Cast anchor cup, cable and process for manufacturing same

A manufacturing process and anchor cup technology, which is applied in the field of casting anchor cups, hot-cast anchor cables and cable manufacturing processes, can solve the problems of affecting cable quality, low cable manufacturing efficiency, and steel wire and steel wire extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

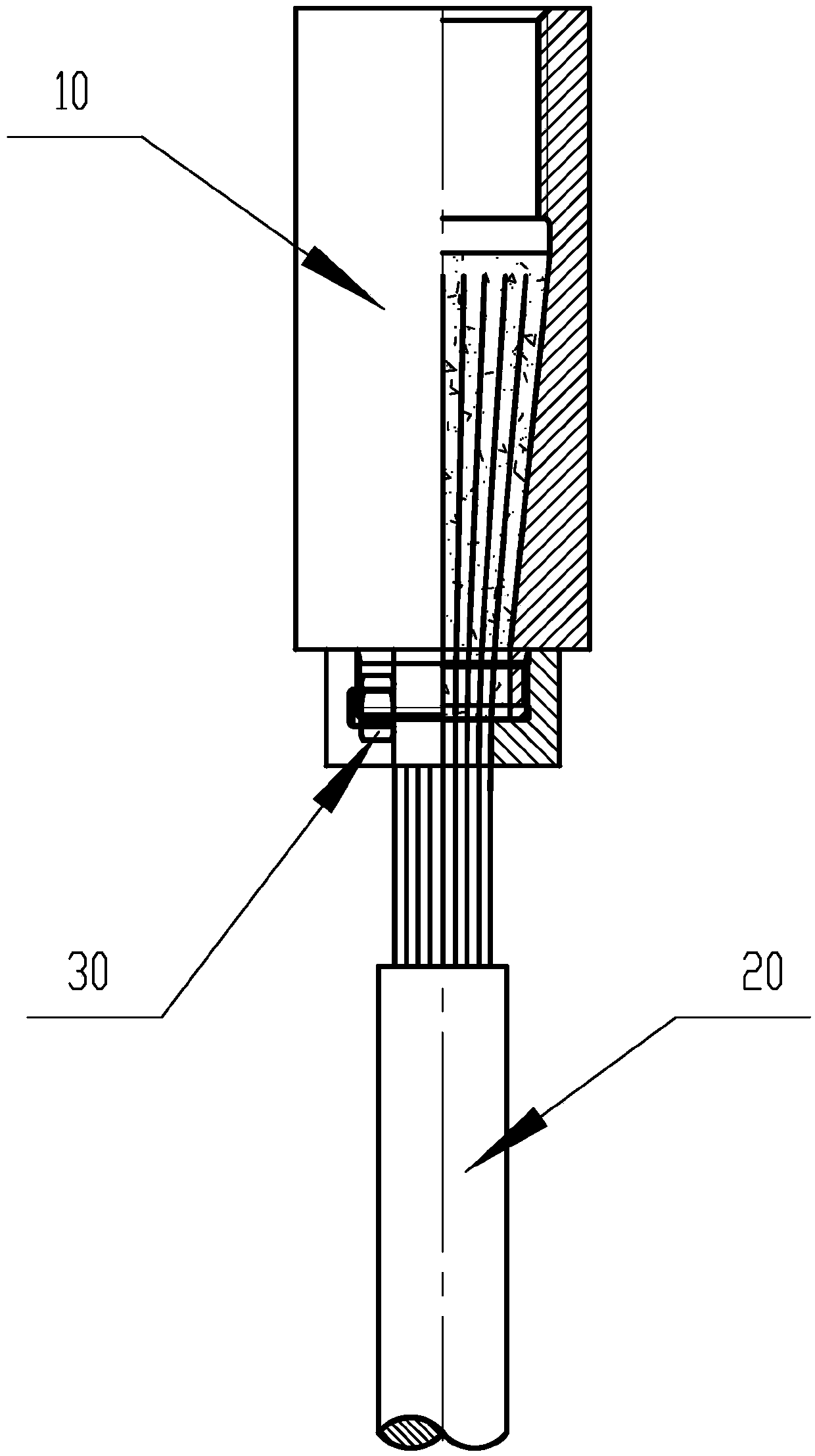

[0033] like Figure 5 As shown, the cable of the present invention includes a casting anchor cup 1, and also includes a cable body 2 and a casting anchor. The upper end of the cable body 2 extends into the casting anchor cup 1 and is fixedly connected with the casting anchor cup 1. Fixed connection. The cable body 2 is fixed in the casting anchor cup 1 by pouring zinc-copper alloy 3 .

