Patents

Literature

60results about How to "Prevent withdrawal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

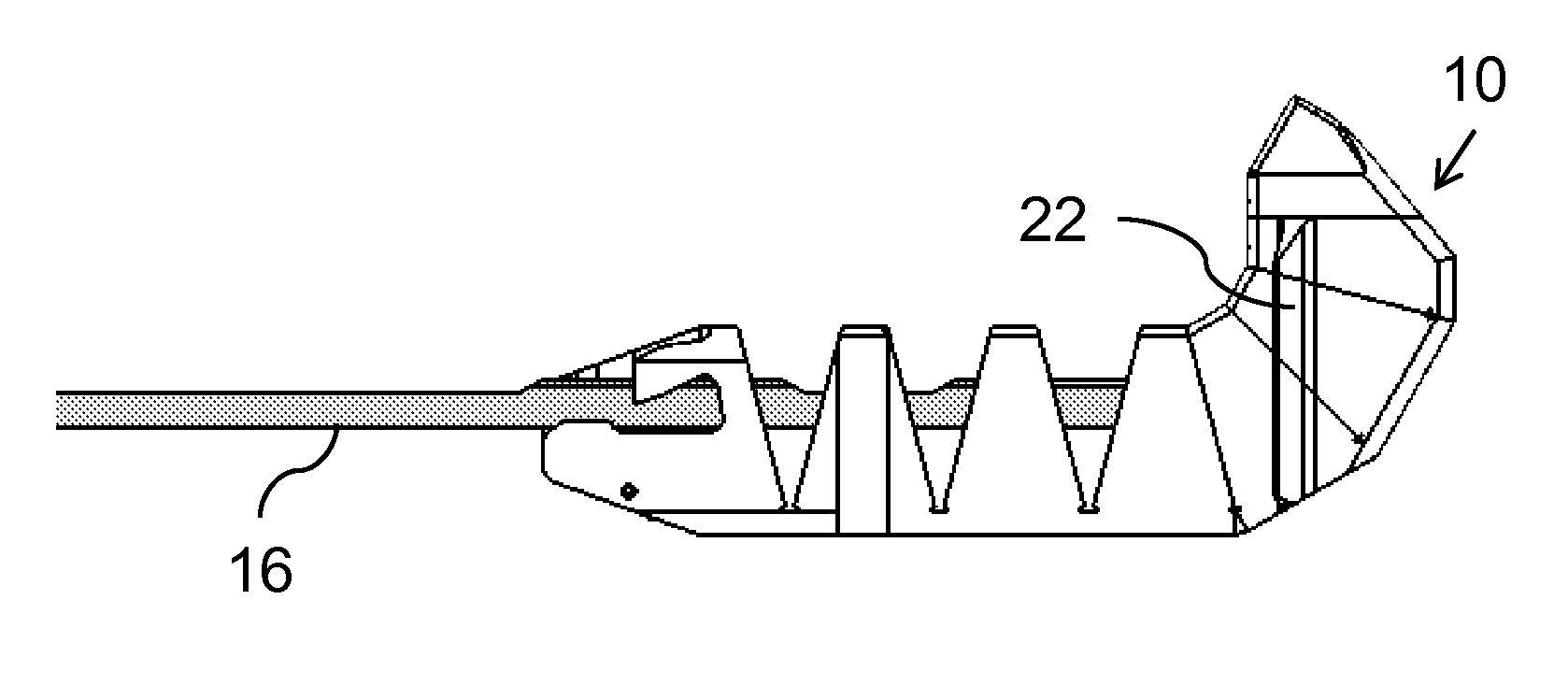

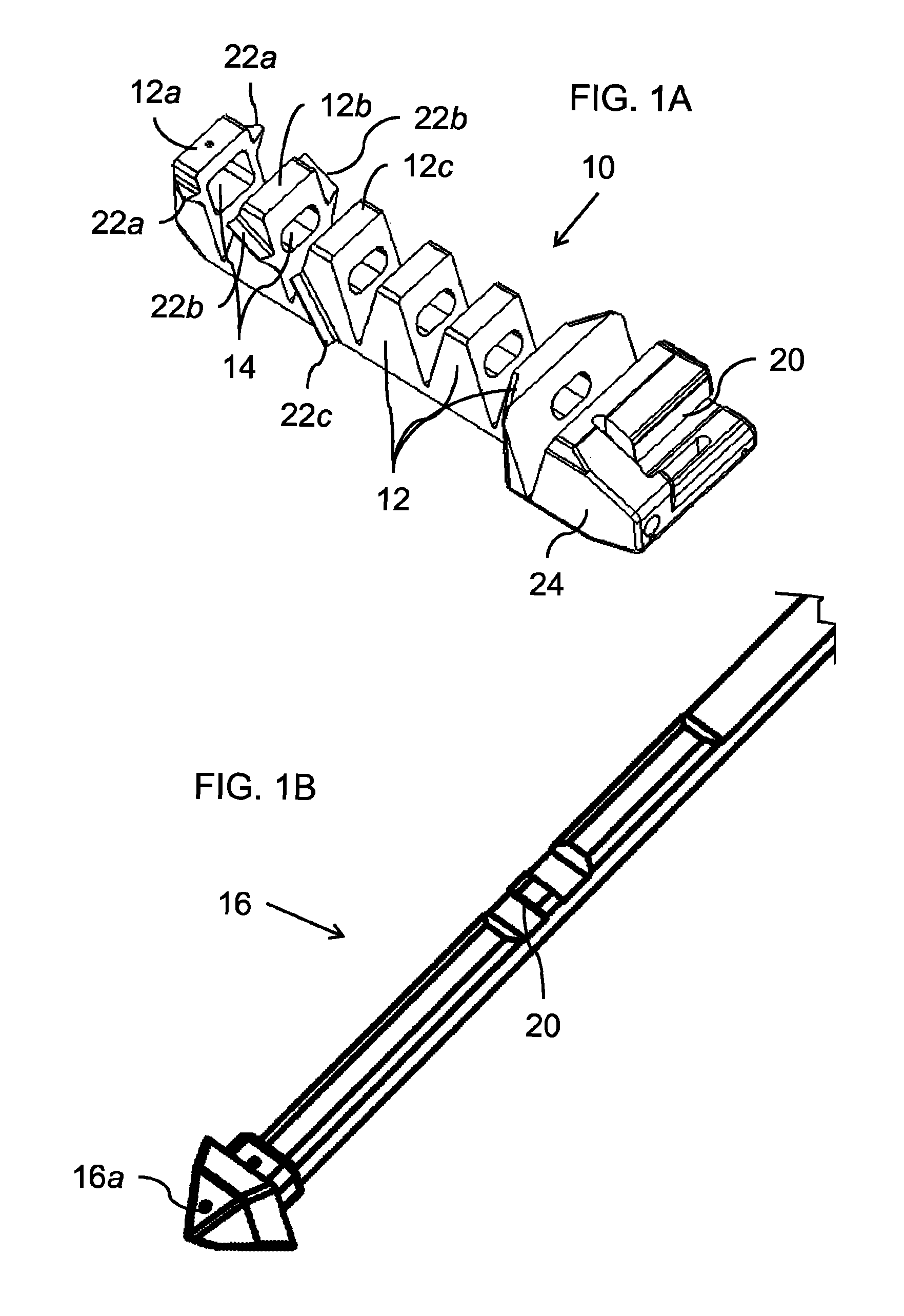

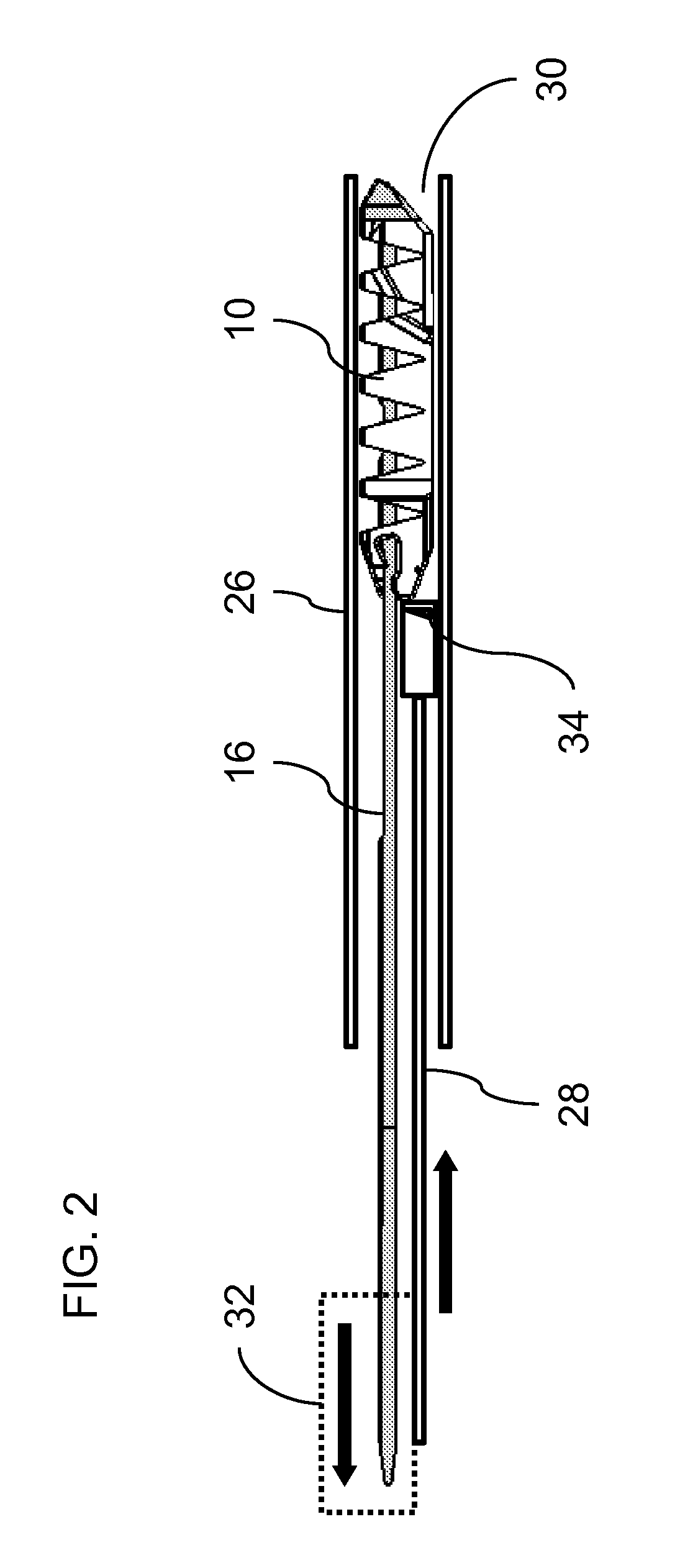

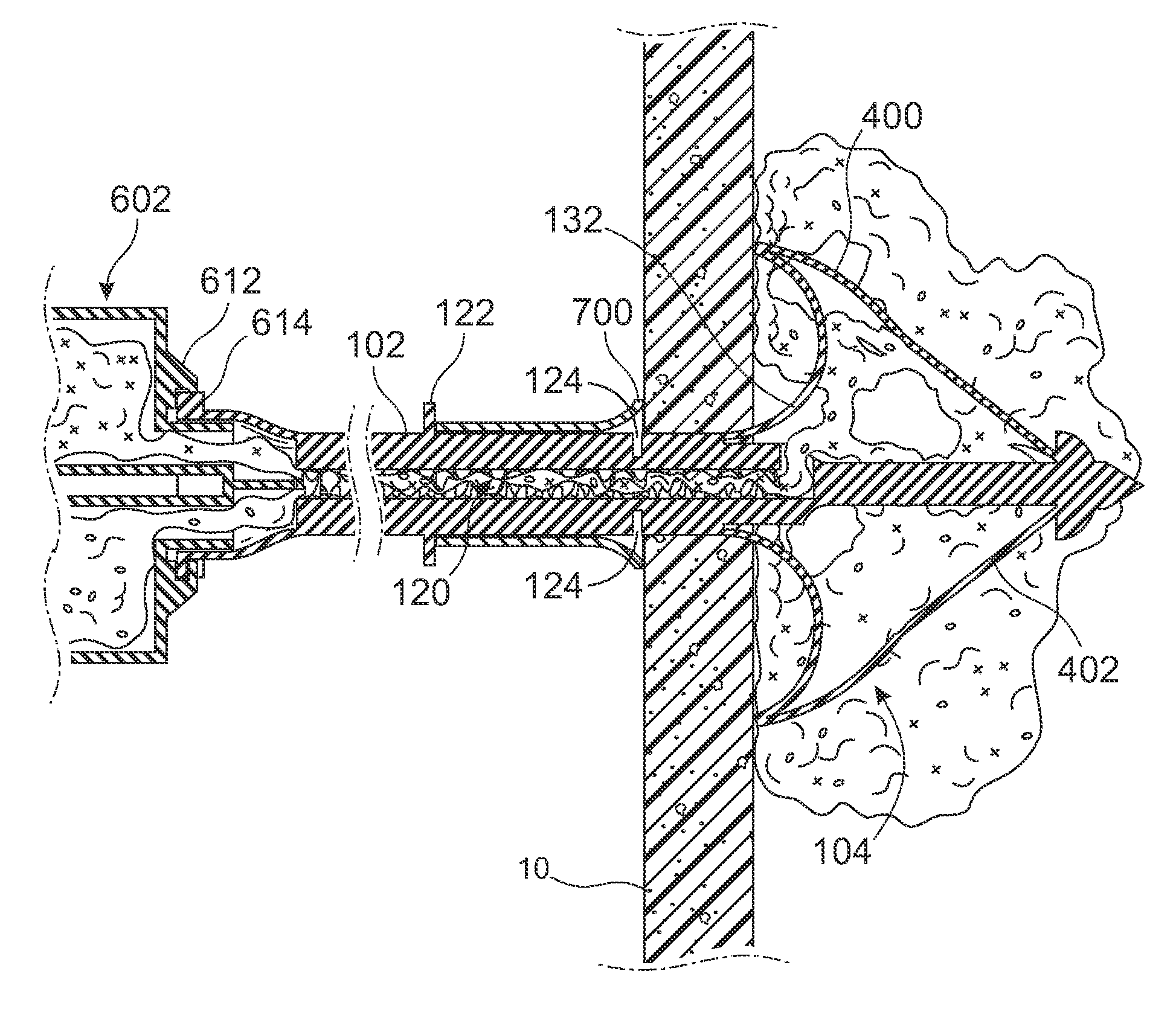

Device and method for spinous process distraction

An implant for maintaining a given minimum inter-spinous-process spacing includes an implant body with a number of segments hingedly interconnected so as to assume a straightened state for delivery along a conduit and a curved deployed state. An elongated tightening element is anchored at the distal segment of the implant body and passes along a channel extending along the implant body. Tension applied to the tightening element biases the implant body from the straightened state to the curved deployed state. Preferably, when the tightening element is deflected to reach the curved deployed state, a locking arrangement locks the tightening element relative to the implant body, thereby retaining the implant in the curved deployed state. A distal portion of the implant body is preferably formed with a set of lateral projections to inhibit withdrawal of the distal portion between adjacent spinous processes after deployment.

Owner:SEASPINE

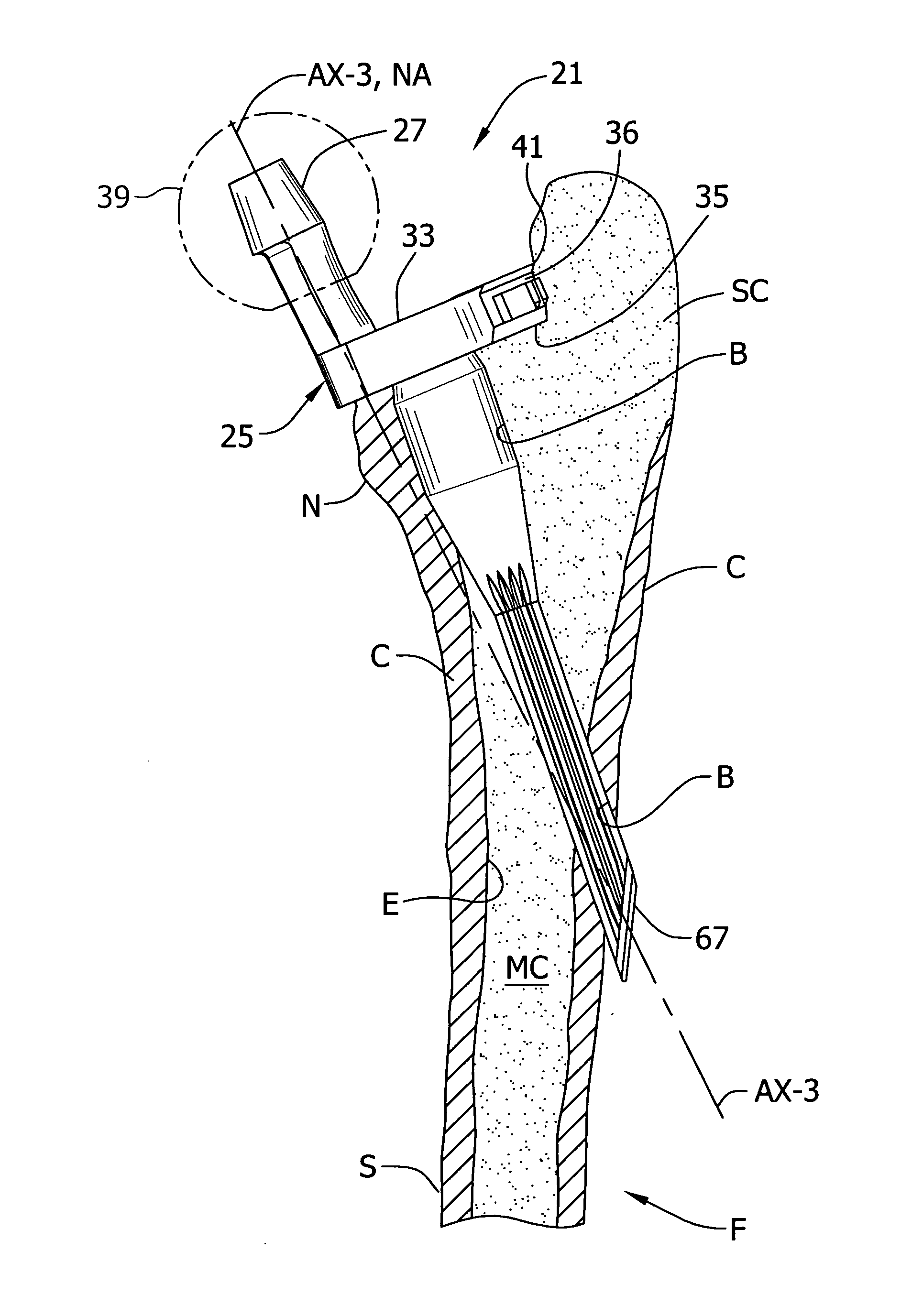

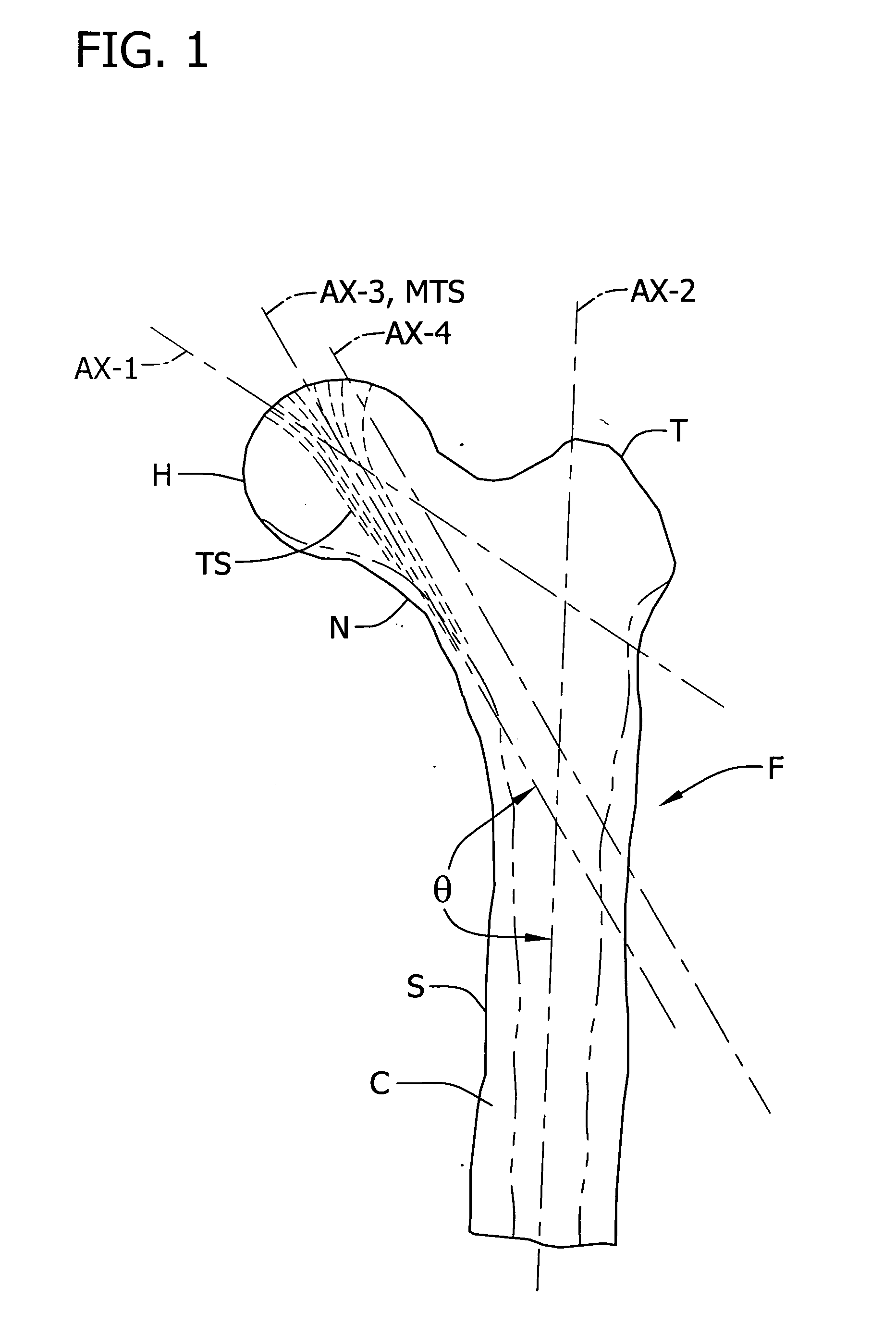

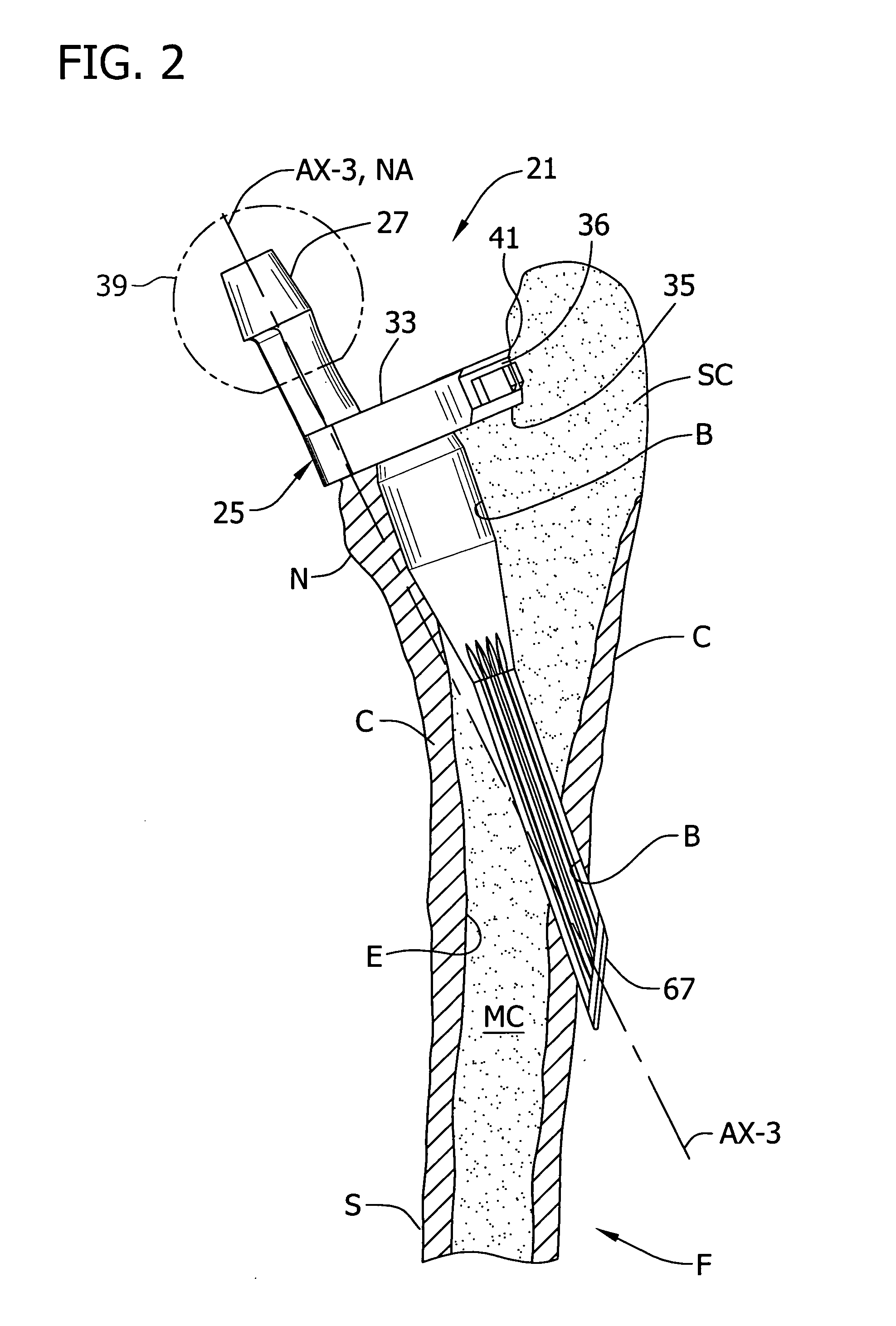

Prosthesis and method of implantation

InactiveUS20060015188A1Easy to implantAvoid crackingBone implantJoint implantsLess invasive surgeryBone prosthesis

A bone prosthesis for implantation at a joint is adapted to closely replicate the normal loading of the femur and is suitable for implantation using a single incision anterior approach, a form of minimally invasive surgery (MIS). The bone prosthesis comprises a stem adapted for orientation with a medial trabecular stream of the femur.

