Movable supporting framework plate supporting structure for roadway

A supporting structure and supporting bone technology, which is applied in the direction of mine roof support, mining equipment, mining equipment, etc., can solve the problems of difficult protection, inability to prevent deformation of surrounding rock, and difficulty in repeated use, so as to achieve good protection and slow down the acceleration of gravity , the effect of reducing the impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings and embodiments, but the present invention is not restricted in any way. Any changes or improvements made based on the teachings of the present invention shall fall within the protection scope of the present invention.

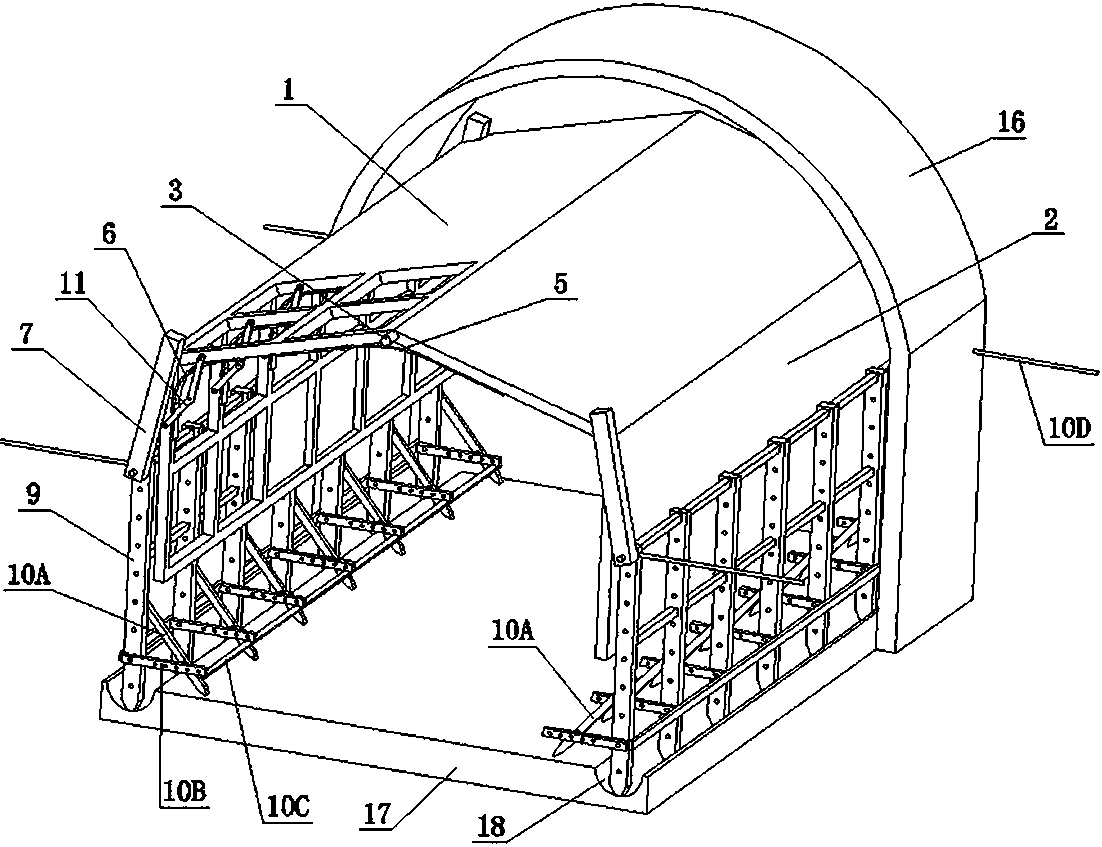

