Threaded connecting part with clamping structure

A threaded connector and clamping structure technology, applied in the field of mechanical parts, can solve the problems of high processing cost, screw damage, damage, etc., and achieve the effect of avoiding the risk of unreliable connection and avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

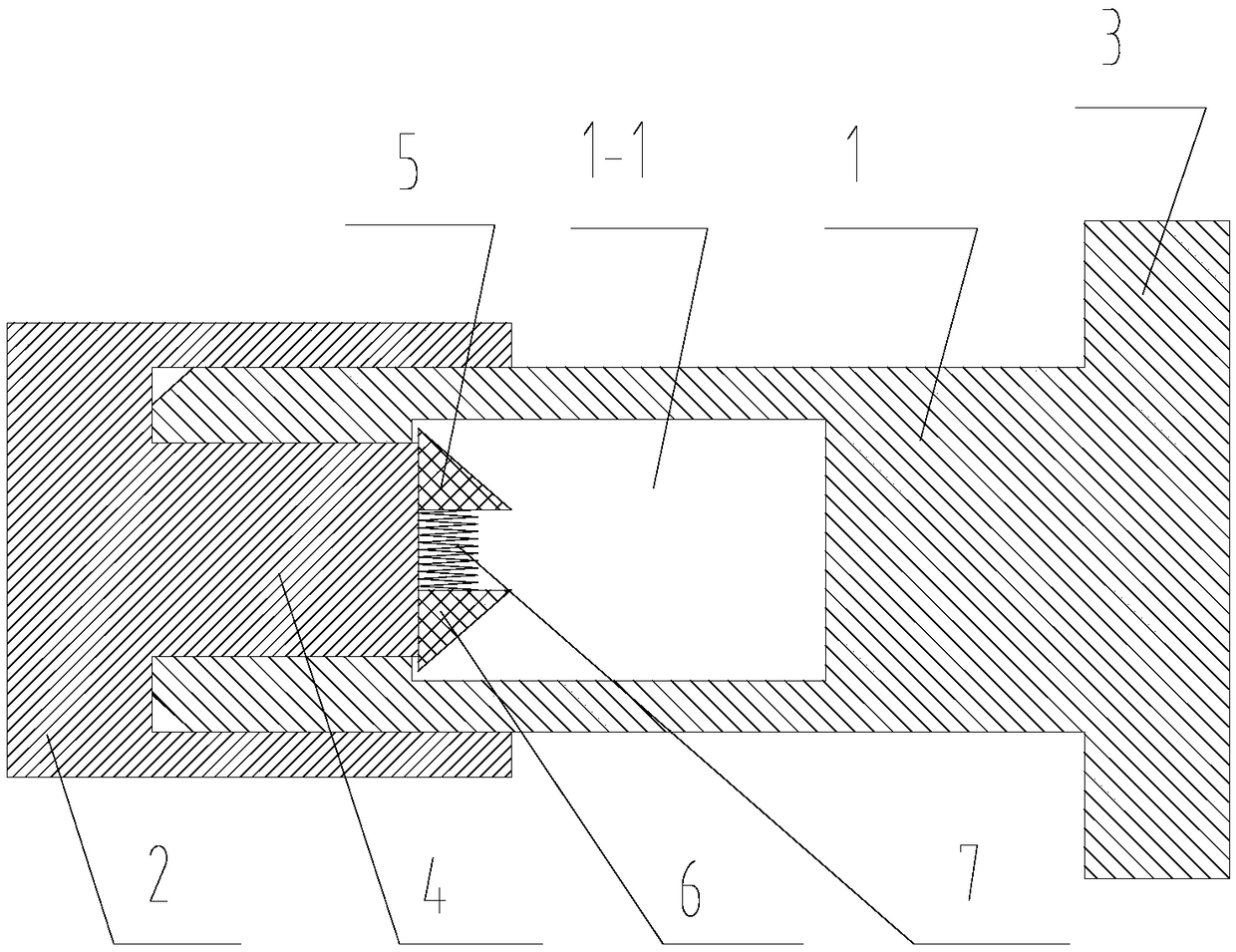

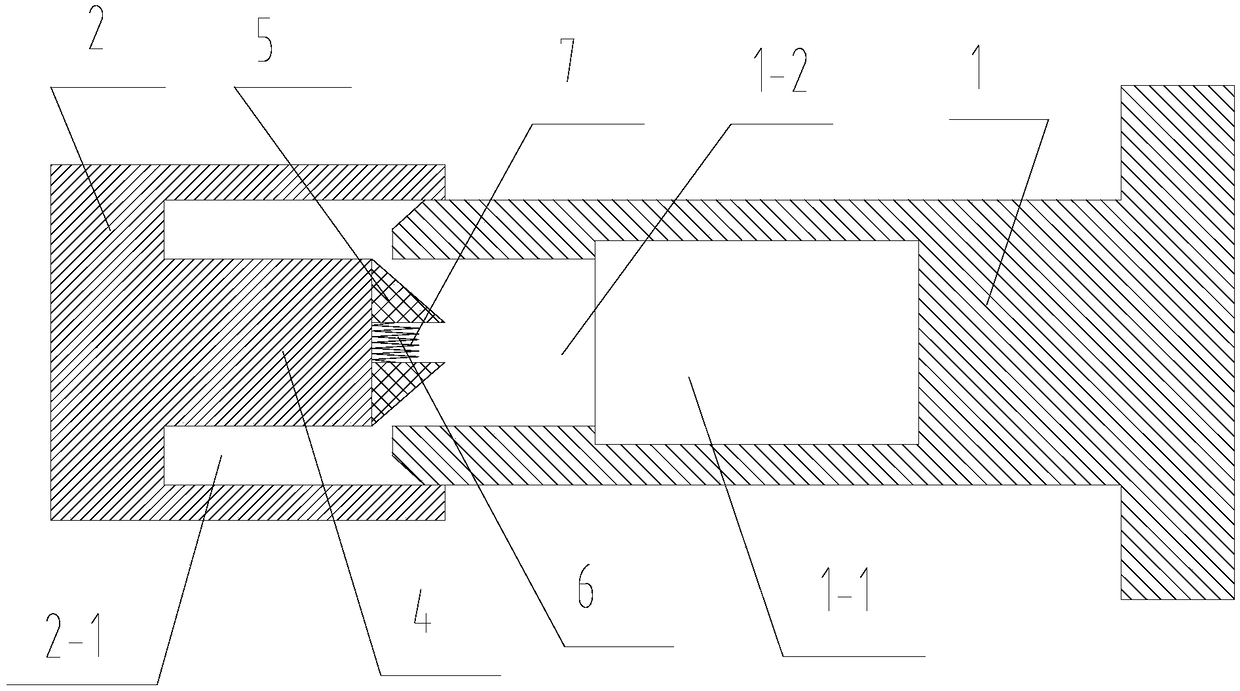

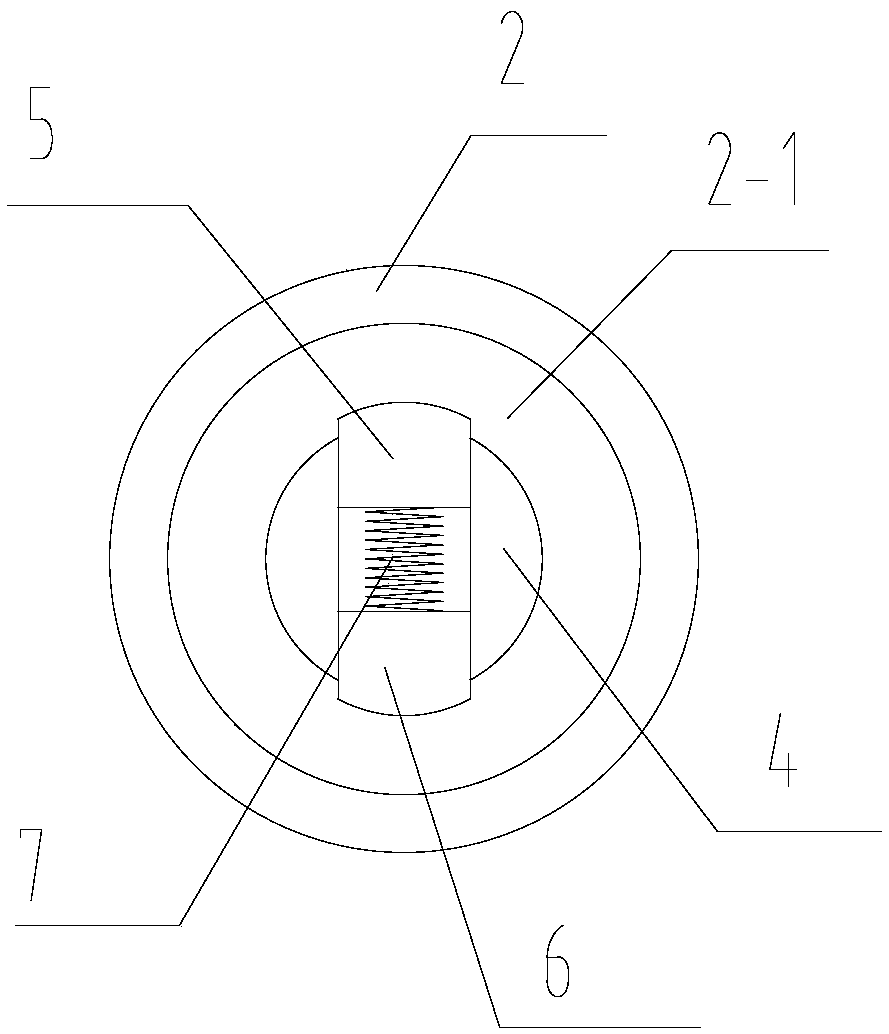

[0020] refer to figure 1 , the present invention proposes a threaded connector with a locking structure, comprising: a screw 1 and a nut 2 . The inside of the screw 1 is provided with a cylindrical cavity 1-1 that coincides with the axis of the screw 1, and the first end of the screw 1 is provided with a cylindrical hole 1-2 that communicates with the cylindrical cavity 1-1 and coincides with the axis of the screw 1. The cylindrical hole 1-2 The circular cross-sectional diameter is smaller than the circular cross-sectional diameter of the cylindrical cavity 1-1. The second end of the screw 1 is fixed with a limiting block 3 . In this embodiment, the limiting block 3 and the screw 1 are integrally formed.

[0021] One end of the nut 2 is provided with a threaded hole 2-1 matching the outer surface of the screw 1, and the inside of the threaded hole 2-1 is provided with a cylinder 4 coincident with the axis of the threaded hole 2-1, and the diameter of the circular section of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com