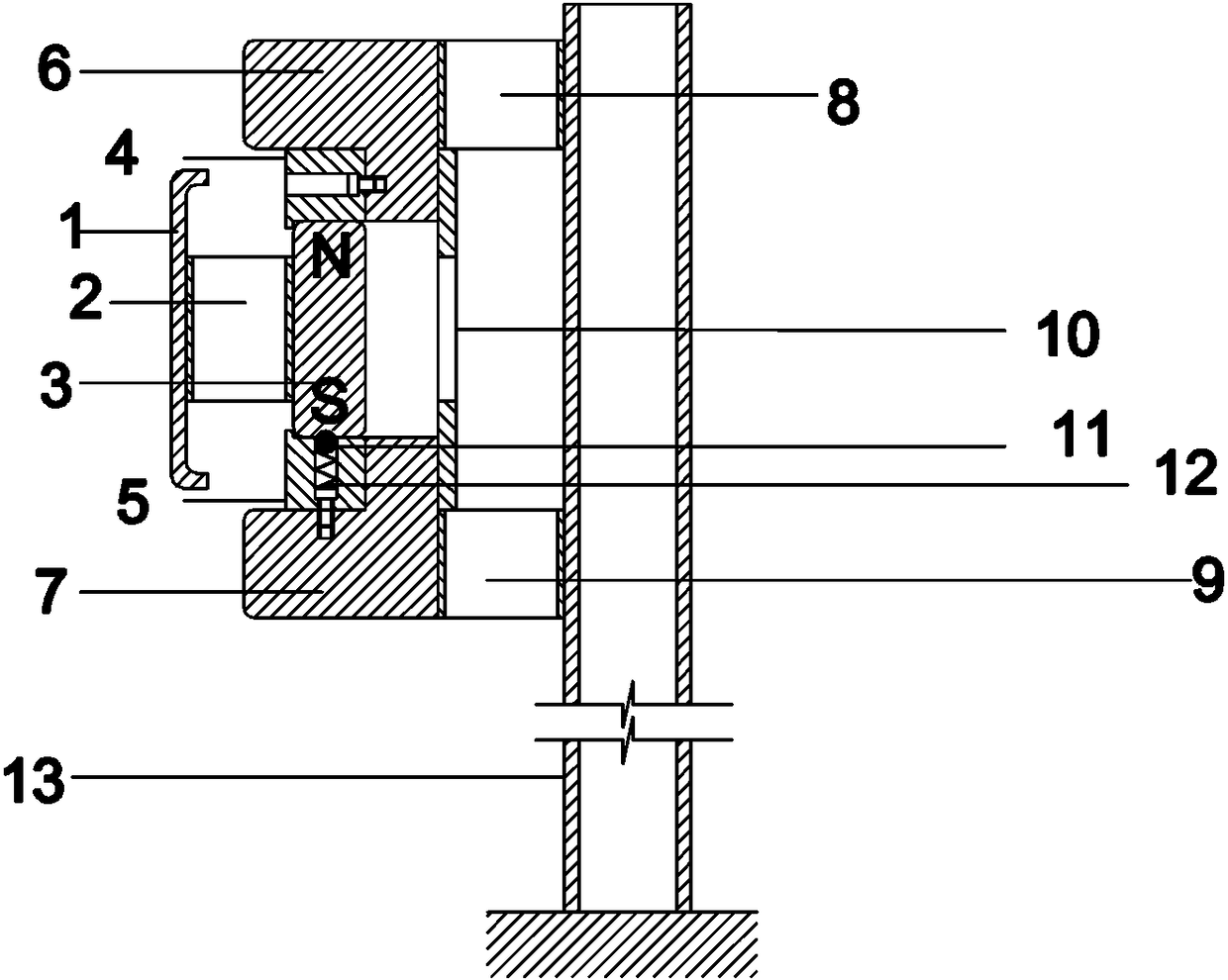

[0021] Such as figure 1 , 2 , 3, 4, 5, and 6, a guardrail with a composite function of vibration reduction and disaster prevention includes a column 13 arranged on the road, and the column 13 is connected with a guardrail 1 through an energy dissipation device.

[0022] The energy dissipation device includes an upper connecting plate 8 and a lower connecting plate 9 connected to one side of the column 13 by bolts, a sealing plate 10 is connected between the upper connecting plate 8 and the lower connecting plate 9 by bolts, and the upper connecting plate 8 The upper magnetic yoke 6 and the lower magnetic yoke 7 are connected with the outside of the lower connecting plate 9 by bolts, the upper non-magnetic conductive body 4 connected in the upper magnetic yoke 6, the lower non-magnetic conductive body 5 connected in the lower magnetic yoke 7, connected in the The permanent magnet 3 between the upper non-magnetic body 4 and the lower non-magnetic body 5, the outside of the perm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com