Comprehensive efficiency evaluation and monitoring method of main shaft hoisting system for lean production

A technology for improving system and comprehensive efficiency, applied in the field of comprehensive efficiency evaluation and monitoring of the main well hoisting system for lean production, to achieve the effect of scientific, comprehensive and effective comprehensive efficiency evaluation and monitoring methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Now, the present invention is explained in detail in conjunction with the embodiments and the accompanying drawings.

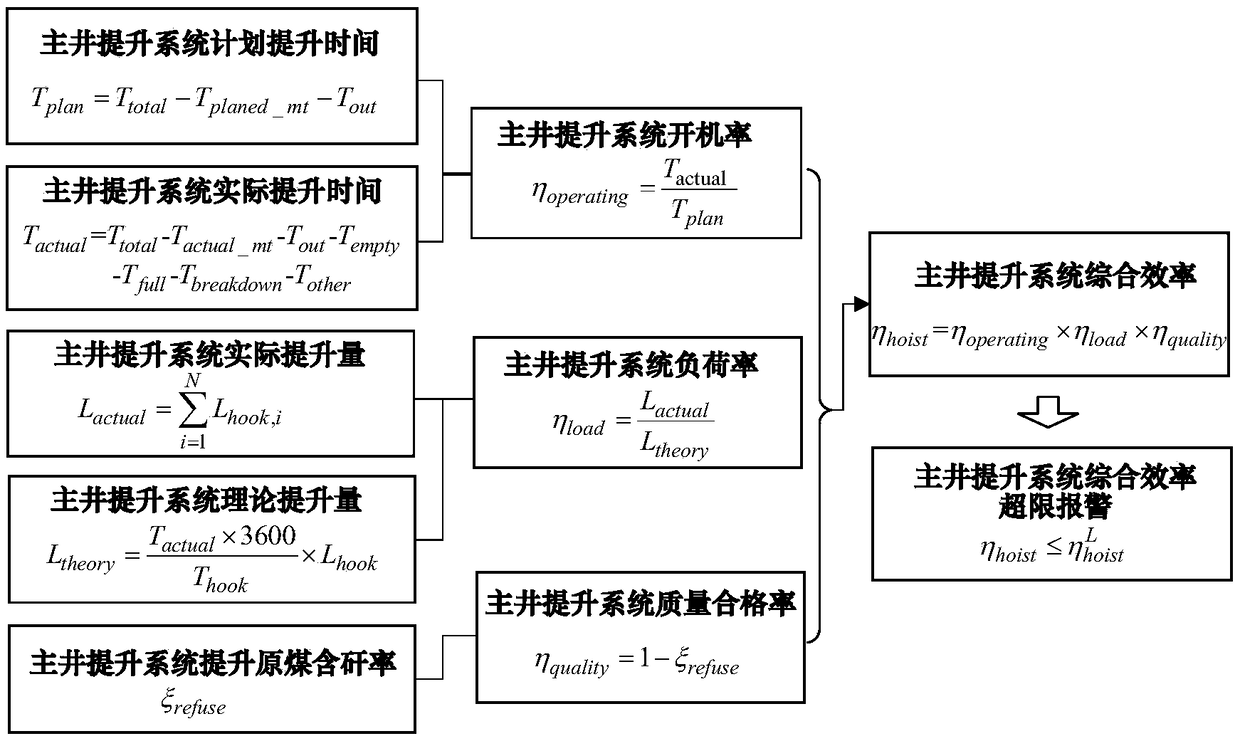

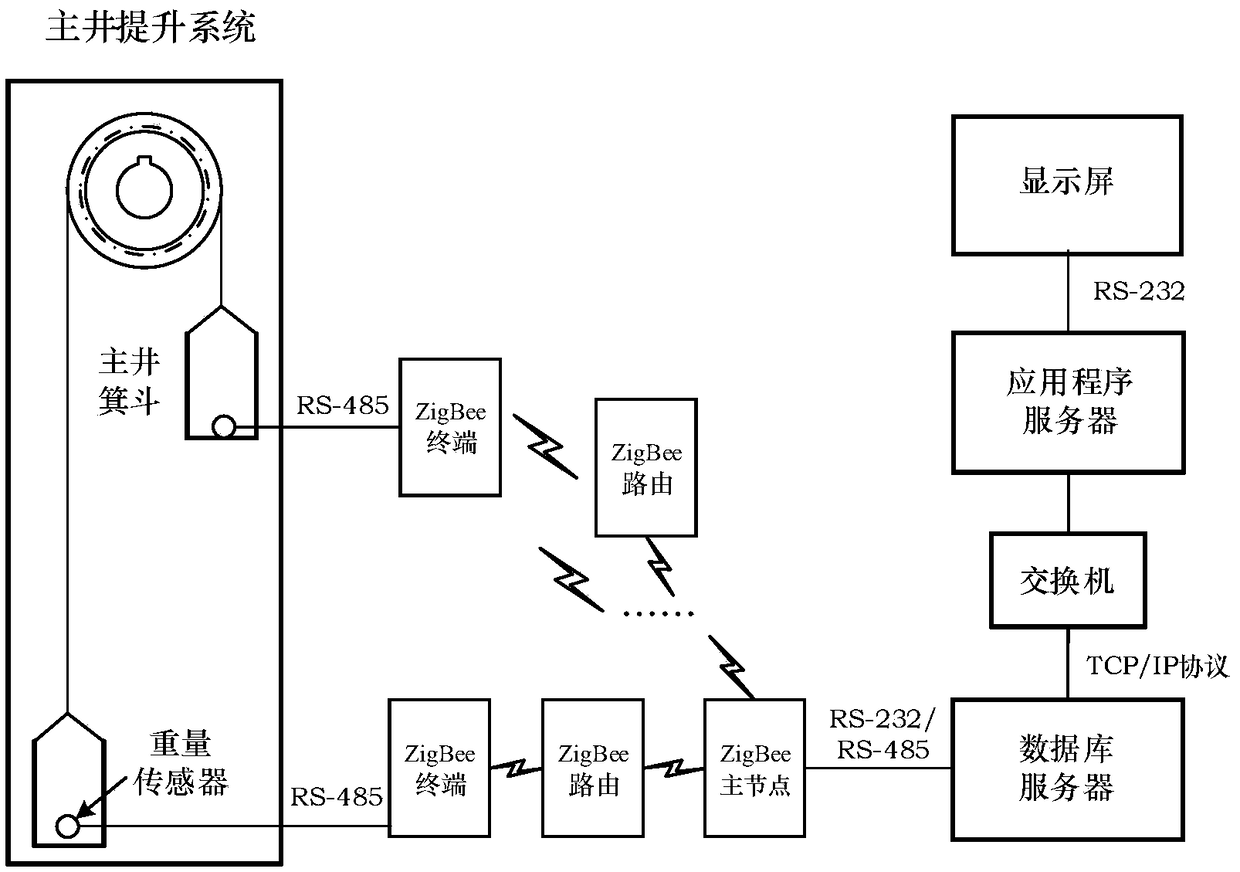

[0040]The invention proposes a comprehensive efficiency evaluation and monitoring method of a main well hoisting system for lean production. The schematic flow chart of the inventive method is as figure 1 As shown, firstly, the planned lifting time and actual lifting time of the main well hoisting system are calculated according to the main well hoisting system evaluation cycle time, planned maintenance time, actual maintenance time, and failure time. Time and planned lifting time to calculate the operating rate of the main shaft hoisting system. According to the hoisting amount of the main well hoisting system per tick in the evaluation period, the actual hoisting amount of the main well hoisting system is obtained by accumulating; according to the actual hoisting time, the theoretical cycle period of the main well hoisting system and the theoretical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com