Owner:THE JAMES B GRIMES & TRACIE LYNN GRIMES 1998 TRUST

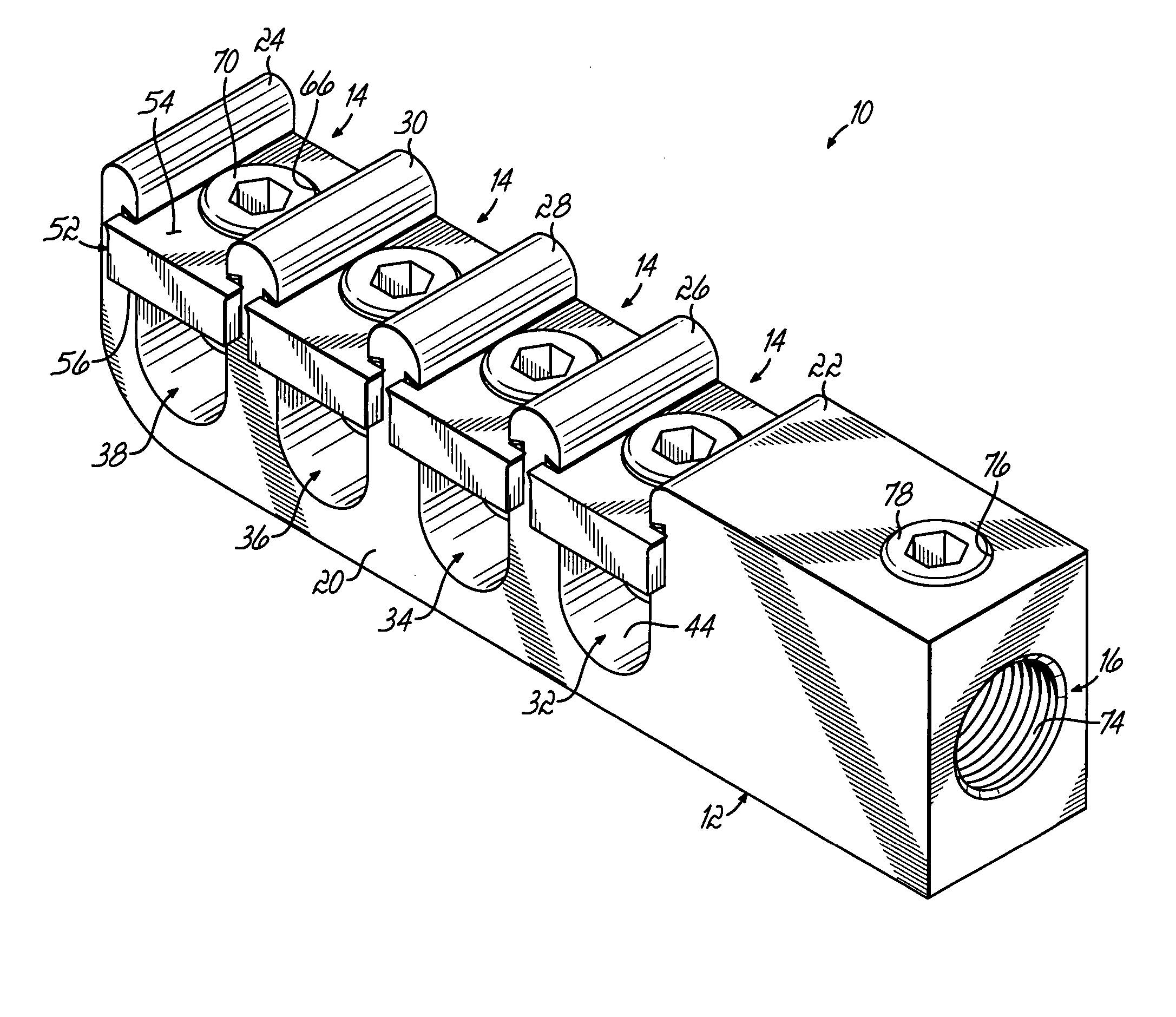

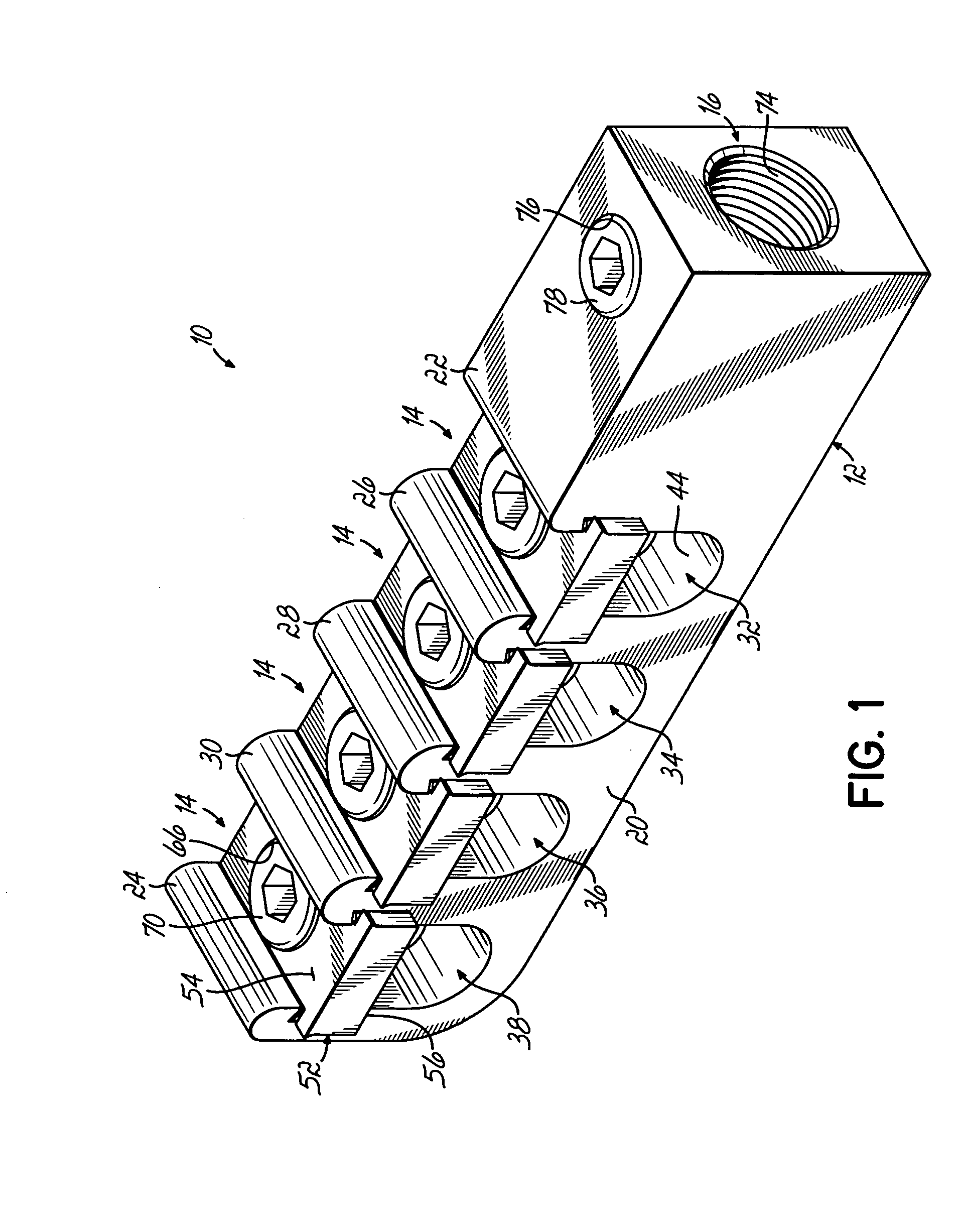

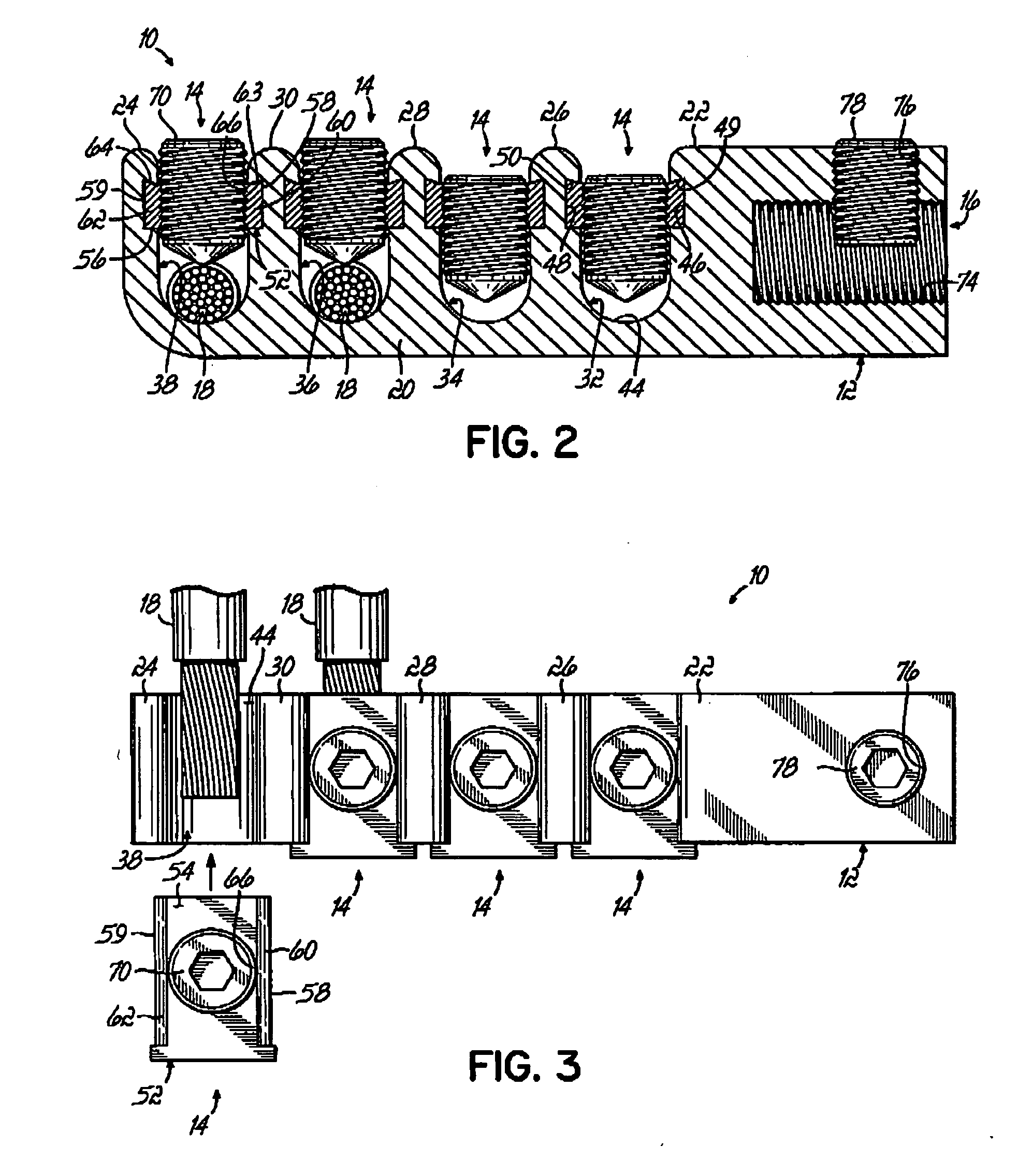

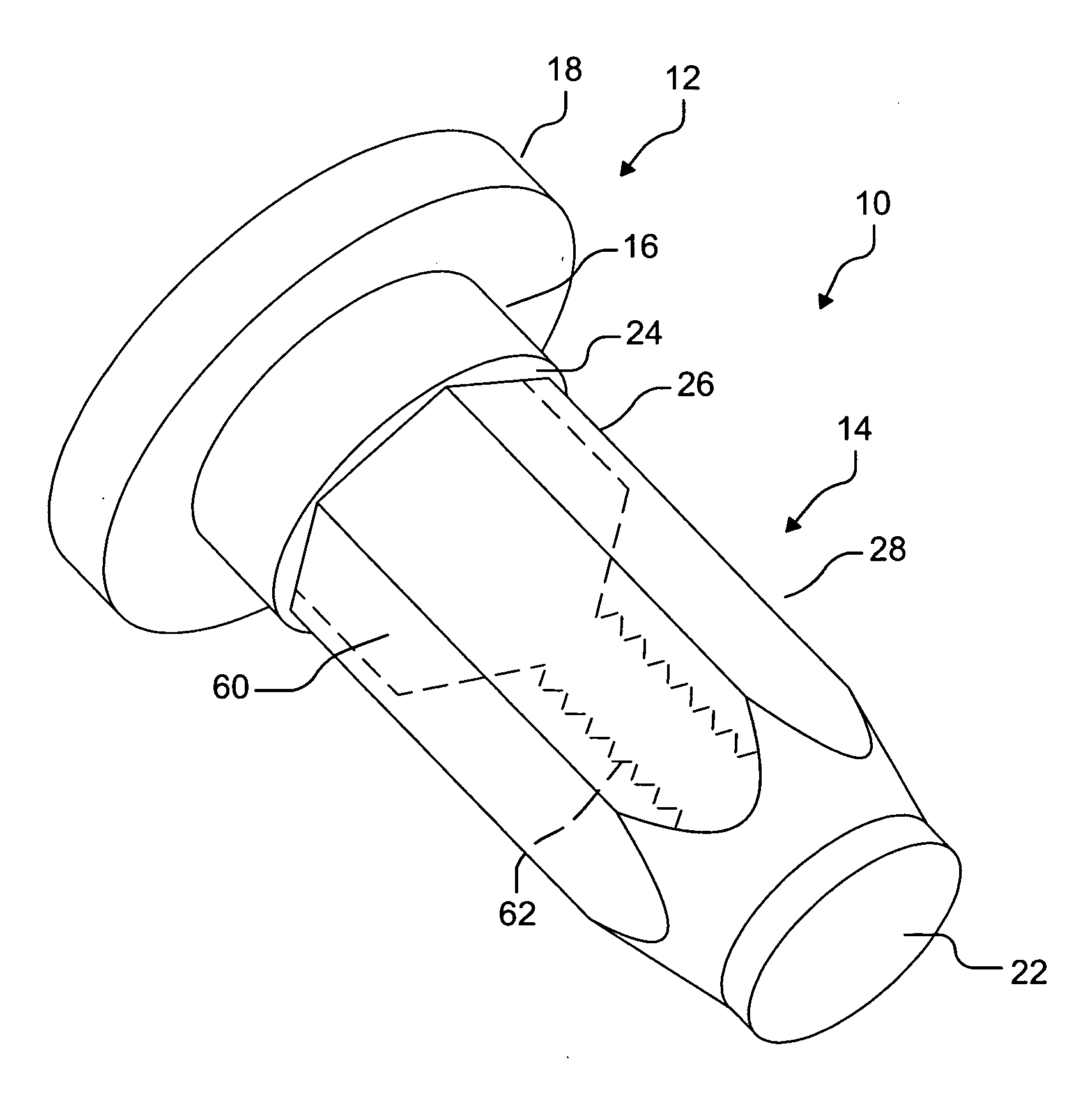

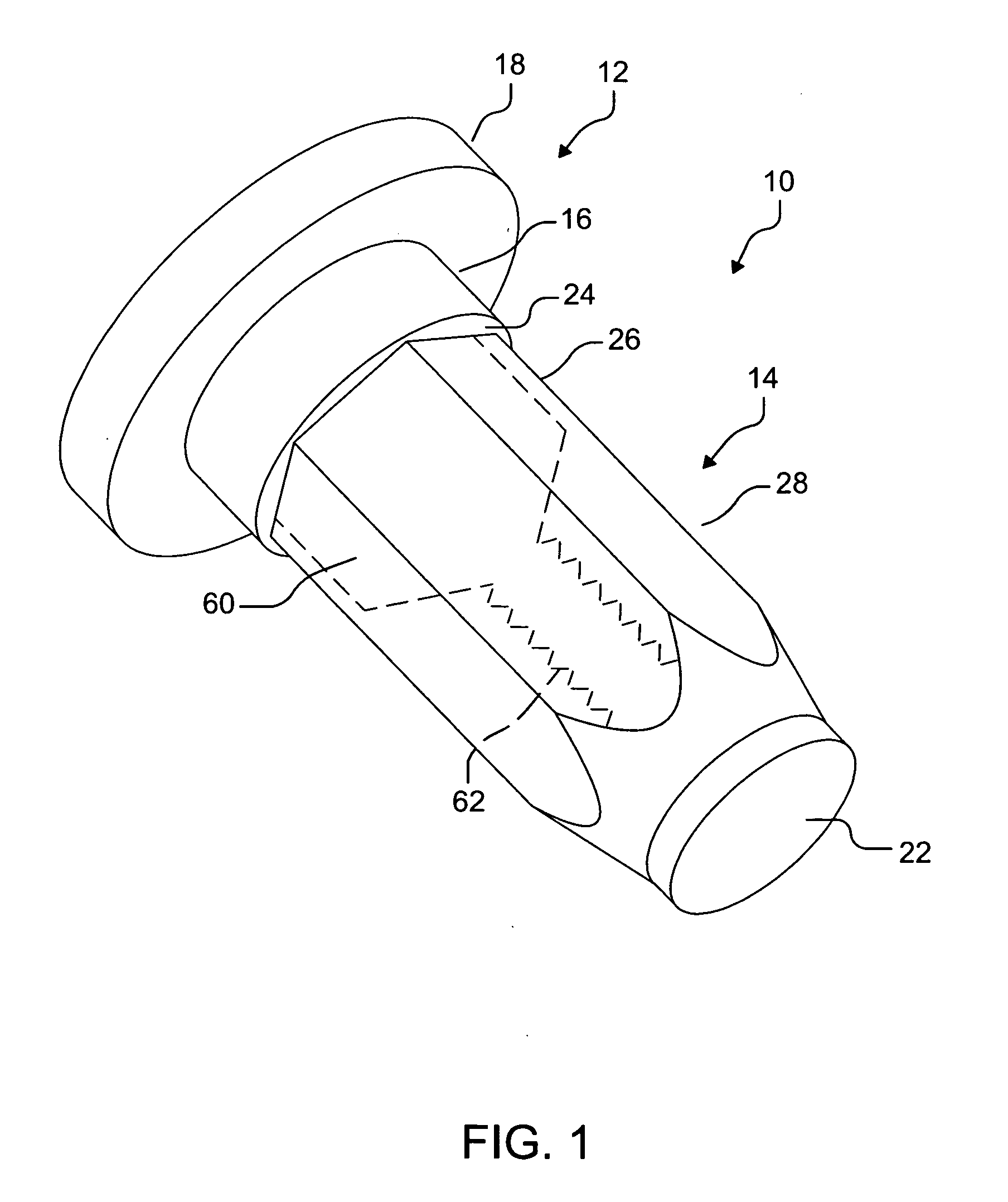

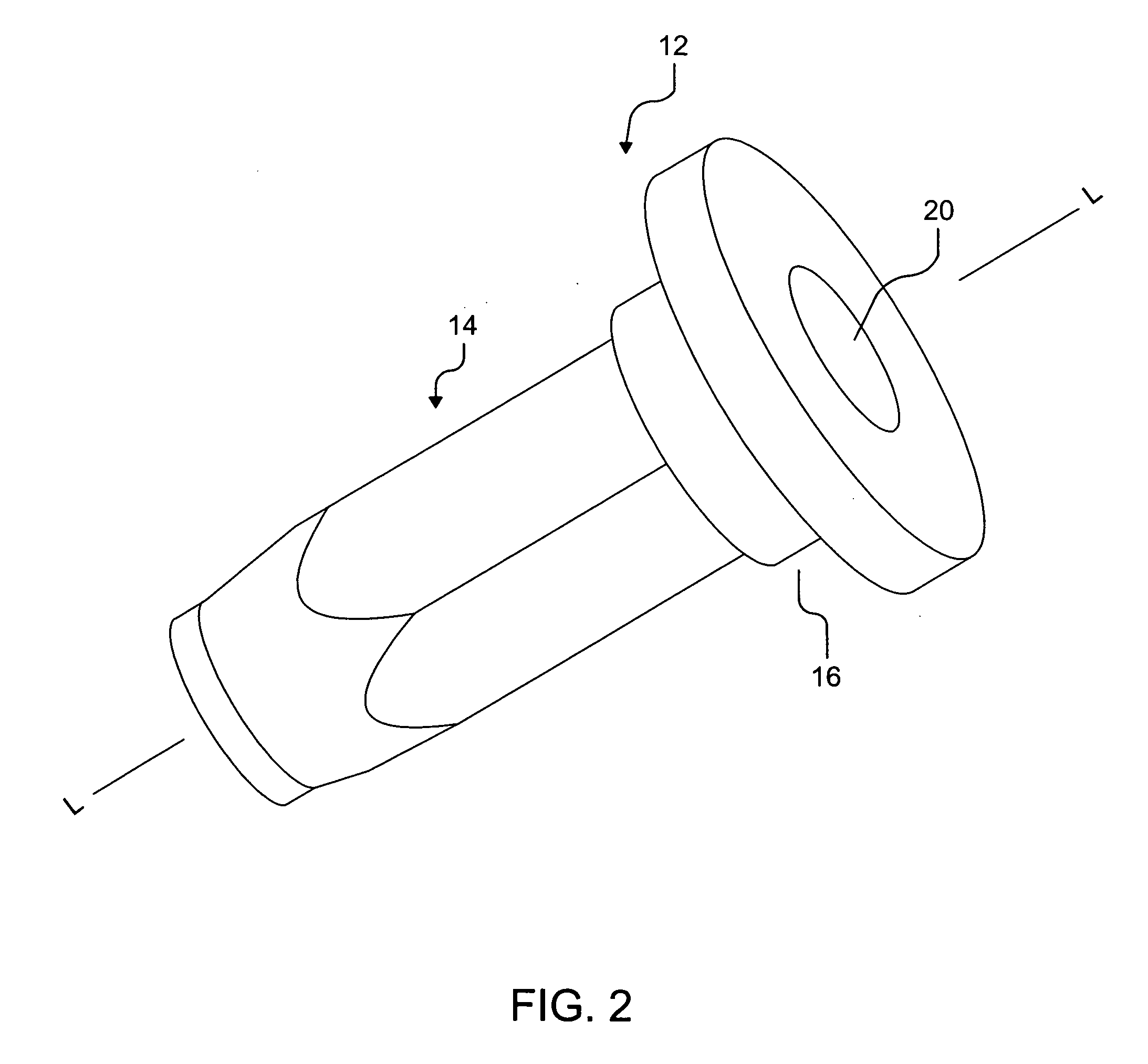

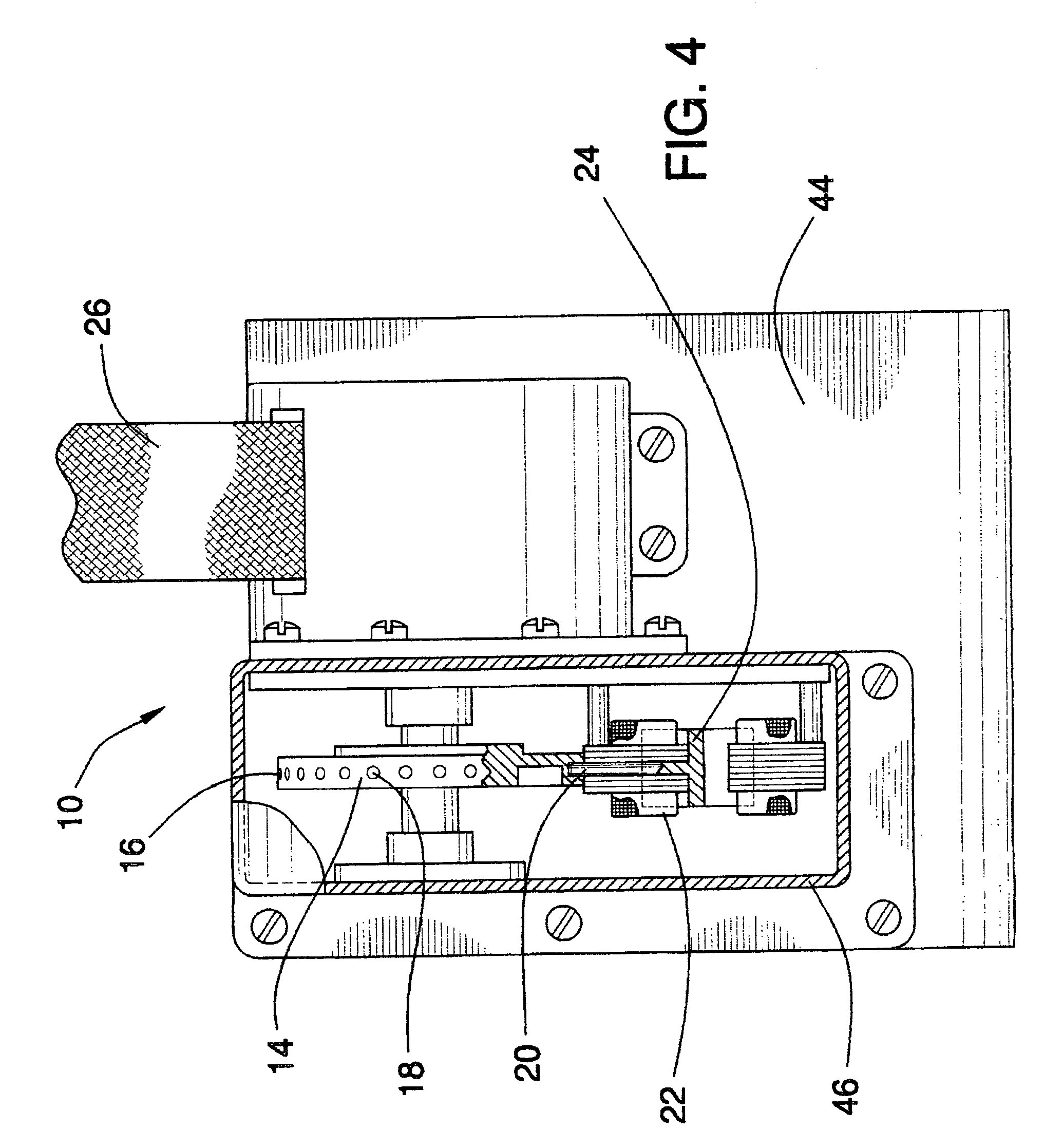

Lay-in electrical connector

InactiveUS20050202732A1Prevent withdrawalElectric connection structural associationsClamped/spring connectionsElectrical conductorMechanical engineering

A stud mounted lay-in electrical connector having a lug body with multiple dividing walls defining multiple conductor-receiving channels, multiple lug caps each associated with one of the conductor-receiving channels, and a bore formed in the body member adapted to be releasably coupled with a transformer stud. The conductor-receiving channels may be configured in two rows to provide twice the number of channels per length of body member. The connector may also comprise a body member having a first portion including a bore adapted to connect to a transformer stud and a second portion carrying the multiple conductor-receiving channels, the second portion removably coupled to the first portion.

