Lofting method of retractable fin stabilizer shell plate

A fin stabilizer, retractable technology, used in the use of hydrofoils to act on the surrounding water surface to reduce ship motion, ship construction, ship design, etc. and other problems to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

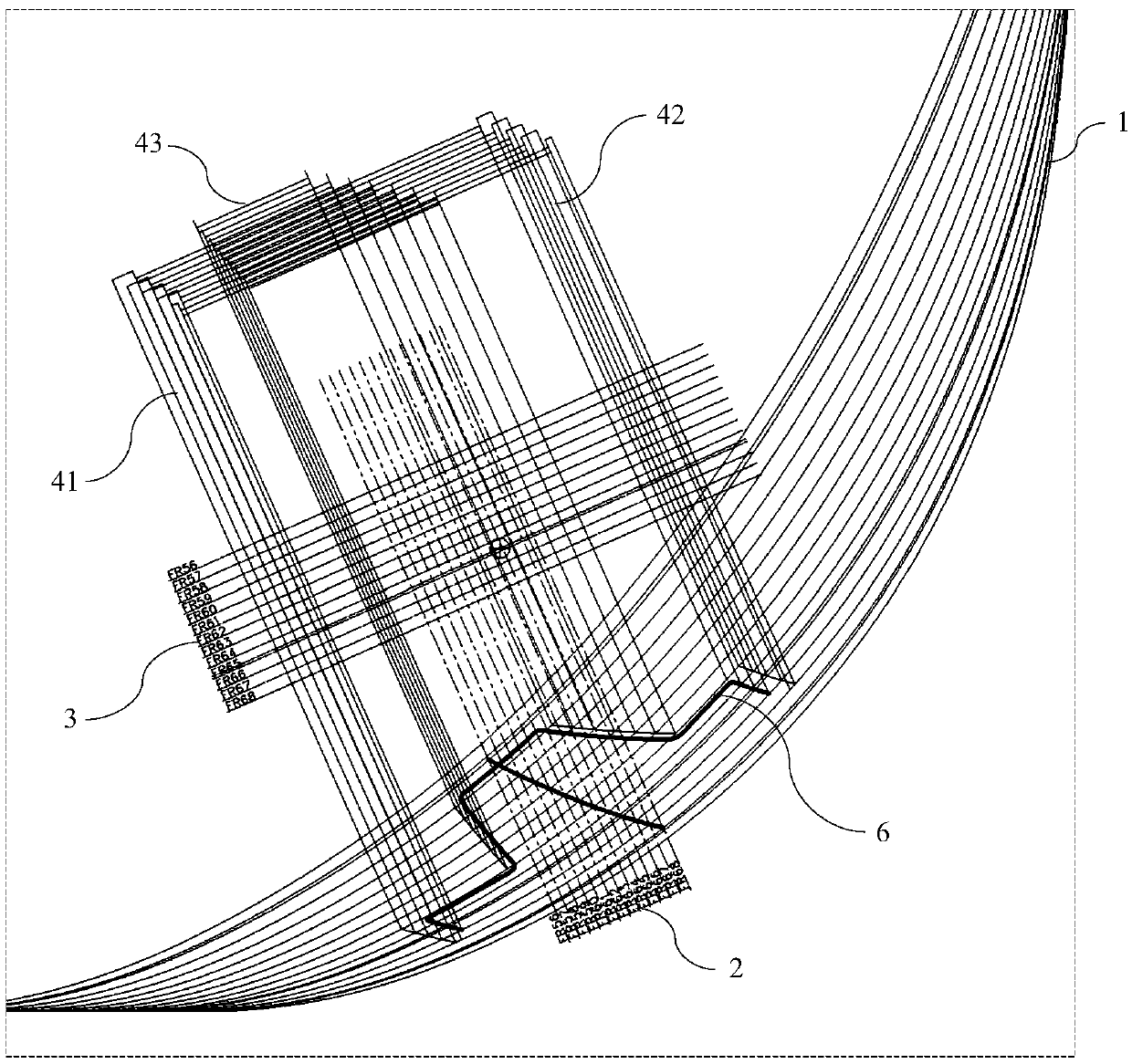

[0024] to combine Figures 1 to 4 As shown, schematically shows the lofting method of the retractable fin stabilizer outer plate of the present invention, including the following steps:

