Pipe joint

A technology for pipe joints and pipes, applied in the field of pipe joints, can solve the problems of scattered parts and time-consuming pipe connection, and achieve the effects of good sealing, simple connection and firmness of reinforcement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

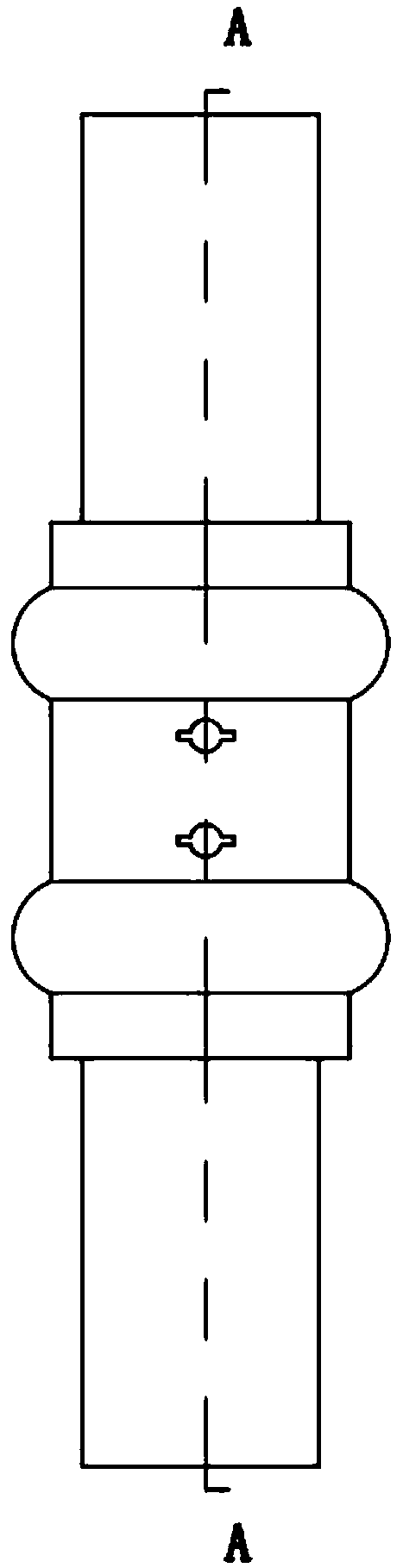

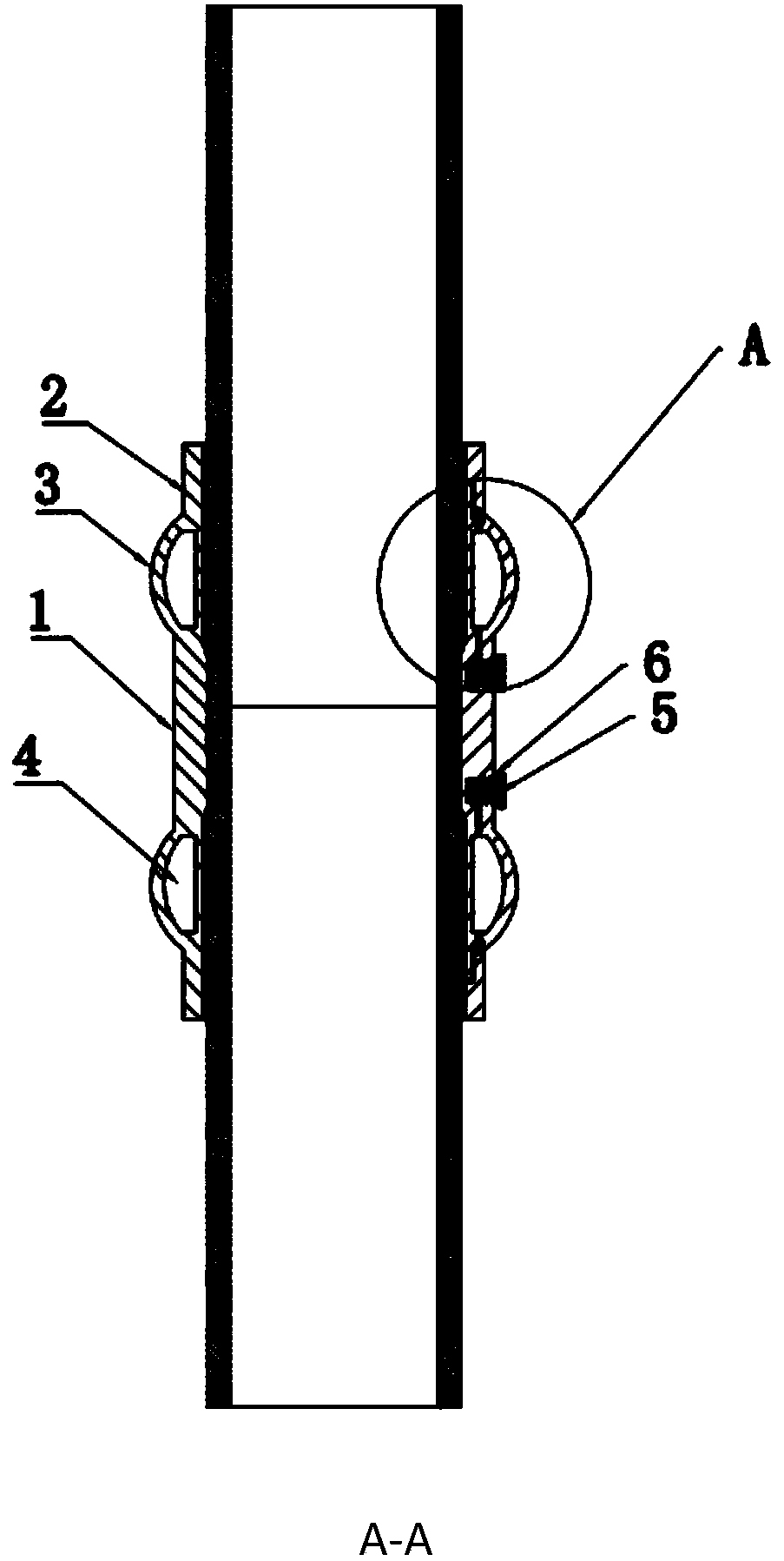

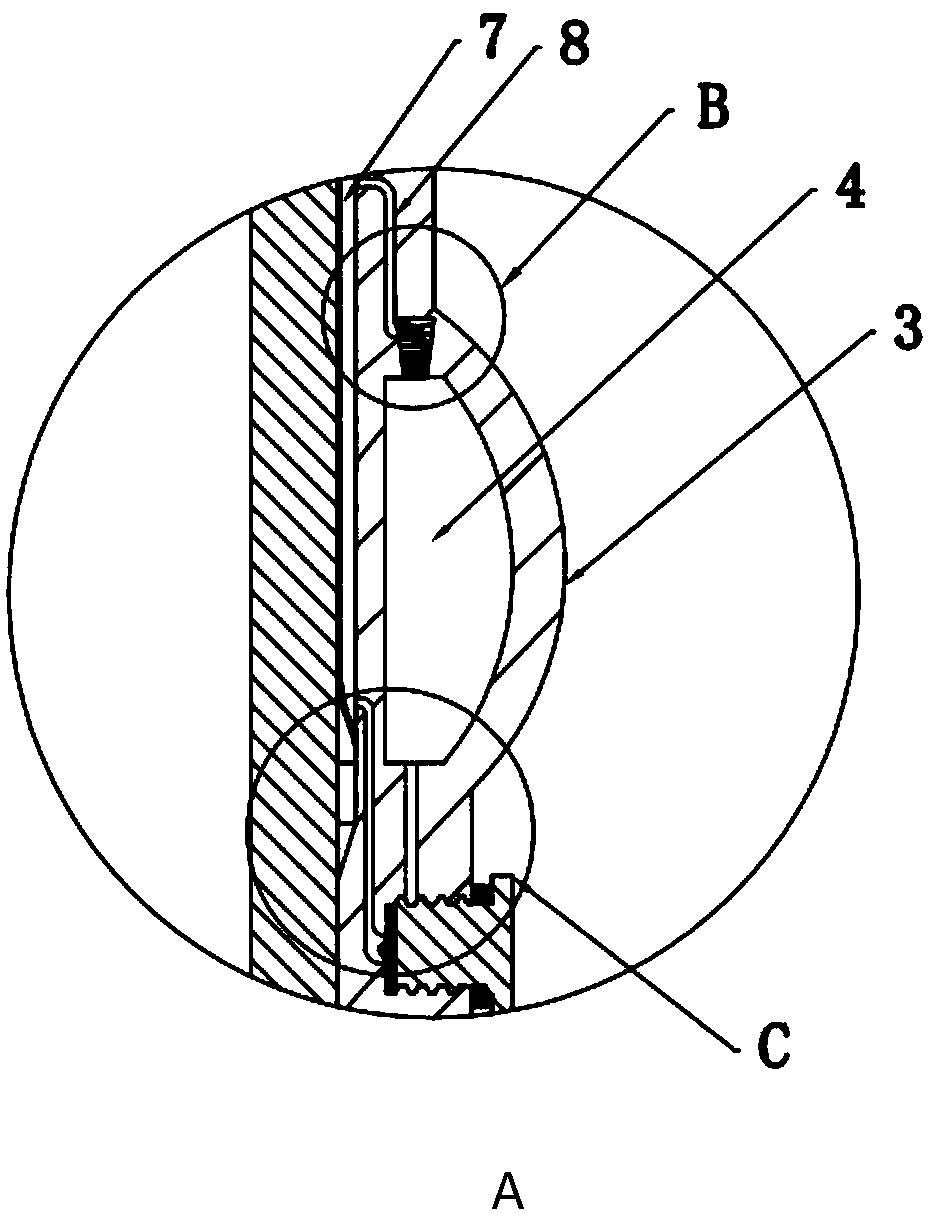

[0030] A pipe joint, refer to Figure 1-Figure 5 As shown, it is suitable for the connection between plastic pipes, rubber pipes or silicone pipes, including a connecting pipe 1 with an inner diameter smaller than the outer diameter of the pipe for interference fit insertion of the pipe and an integrally extending outward from both ends of the connecting pipe 1 with an inner diameter larger than the outer diameter of the pipe. The matching pipe 2 of the outer diameter of the pipe, the matching pipe 2 and the connecting pipe 1 are all made of elastic material, which can be silica gel or rubber, preferably silica gel, and the inner wall of the matching pipe 2 is annularly folded with an inflatable air bag layer 7, The airbag layer 7 is made of silica gel, and the outer wall of the matching tube 2 is provided with a gas storage mechanism made of elastic material, the gas storage mechanism is preferably made of silica gel, and the gas storage mechanism refers to figure 2 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com