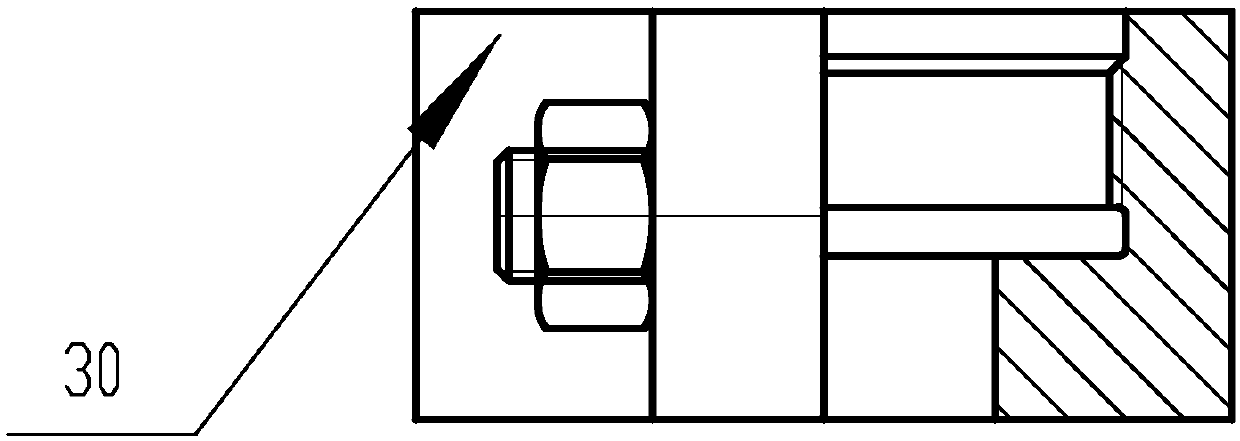

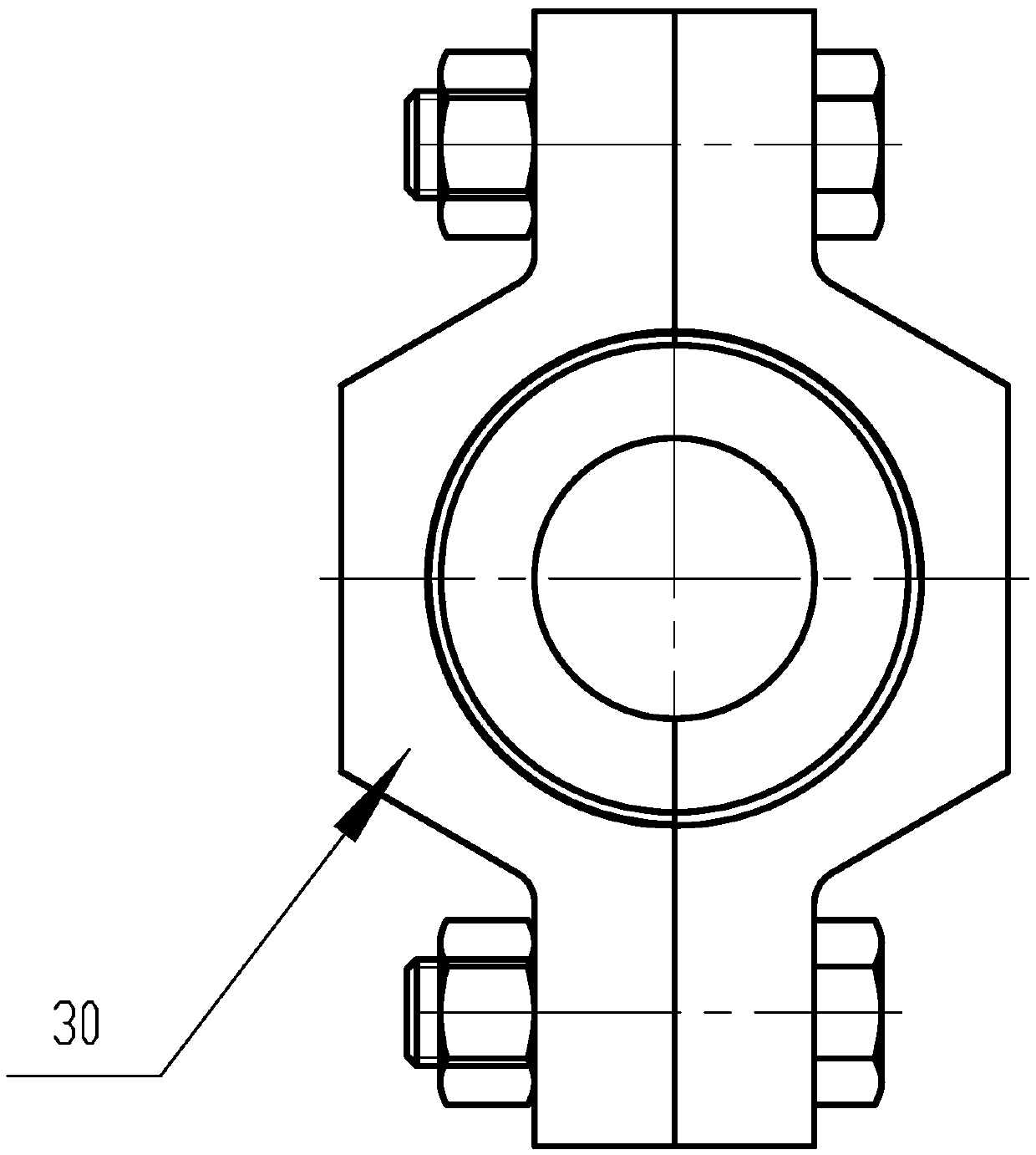

[0034] like Figure 4 As shown, the casting anchor cup includes a cylindrical anchor cup body 11 , an extension sleeve 12 and a constraint positioning ring 13 , and the anchor cup body 11 , the extension sleeve 12 , and the constraint positioning ring 13 are coaxially arranged.

[0035] like Figure 4 As shown, the anchor cup body 11 has an inner hole 111, the middle part of the inner hole 111 is a tapered hole, the tapered hole is larger than the lower part, and the bottom of the inner hole 111 is a threaded hole, and the outer diameter of the threaded hole is larger than the small diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com