Owner:ILSCO

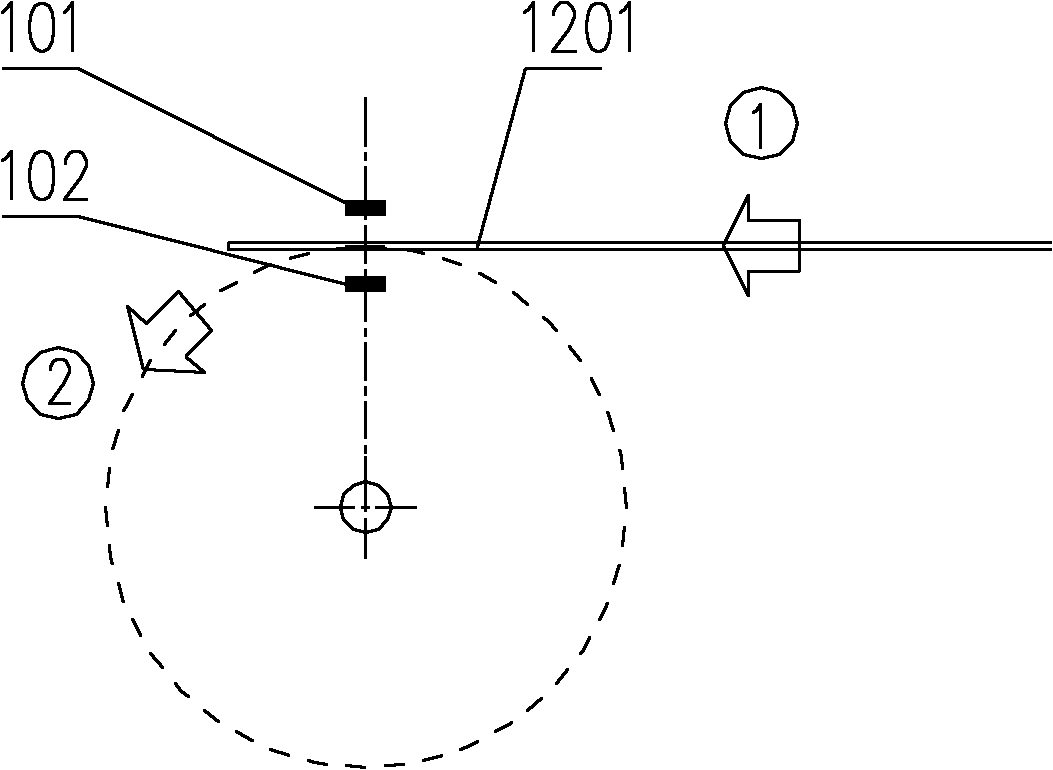

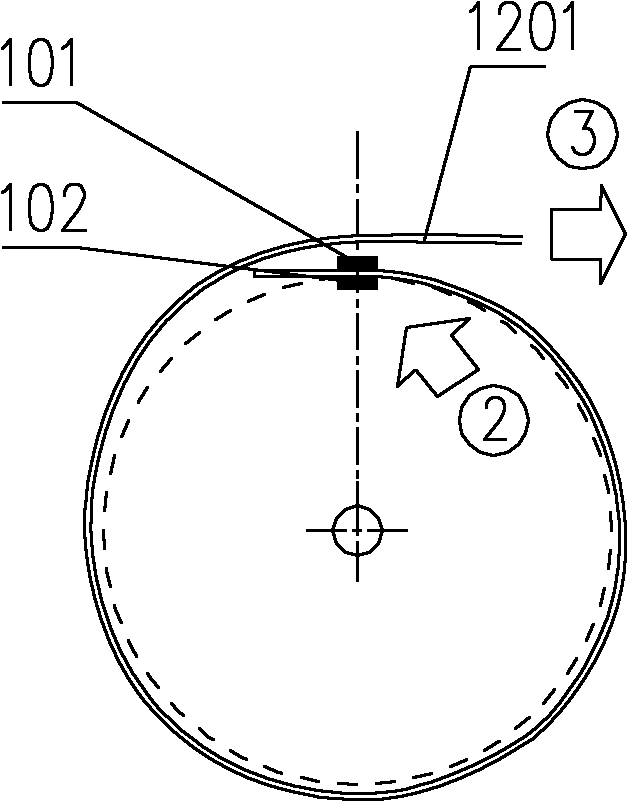

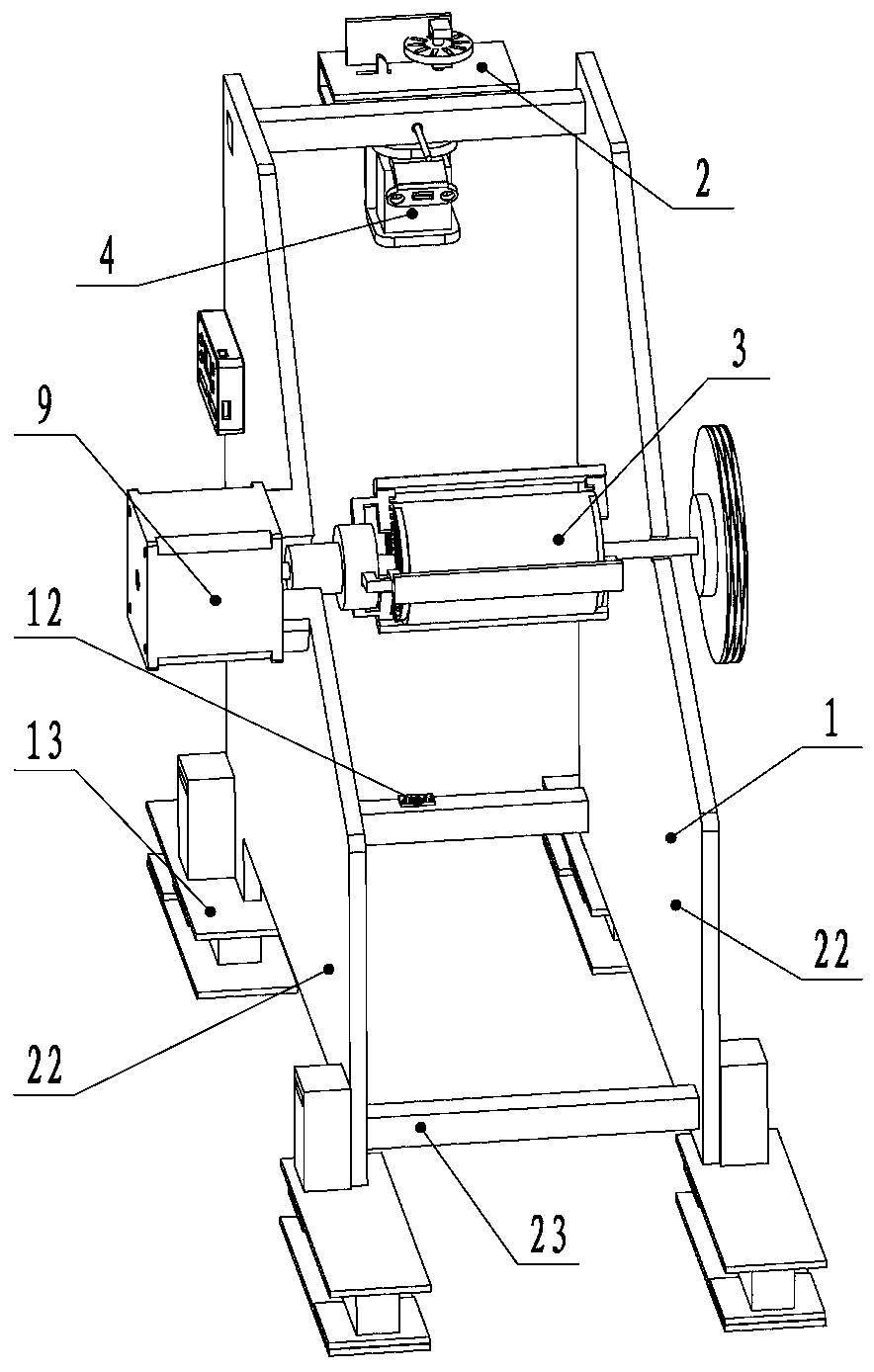

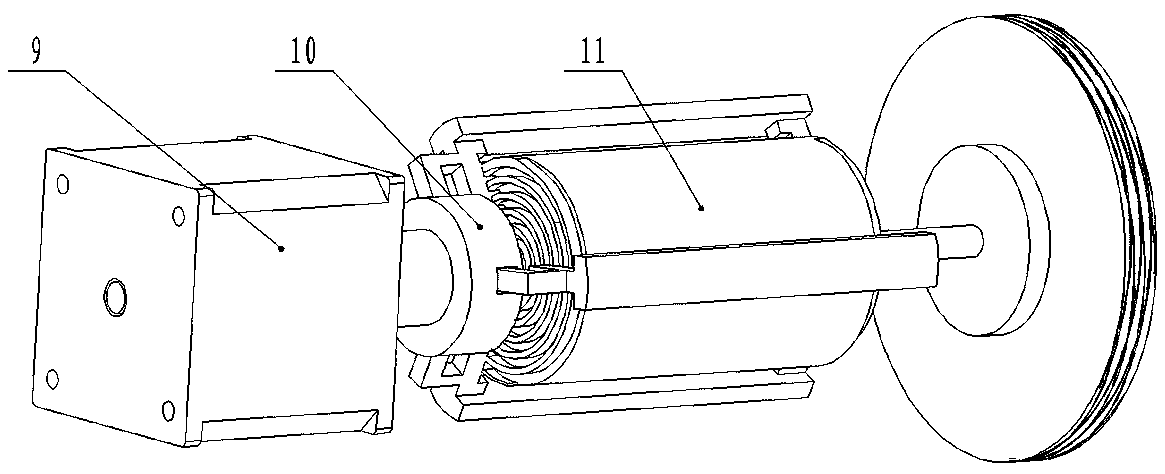

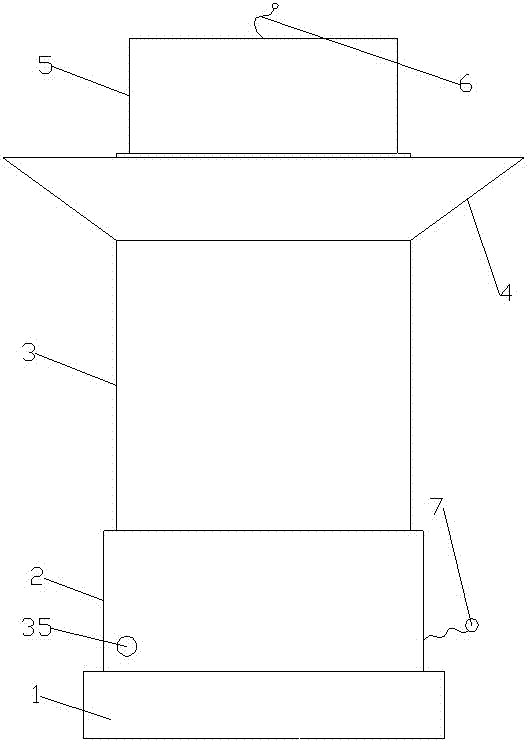

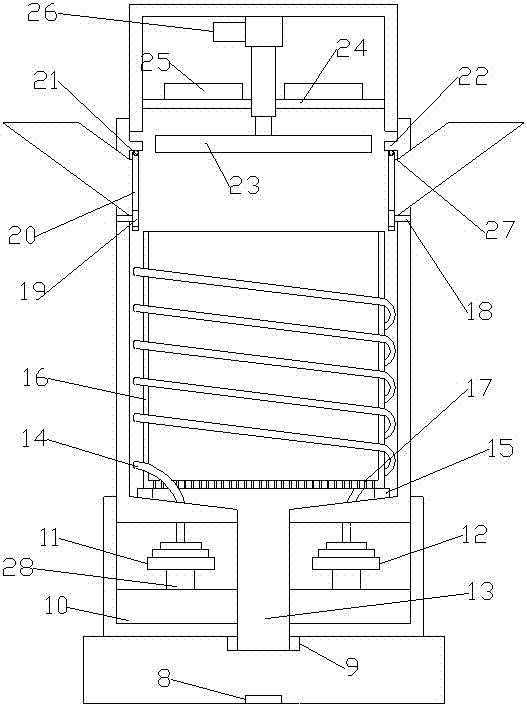

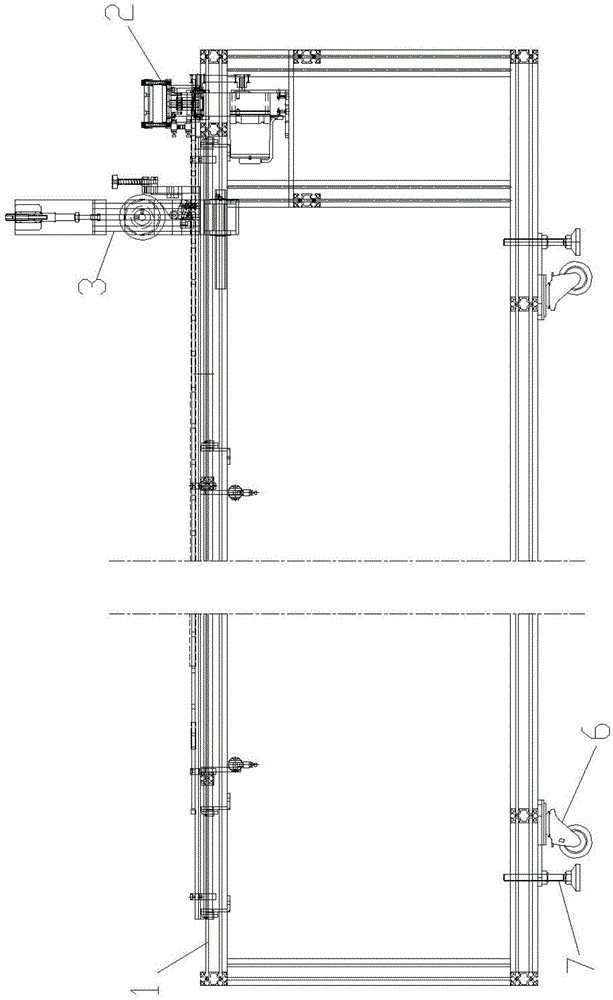

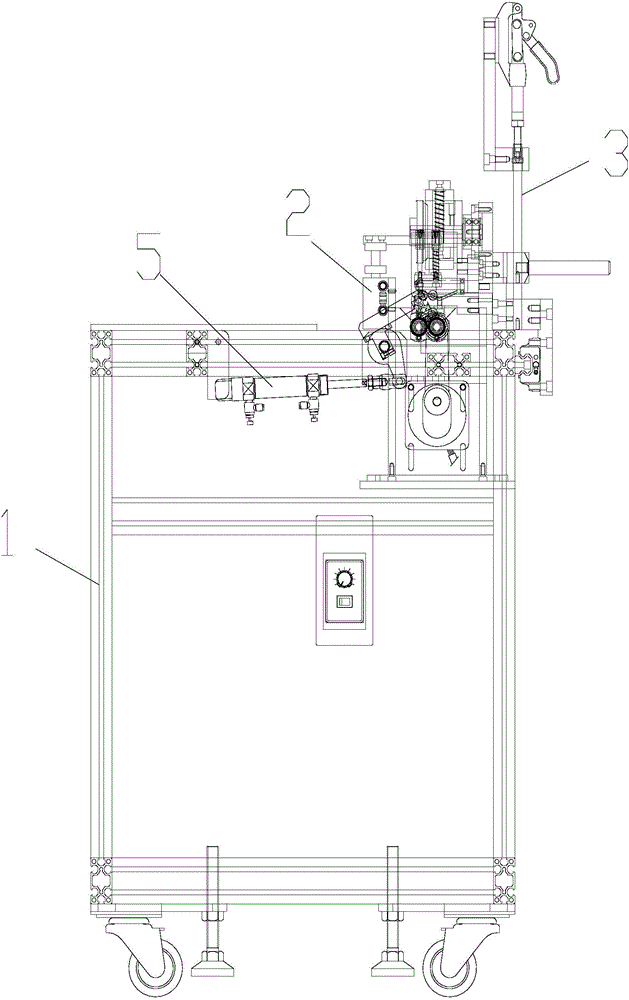

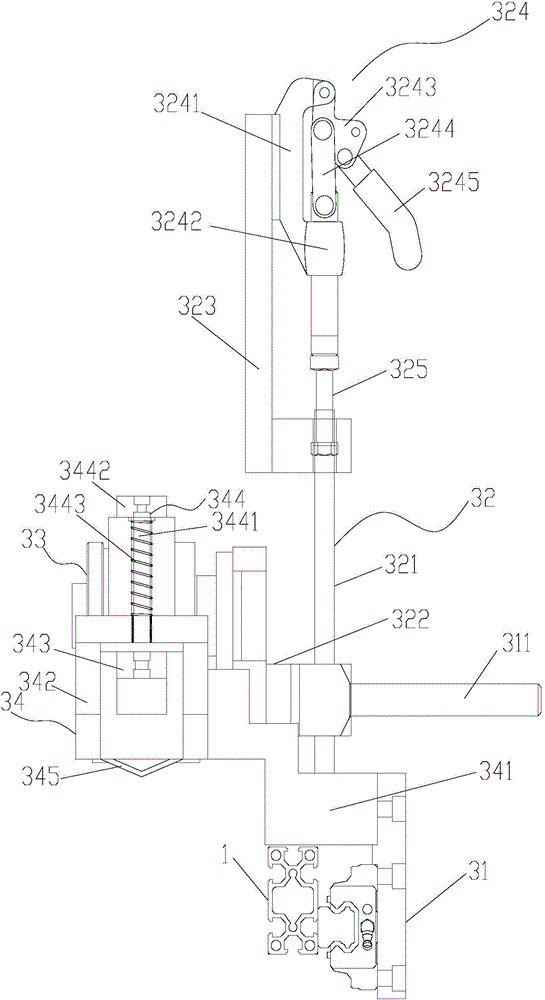

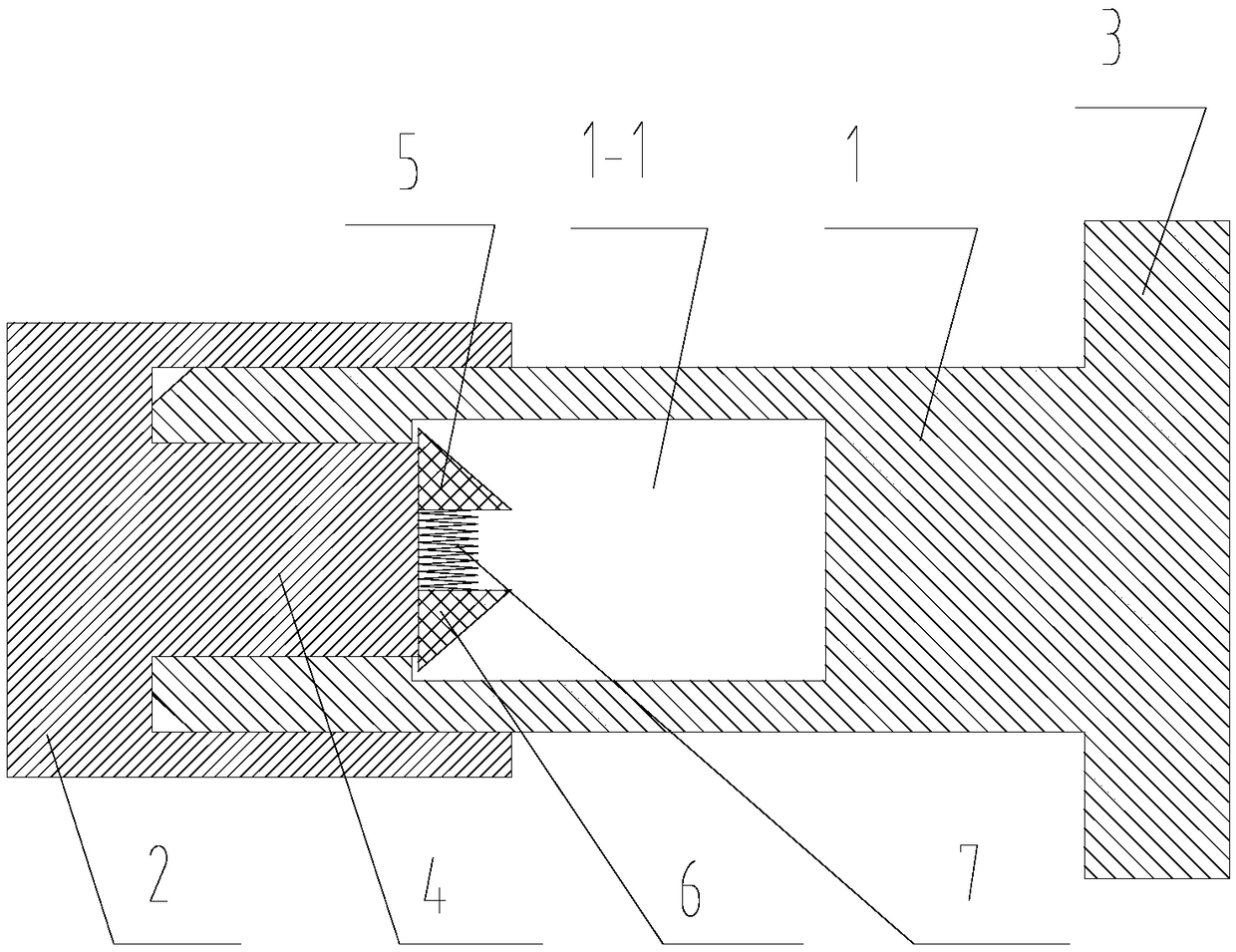

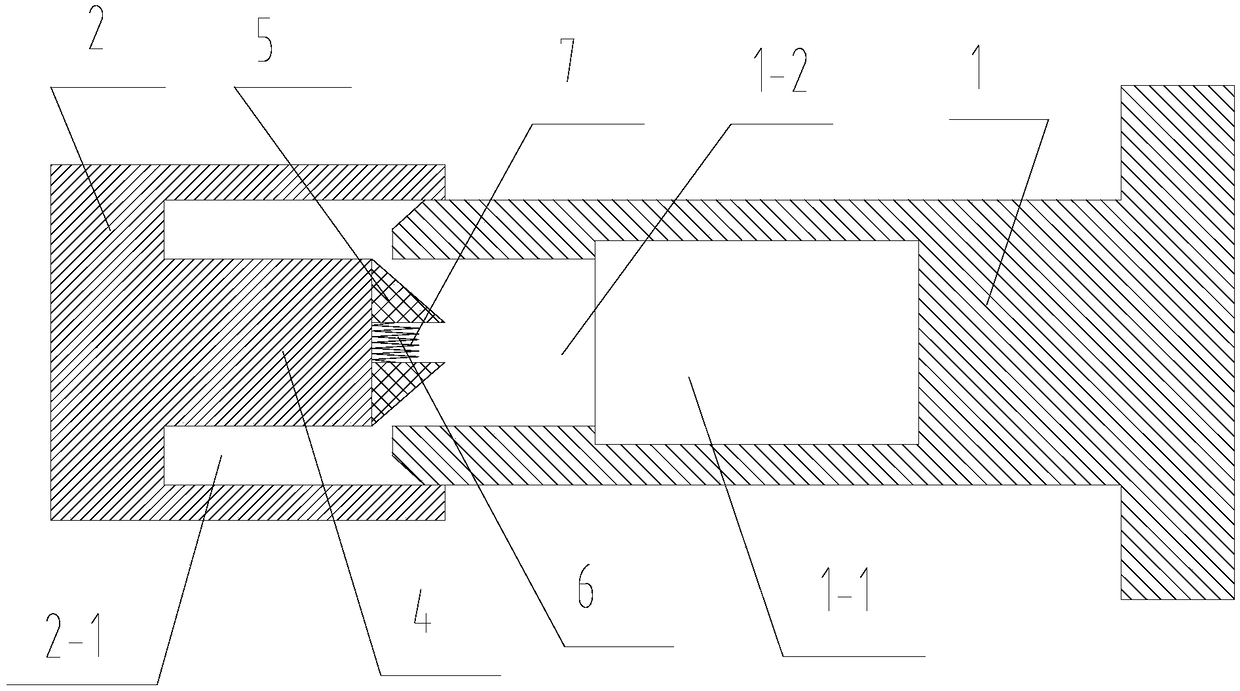

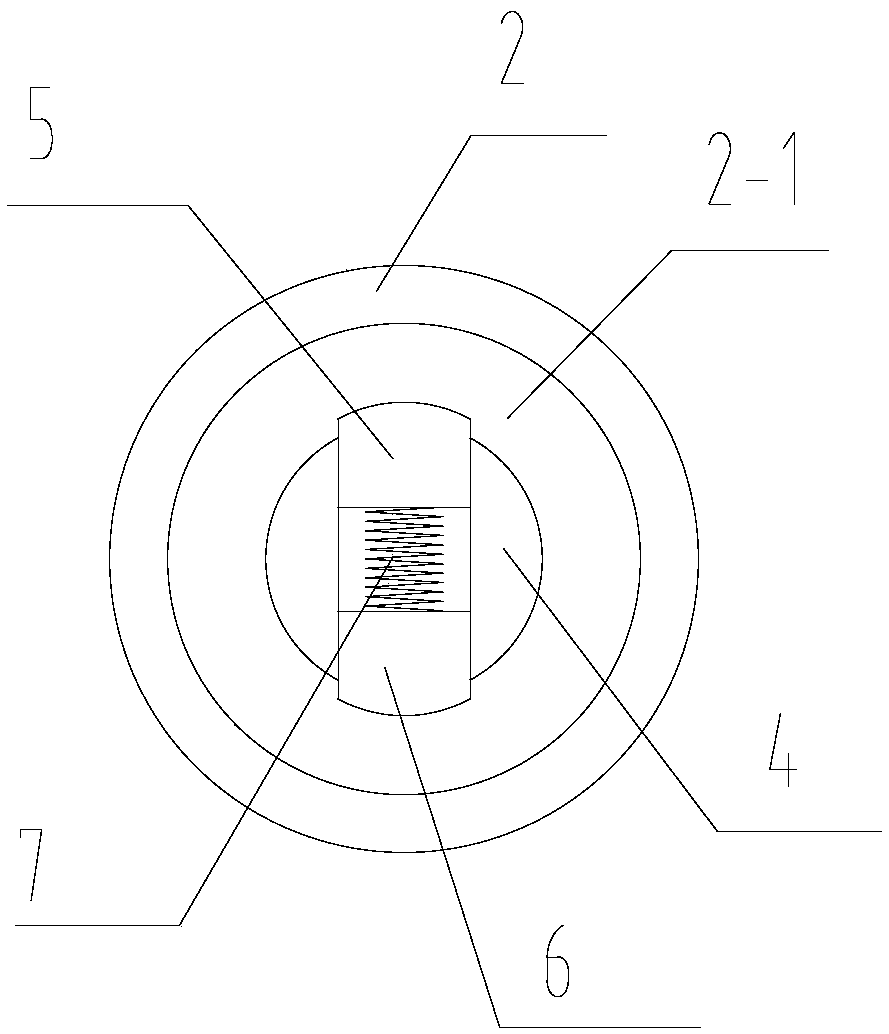

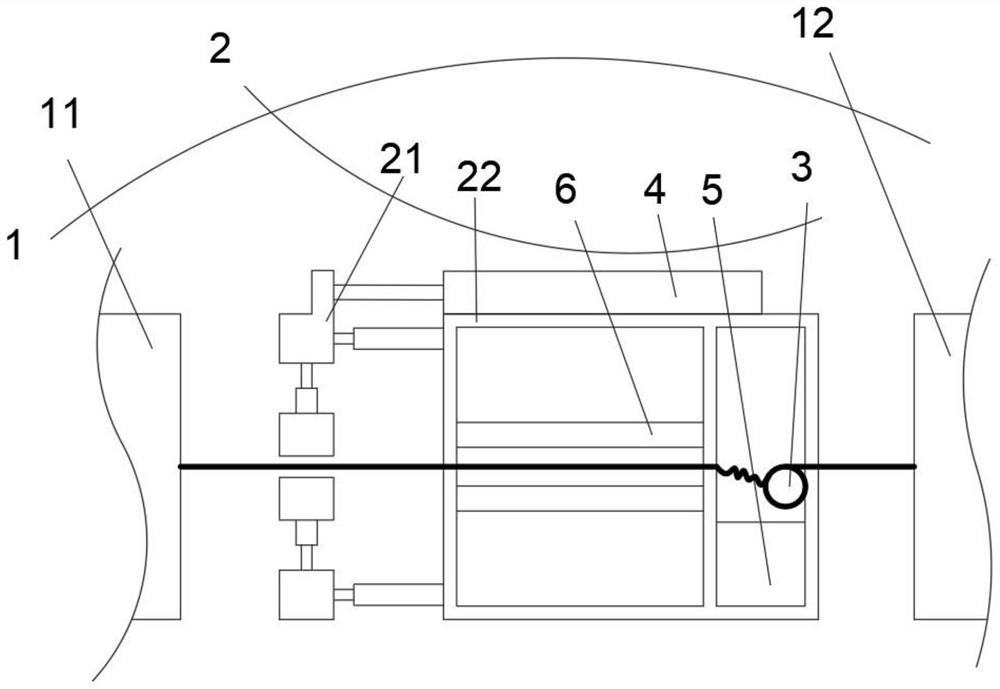

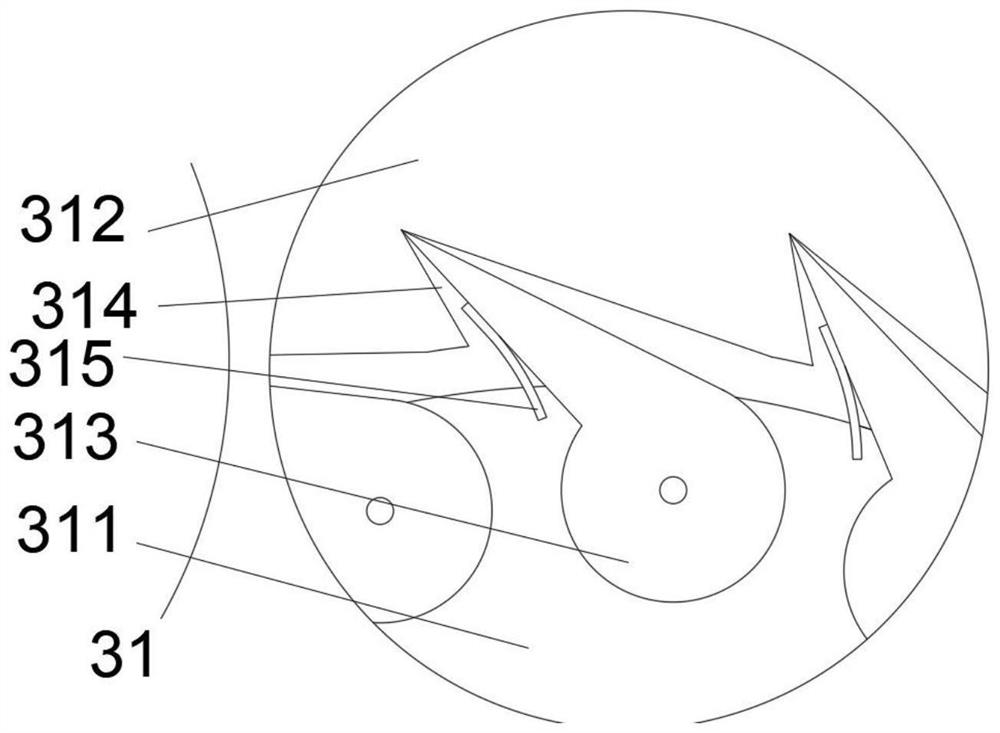

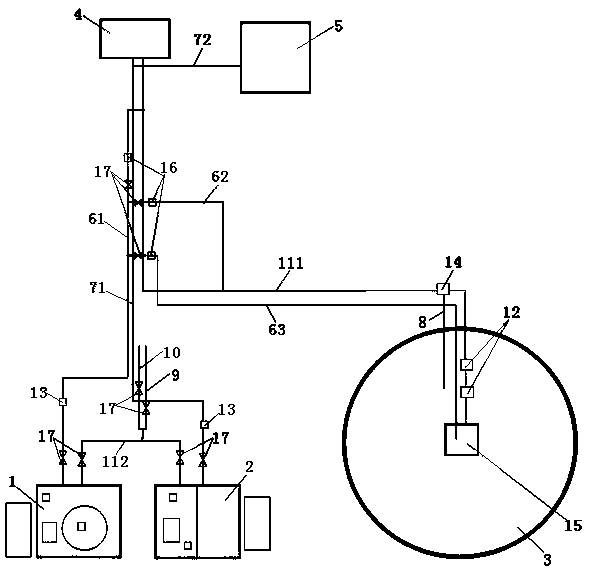

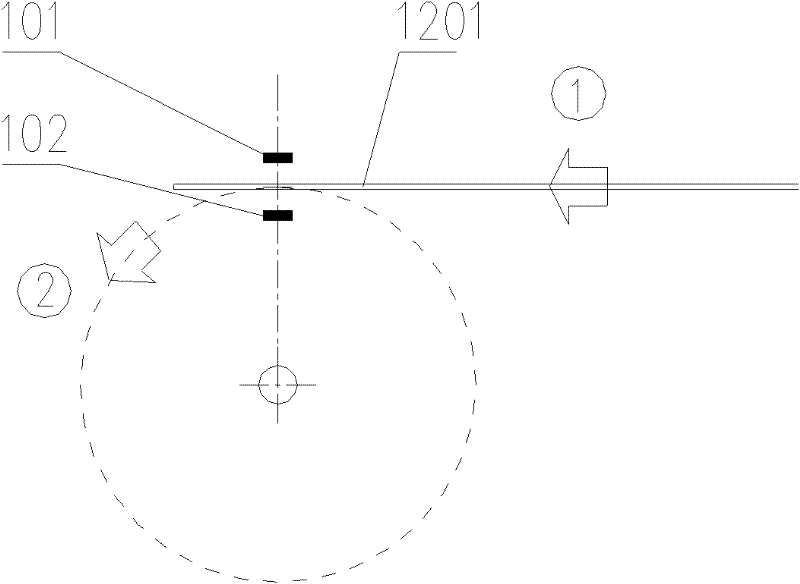

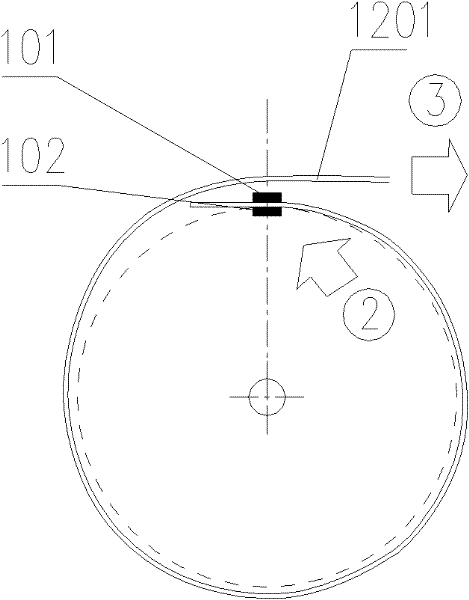

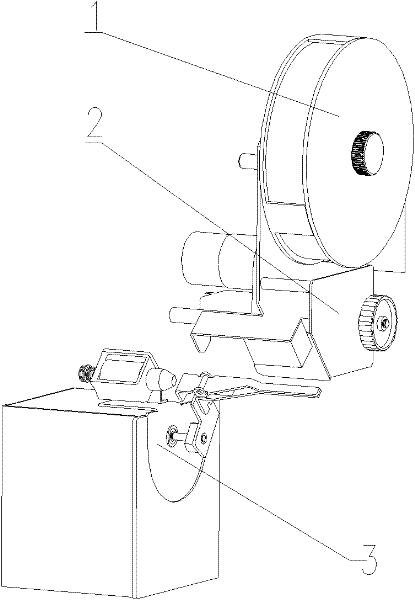

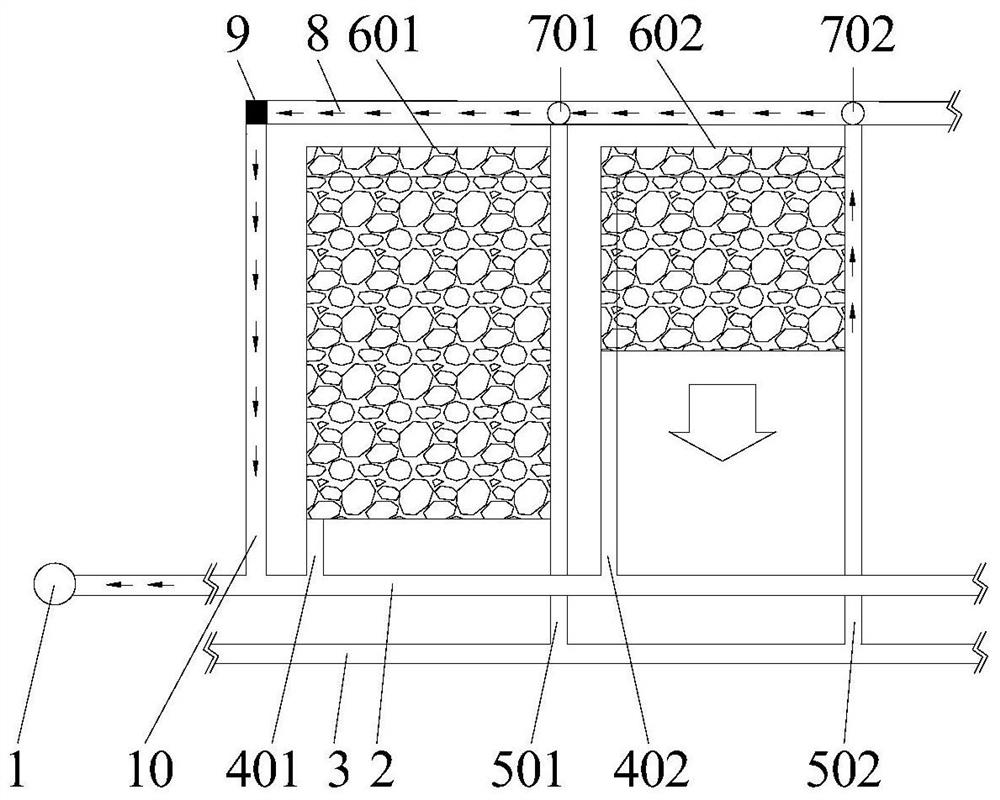

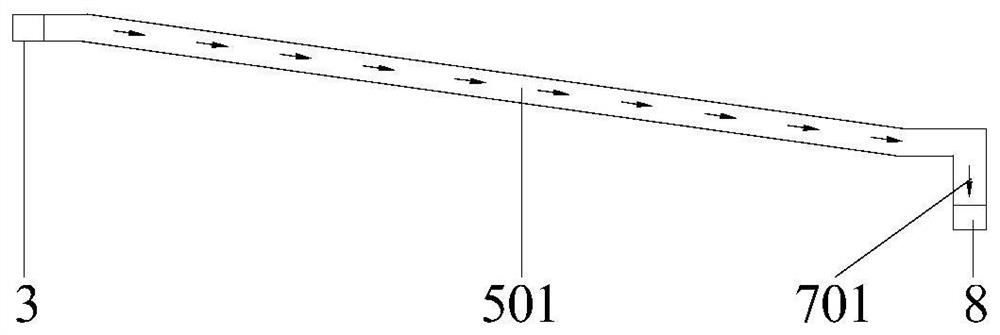

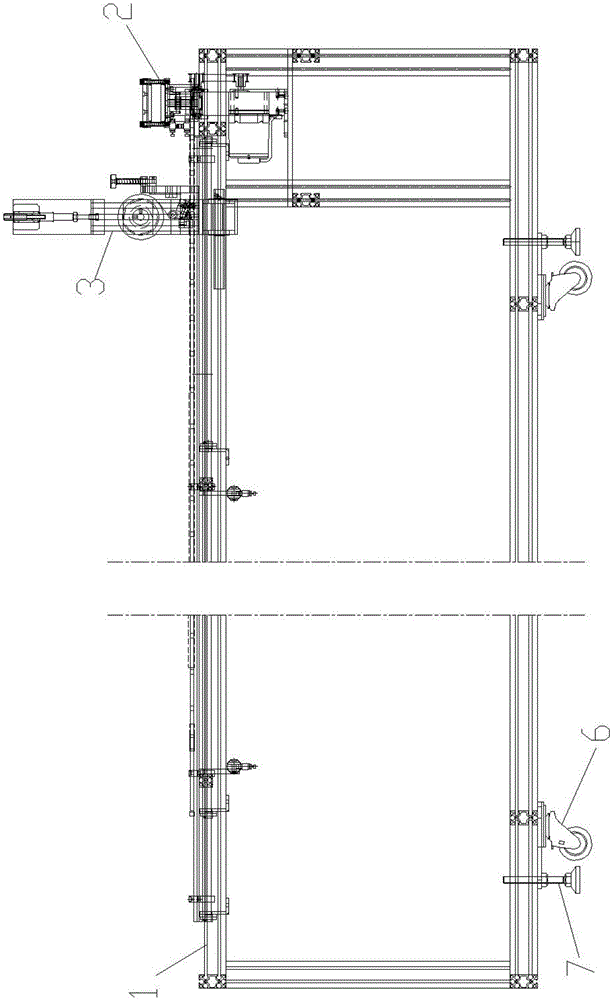

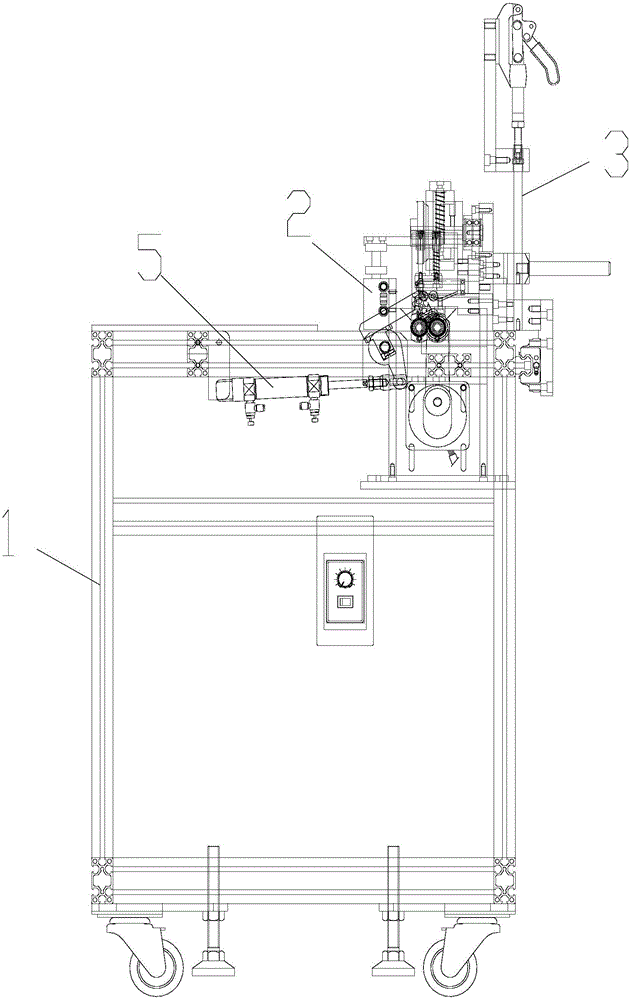

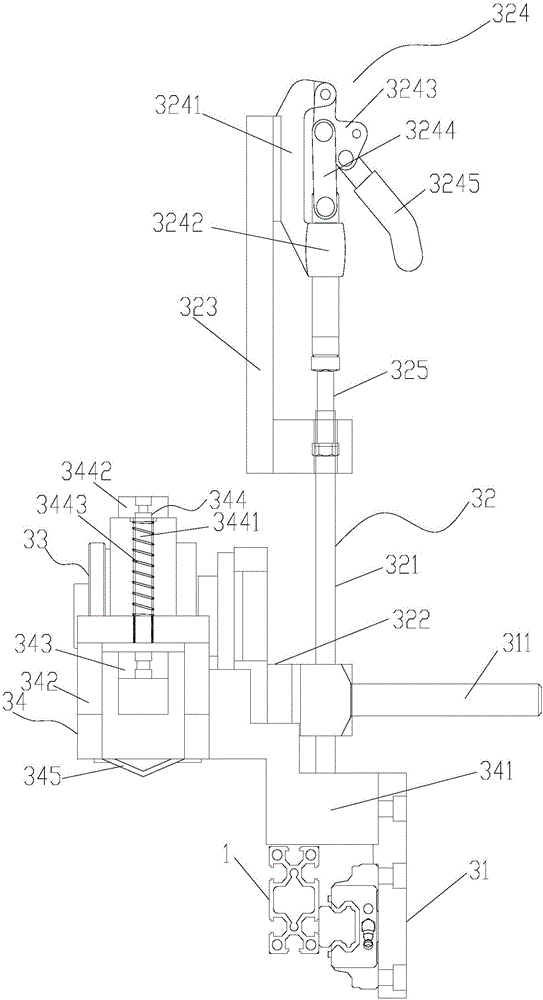

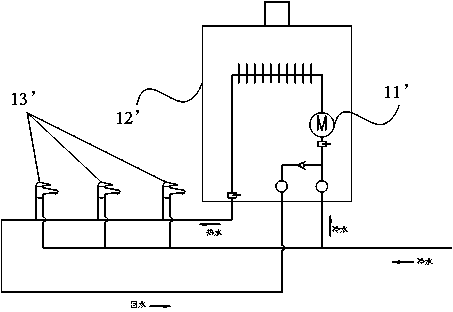

Strip medium strapping mechanism and strapping method

ActiveCN102101541APrevent withdrawalImprove the success rate of bundlingBinding material applicationBundling machine detailsEngineeringStrapping

The invention discloses a strip medium strapping mechanism, which comprises a clamping device used for clamping and dragging a strip medium to coil an object to be strapped, a triggering device used for triggering a clamping opening of the clamping device to open, and a driving device used for driving the clamping device to rotate, wherein the rotating direction of the clamping device is opposite to the strip medium conveying direction. The invention also discloses a strip medium strapping method, which comprises