Ceiling splicing structure and splicing method thereof

A technology for suspended ceilings and splicing panels, applied in the direction of ceilings, building components, building structures, etc., can solve problems such as affecting the aesthetics of the ceiling structure, affecting the structure of the concrete layer, and prone to cracks, and achieving good splicing effect, improving effect and improving quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

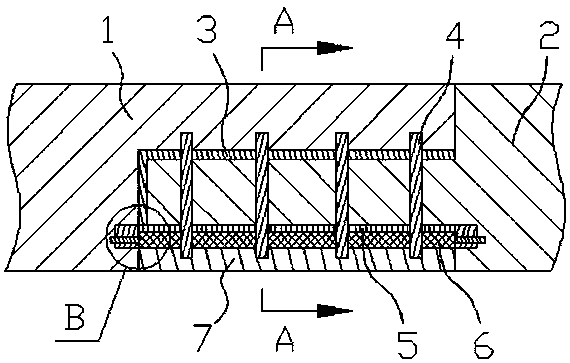

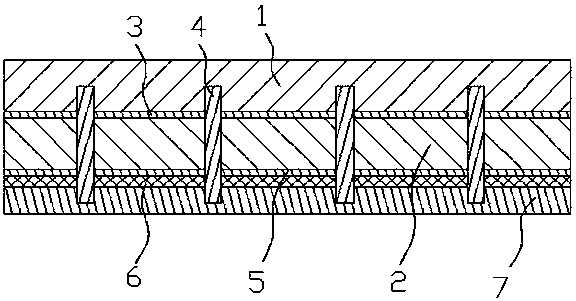

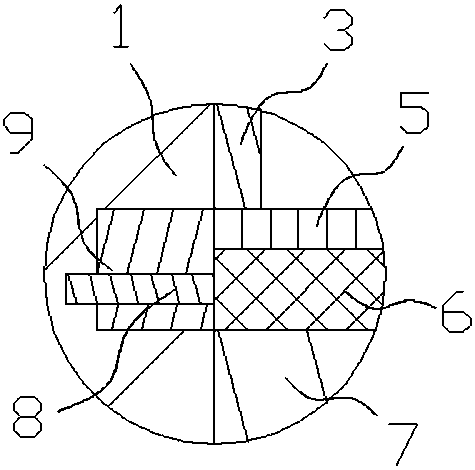

[0026] ①. First, the first splicing block and the second splicing block are cut and formed from the first splicing plate and the second splicing plate respectively by cutting equipment, and then the first splicing block and the second splicing block are assembled and spliced from the bottom to the top hole, and then open a square matching groove on the sides of the first splicing plate and the second splicing plate, and then use the punching equipment to open a wire mesh fixing bolt matching pin hole in the square matching hole;

[0027] ②. Put the first splicing plate processed in step ① upside down, and then apply adhesive glue on the lower surface of the first splicing block and the side of the first splicing plate, and then insert the wire mesh fixing pin of the steel mesh into the second splicing plate. The wire mesh fixing pins in the splicing plate fit into the pin holes, and then put the end of the second splicing block on the first splicing block, and then push the f...

Embodiment 2

[0031] ①. First, the first splicing block and the second splicing block are cut and formed from the first splicing plate and the second splicing plate respectively by cutting equipment, and then the first splicing block and the second splicing block are assembled and spliced from the bottom to the top hole, and then open a square matching groove on the sides of the first splicing plate and the second splicing plate, and then use the punching equipment to open a wire mesh fixing bolt matching pin hole in the square matching hole;

[0032] ②. Put the first splicing plate processed in step ① upside down, and then apply adhesive glue on the lower surface of the first splicing block and the side of the first splicing plate, and then insert the wire mesh fixing pin of the steel mesh into the second splicing plate. The wire mesh fixing pins in the splicing plate fit into the pin holes, and then put the end of the second splicing block on the first splicing block, and then push the f...

Embodiment 3

[0036] ①. First, the first splicing block and the second splicing block are cut and formed from the first splicing plate and the second splicing plate respectively by cutting equipment, and then the first splicing block and the second splicing block are assembled and spliced from the bottom to the top hole, and then open a square matching groove on the sides of the first splicing plate and the second splicing plate, and then use the punching equipment to open a wire mesh fixing bolt matching pin hole in the square matching hole;

[0037]②. Put the first splicing plate processed in step ① upside down, and then apply adhesive glue on the lower surface of the first splicing block and the side of the first splicing plate, and then insert the wire mesh fixing pin of the steel mesh into the second splicing plate. The wire mesh fixing pins in the splicing plate fit into the pin holes, and then put the end of the second splicing block on the first splicing block, and then push the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com