[0025] Step S1, combining figure 1 As shown, obtain the rib shape line diagram, which includes the rib line 1 of the hull, and mark the fin stabilizer centerline 2, fin box structure contour line 4 and fin box centerline 3 on the rib shape line diagram, where , the fin box structure contour line 4 includes the fin box upper structure line 41, the fin box lower structure line 42 and the fin box roof line 43;

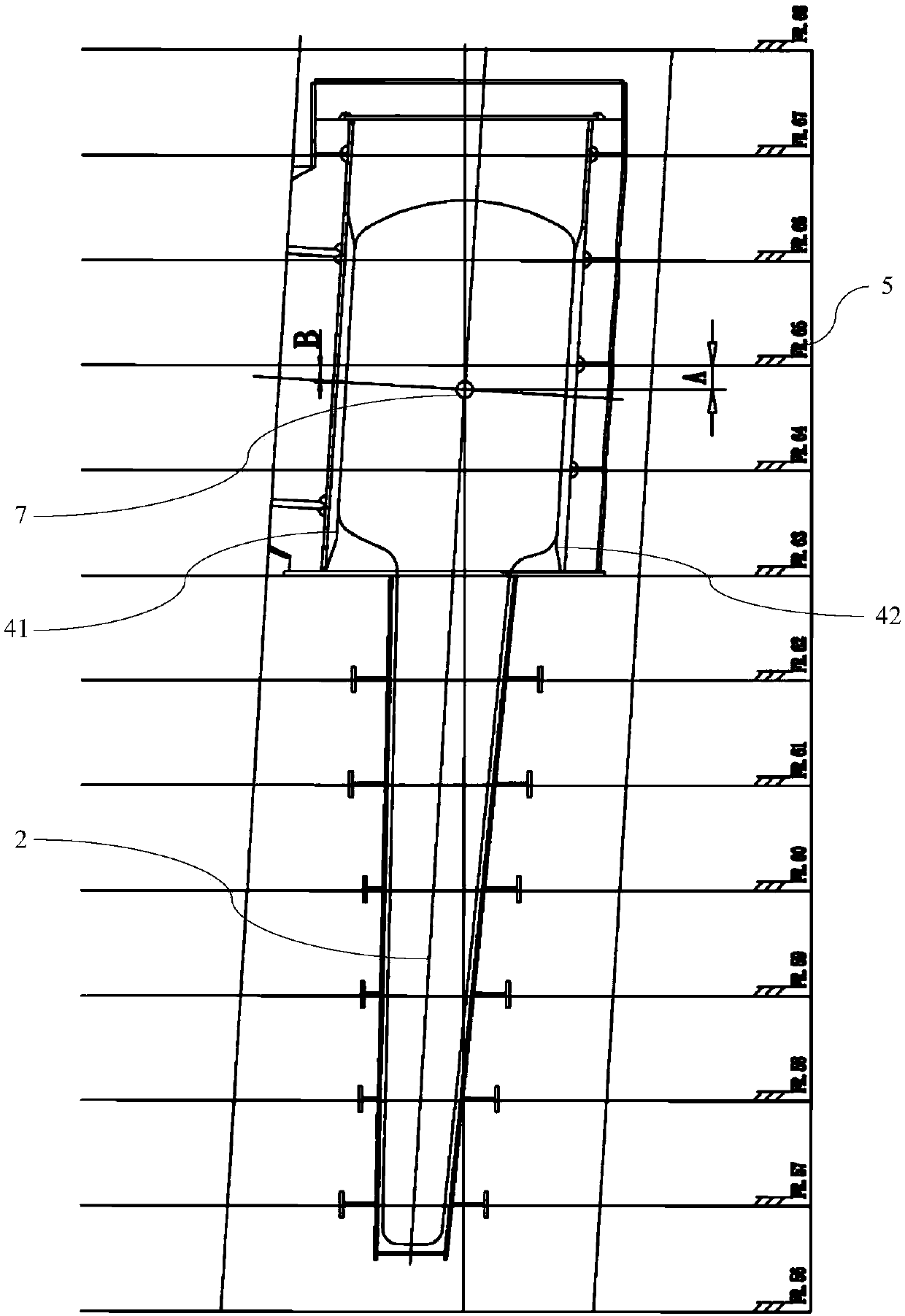

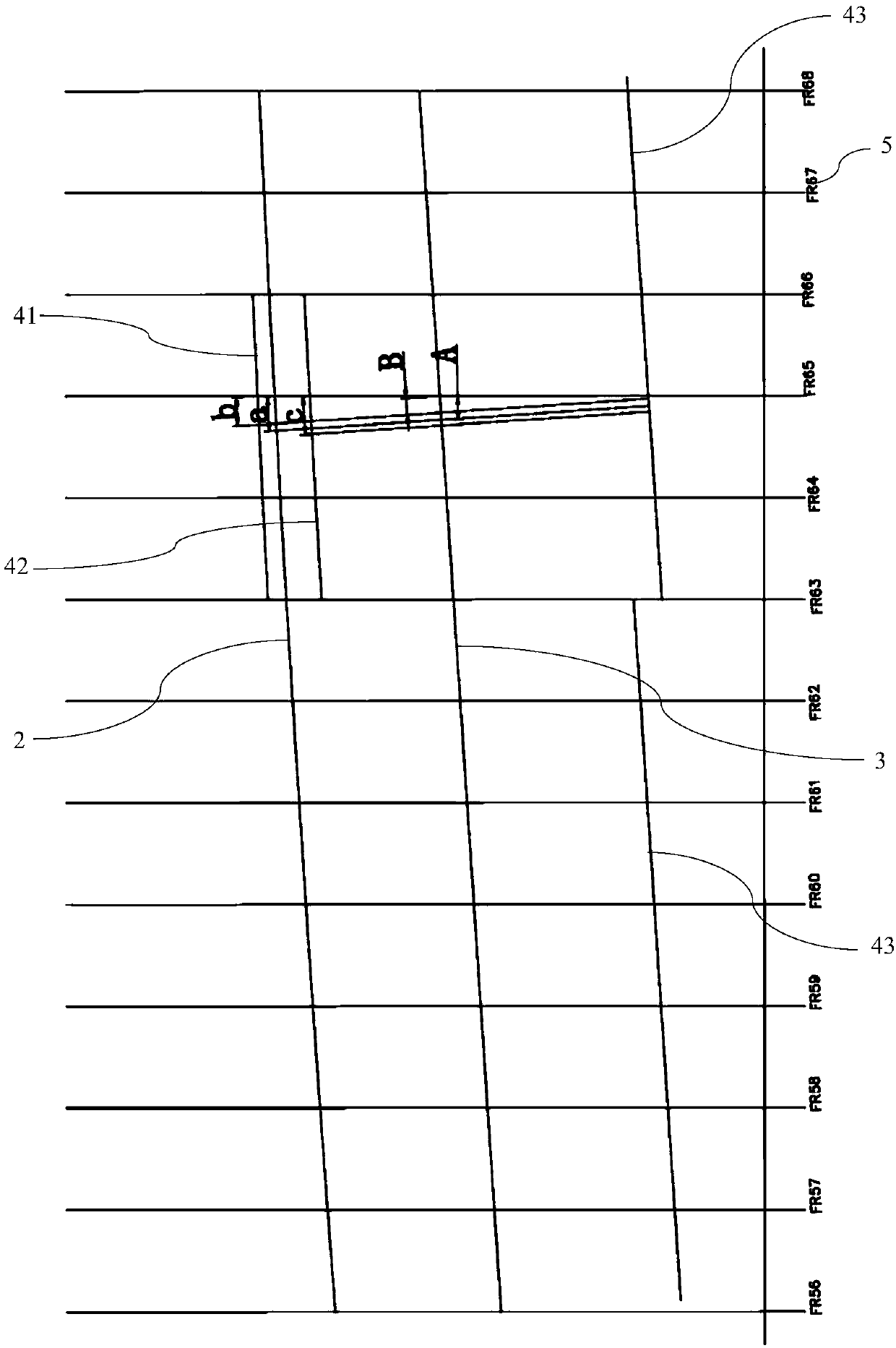

[0026] Step S2, such as figure 2 As shown, obtain the projection diagram of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com