the following steps of: (1) clamping the strip medium; (2) dragging the strip medium and strapping the object to be strapped through coiling; and (3) lapping the head and tail of the strip medium and cutting the strip medium, wherein in the step (2), the rotating direction of the clamping device is opposite to the strip medium conveying direction. The strip medium is dragged to coil along the direction opposite to the strip medium conveying direction, so that the strip medium can be prevented from returning, and the strapping success rate is effectively improved.

Owner:GUANGZHOU INTELLICASH FINANCIAL TECH +1

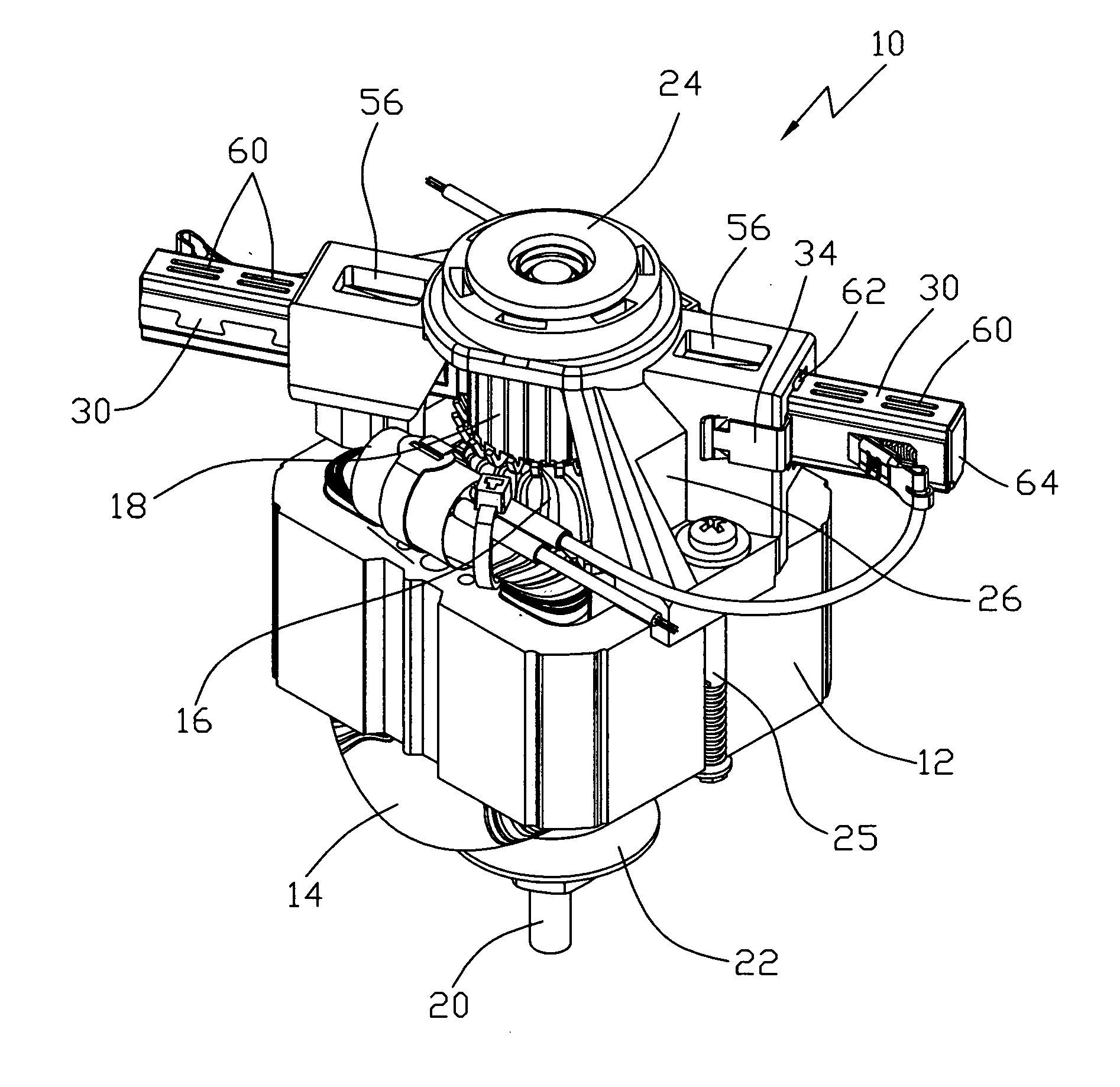

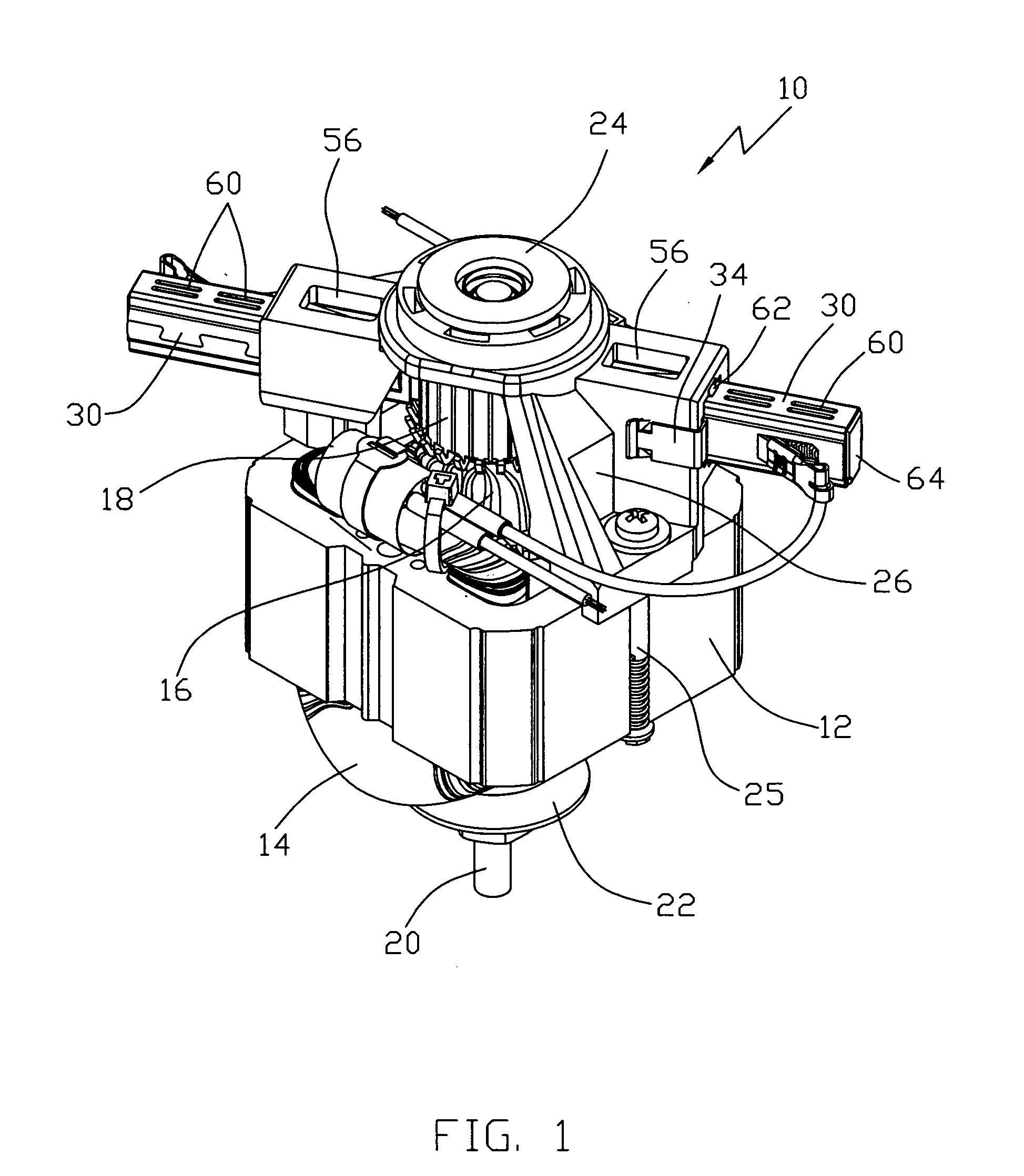

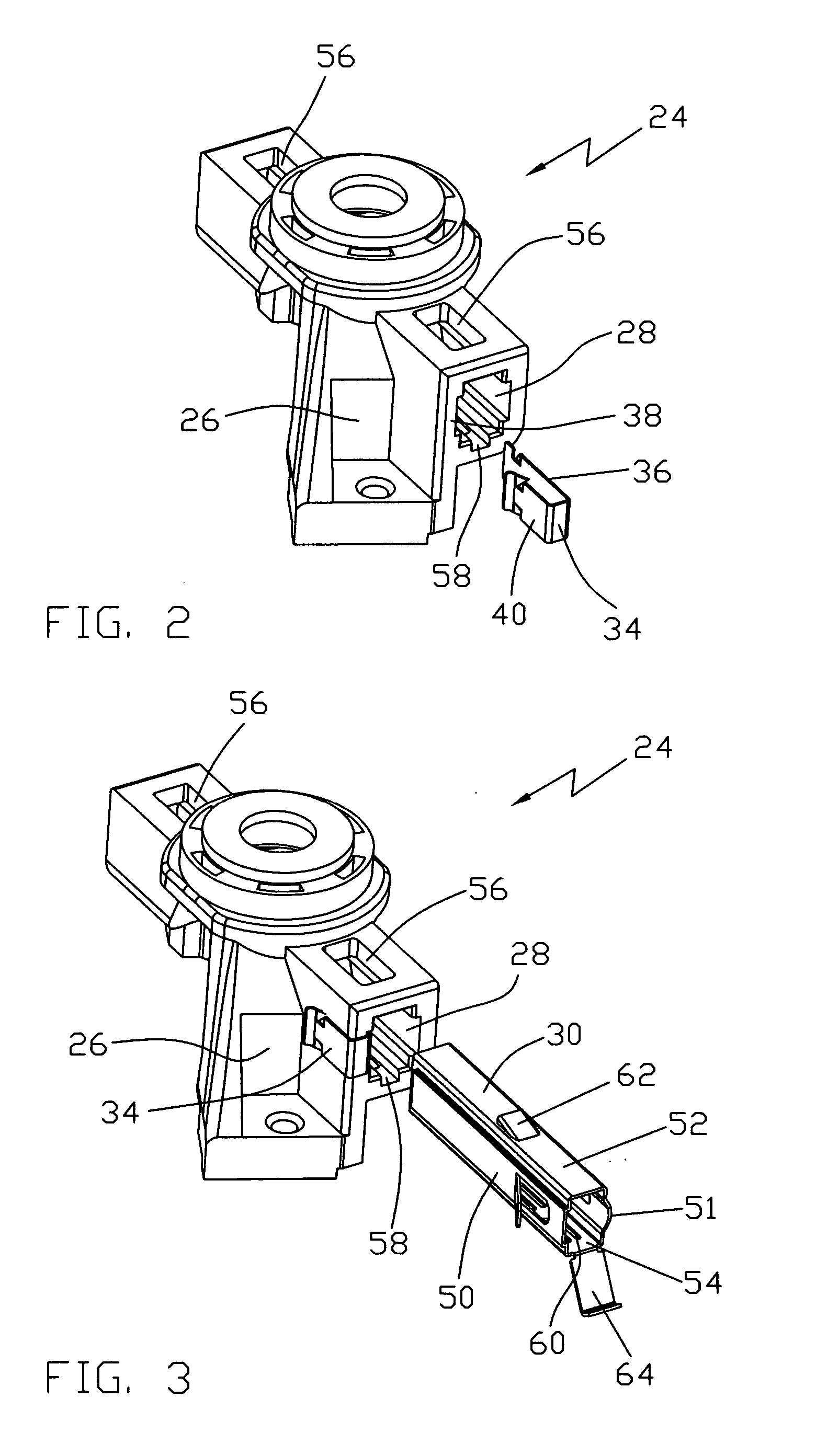

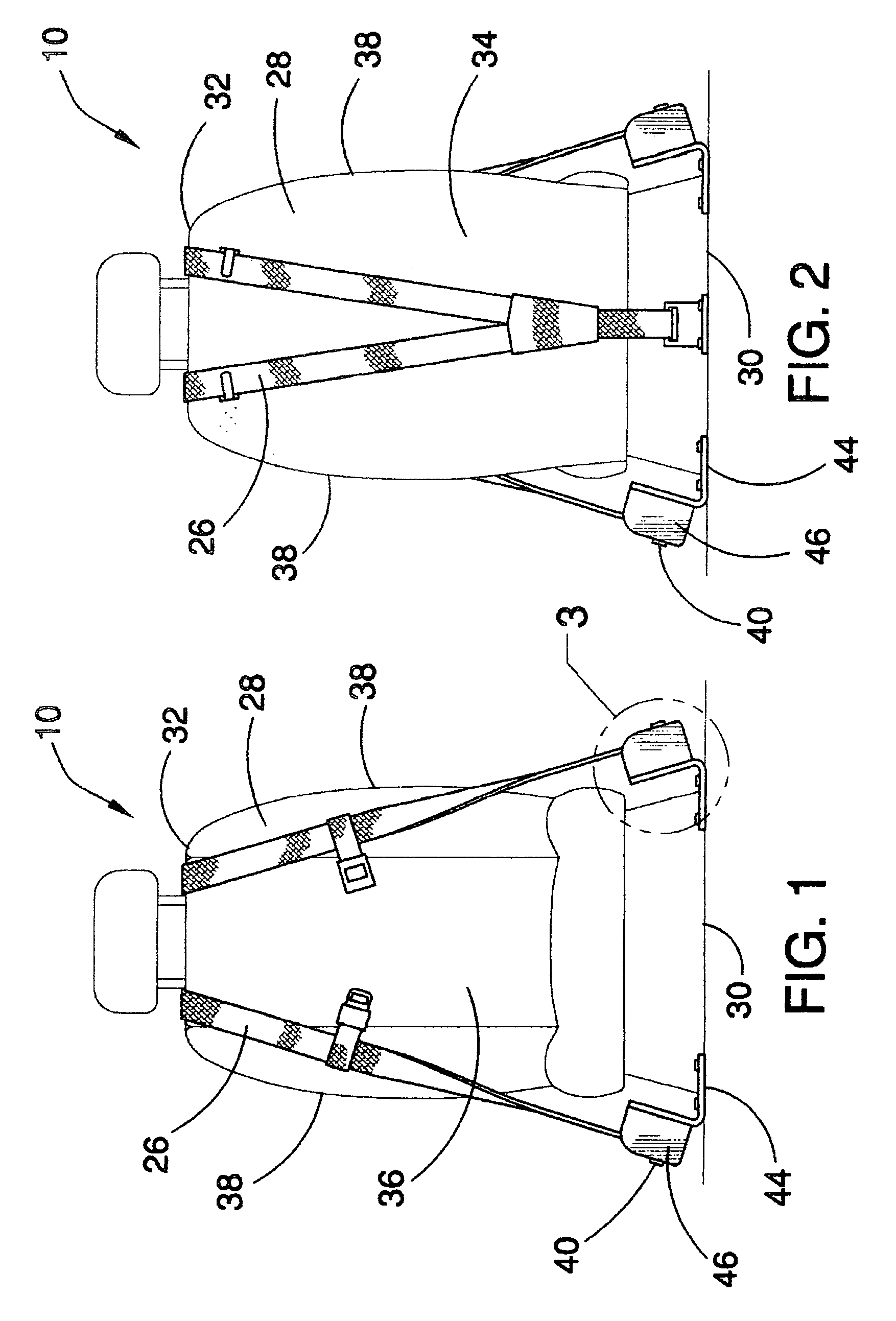

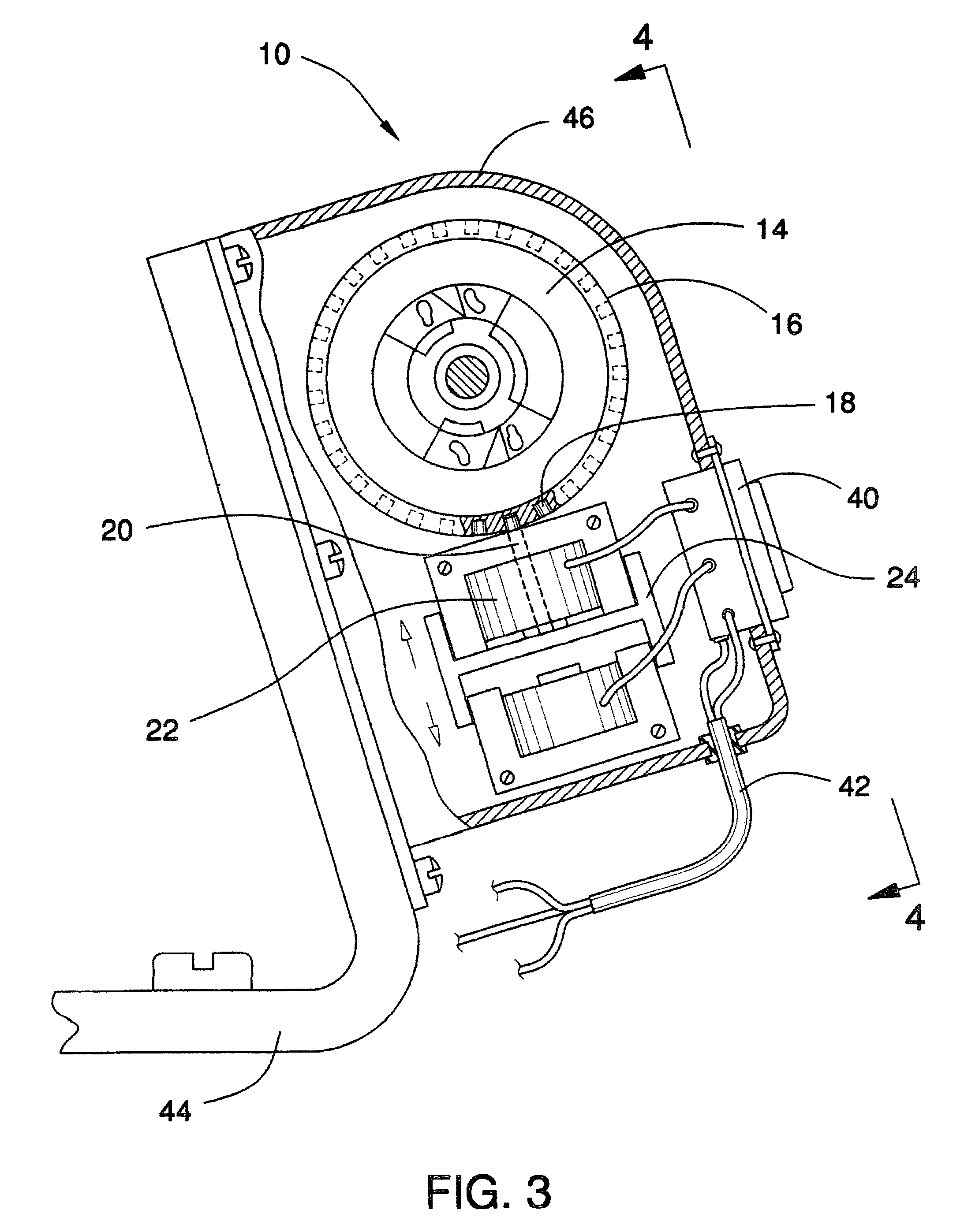

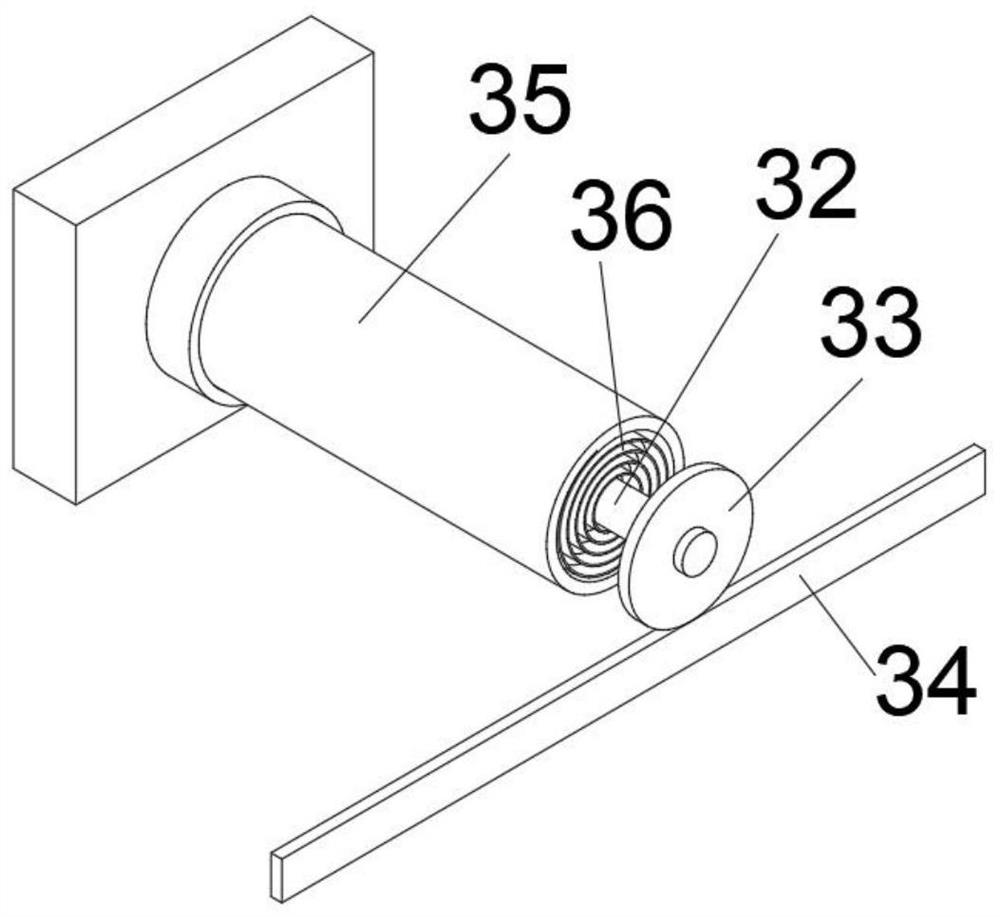

Brush holder assembly for an electric motor

ActiveUS20050121994A1Reduce lateral playPrevent withdrawalRotary current collectorSupports/enclosures/casingsElectric machineClassical mechanics

A universal motor has a brush cage assembly in which a U-shaped clip 34 is located about a wall of a through hole 28 of a bearing bracket 24 for receiving a brush cage 30. The clip 34 has an outer limb 42 with inwardly and rearwardly directed barbs 44 to grip an outer surface of the wall to prevent removal of the clip 34 and an inner limb 36 with outwardly and forwardly directed barbs 42 which resiliently deform as the cage 30 is inserted to snare the cage 30 should it move in the opposite direction. The clip 34 thus prevents withdrawal of the brush cage 30 and provides a lateral spring force against the cage 30 to reduce cage lateral position tolerance and movement.

