Intelligent prestress system

A prestressed and prestressed tendon technology, applied in the field of prestressed systems, can solve the problems of reduced concrete performance, inability to control large structural deformations, and difficulty in fully functioning restoring force, achieving the effect of simple structure and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

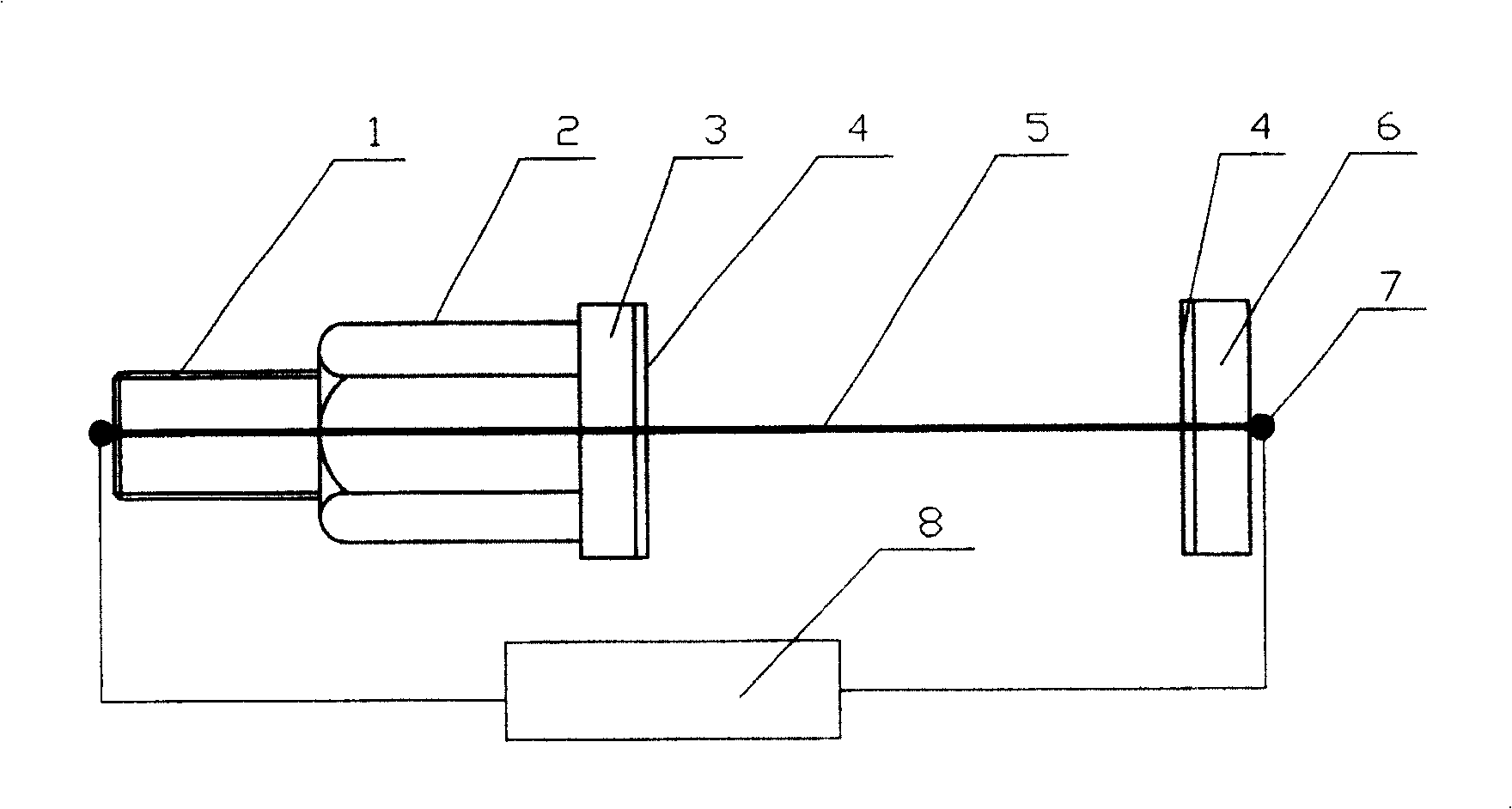

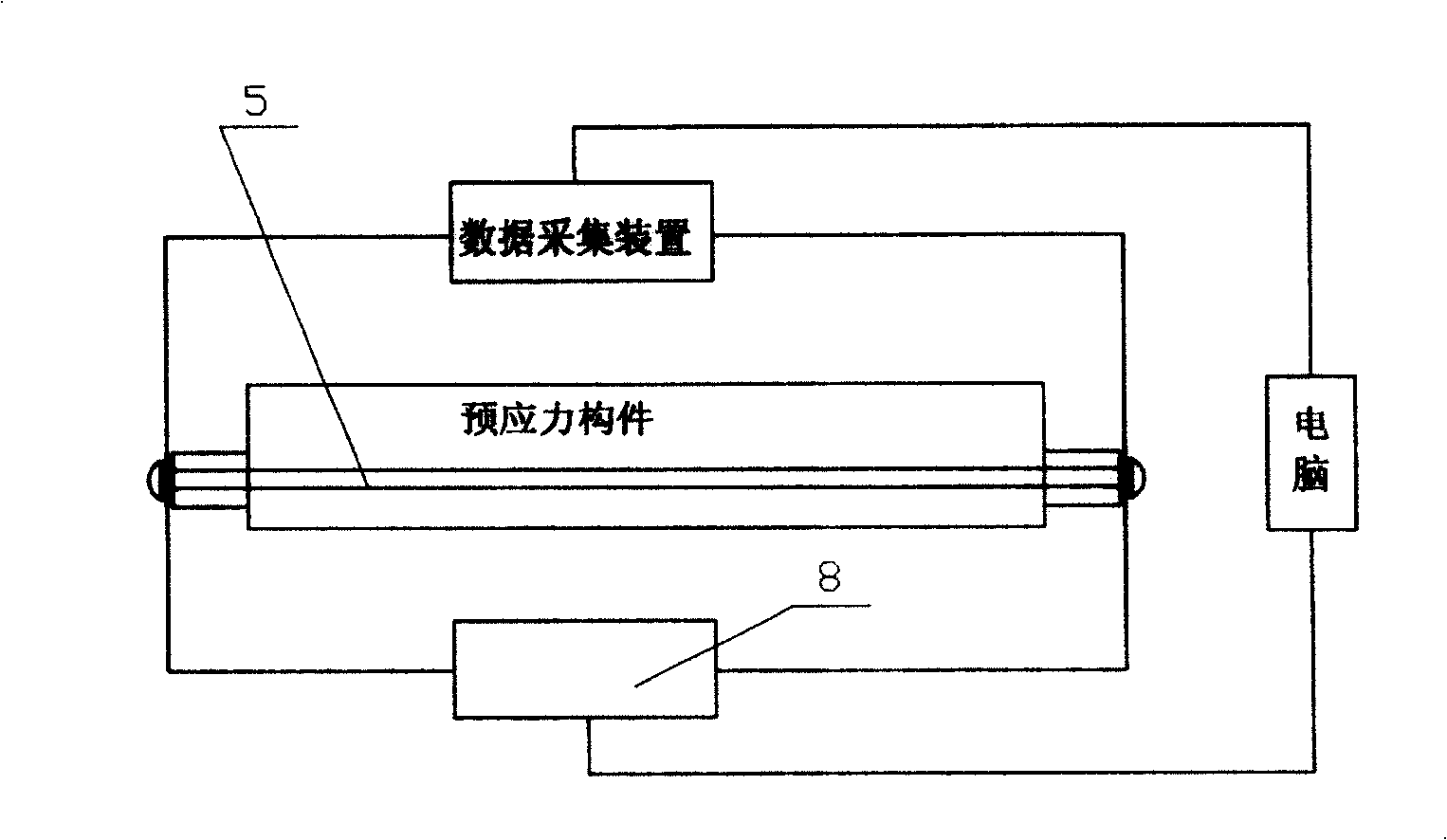

[0011] Such as figure 1 As shown, the intelligent prestressing system of the present invention includes an anchorage and a prestressing tendon 5, the prestressing tendon 5 is made by stretching a shape memory alloy in a low-temperature martensite state, and the two ends of the prestressing tendon 5 are connected to the adjustable DC The power supply is connected in 8 phases. The prestressed tendon 5 can be set in two forms in vitro or in vivo according to actual needs, and the anchors at both ends of the prestressed tendon 5 are used for fixing and tensioning. The anchorage is divided into two parts: a fixed end and a tensioned end. In this embodiment, The fixed end is provided with a fixed anchor plate 6, the inner side of the fixed anchor plate 6 is provided with an insulating plate 4, the tension end is provided with a backing plate 3, the inner side of the backing plate 3 is also provided with an insulating plate 4, and the outer side of the backing plate is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com