Forming method of superplastic forming/diffusion connecting four-layer structure of grid with variable depth-width ratio

A technology of diffusion joining and superplastic forming, applied in the field of surface wrinkle prevention, which can solve problems such as surface wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

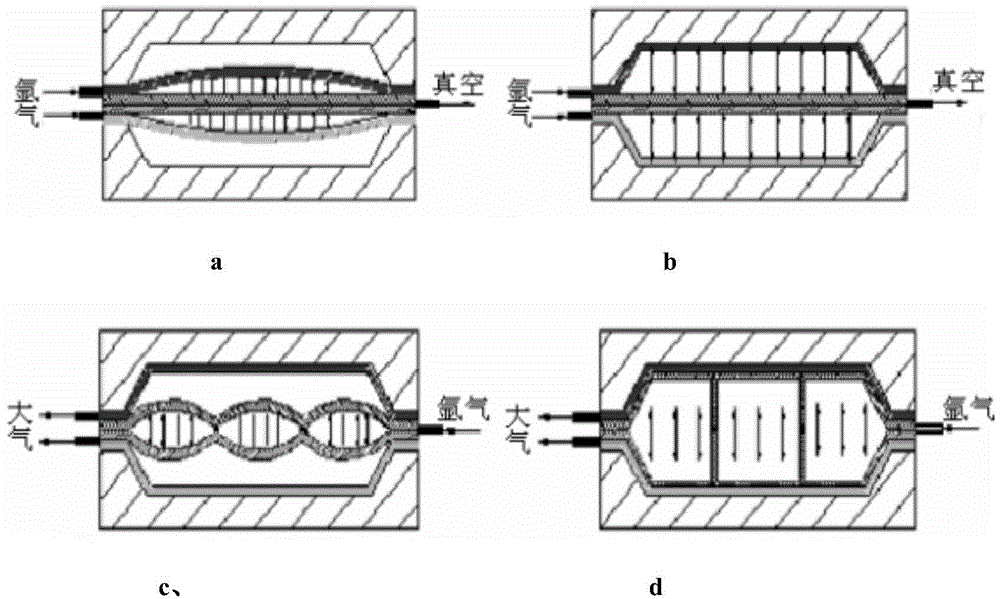

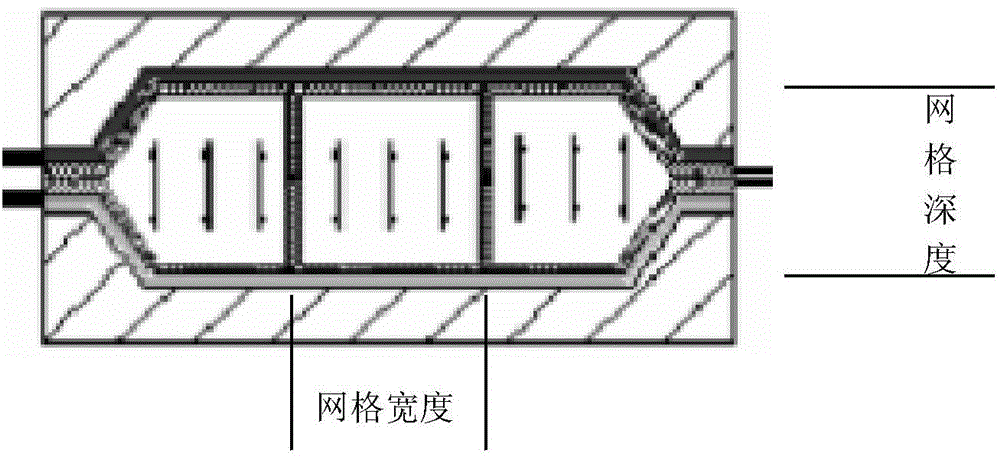

Method used

Image

Examples

Embodiment

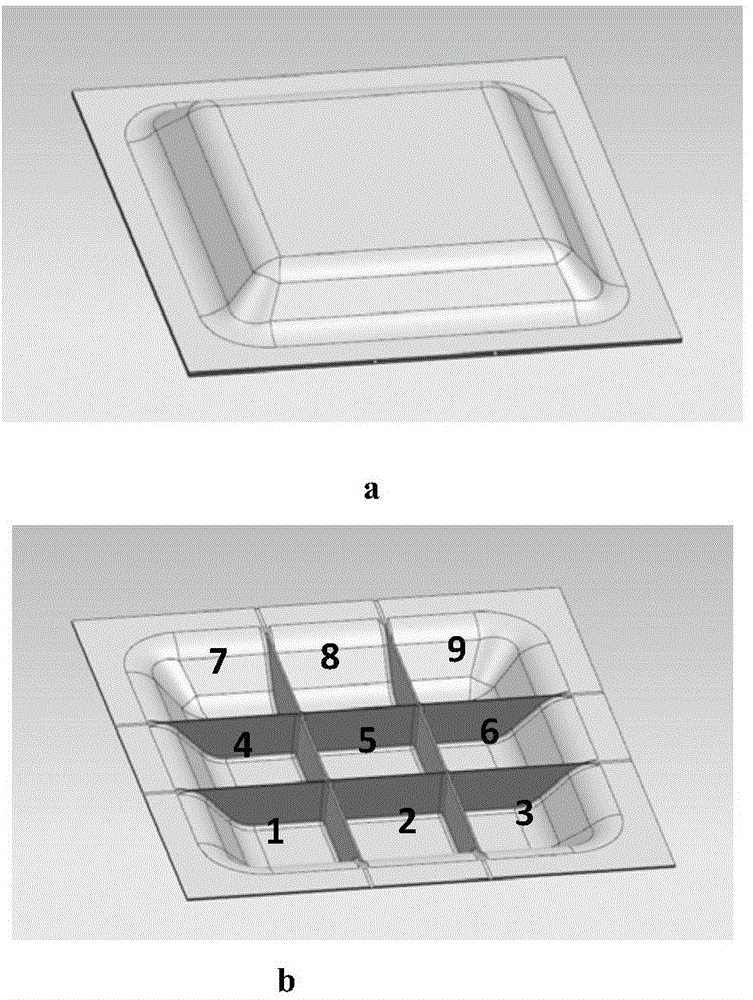

[0032] by figure 2 The four-layer thin-walled structure shown as an example was formed by anti-wrinkle superplastic forming / diffusion bonding process. The specific process is as follows:

[0033] 1) It is estimated that there are 9 grids in this part, and they are sorted from bottom to top as 1, 2, 3, 4, 5, 6, 7, 8, 9; 2, 4, 6, and 8 grids The aspect ratio is the same, and the aspect ratios of grids 1, 3, 7, and 9 are the same; and grid 5 at the center has the largest aspect ratio, followed by grids 2, 4, 6, and 8. The smallest ratio is the 1st, 3rd, 7th, and 9th grids;

[0034] 2) Design air path: The air intake sequence of 9 grids is: No. 5 → No. 2, 4, 6, and No. 8 → No. 1, 3, 7, and 9; determined by the process characteristics of superplastic forming / diffusion connection, the parts The starting point of forming air intake is generally at the edge of the part. Therefore, the starting point of forming the air intake of this part is set at the center of the lower edge of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com