Method and tool of measuring distance between shafts for straightening roller, and manufacturing method of the tool

A measurement method and a technology of a measurement tool, which are applied in the field of straightening technology, can solve the problems of large influence on measurement accuracy, high requirements for on-site vibration, and large relationship between level measurement accuracy and distance, and achieve high measurement accuracy and simple vertical distance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

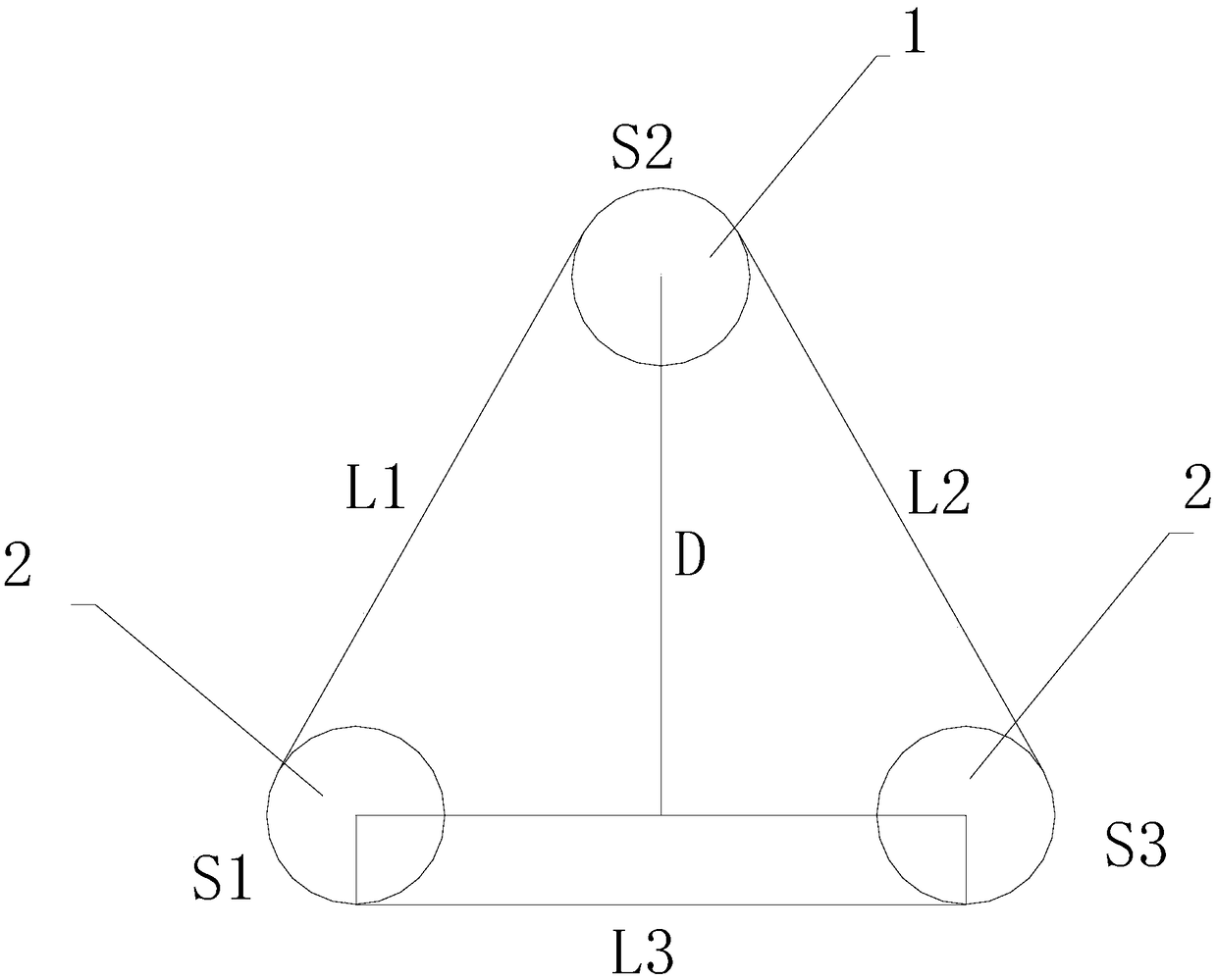

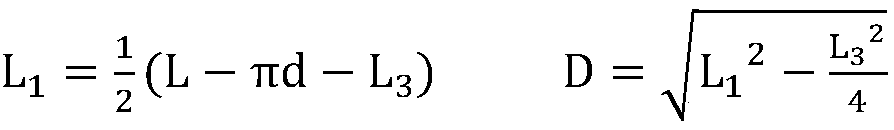

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, calculate the corresponding values of the outer circumference of the three major shafts of the rollers and the distance between the straightening rollers, make a corresponding table as shown in Table 1, and measure the outer circumference of the major shafts of the three rollers Finally, the distance between the straightening rollers can be obtained by checking the corresponding relationship table. In this embodiment, the corresponding values of the outer winding circumference and the distance between the straightening rollers are first made into a ready-made table, and after measuring the outer winding circumferences of the three major shafts, the corresponding straightening roller distances are searched in the corresponding relationship table. The measured distance between the straightening rollers can be quickly obtained on site.

[0036] Table 1 The relationship between the axis spacing and the circumference of the outer circle

[0037] ...

Embodiment 2

[0040] In this embodiment, the major axis of the pressing roller 1 and the major axis of the fixed roller 2 can be drawn in drawing software such as cad according to their size and position, and then the outer winding of the major axes of the three rollers can be measured by using the measuring function of the drawing software. The value of the circumference and the corresponding value of the distance between the straightening rollers.

Embodiment 3

[0042] In this embodiment, the length value marked on the tape measure is used as the corresponding outer winding circumference value, and the corresponding straightening roller shaft spacing value is marked at the corresponding outer winding circumference value, and the aforementioned tape measure is used to wind the three rollers to Measure the outer winding circumference of the three rollers on the outer circumference of the shaft, and mark the distance between the straightening rollers on the tape measure corresponding to the outer winding circumference as the actual measured distance between the straightening rollers. The tape measure of prior art is used for weighing length, therefore also can measure circumference, present embodiment uses the length position represented by tape measure as corresponding outer circumference circumference, for example tape measure 6353mm length position, promptly represents outer circumference circumference value 6352mm, mark the correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com