Liquid crystal display panel

A liquid crystal display panel and display area technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as uneven color at the edge, large jagged display area, etc., to reduce the jagged phenomenon, increase the resolution, and reduce the pixel area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

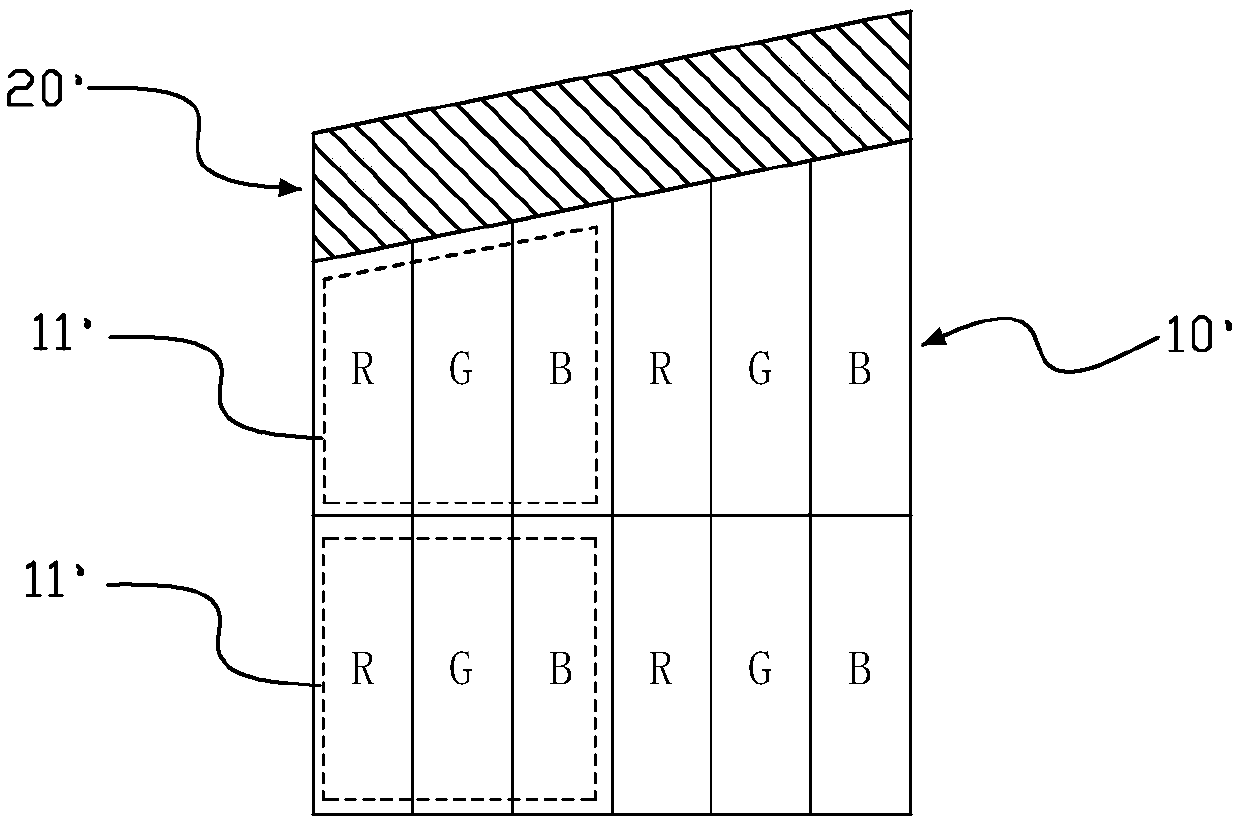

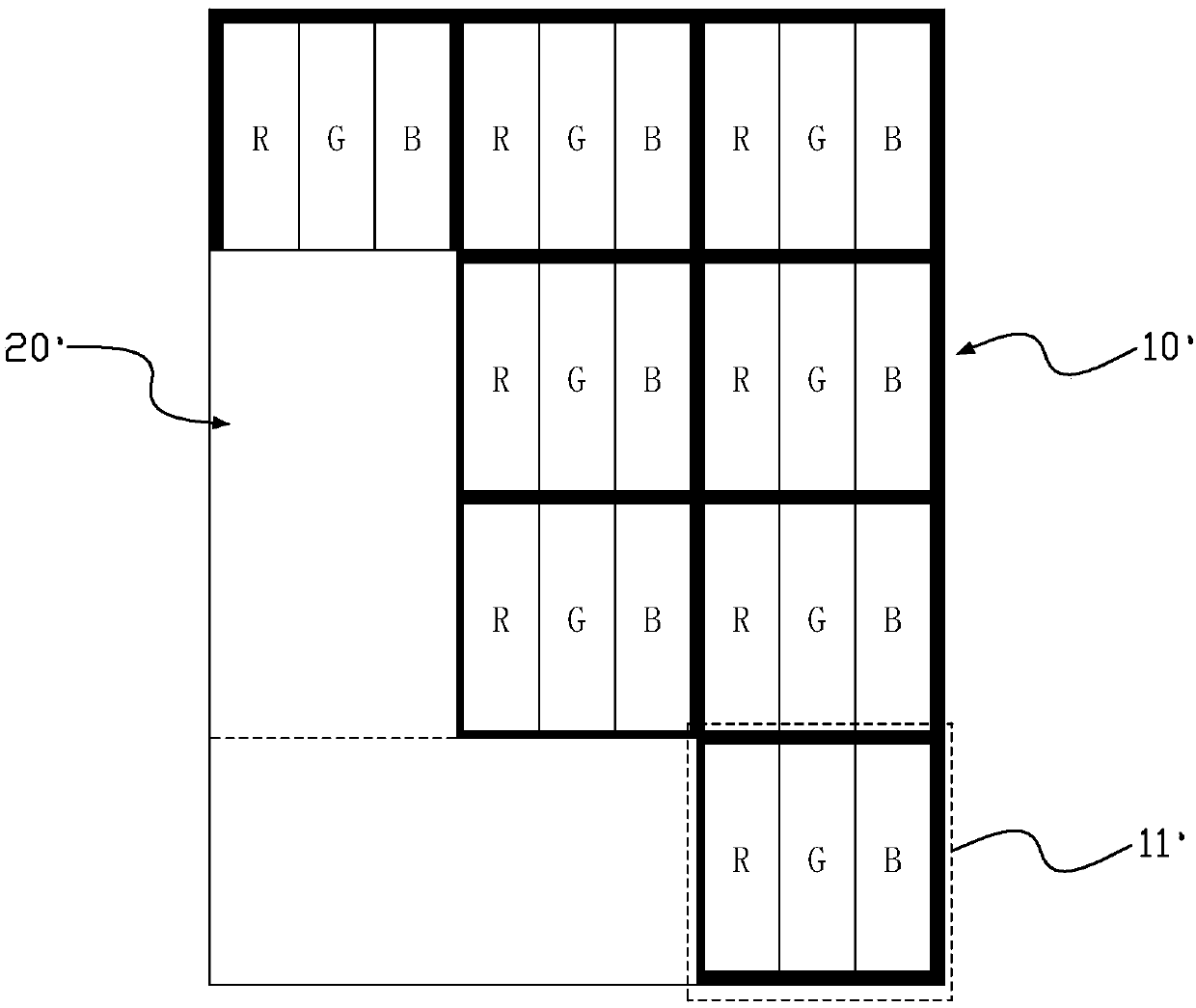

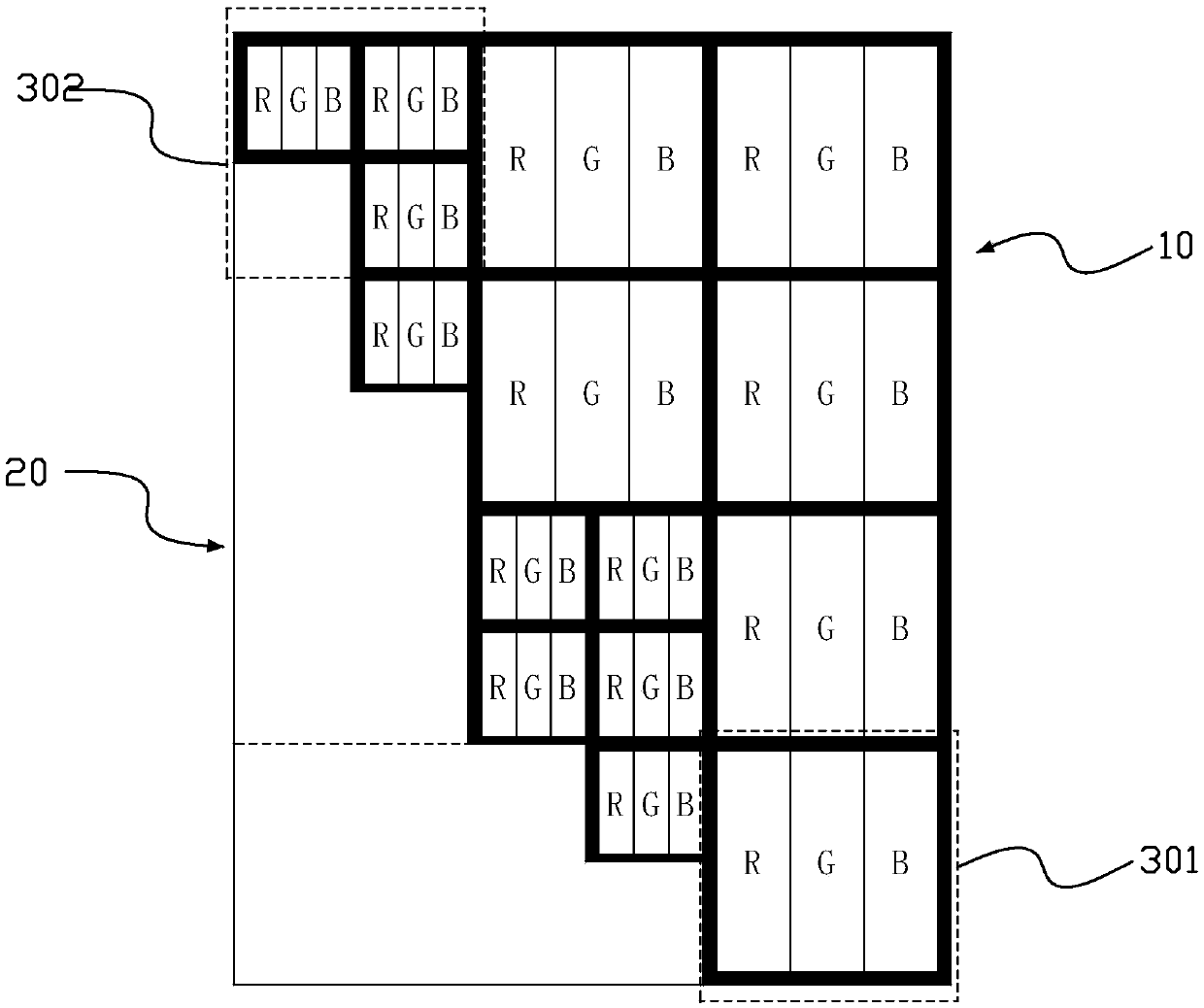

[0033] image 3 is a partial plan view of the liquid crystal display panel in the first embodiment of the present invention, Figure 4 is a schematic diagram of a partial structure on the first substrate in the first embodiment of the present invention, Figure 5 It is a schematic diagram of a partial structure on the second substrate in the first implementation of the present invention. Please refer to Figure 3 to Figure 5 The liquid crystal display panel provided by this embodiment