Multifunctional bolt

A multi-functional bolt technology, applied in the field of mechanical parts, can solve problems such as the inability to disassemble the nut, the nut disengagement, and the complicated implementation of the stop method, and achieve the effect of non-detachable and safe and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

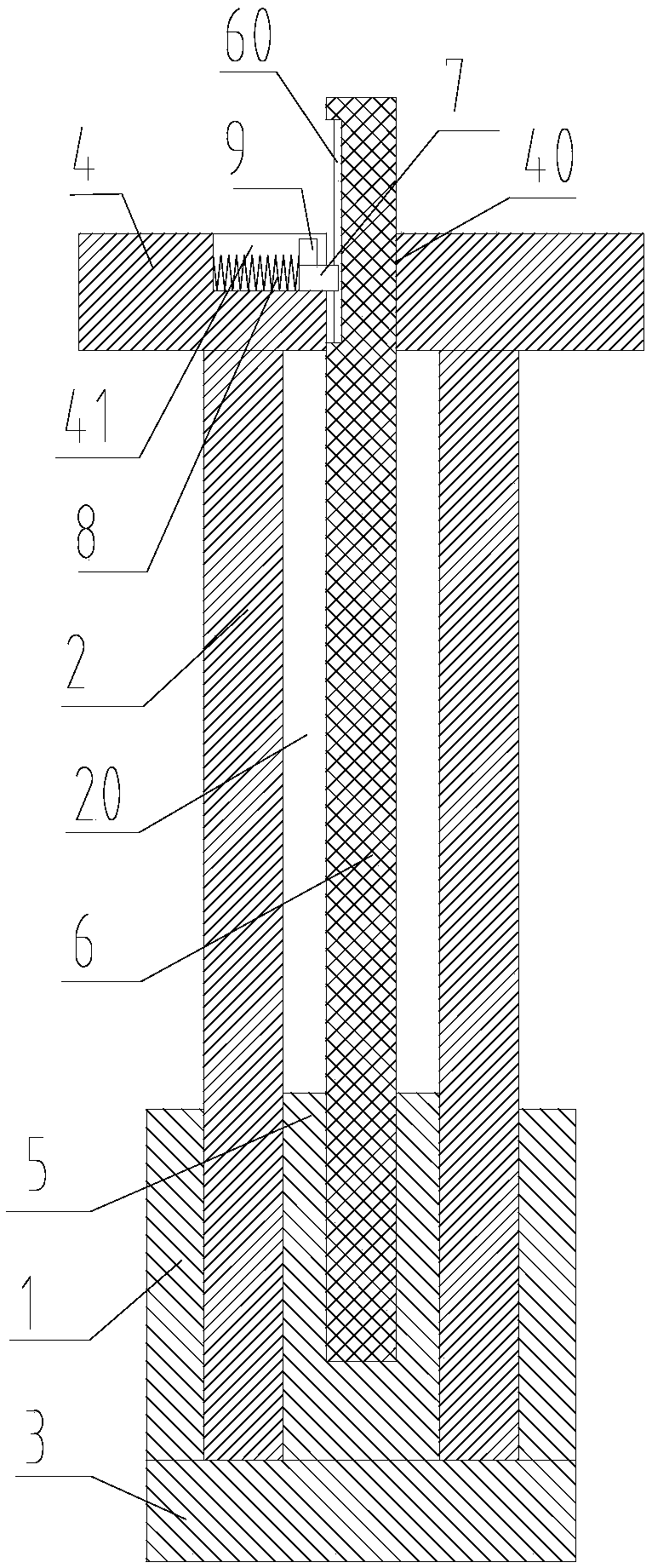

[0017] Reference figure 1 , A multifunctional bolt proposed by the present invention includes: a first nut 1, a first screw 2, a first end cover 3, a second end cover 4, a second nut 5 and a second screw 6.

[0018] The first end cover 3 is installed on the first end surface of the first nut 1, and the second nut 5 is installed on the inner circumference of the first nut 1 and fixedly connected with the first end cover 3. In this way, the first end cover 3, the first nut 1 and the second nut 5 form a nested nut structure.

[0019] The inside of the first screw 2 is provided with a first cylindrical hole 20 penetrating through its two end faces, and the second end cover 4 is installed on the second end face of the first screw 2, and the first screw 2 and the second end cover 4 cooperate to form a bolt structure . The second end cover 4 is provided with a second cylindrical hole 40 communicating with the first cylindrical hole 20, and the second cylindrical hole 40 penetrates the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com