Wafer clamping assembly and method for clamping wafer

A wafer and fixture technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of the wafer 10 being bounced, unable to effectively align and pick up the wafer, etc., and achieve the effect of rapid movement and rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

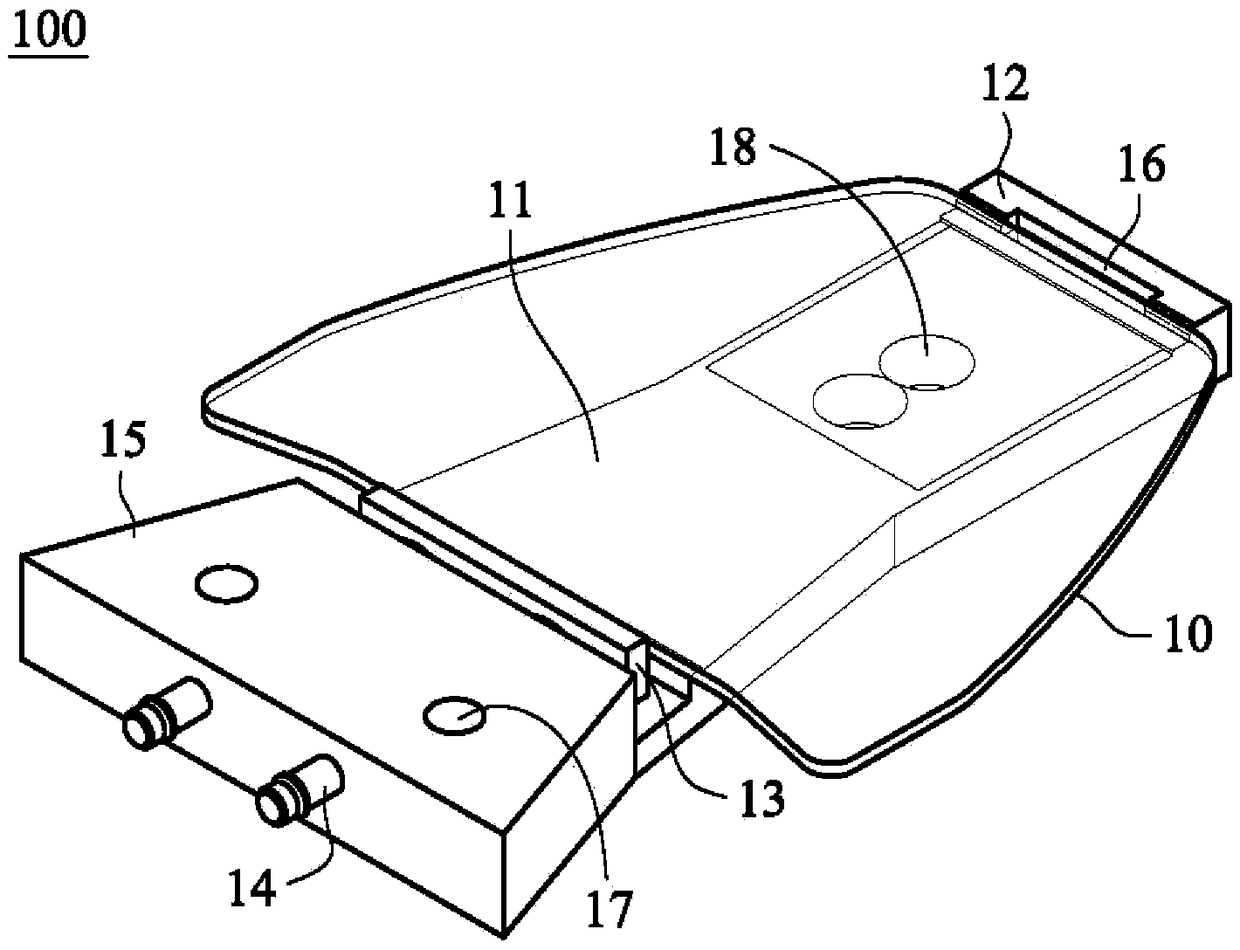

[0030] Figure 1A A perspective view of a wafer holder 100 suitable for a robotic system according to an embodiment of the present invention is shown. figure 2 show Figure 1A A top view of the wafer holder 100. The wafer holder 100 of this embodiment can temporarily hold the wafer 10 at a fixed position to avoid movement or separation. The wafer holder 100 is specifically (but not limited) used to hold a wafer without touching the top or bottom of the wafer. When the wafer holder 100 is used as a manipulator to cooperate with other components of the robot system to pick up and place the wafer 10 (such as optical lens or glass), the wafer holder 100 can also be called a robot fork.

[0031] In this embodiment, the wafer holder 100 may include a platform 11 having a flat top surface. The platform 11 is located under the wafer 10 for supporting the wafer 10 .

[0032] The wafer holder 100 of this embodiment may include a stopper 12 disposed on the front end of the platform 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com