Simulation analysis method of wheel-rail contact cycle loading and unloading based on finite element simulation

A simulation analysis and finite element technology, applied in the theoretical and practical field of computer simulation of wheel-rail contact, can solve problems such as the implementation method of the wheel-rail circulation action has not yet been described, the influence of boundary effects is not considered, and it is difficult to eliminate errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

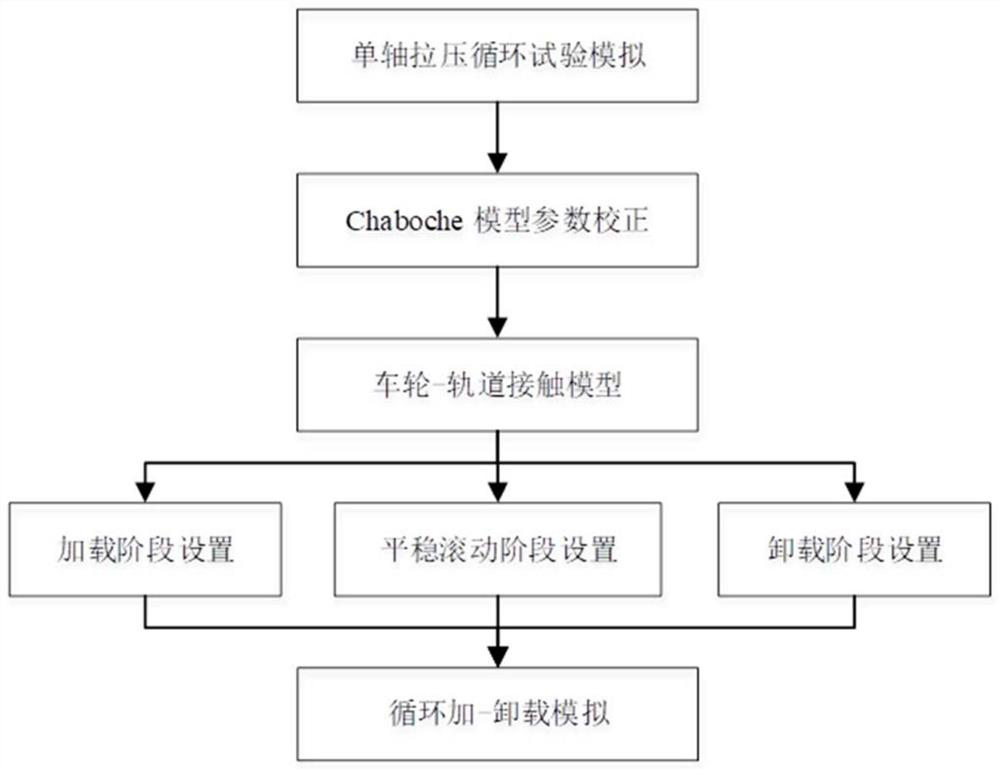

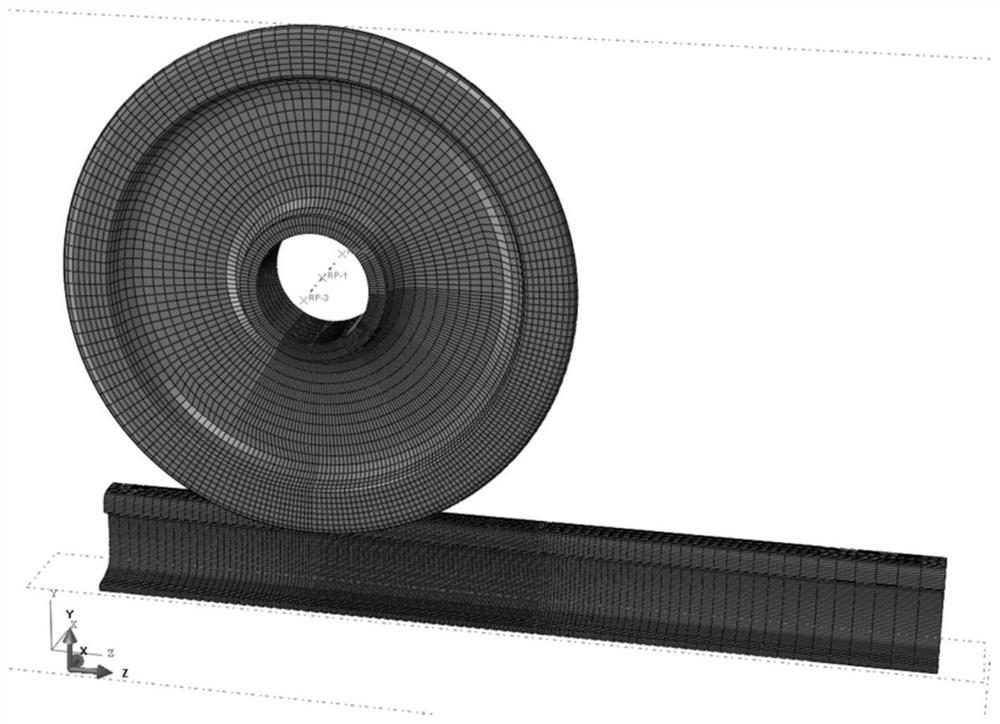

[0023] The invention provides a wheel-track contact cycle loading-unloading simulation analysis method based on finite element simulation, and its operation flow is as follows figure 1 As shown, the specific steps are as follows:

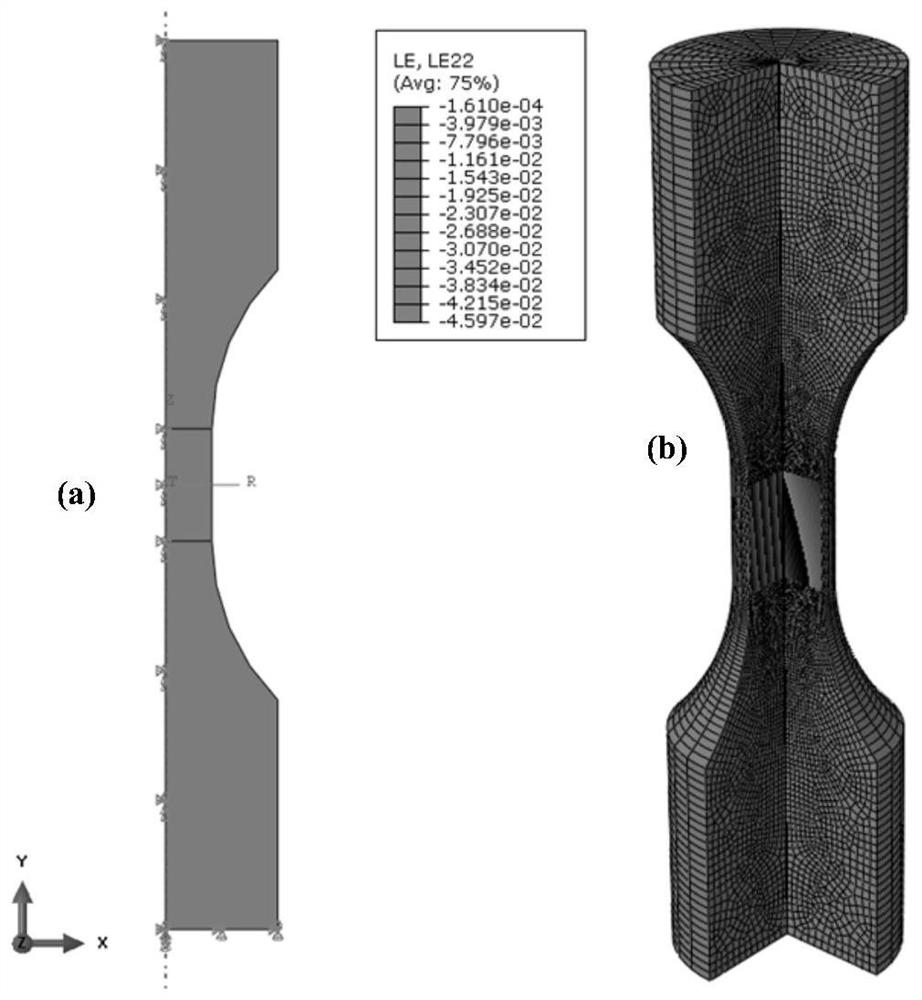

[0024] (1) Using the finite element software ABAQUS, establish a dog-bone type smooth cylindrical sample model, the diameter of the cylinder is 14mm, and the length of the cylinder is 25.4mm, such as figure 2 As shown in (a); the vertical stress and strain of the internal unit of the cylinder are monitored, and the real stress-strain curve is drawn. The vertical strain contours of multiple loadings are shown in 2(b).

[0025] (2) Carry out uniaxial tension-compression cycle test simulation, and correct the nonlinear hardening parameters of the material according to the laboratory test results and the Chaboche model. The ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com