Owner:JOHNSON ELECTRIC SA

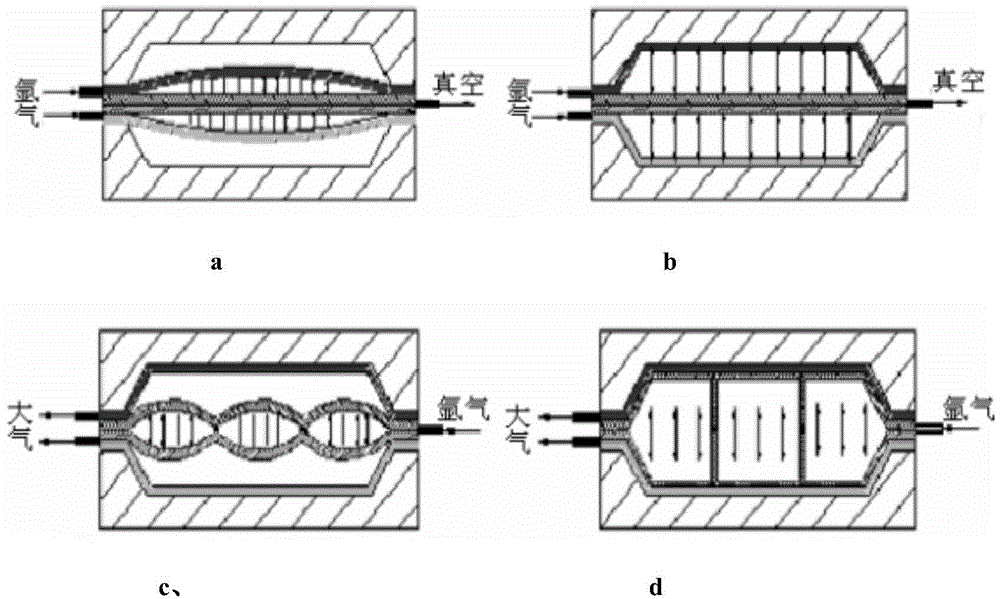

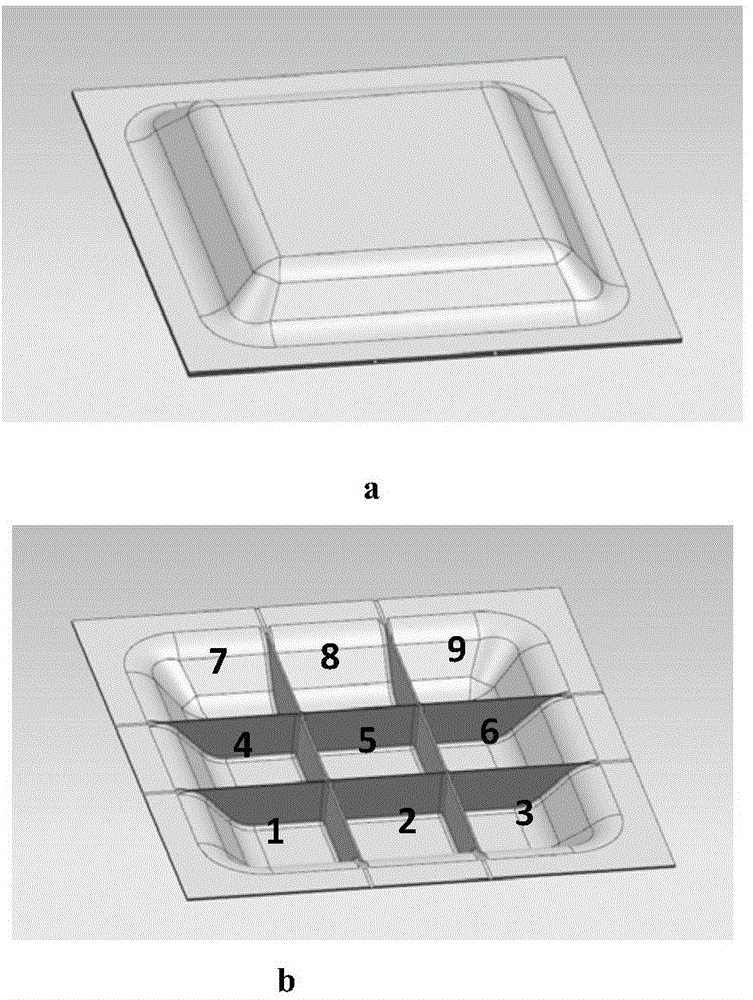

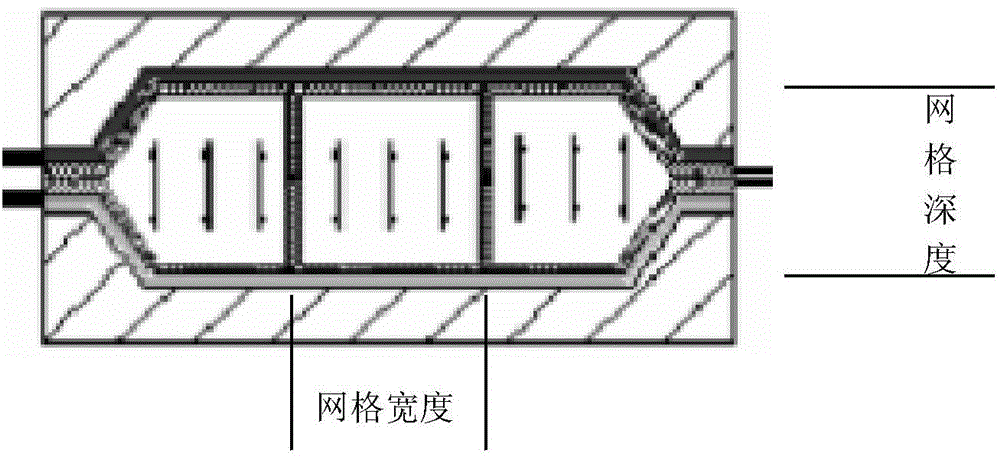

Forming method of superplastic forming/diffusion connecting four-layer structure of grid with variable depth-width ratio

The invention relates to a forming method of a superplastic forming / diffusion connecting four-layer structure of a grid with variable depth-width ratio, and belongs to the technical field of surface wrinkle prevention, and the surface of the four-layer structure formed by virtue of the method is flat and winkle-free. According to the method, in the process of forming a core board into a grid, the grids with different depth-width ratios are different in expanding start time, i.e., the grid with higher depth-width ratio is formed before the grid with lower depth-width ratio, and the grids with approximate depth-width ratios are approximate in expanding start time, so that the contact start time of each grid and a panel at the position of the grid is approximate; meanwhile, in the grid forming process, the air pressure between the panel and the core board is always kept high, so that the part, which is contacted with the panel, of the grid is not subjected to diffusion connection immediately in the expanding process; due to the effects of two aspects, the problem that the panel draws back along with deformation of the core board in a grid continuous expanding process can be prevented, and thus wrinkles are prevented from occurring.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

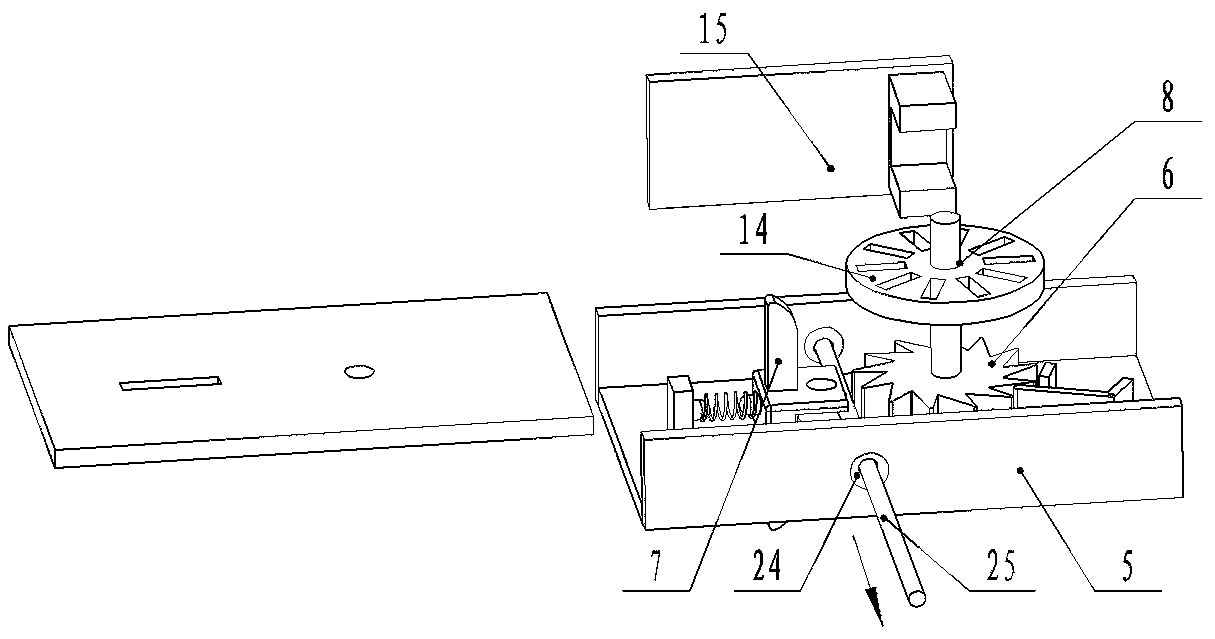

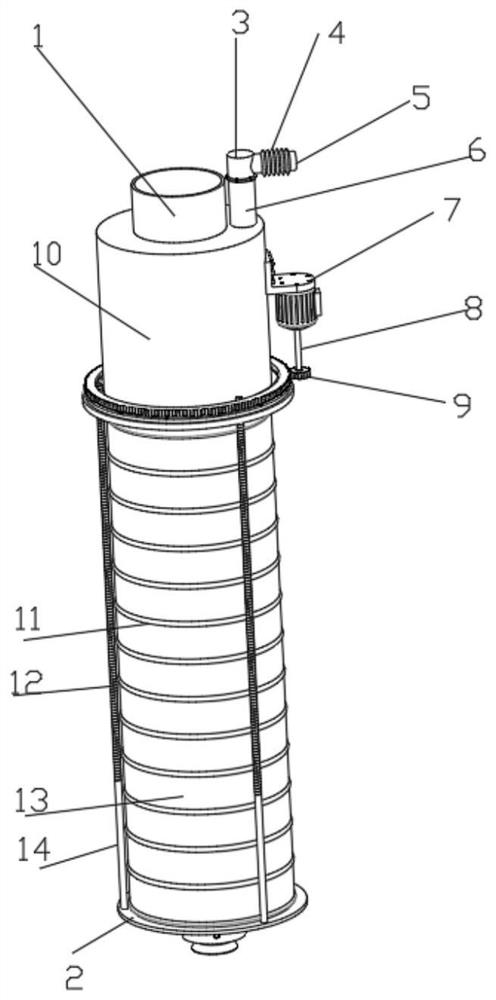

Intelligent anti-sticking spool for 3D printing

PendingCN109822905AAlleviate wire jam problemPrevent withdrawalAdditive manufacturing apparatus3D object support structuresLaser rangingDrive motor

The invention belongs to the technical field of 3D printing and provides an intelligent anti-sticking spool for 3D printing. The intelligent anti-sticking spool comprises a control module and a spoolholder, wherein a unidirectional extruding mechanism, a consumable driving mechanism and a laser ranging device are arranged on the spool holder; the unidirectional extruding mechanism comprises a discharging box, a ratchet wheel, a feeding mechanism and a code disc counter; a clearance is left between the feeding mechanism and the ratchet wheel to allow a filament to pass through; the code disc counter is arranged above the ratchet wheel and used for measuring the rotational speed of the ratchet wheel; the consumable driving mechanism comprises a driving motor, a connecting shaft and a central shaft, which is connected with an output shaft of the driving motor through the connecting shaft; a consumable is fixedly arranged at the periphery of the central shaft; the laser ranging device isused for measuring the radius of the consumable; and the control module is used for measuring the drawing speed of a printer according to a measurement value of the code disc counter and for controlling the rotational speed of the driving motor according to the drawing speed of the printer and the radius of the spool. The intelligent anti-sticking spool can prevent sticking during printing and canbe widely used in the field of 3D printing.

Owner:陈科地 +1

Anchor device with double-sectioned head and method of using the same

Owner:AVK INDAL PRODS

Boron carbide preparing method

PendingCN109399636AImprove heat utilizationReduce power consumptionCarbon compoundsRotary kilnThermal efficiency

The invention provides a boron carbide preparing method. The boron carbide preparing method comprises mixing boron materials and carbon materials into solid materials in a protective atmosphere, thenfeeding the solid materials into a direct-heat type rotary kiln or a direct-heat type shaft kiln; in the direct-heat type rotary kiln or the direct-heat type shaft kiln, the boron materials are sequentially preheated, heated, cooled and discharged to prepare boron carbide; in a heating section, power electrodes are applied to directly electrifying the carbon materials in the heating section and / ormaterials converted during heating, and the materials are heated through resistance of the materials in the heating section or contact resistance between the particles or blocks of the materials, andthe maximum temperature of the materials passing through the direct-heat type rotary kiln or the direct-heat type shaft kiln is not lower than 1250 DEG C. The boron carbide preparing method has the advantages of being high in thermal efficiency, low in power consumption, good in product consistency, stable in process, low in volatilization loss of the boron material and high in productivity.

Owner:冯良荣

Solid-liquid separation sealed odor resisting garbage can

ActiveCN106945965AOvercome the flaws in its own designReduce the rate of corruptionRefuse receptaclesEnvironmental resistanceCompression device

The invention relates to a solid-liquid separation sealed odor resisting garbage can. A sealing cover body is mounted at the top of a cylinder; a solid-liquid separation compression device is mounted in the sealing cover body; a garbage feeding opening bin is formed in the lower position of the top of the cylinder; the bottom of the garbage feeding opening bin communicates with the cylinder; a solid-liquid separation pipe is arranged at the bottom of the cylinder; the bottom of the solid-liquid separation pipe communicates with a liquid recovery tank; the outer side of the solid-liquid separation pipe between the liquid recovery tank and the cylinder is sleeved with an odor resisting start device protective cover; an odor resisting start device is mounted in the odor resisting start device protective cover, and is connected with a cold transfer pipe mounted on the inner wall of the cylinder; a sleeve is mounted on the inner side of the cold transfer pipe; and a solid-liquid separation hole is formed in the bottom of the sleeve. The solid-liquid separation sealed odor resisting garbage can is simple in structure, convenient to operate, high in efficiency, environment-friendly, high in working and operating efficiency, high in automation degree, obvious in odor resisting effect, tight in sealing, clean, sanitary and liable to clean and treat, and adopts solid-liquid separation.

Owner:南阳市寅兴实业有限公司

Wall Anchor

Owner:HANRATTY BRENT

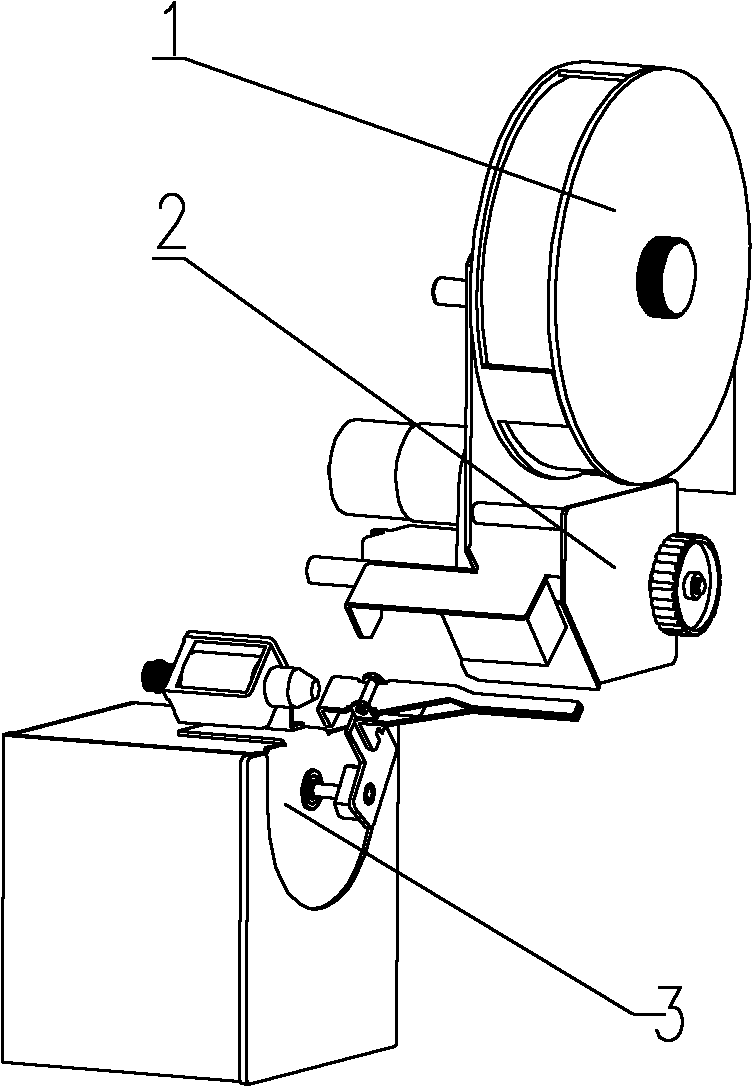

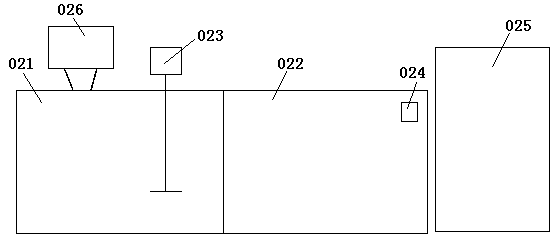

Aluminum foil tape coating device for pipe material

The invention relates to an aluminum foil tape coating device for a pipe material. The aluminum foil tape coating device comprises a rack, wherein a mounting platform is arranged on the rack; a mounting groove used for placement of the pipe material is formed in the mounting platform; a positioning device used for limiting the end part of the pipe material is arranged at one end of the rack; an aluminum foil tape sticking machine is arranged on the side surface of the rack, correspond to the mounting groove, and is connected with the rack in a sliding manner. The aluminum foil tape coating device has the characteristics that the structure is simple, use is convenient, time is saved, the working efficiency is improved, the cost is reduced and the automatic operation is realized.

Owner:常州市常蒸制冷科技有限公司

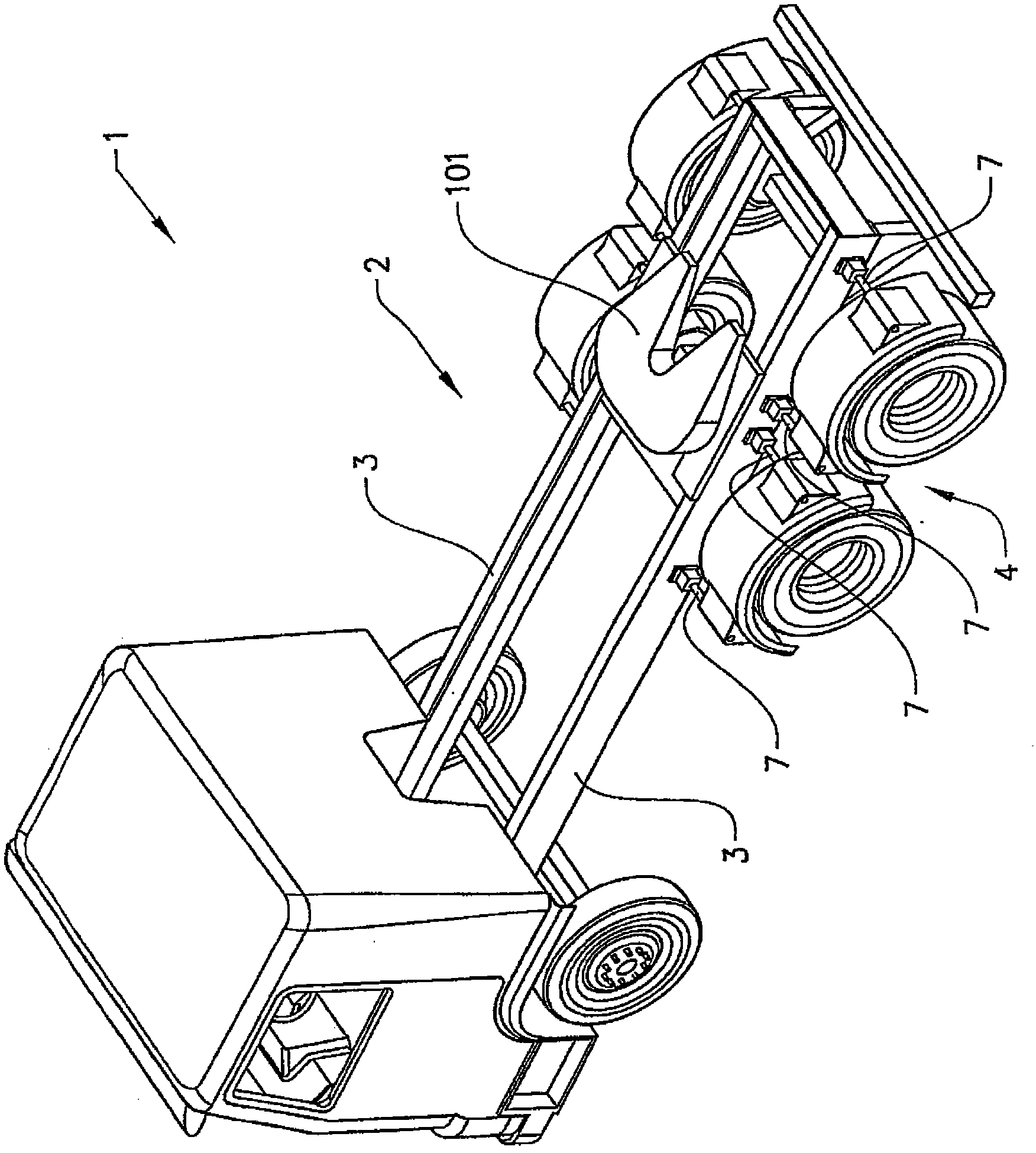

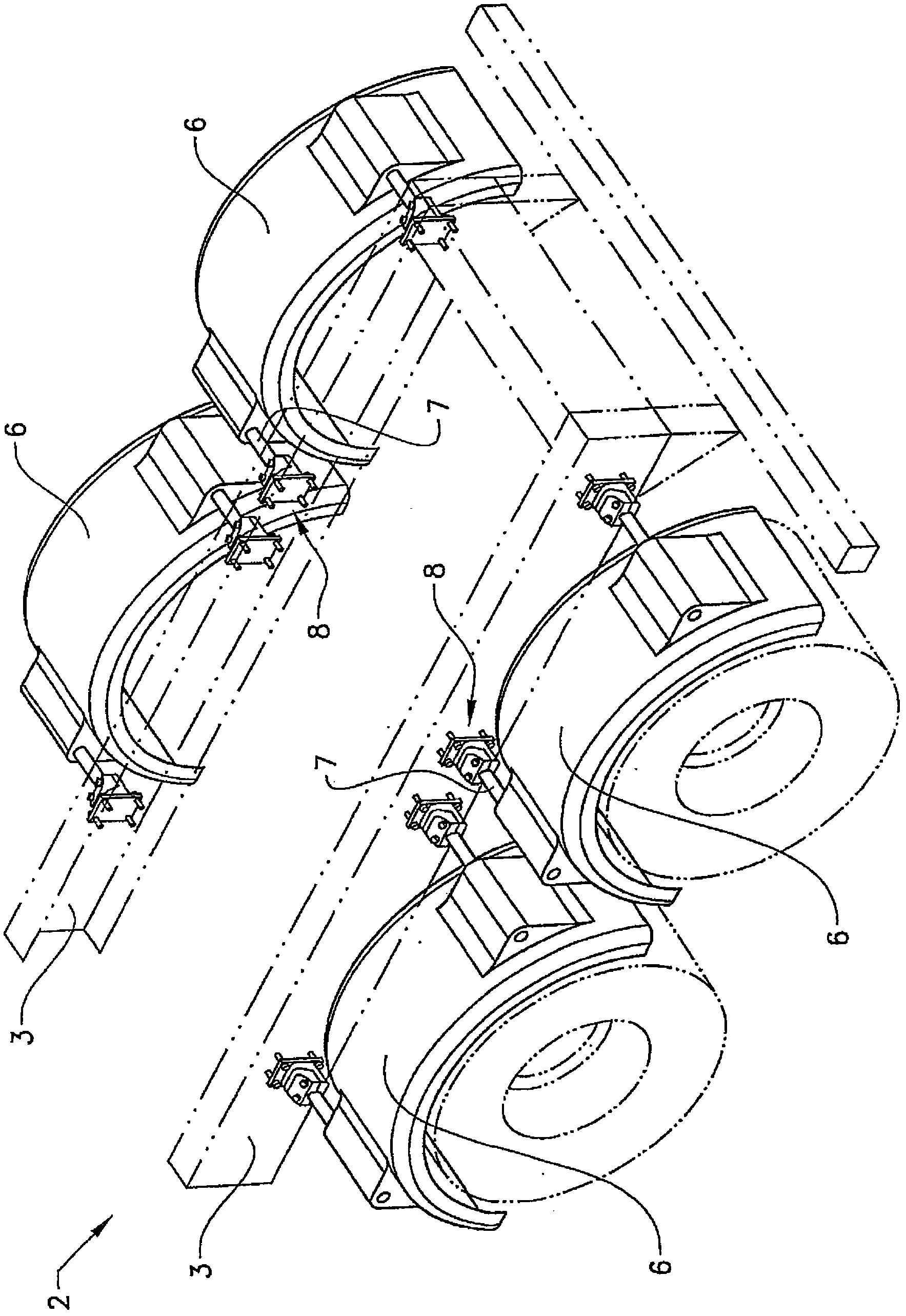

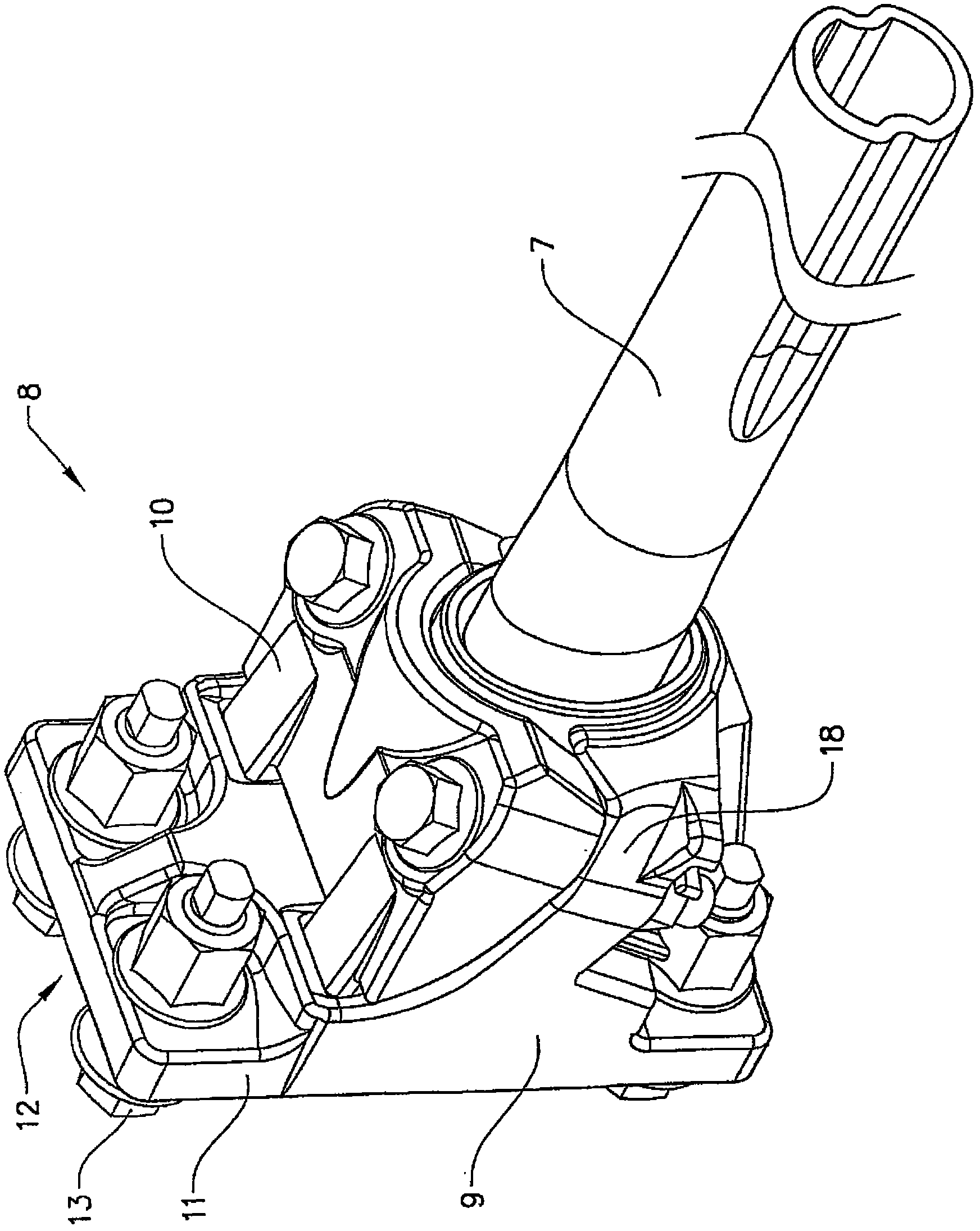

A device for attaching a stay to a vehicle frame and a vehicle comprising the device

ActiveCN102421657APrevent withdrawalEasy to assembleSuperstructure subunitsVehicle frameSupport surface

The invention relates to a device (8) for attaching a stay (7) to a vehicle frame (2). The device (8) comprises an attachment member (9) configured for being attached to the vehicle frame (2), wherein the attachment member (9) comprises a first support surface (15) for supporting an upper surface of a first end (28) of the stay (7) and a second support surface (19) at a distance from the first support surface (15) for supporting a lower surface of the stay (7) at a distance from the first end of the stay. The device comprises a clamp member (10) for clamping the stay (7) against the second support surface. The clamp member (10) is movably arranged in relation to the second support surface (19) between an open position and a clamping position. The clamp member (10) is arranged so that a clamp surface (20) of the clamp member (10) can be positioned at a sufficient distance from the second support surface (19) in the open position for allowing a pivoting motion of the stay (7) about a pivot point at the first support surface (15) to a position resting on the second support surface (19) during assembly.

