A plug-in sheath fixing structure

A technology for fixing structures and sheaths, which is applied in the field of auto parts, can solve problems such as laboriousness, poor maintenance of vehicles, and difficult separation of female end sheaths, and achieves the effect of convenient disassembly and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

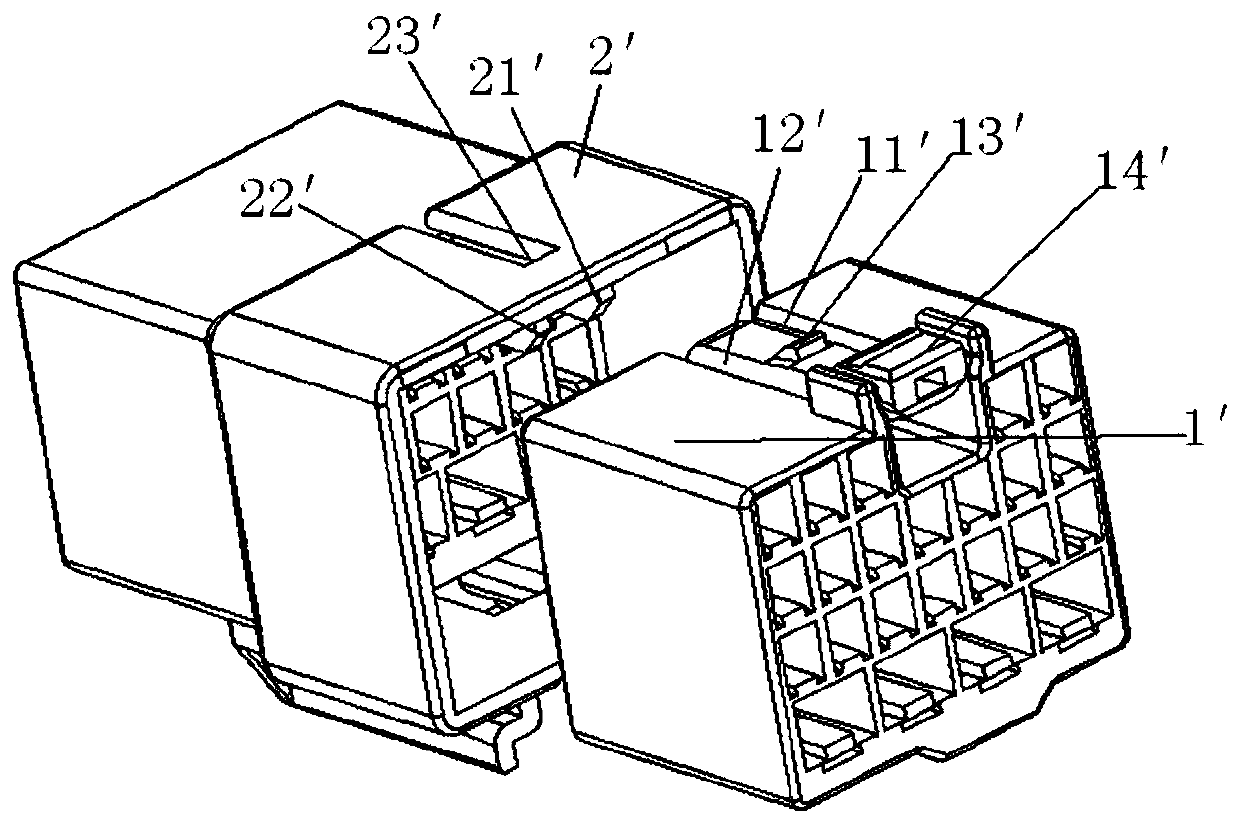

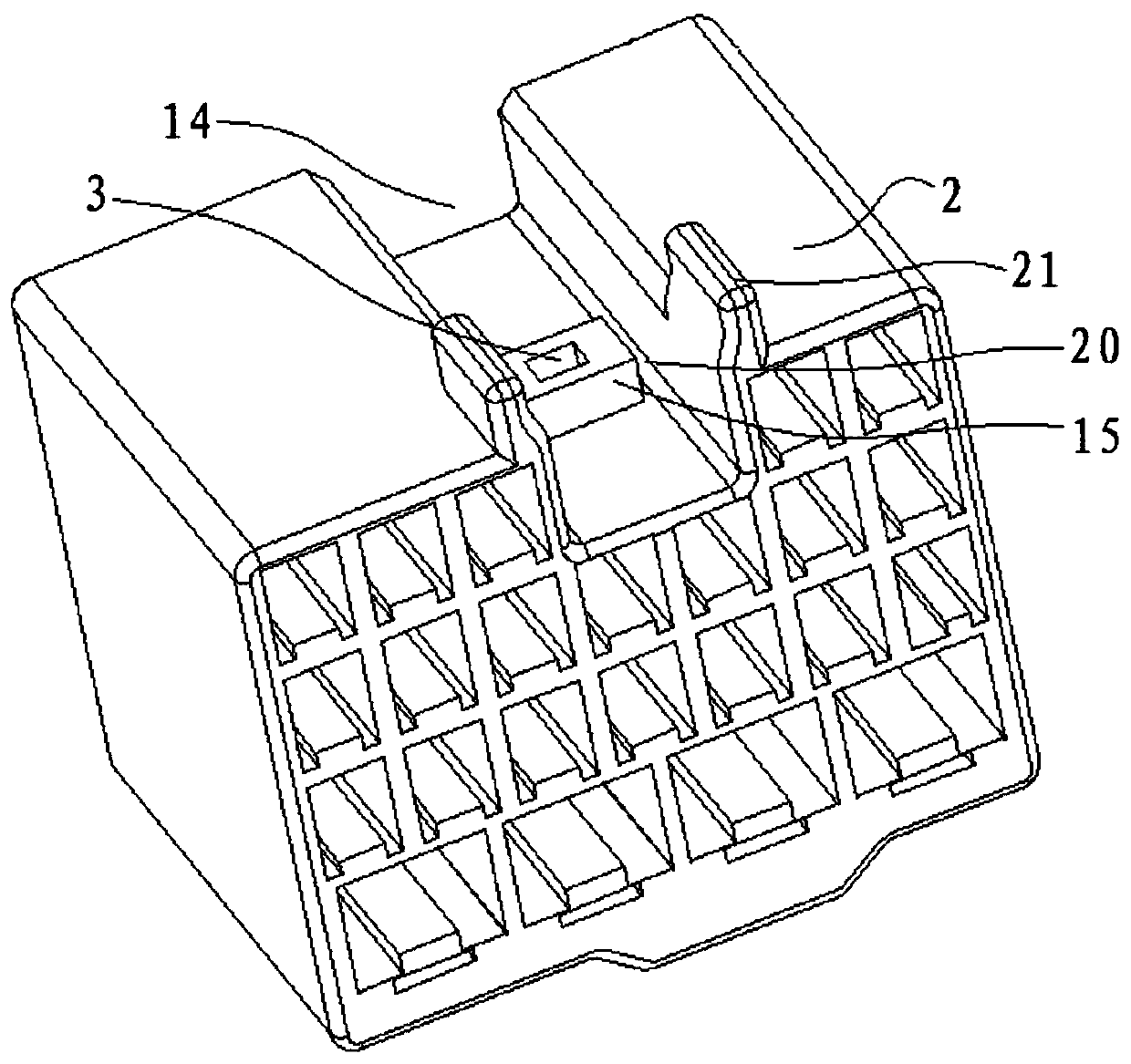

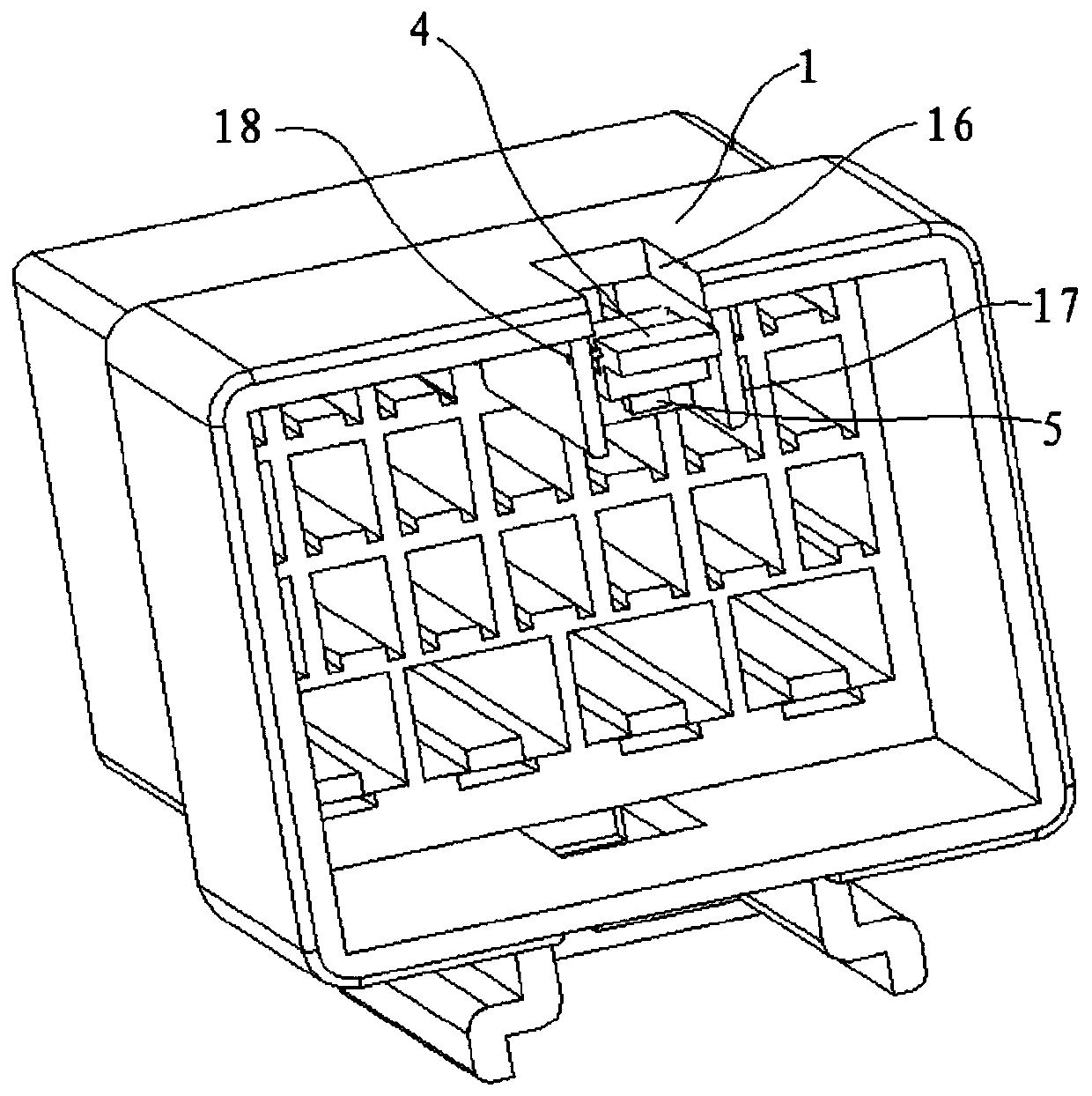

[0026] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

[0027] Such as Figure 2 to Figure 7 As shown, an embodiment of the present invention: a plug-in sheath fixing structure, including a detachably connected male-end plug-in sheath 1 and a female-end plug-in sheath 2, wherein: the female-end plug-in sheath 2 is recessed with Card slot 3; the male-end plug-in sheath 1 is provided with a pressing fixture 4, and the pressing-fixing piece 4 is rotatably connected to the male-end plug-in sheath 1, and the free end of the pressing-fixing piece 4 A clamping block 5 that is fixedly fitted with the clamping slot 3 is provided on the top.

[0028] In the above embodiment, by setting the pressing fixing part 4 connected by rotation, rotating the pressing fixing part 4, the block 5 is fixedly matched with the slot 3, and the assembly of the male end plug-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com