High-performance butterfly valve

A high-performance, butterfly valve technology, applied in abrasive medium conditions, hard-sealed butterfly valves, and high-temperature fields, can solve the problems of reduced sealing performance of the sealing pair, wear of the sealing surface, complex processing technology, etc., to achieve reliable sealing performance and long product life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

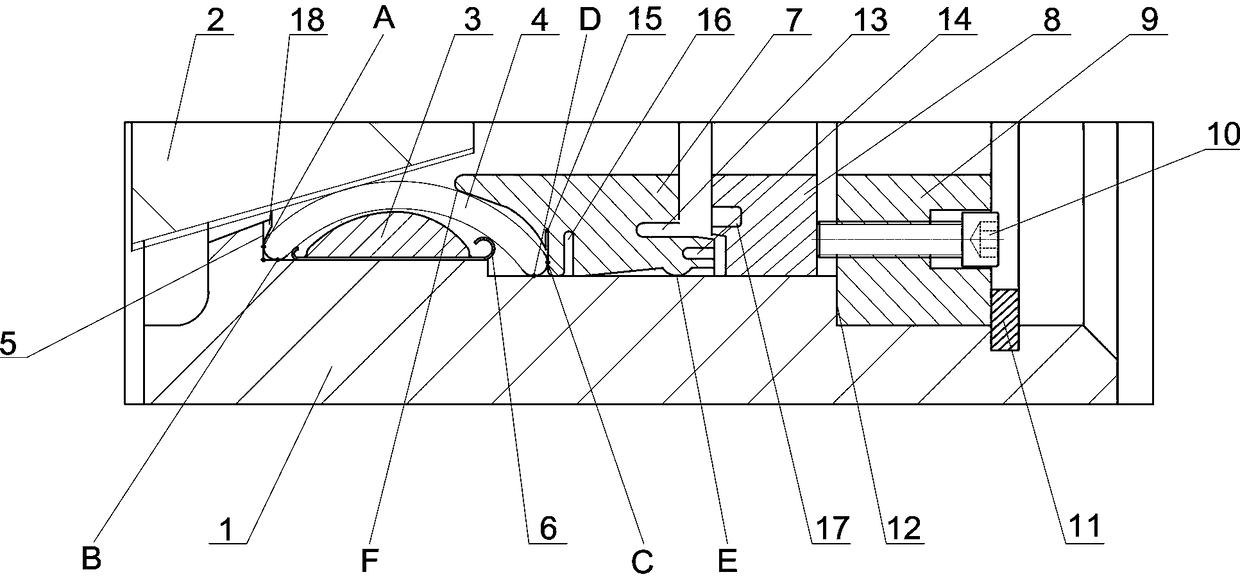

[0012] Such as figure 1 The high-performance butterfly valve shown includes a valve body 1, a valve seat, a butterfly plate 2, and a valve stem. The butterfly plate 2 has a conical metal sealing surface, and a three-eccentric structure is adopted between the butterfly plate 2, the valve stem, the valve body, and the valve seat. The valve seat adopts a flexible self-sealing valve seat, and the flexible self-sealing valve seat is composed of an arc-shaped metal sealing ring 4, which is embedded in the inner wall of the channel of the valve body 1, and the arc-shaped metal sealing ring 4 It is a metal ring concentric with the channel of the valve body 1. The cross section of the metal ring is arc-shaped. The arc surface of the arc-shaped metal ring cooperates with the sealing surface of the butterfly plate 2 to form a sealing pair. The arc-shaped metal seal ring 4 The left end has a left arc surface, and the right end has a right arc surface, that is, the left and right ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com