Owner:VOLVO LASTVAGNAR AB

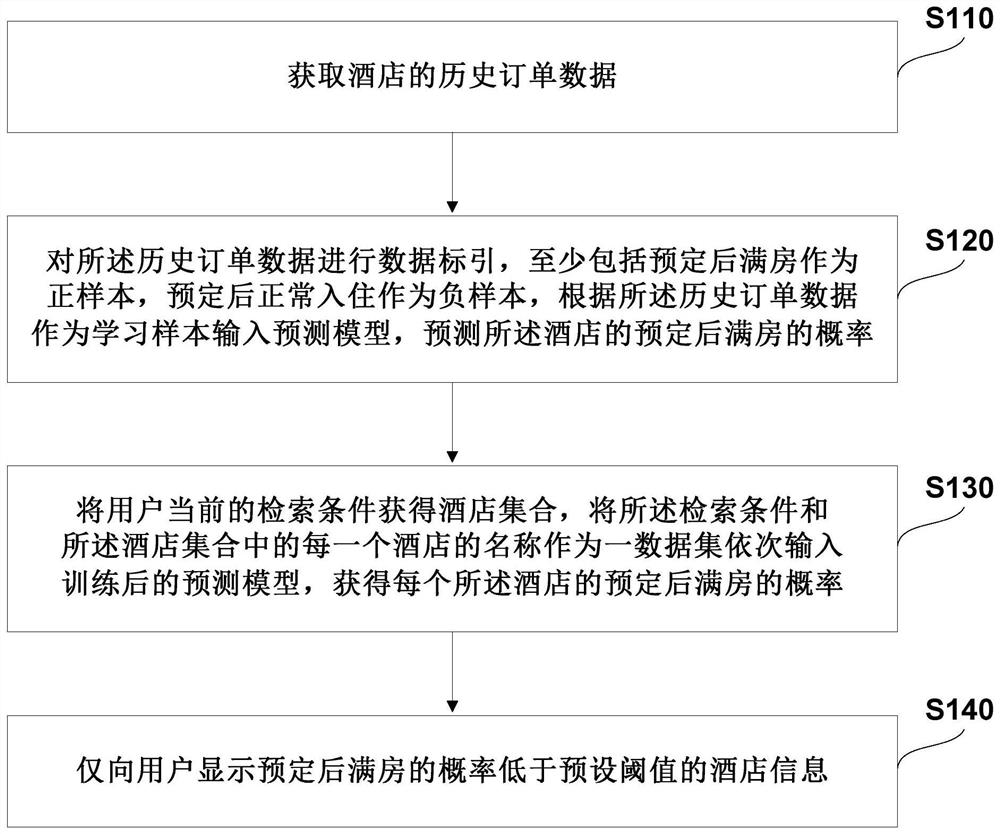

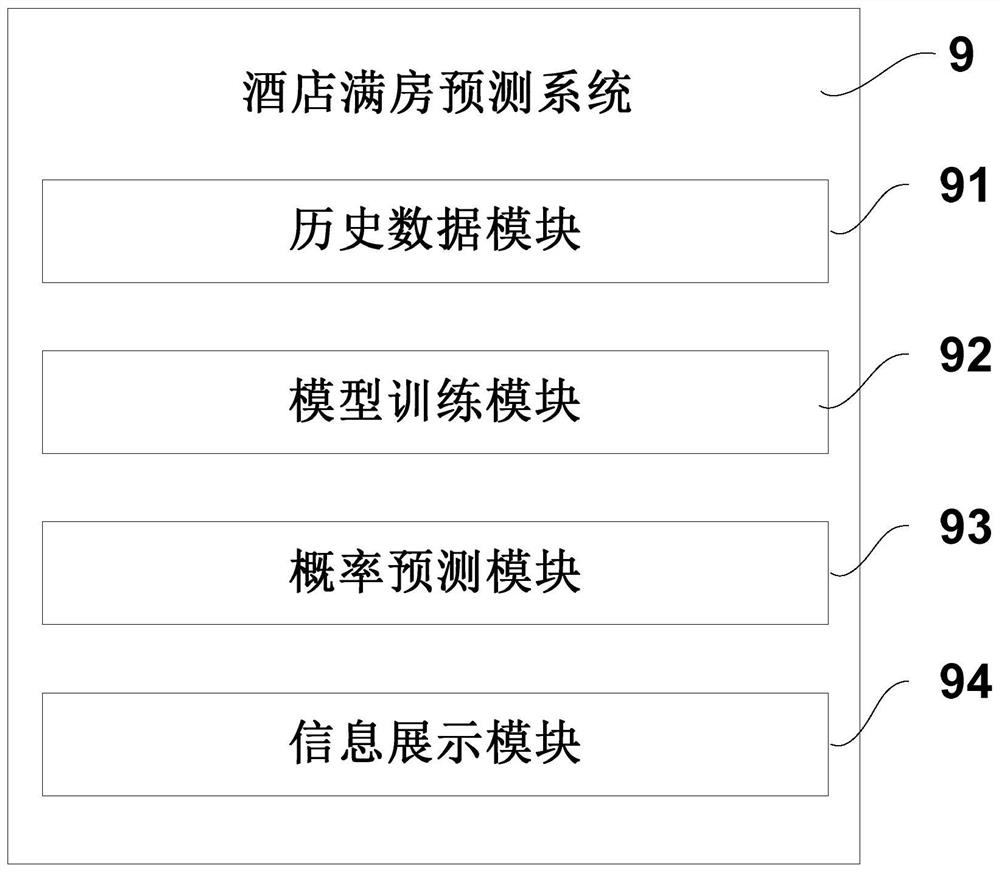

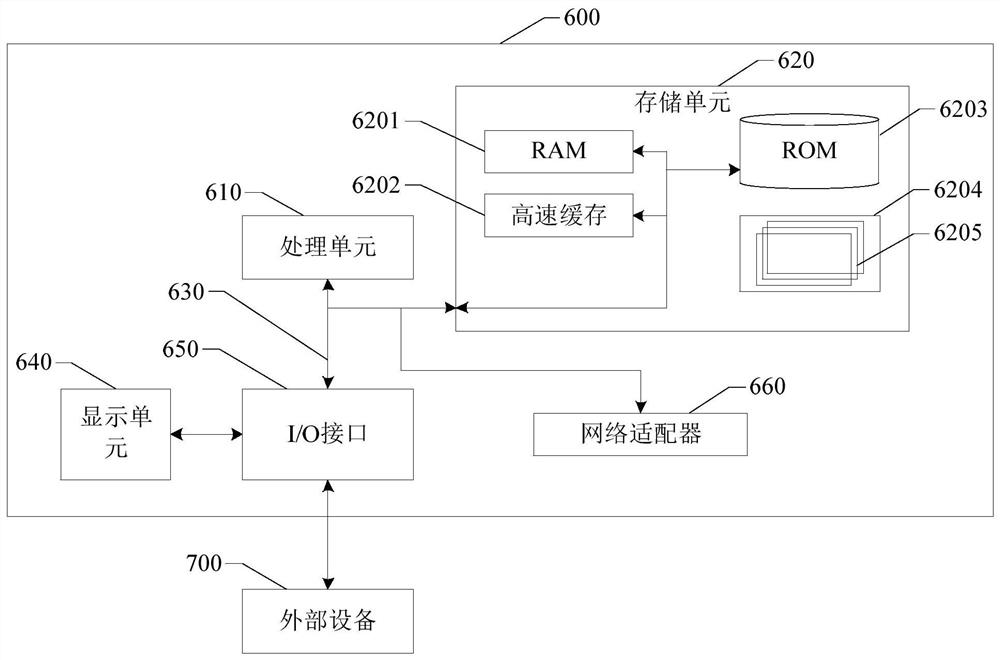

Hotel full-room prediction method, system and device and storage medium

PendingCN111861801APrevent withdrawalImprove experienceForecastingCharacter and pattern recognitionPositive sampleData set

The invention provides a hotel full-room prediction method, system and device, and a storage medium. The method comprises the steps: obtaining the historical order data of a hotel; performing data indexing on the historical order data, at least including taking a reserved full room as a positive sample and taking a reserved normal check-in as a negative sample, inputting the historical order dataas a learning sample into a prediction model, and predicting the probability of the reserved full room of the hotel; obtaining a hotel set according to the current retrieval condition of the user, taking the retrieval condition and the name of each hotel in the hotel set as a data set to be sequentially input into the trained prediction model, and obtaining the probability that each hotel is fullafter reservation; and only displaying hotel information of which the probability of room fullness after reservation is lower than a preset threshold to the user. The method can accurately and efficiently predict the full-house probability, thereby reducing the full-house proportion, effectively preventing the customer from being withdrawn after ordering, and obviously enhancing the user experience.

Owner:CTRIP COMP TECH SHANGHAI

Threaded connecting part with clamping structure

InactiveCN108644220ARealize deadlockAvoid the risk of unreliable connectionsNutsBoltsEngineeringMechanical engineering

Owner:合肥仨力机械制造有限公司

Method for producing a liquid crystal device with low zenithal anchoring energy, and resulting device

InactiveUS7087270B2Prevent withdrawalIncrease effectivenessLiquid crystal compositionsRadiation applicationsLiquid crystal devicesAzimuth

A method of making nematic liquid crystal devices where low energy zenith anchoring of the liquid crystal is obtained over confinement plates. A polymer or copolymer is deposited based on PVC onto a substrate. The polymer deposit is stabilized. An azimuth orientation is defined for the deposit to induce controlled azimuth anchoring of the liquid crystal.

Owner:NEMOPTIC

Textile thread layer carding device for textile machine

PendingCN112410997APrevent withdrawalAffect operationWeft knittingLoomsComputer architectureMechanical engineering

The invention discloses a textile thread layer carding device for a textile machine. The textile thread layer carding device comprises the textile machine, a carding device is arranged in the textilemachine, a pre-loosening assembly is arranged at the rear end of the carding device, a thread pulling assembly is arranged on the upper side of the pre-loosening assembly, a thread blowing assembly isarranged on the lower side of the pre-loosening assembly, and an impurity removing assembly is arranged on the front side of the pre-loosening assembly. The pre-loosening assembly is used for pre-releasing a thread with a certain length when the textile machine draws the thread, and preventing the thread from being pulled excessively during thread drawing; the thread blowing assembly blows up thereleased thread when the thread is pulled, so that the thread floats in the air, friction between the thread and the carding device is reduced, force borne by the thread during thread drawing is further reduced, and the effect of protecting the thread is achieved; the thread pulling assembly tightens the thread and prevents the thread from loosening in the spinning process after thread pulling iscompleted; and the impurity removing assembly separates and recycles fluff and impurities on the thread. The textile thread layer carding device for a textile machine has the advantages of preventingthe thread from being pulled broken, cleaning the thread and recycling the fluff.

Owner:单兆君

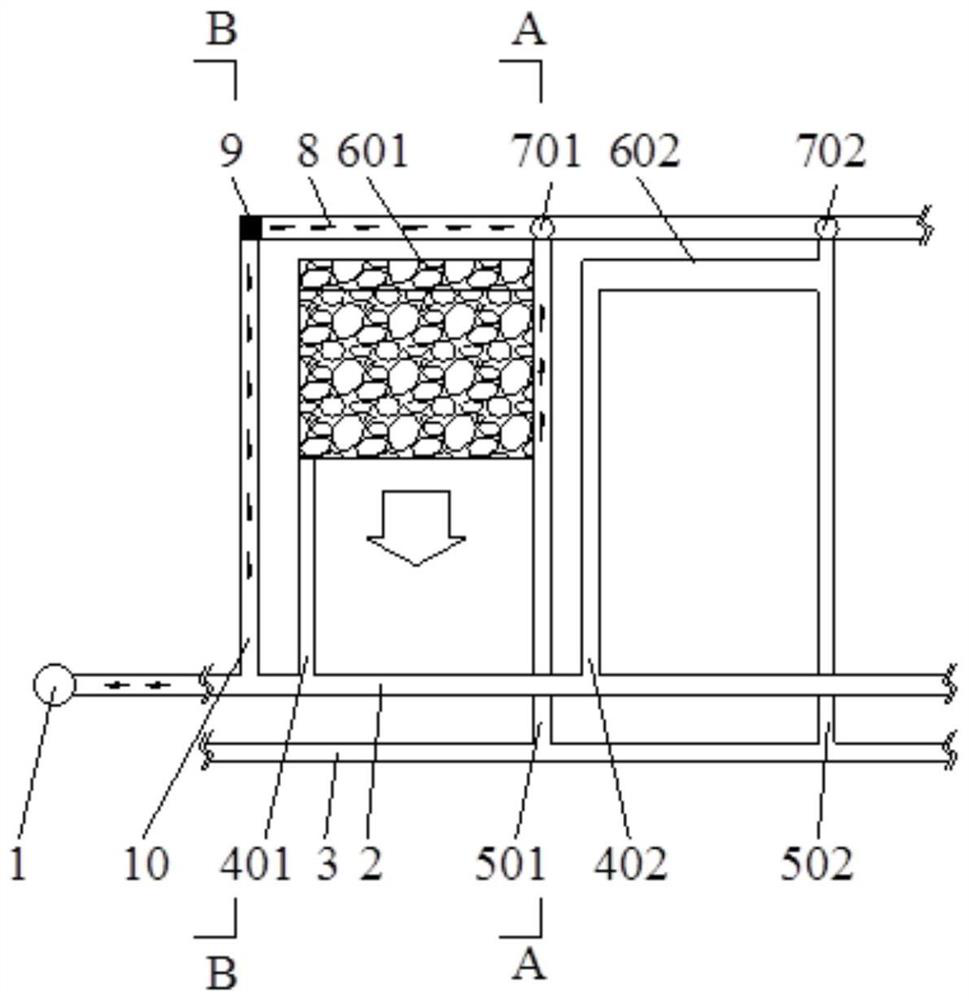

Coal preparation plant slime water intelligent dosing system and dosing method

PendingCN111470583AReduce lossDosage controlWater/sewage treatment by ion-exchangeProcess engineeringEnvironmental engineering

The invention relates to a coal preparation plant slime water intelligent dosing system and dosing method, and belongs to the technical field of coal washing. According to the system, one end of a No.1 slime water feeding pipeline is connected with a concentration tank, and the other end of the No.1 slime water feeding pipeline is connected with a protection box; one end of a first cation dosing pipeline is connected with cation dosing equipment, and the other end of the first cation dosing pipeline is connected with a protection box; one end of a first anion dosing pipeline is connected withanion dosing equipment, and the other end of the first anion dosing pipeline is connected with a first slime water feeding pipeline; one end of a second anion dosing pipeline is connected with the first anion dosing pipeline, and the other end of the second anion dosing pipeline is connected with the first slime water feeding pipeline; one end of a third anionic dosing pipeline is connected with the first anionic dosing pipeline, the other end of the third anionic dosing pipeline is connected with the concentration tank, one end of the second slime water feeding pipeline is connected with theanionic dosing equipment, and the other end of the second slime water feeding pipeline is connected with the cationic dosing equipment.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

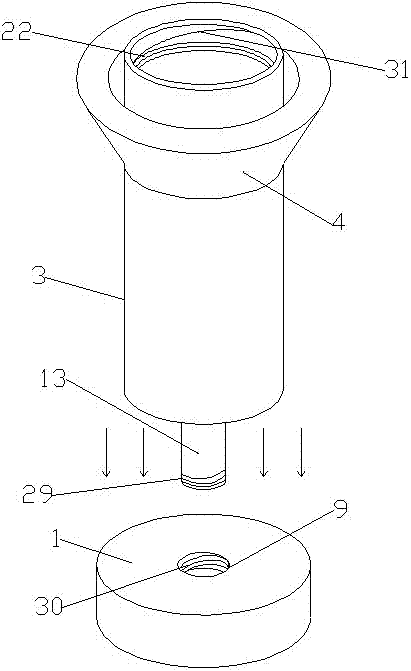

Dry ash sealing and telescopic bulk device

PendingCN113277340AReduce relative spacingImprove stabilityDispersed particle filtrationLoading/unloadingThermodynamicsStraight tube

The invention discloses a dry ash sealing telescopic bulk device, and relates to the technical field of dry ash conveying. The dry ash sealing telescopic bulk device comprises a discharging pipe and a tank car, wherein a feeding hole is formed in the middle end of the top of the tank car, six groups of telescopic sleeves are arranged at the bottom of the discharging pipe, the bottoms of the inner walls of the upper group of telescopic sleeves make contact with the outer walls of the tops of the lower group of telescopic sleeves in an attached mode, the bottom of the telescopic sleeve at the lowest end is fixedly connected to a discharging inner ring, the outer wall of the upper end of the discharging pipe is fixedly connected to a dust collection sleeve, the top of the dust collection sleeve is fixedly connected to a straight pipe, the straight pipe is connected to a filtering structure used for filtering dust, the filtering structure has a blockage clearing function, the top of the straight pipe is in threaded connection with the straight pipe, and the side wall of the straight pipe is fixedly connected to a supporting ring. According to the above solution, no gap exists after each stage of telescopic sleeves is expanded, so that dry ash does not escape due to the existence of pressure difference in the falling process of the discharging pipe.

