Rear single-propeller type composite wing manned craft

A propeller and composite wing technology, applied in the field of aircraft, can solve the problems of low safety factor, high take-off and landing requirements, easy crash, etc., and achieve the effects of high wing structure strength, reduction of gravitational acceleration, and improvement of safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

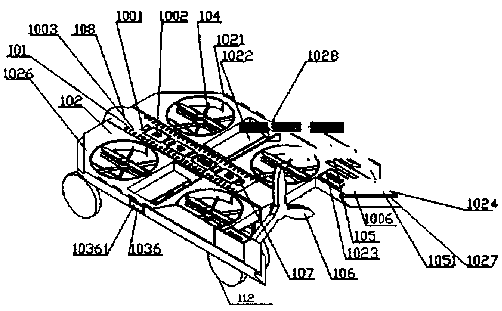

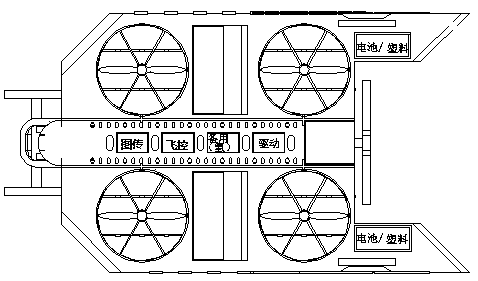

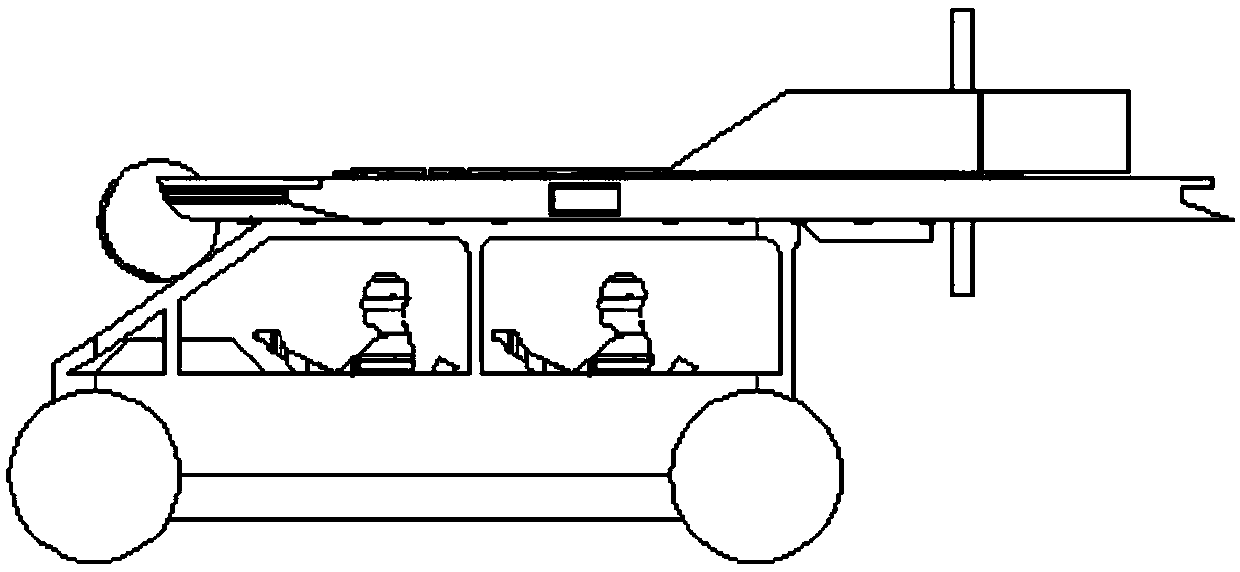

[0024] Such as Figure 1 to Figure 5 As shown, a rear single propeller compound wing manned aircraft includes a rear single propeller compound wing aircraft, and the manned cabin is installed below the body.

[0025] Wherein, the rear single propeller compound wing aircraft includes a body 101, a compound lift wing 102 and a propeller 106 fixedly installed on both sides of the body 101; wherein, the body 101 is set as a deck platform; the compound lift The wing 102 has a built-in self-enclosed ducted fan 104, and a wing hinge (1027) is designed on the outside of the compound lift wing 102; a wing tail (1024) is also arranged at the tail end of the compound lift wing.

[0026] As a further improvement of the present invention, the propeller 106 is a variety of power structures such as electric propellers and oil-powered propellers.

[0027] As a further improvement of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com