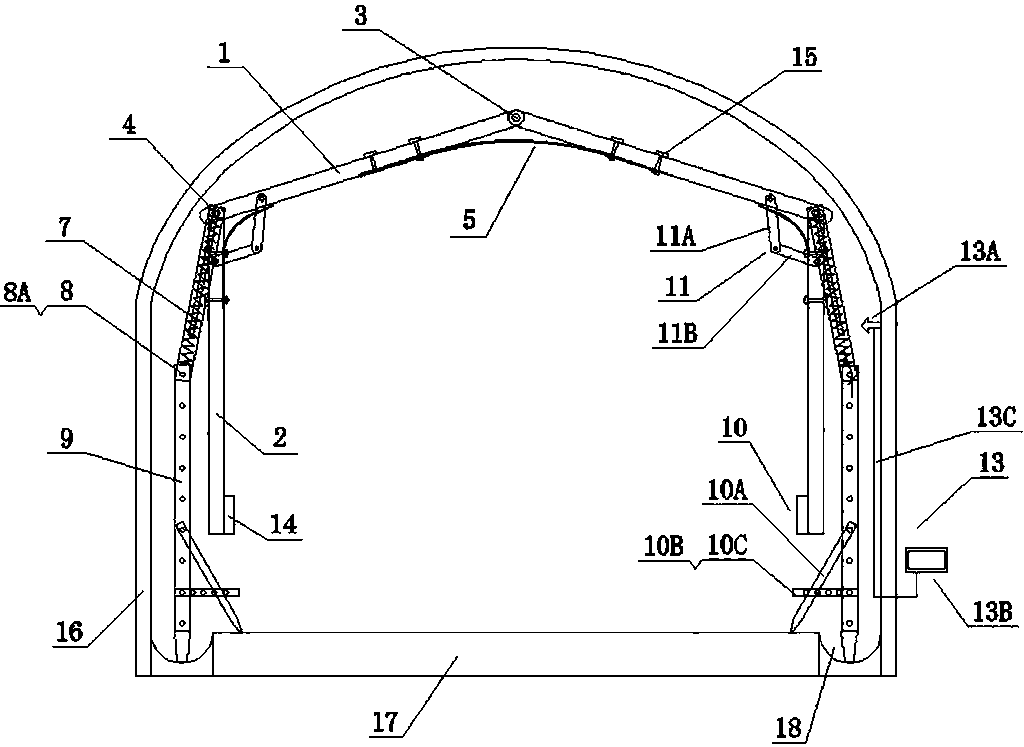

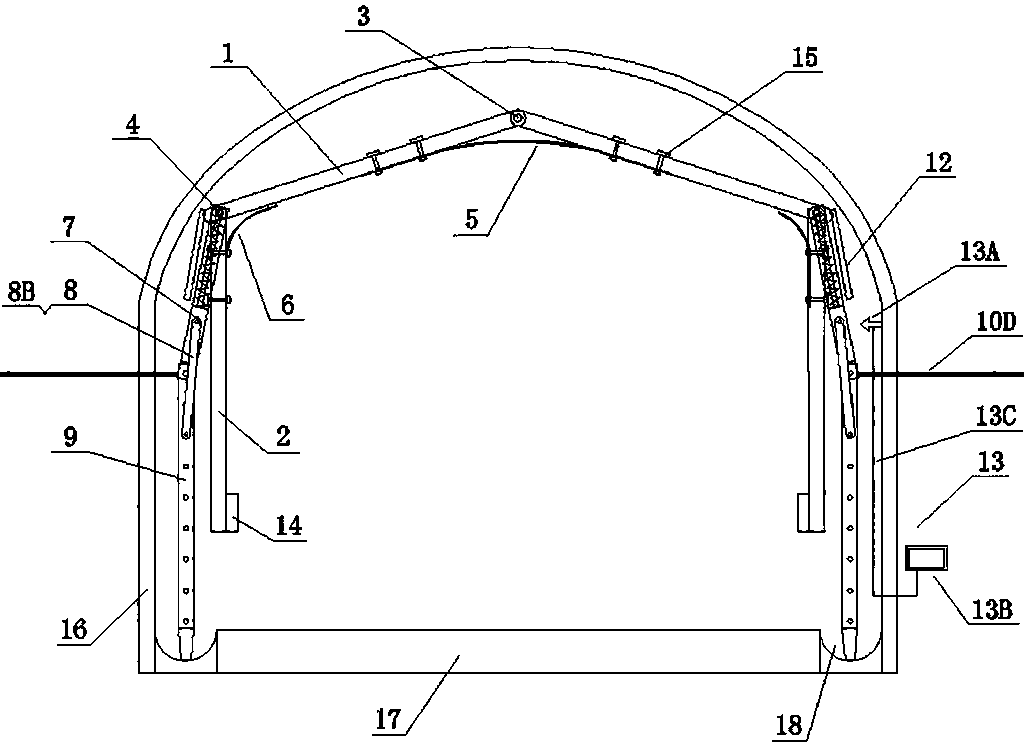

[0022] Such as Figure 1 to 5 As shown, the present invention includes an upper baffle 1, a side baffle 2, a top rotating shaft 3, a side rotating shaft 4, an elastic piece 5, a limiting elastic piece 6, an elastic compression rod 7, a torsion support mechanism 8, a pillar 9, and a pillar support mechanism 10. One end of the upper baffle 1 is hinged with the top shaft 3 and the other end is fixedly connected or hinged with the side shaft 4, the upper end of the side baffle 2 is fixedly connected or hinged with the side shaft 4, and the top shaft 3 extends along the direction of the roadway The upper baffle 1 arranged and hinged on both sides forms an inverted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com