Owner:中电国瑞供应链管理有限公司淮南分公司

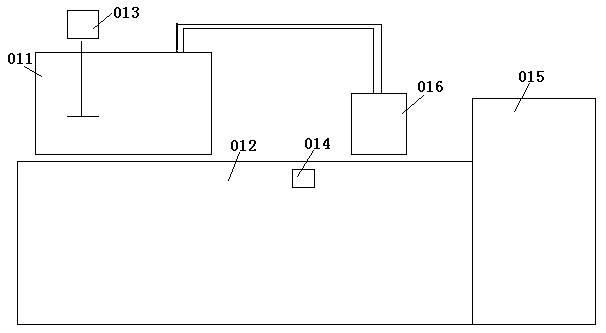

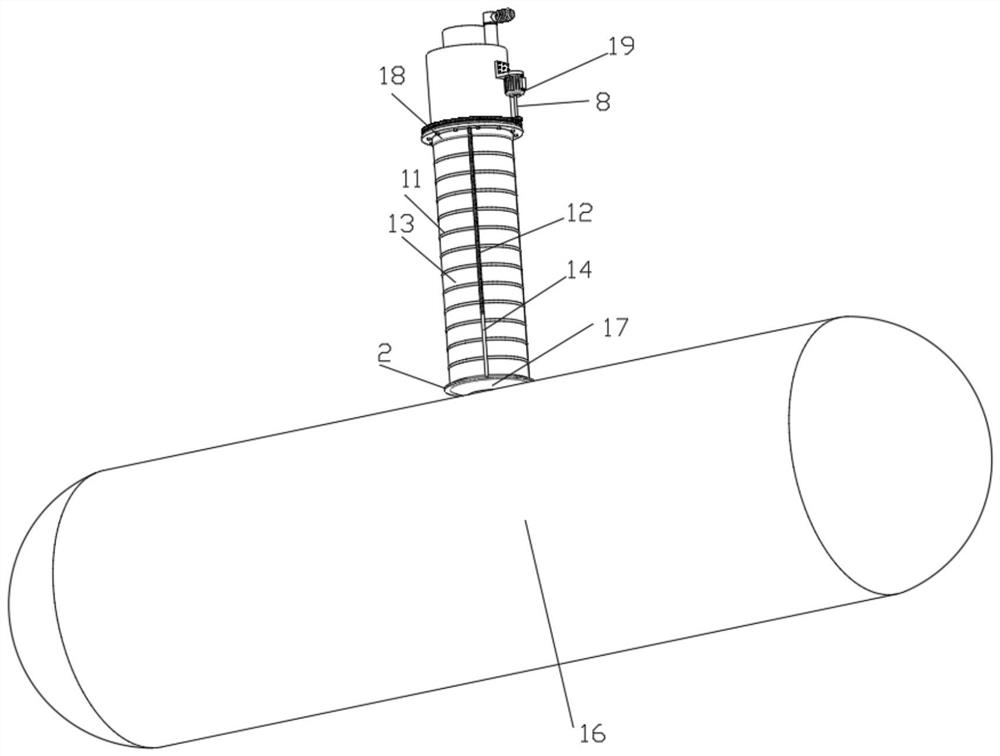

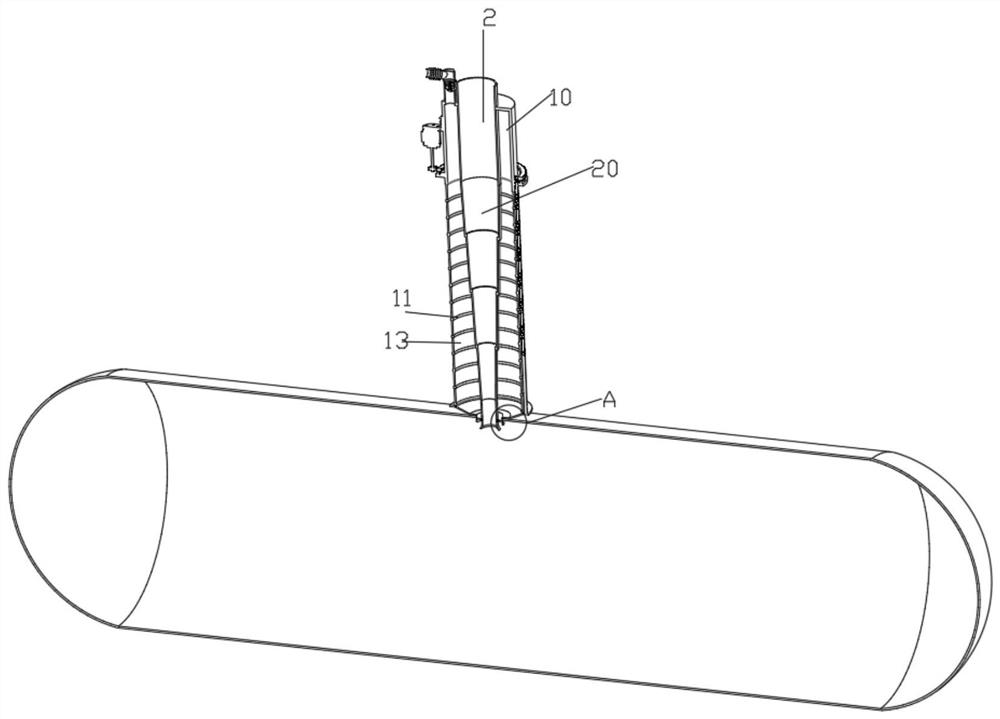

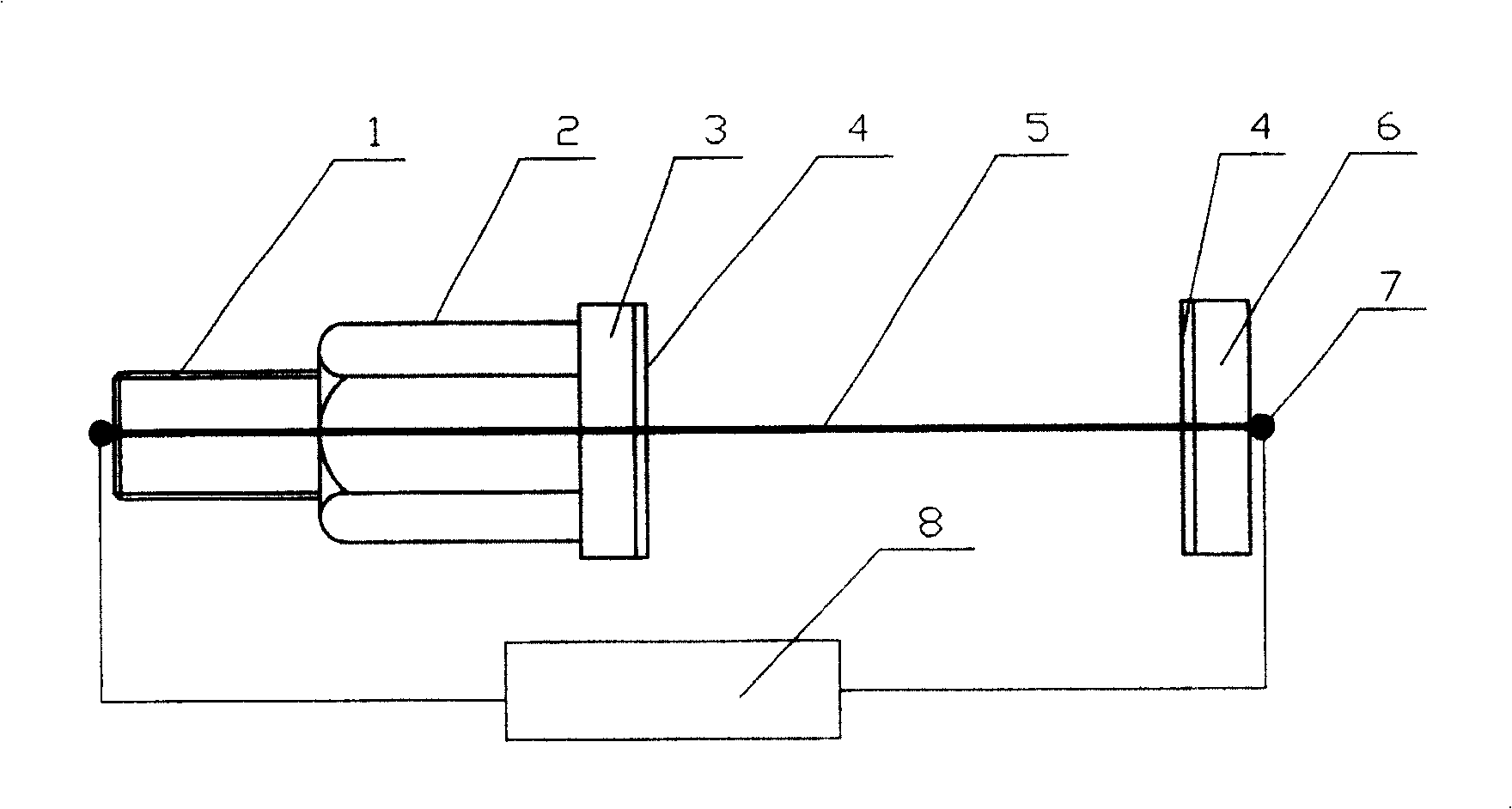

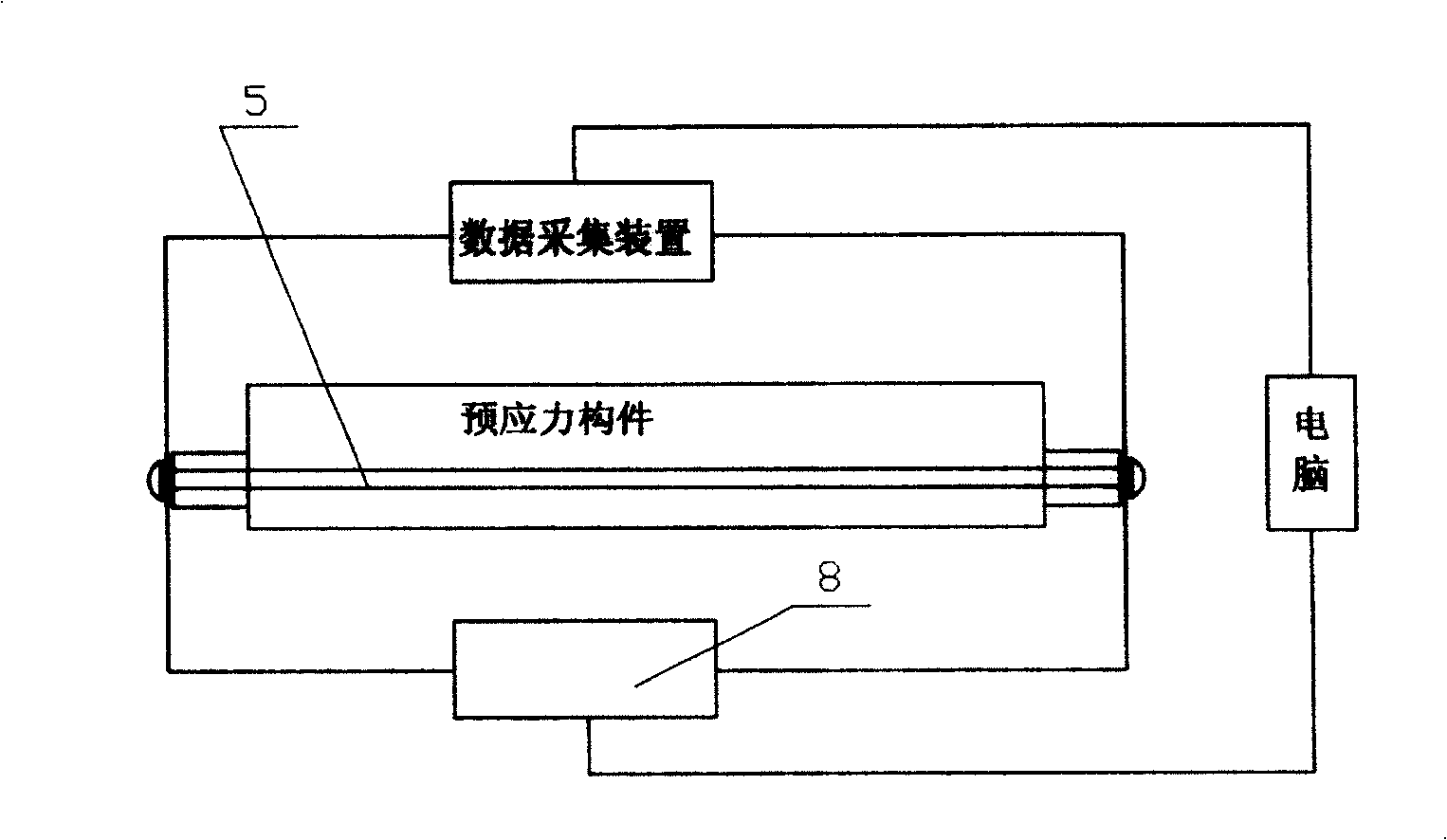

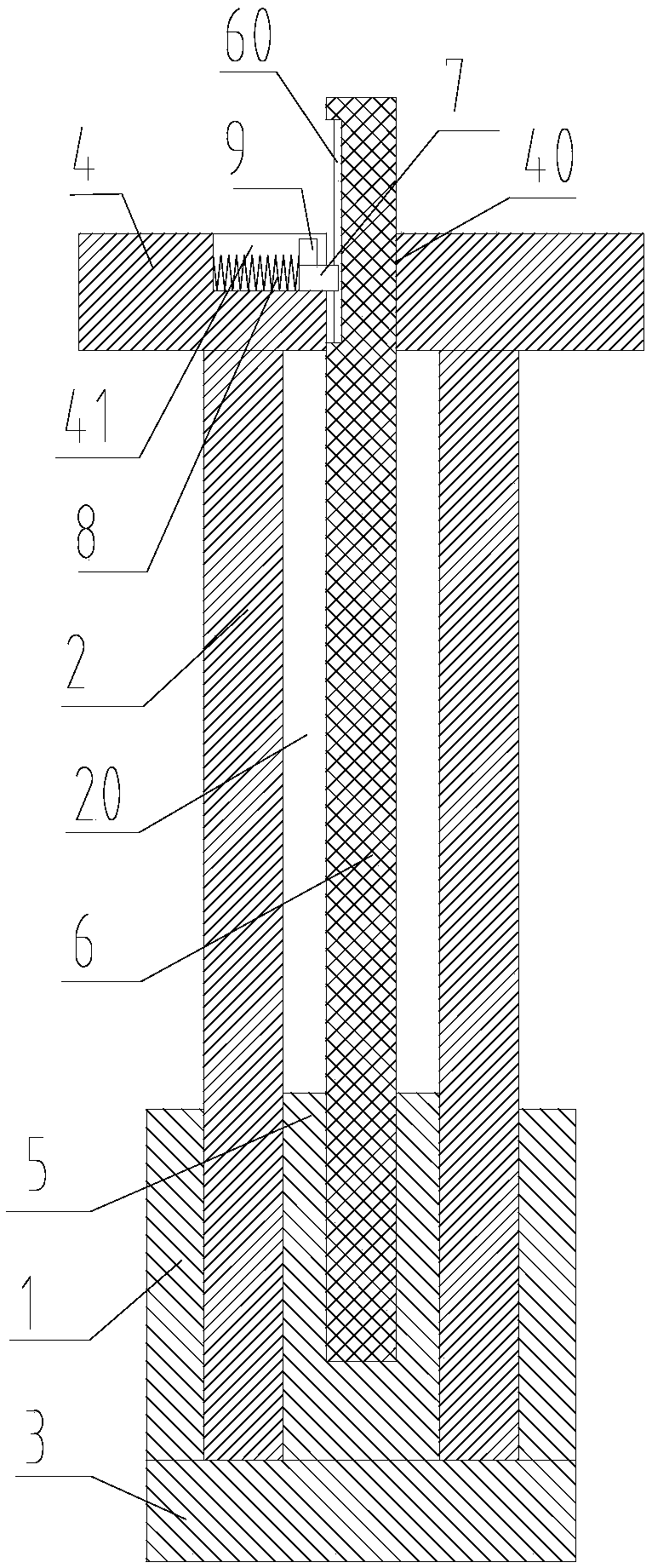

Intelligent prestress system

InactiveCN100445499CControl stressControl deformationBuilding reinforcementsBuilding material handlingControl systemPre stress

The invention discloses an intelligent prestressing system, which includes an anchor and a prestressing tendon. The prestressing tendon is made of a shape memory alloy stretched in a low temperature martensitic state, and the two ends of the prestressing tendon are connected to the adjustable DC The power supply is connected. The present invention uses shape memory alloys as materials to make prestressed tendons, and an adjustable DC power supply energizes the prestressed tendons so that the shape memory alloys generate a restoring force, and the restoring force of the shape memory alloys is used to change the force of the prestressed components conditions, thereby controlling the stress and deformation of prestressed members. The invention has a simple structure and can be precisely controlled by a control system conveniently.

Owner:TONGJI UNIV

Strip medium strapping mechanism and strapping method

ActiveCN102101541BPrevent withdrawalImprove the success rate of bundlingBinding material applicationBundling machine detailsStrappingBand shape

The invention discloses a strip medium strapping mechanism, which comprises a clamping device used for clamping and dragging a strip medium to coil an object to be strapped, a triggering device used for triggering a clamping opening of the clamping device to open, and a driving device used for driving the clamping device to rotate, wherein the rotating direction of the clamping device is opposite to the strip medium conveying direction. The invention also discloses a strip medium strapping method, which comprises the following steps of: (1) clamping the strip medium; (2) dragging the strip medium and strapping the object to be strapped through coiling; and (3) lapping the head and tail of the strip medium and cutting the strip medium, wherein in the step (2), the rotating direction of the clamping device is opposite to the strip medium conveying direction. The strip medium is dragged to coil along the direction opposite to the strip medium conveying direction, so that the strip medium can be prevented from returning, and the strapping success rate is effectively improved.

Owner:GUANGZHOU INTELLICASH FINANCIAL TECH +1

Water-rich roof upward mining face drainage system based on gob-side entry retaining

ActiveCN113107595AImprove drainage capacityReduce the amount of development workDrainageArchitectural engineeringWater flow

The invention discloses a water-rich roof upward mining face drainage system based on gob-side entry retaining. The system is characterized in that a water-rich roof upward mining face transportation roadway adopts a gob-side entry retaining technology, that is, during working face stopping, certain technical means is adopted to reserve a working face transportation roadway as a working face drainage roadway, and the working face drainage roadway is a gob-side roadway. The drainage system is composed of the gob-side roadway, a drainage hidden vertical shaft, a shared drainage connecting roadway, a drainage pumping station, a special drainage roadway, an auxiliary transportation main roadway and an auxiliary shaft which are sequentially connected, and gushing water of a working face goaf forms the drainage system through the gob-side roadway, the drainage hidden vertical shaft, the shared drainage connecting roadway, the drainage pumping station, the special drainage roadway, the auxiliary transportation main roadway and the auxiliary shaft and is pumped and drained to the ground. After the drainage system is formed, the mine drainage capacity is effectively improved, the workload of drainage connecting roadway development is reduced, meanwhile, mine water is prevented from flowing through a mining roadway in a service period, and the long-term weakening influence, on surrounding rock of the mining roadway, from mine water is reduced.

Owner:HENAN POLYTECHNIC UNIV

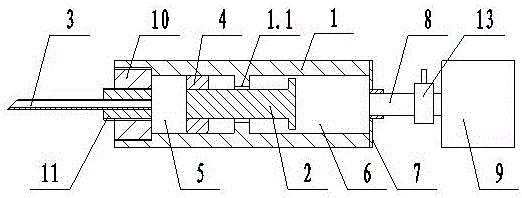

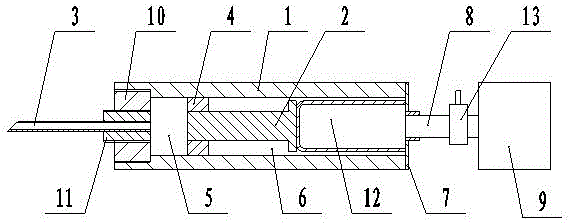

Injection device for animals

InactiveCN105877869AReduce the clamping processAvoid contactInfusion syringesMedical devicesReusabilityEngineering

The invention discloses an animal injection device, which comprises an injection tube and a push rod. The left end of the syringe is provided with an injection needle, and the left end of the push rod is provided with a piston matching the injection tube. It is characterized in that the piston The left and right sides of the injection tube respectively form a drug injection area and an air cavity, the right end of the injection tube is provided with a sealing plate, and the sealing plate is provided with a flexible tube communicating with the air cavity, and the end of the flexible tube is Features hand grip airbags. The invention has very obvious beneficial effects: simple and stable structure, low cost, convenient installation, disassembly and use, high work efficiency, good safety performance and experimental accuracy, and can be used repeatedly.

Owner:NINGBO UNIV

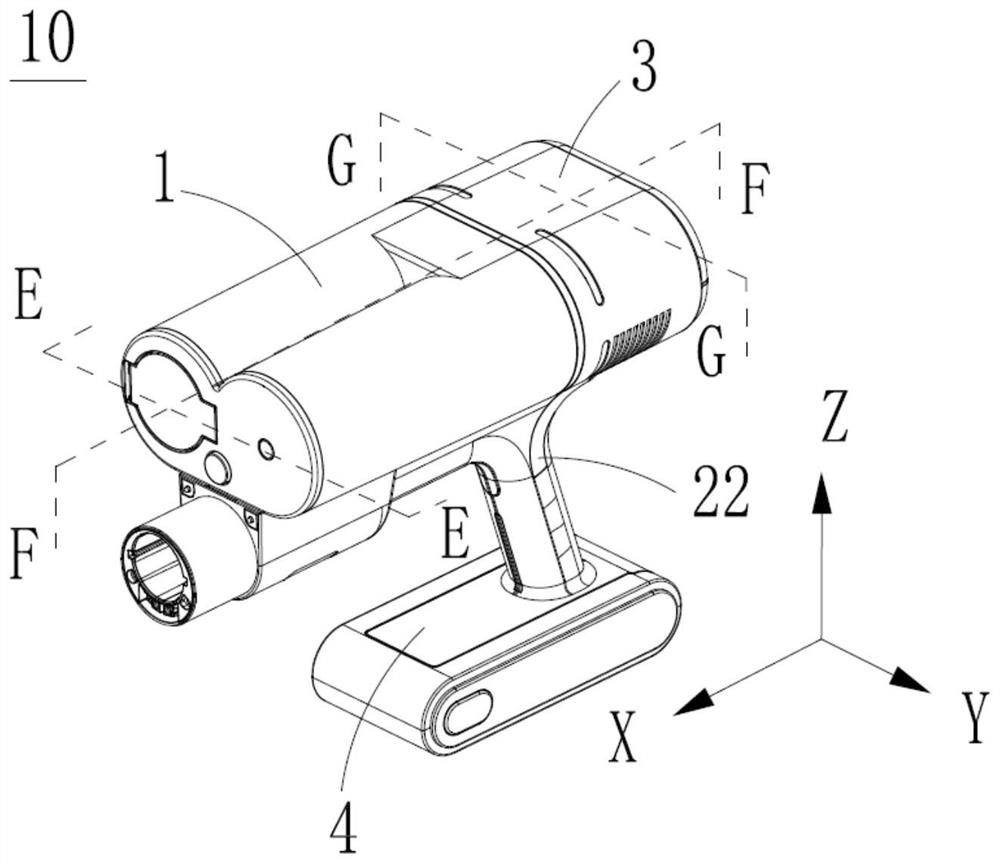

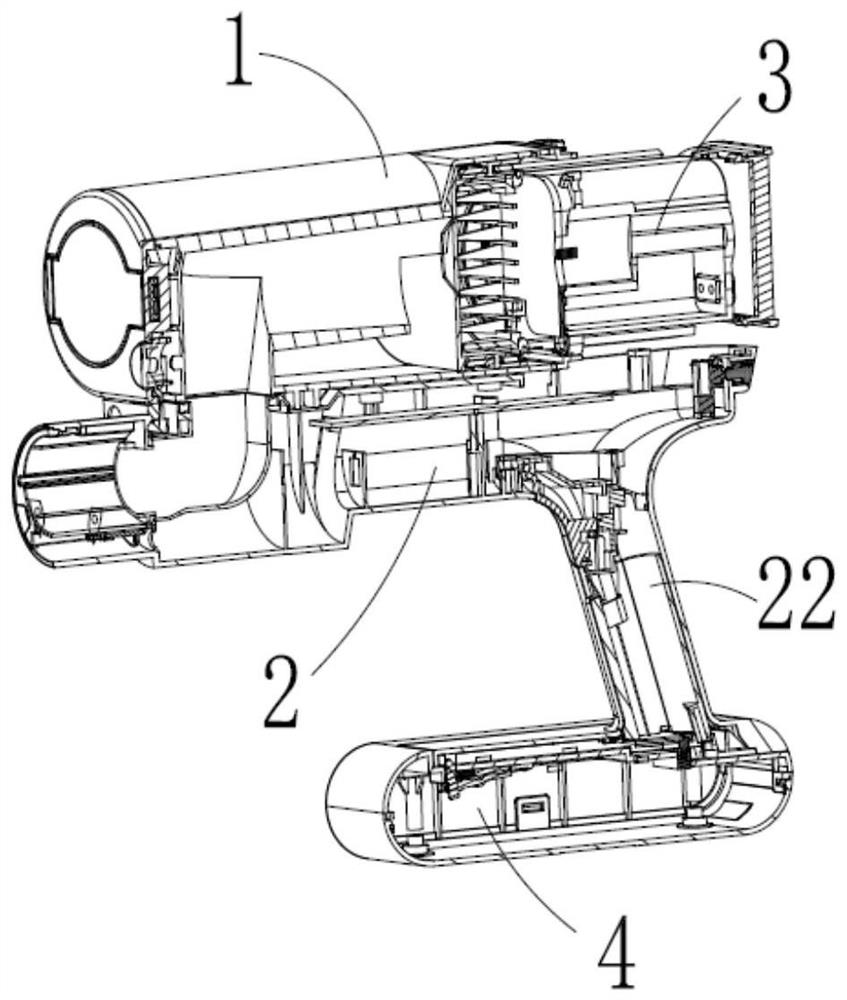

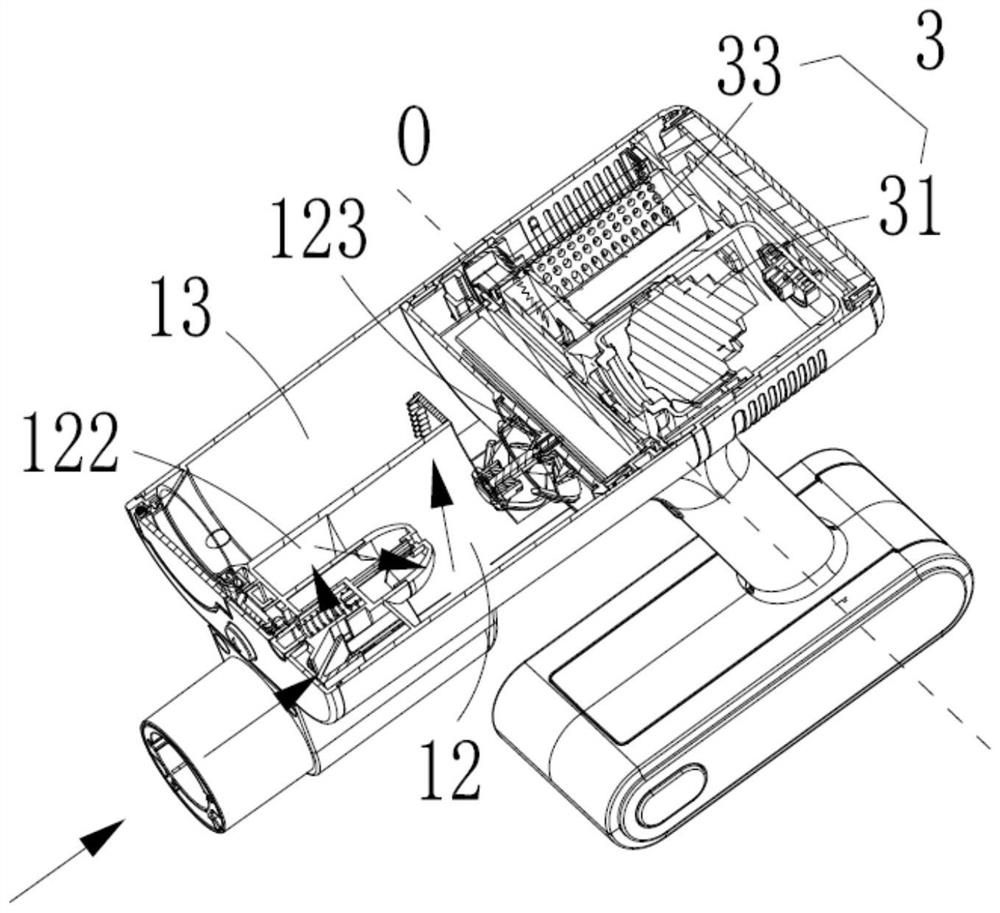

Surface cleaning device with dust cup assembly

ActiveCN114794964APrevent withdrawalHuman health protectionSuction filtersThermodynamicsSurface cleaning

The invention discloses surface cleaning equipment with a dust cup assembly, the dust cup assembly comprises a cyclone separation chamber and a dust collection chamber, and the cyclone separation chamber is arranged on the outer side of the dust collection chamber and communicates with the dust collection chamber through a dust throwing opening; the dust cup assembly further comprises an air outlet formed in the cyclone separation chamber and a filtering structure arranged at the air outlet, and the filtering structure is rotatably arranged at the air outlet so as to filter air flow before the air flow is discharged from the air outlet. A baffle plate extending in the dust collecting chamber is arranged at the dust throwing opening so as to prevent part of dirt in the dust collecting chamber from being pumped back into the cyclone separation chamber; at least one protrusion protruding towards the direction of the bottom of the dust collection chamber is arranged on the side, facing the bottom of the dust collection chamber, of the baffle. The baffle is arranged at the ash throwing opening, the protrusion is arranged below the baffle, and therefore the hair can be effectively prevented from being pumped back to the cyclone separation chamber.

Owner:SUZHOU JIANDANYOUWEI TECH CO LTD

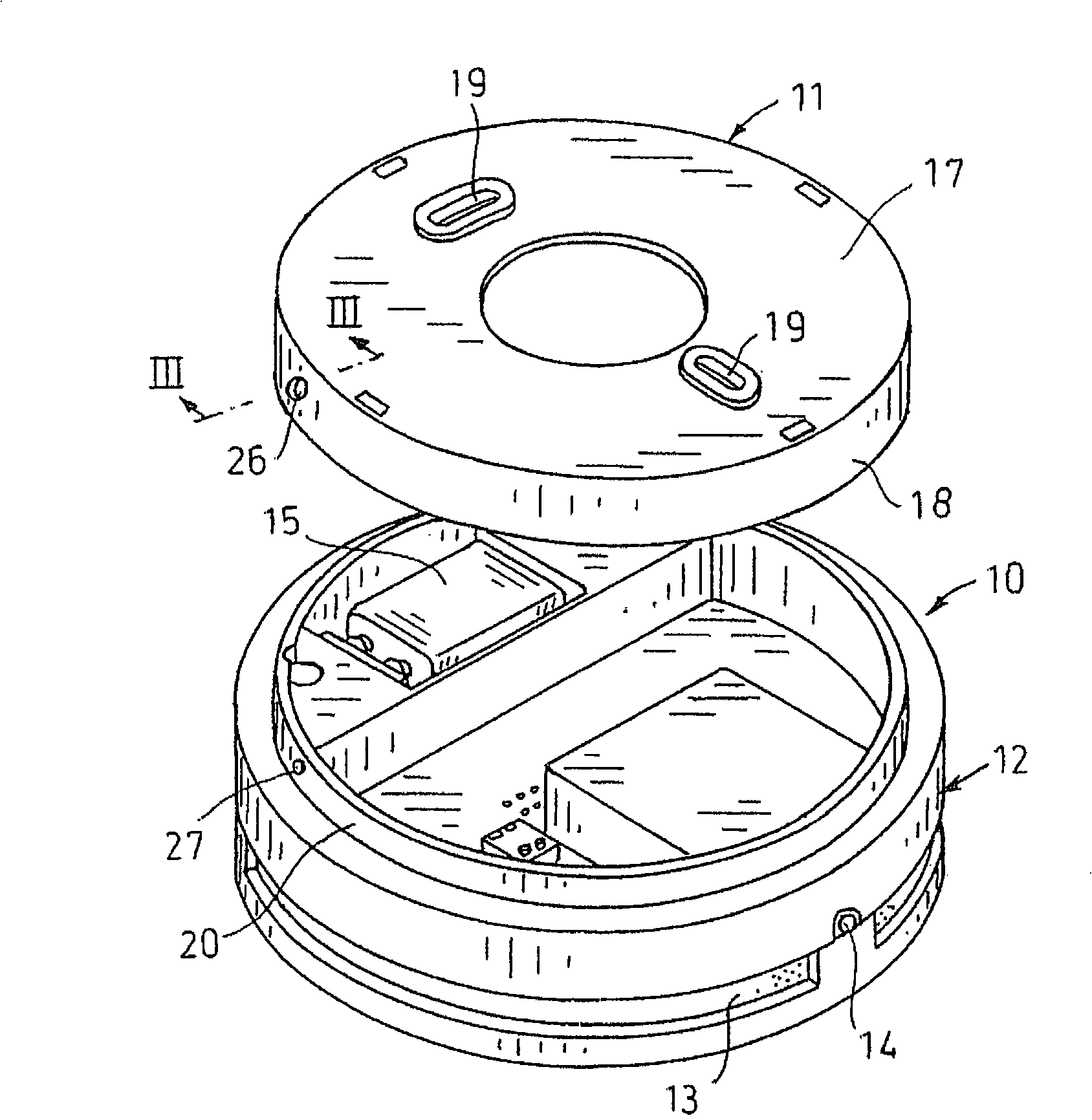

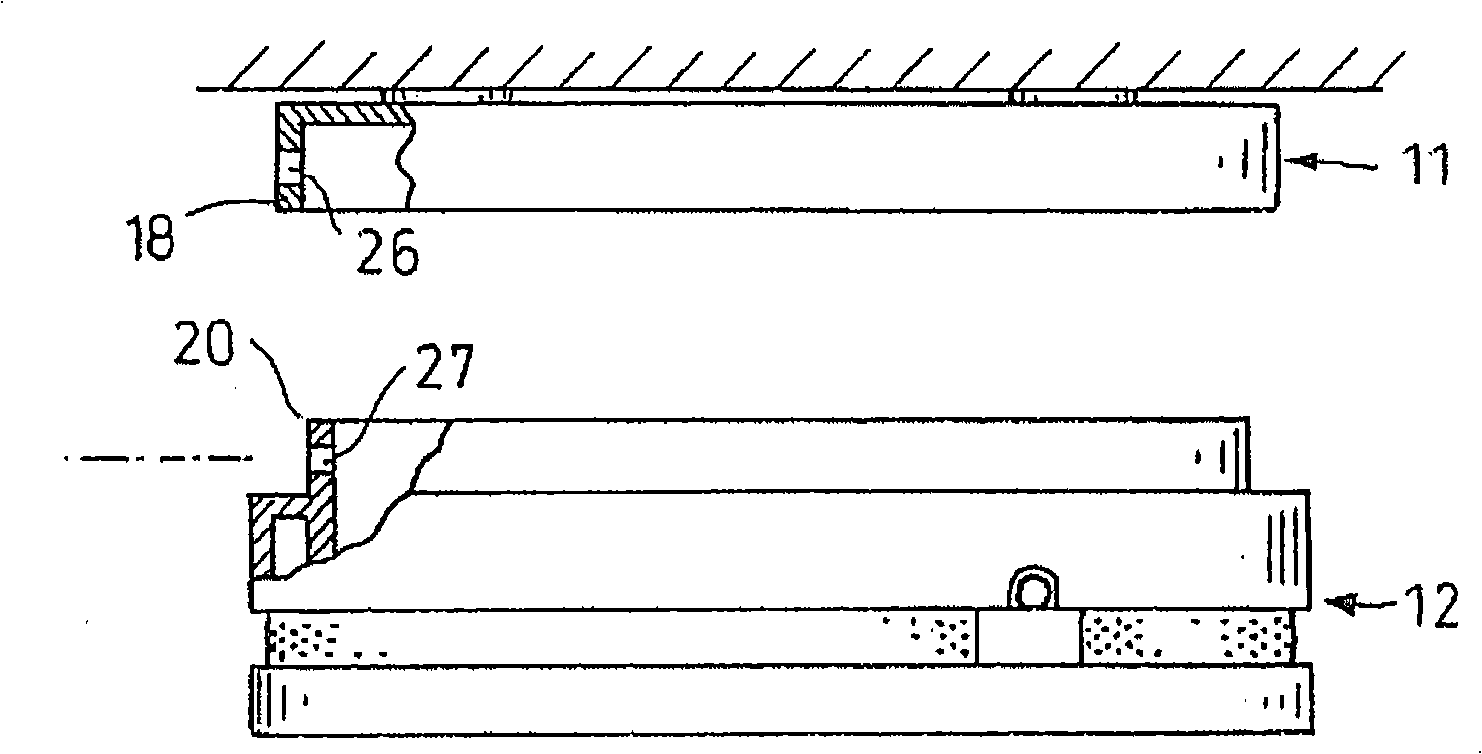

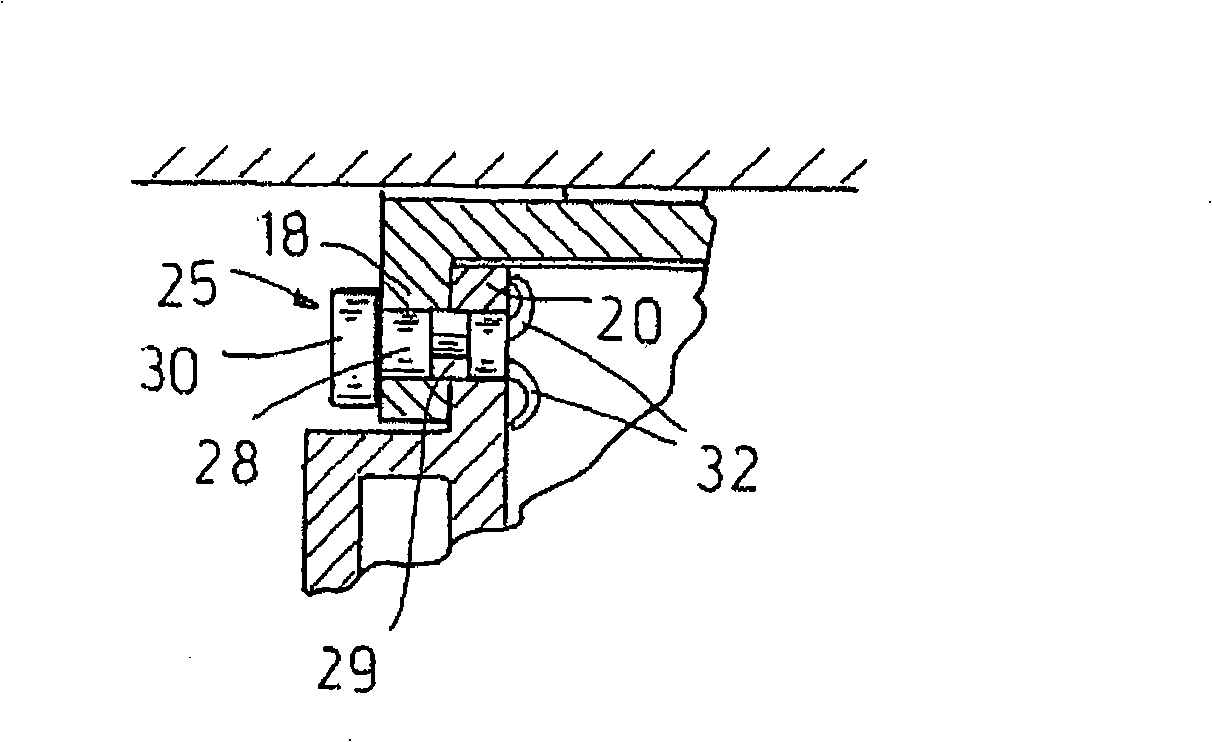

Danger detector

Disclosed in a danger detector having a two-part housing (10), inside of which a battery (15) is located and which contains a wall (18, 20) on both housing parts. Both walls (18, 20), which are opposite one another when the housing is closed, contain holes (26, 27) through which a lead element is placed. When the housing is opened, the lead element is destroyed and this can be seen from the outside. This indicates an unauthorized opening of the housing.

Owner:MERTEN GMBH & CO KG

Pipe wrapping device with aluminum foil tape

The invention relates to an aluminum foil tape coating device for a pipe material. The aluminum foil tape coating device comprises a rack, wherein a mounting platform is arranged on the rack; a mounting groove used for placement of the pipe material is formed in the mounting platform; a positioning device used for limiting the end part of the pipe material is arranged at one end of the rack; an aluminum foil tape sticking machine is arranged on the side surface of the rack, correspond to the mounting groove, and is connected with the rack in a sliding manner. The aluminum foil tape coating device has the characteristics that the structure is simple, use is convenient, time is saved, the working efficiency is improved, the cost is reduced and the automatic operation is realized.

Owner:常州市常蒸制冷科技有限公司

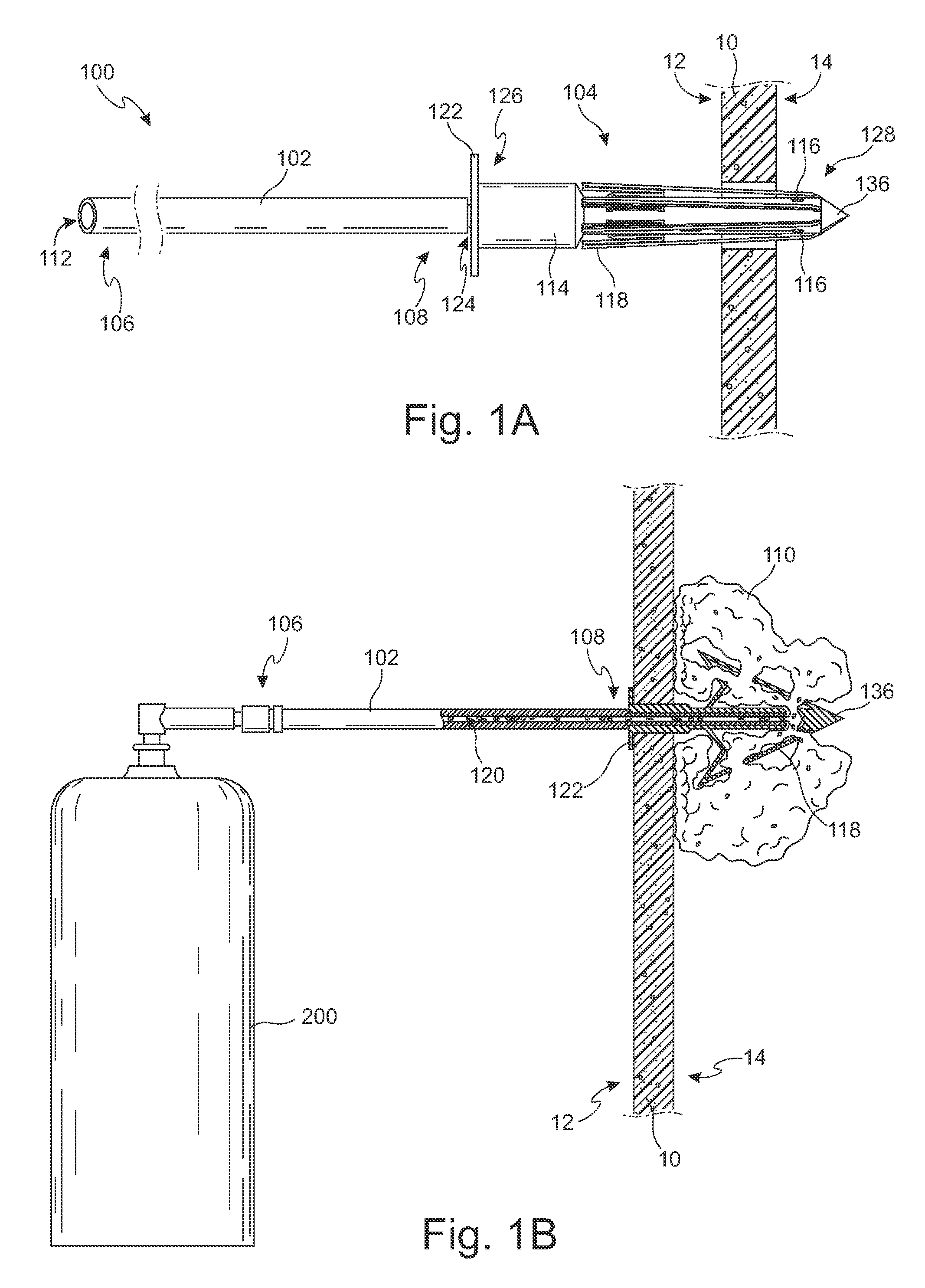

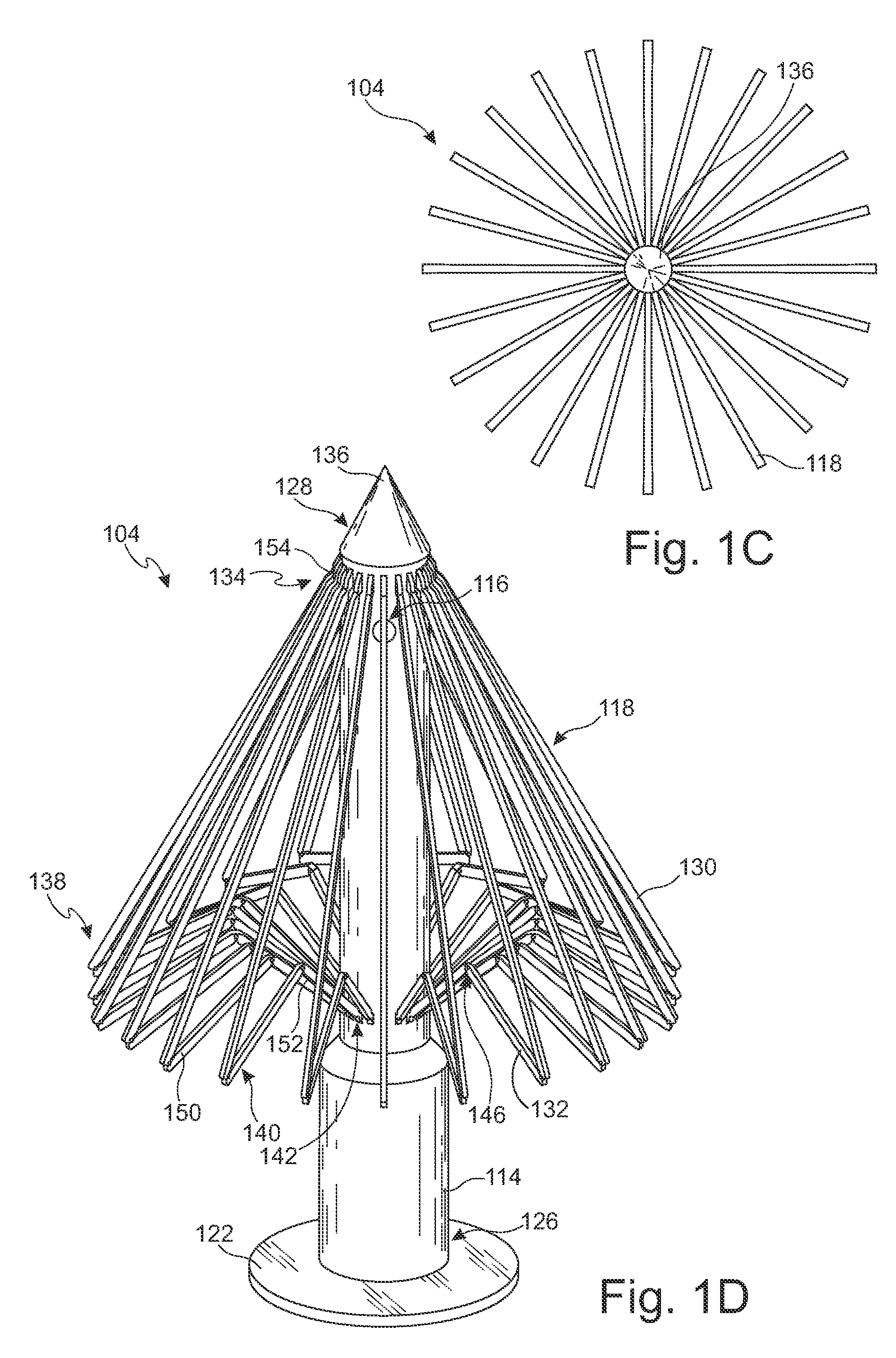

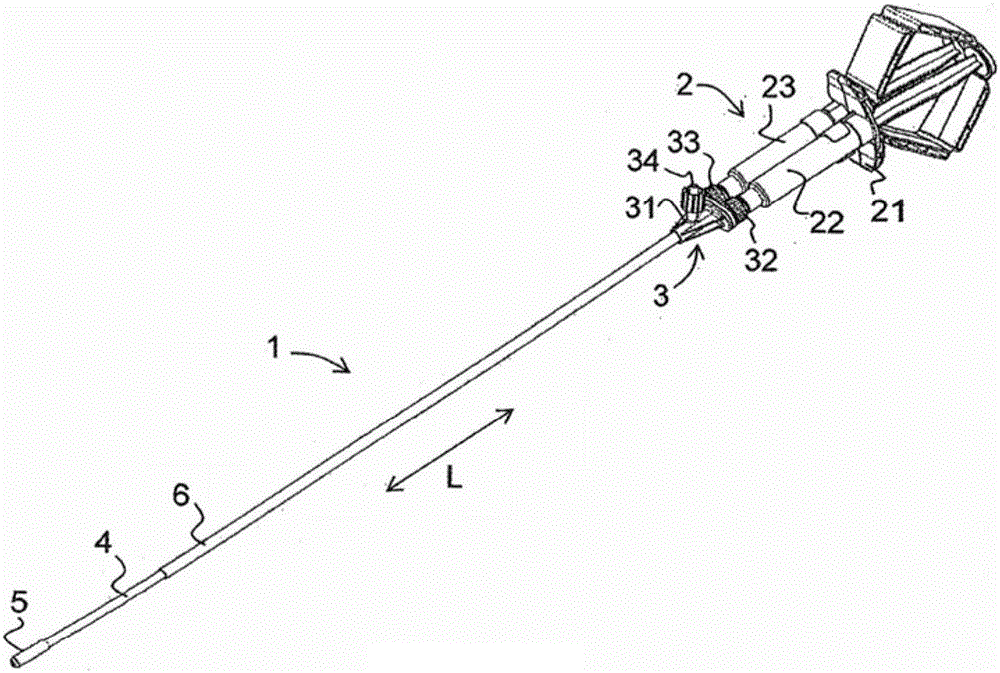

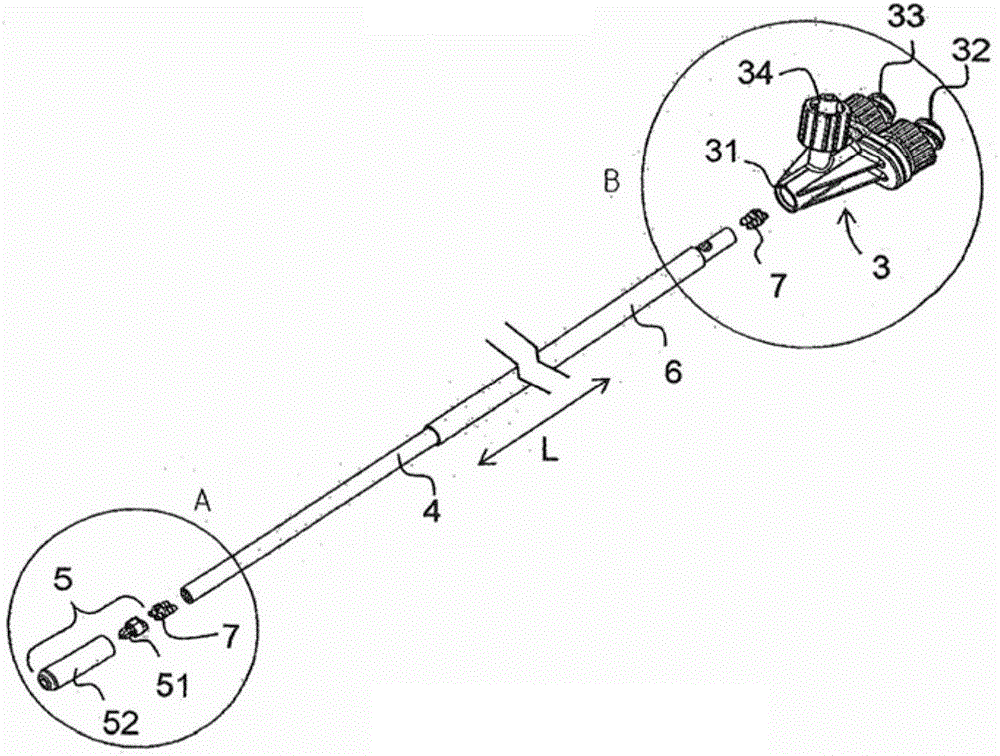

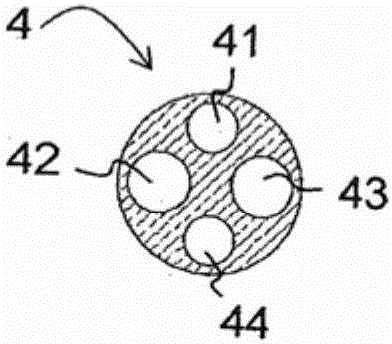

Laparoscopic spray applicator and adapter

Owner:MEDMIX SYST

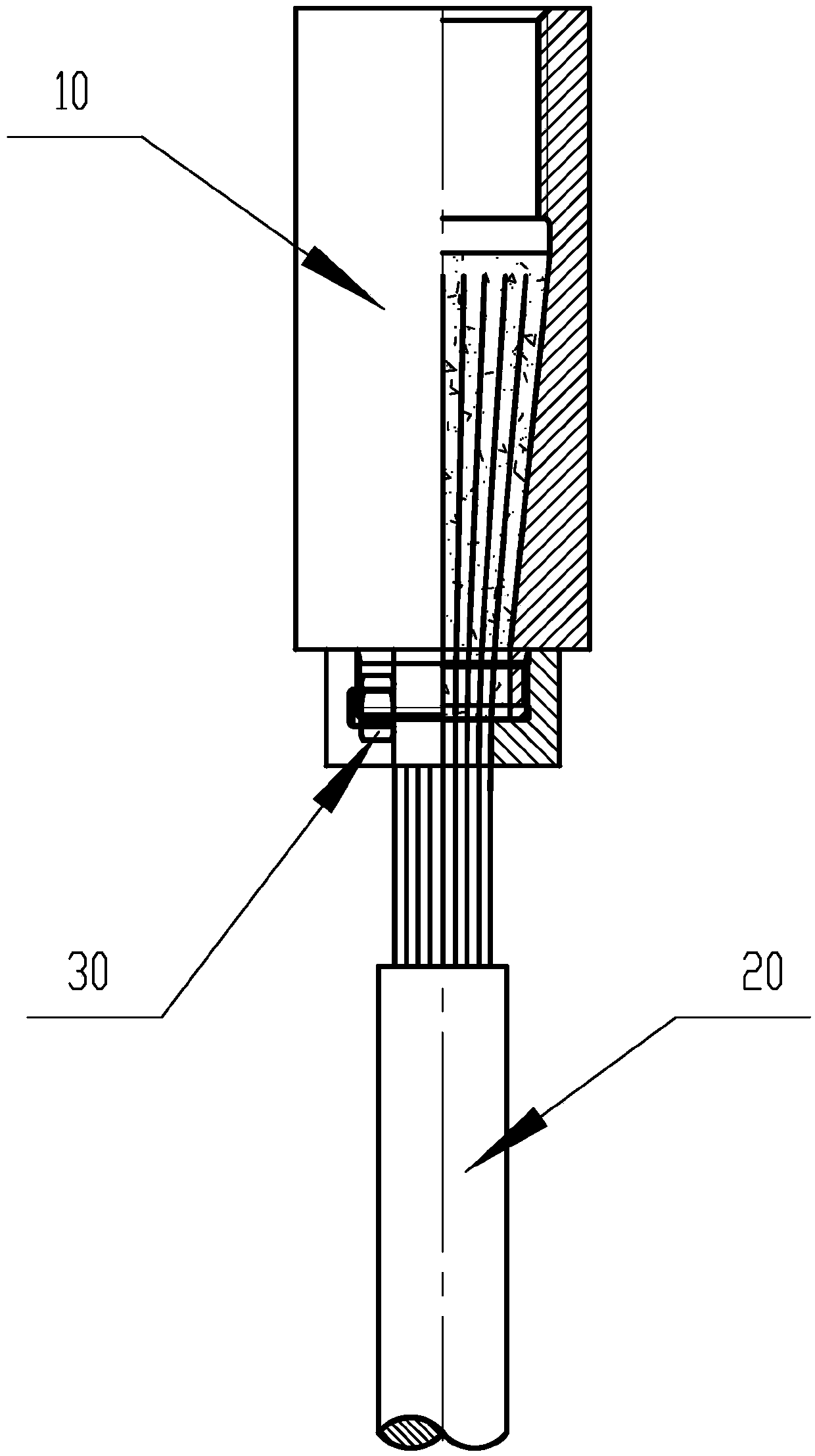

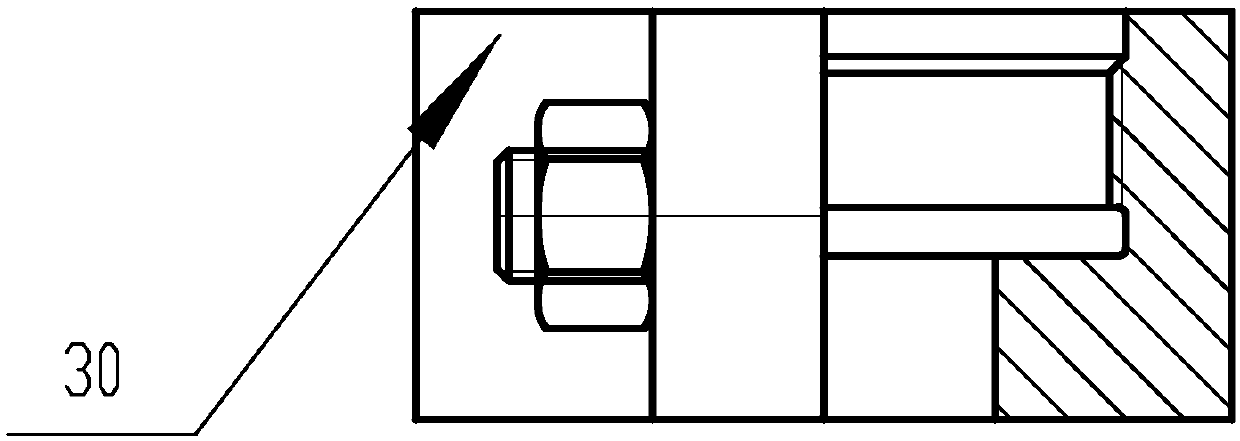

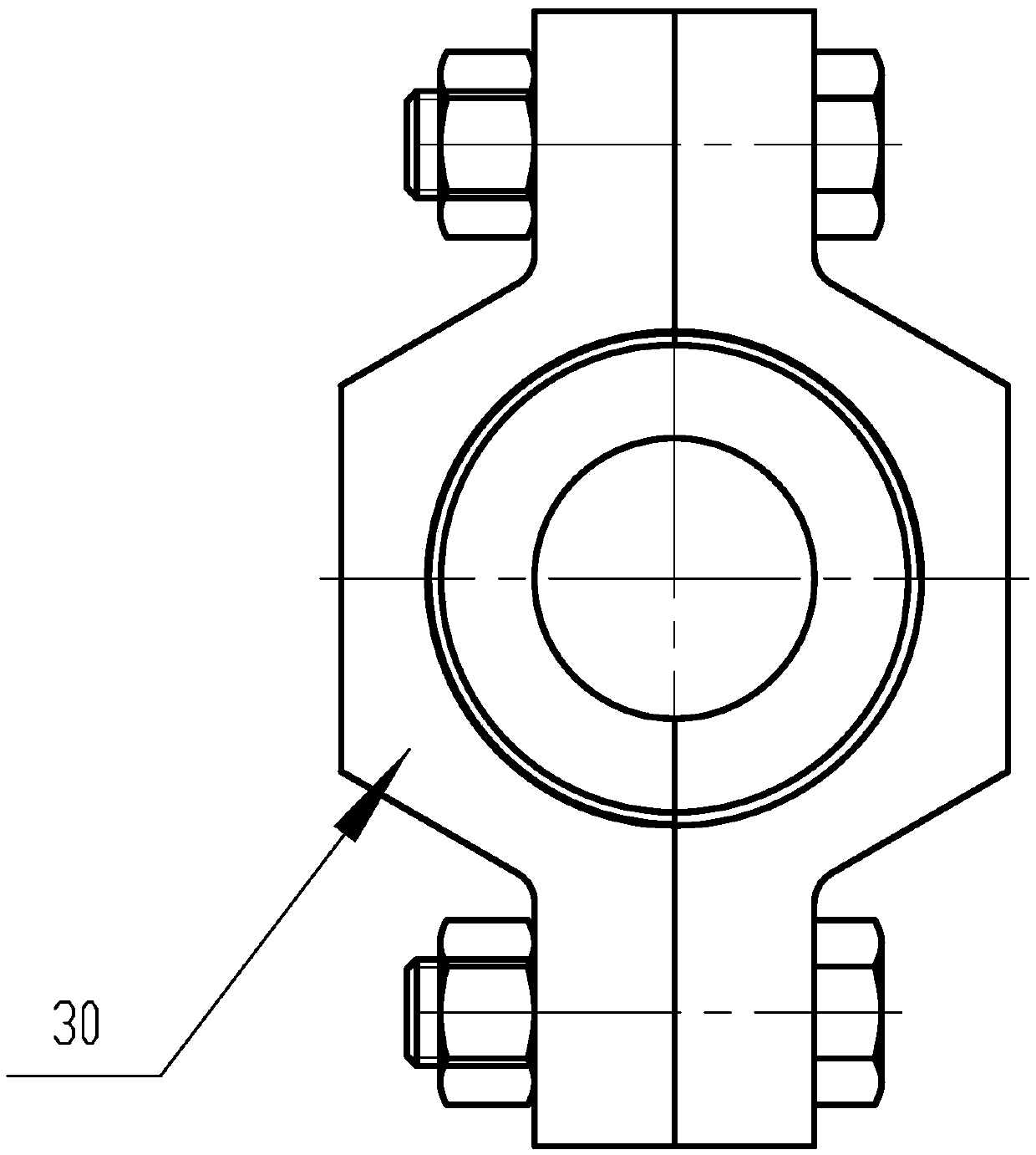

Cast anchor cup, cable and process for manufacturing same

ActiveCN109653092AAchieve positioningQuality improvementBridge structural detailsEngineeringScrew thread

The invention discloses a cast anchor cup, a cable and a process for manufacturing the same, and relates to a cast anchor cup, a hot-cast anchor cable and a process for manufacturing the same. The cast anchor cup comprises an anchor cup body, a lengthening sleeve and a constraint positioning ring. An end of the lengthening sleeve extends into the anchor cup body and is connected with the anchor cup body in a threaded manner, and the constraint positioning ring is arranged in the lengthening sleeve and is positioned at the lower end of the lengthening sleeve. The cable comprises a cable body, the cast anchor cup and cast anchors. The cast anchor cup and the cast anchors are fixedly connected with two ends of the cable body. The process for manufacturing the cable includes casting the lengthening sleeve and the anchor cup body with each other. The cast anchor cup, the cable and the process have the advantages that the structure of the cast anchor cup is improved, the lengthening sleeve and the constraint positioning ring are designed, accordingly, the cast anchor cup and the cable body can be accurately positioned relative to each other, casting tools do not need to be designed, manufactured and mounted, and the cable manufacturing efficiency can be improved; the lengthening sleeve and the anchor cup body are cast with each other, the steel wire anchorage lengths can be prolonged, steel wires can be prevented from being broken away, and accordingly the quality of the cable can be improved.

Owner:JULI SLING

Multifunctional bolt

The invention provides a multifunctional bolt. The multifunctional bolt comprises a first nut, a first screw rod, a first end cover, a second end cover, a second nut and a second screw rod. The firstend cover is mounted on the end face of the first end of the first nut. The second nut is mounted on the inner periphery of the first nut and is fixedly connected with the first end cover. The first end cover, the first nut and the second nut constitute a nested nut structure. The second end cover, the first screw rod and the second screw rod constitute a nested bolt structure. When the nested nutstructure and the nested bolt structure are connected, the first screw rod is in threaded connection with the first nut, the second screw rod is in threaded connection with the second nut, and a sliding block is inserted into a corresponding groove. The multifunctional bolt provided by the invention can prevent the first nut from getting loosened from the first screw rod under a threaded connection state, the connecting safety and reliability are guaranteed, and detachably connection of the first nut and the first screw rod is achieved; the problem that an existing fastener with the locking function cannot be dismounted is solved.

Owner:合肥仨力机械制造有限公司

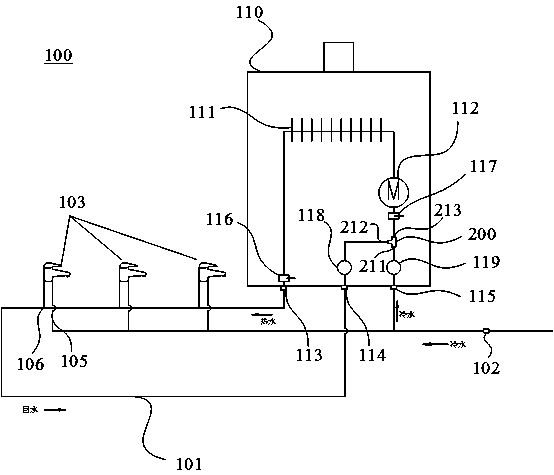

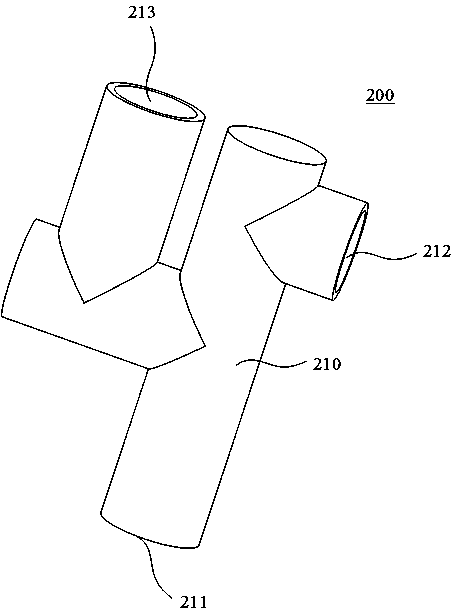

Switching valve, circulating booster water heater and water heater circulating pressurization system

ActiveCN111350839APrevent withdrawalFluid heatersOperating means/releasing devices for valvesReciprocating motionEngineering

The invention discloses a switching valve, a circulating booster water heater and a water heater circulating pressurization system. The switching valve comprises a shell, and a valve element part, theshell is provided with a first fluid inlet, a second fluid inlet and a fluid outlet, the valve element part is mounted in the shell and can reciprocate between the first fluid inlet and the second fluid inlet, the valve element part comprises an impeller and a valve plug which are connected, according to the switching valve, the valve element part with an impeller can achieve the function of automatically closing the second fluid inlet when the fluid flows towards the fluid outlet from the first fluid inlet, the switching valve can be used for the switching valve of the circulating booster water heater, when water is output at the water using end, the water returning path is closed, hot water in the water returning path is prevented from being drawn back to the water heater, and the circulating booster water heater with the switching valve and the water heater circulating pressurization system have the same effect.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com