has a display area 10 and a non-display area 20, the non-display area 20 surrounds the display area 10, and the liquid crystal display panel includes a first substrate 30 and a second substrate 40 opposite to the first substrate 30 , the first substrate 30 is provided with a plurality of central pixel units 301 located in the middle of the display area 10 and a plurality of edge pixel units 302 located between the central pixel unit 301 and the non-display area 20, and each central pixel unit 3...

no. 2 example

[0041] Figure 9 is a schematic diagram of a partial structure on the first substrate in the second embodiment of the present invention, Figure 10 for Figure 9 A cross-sectional view along the A-A direction, Figure 11 for Image 6 The cross-sectional view along the B-B direction. Please combine Figure 9 to Figure 11 The difference between this embodiment and the first embodiment is that along the direction toward the second substrate 40, the first substrate 30 is sequentially provided with a common electrode 35, a metal conducting line 31 and an edge pixel electrode 36b, that is, an edge pixel electrode 36b is provided above the common electrode 35 .

[0042] Specifically, combine Figure 10 , along the direction toward the second substrate 40, the first substrate 30 is sequentially provided with a gate insulating layer 306, a data line 34, a first insulating layer 303, a common electrode 35, a second insulating layer 304, and a metal conducting line 31 , the third ...

no. 3 example

[0045] Figure 12 is a schematic diagram of a partial structure on the first substrate in the third embodiment of the present invention, Figure 13 for Figure 12 The cross-sectional view along the direction A-A. Please combine Figure 12 with Figure 13 The difference between this embodiment and the second embodiment is that, along the direction toward the second substrate 40, the first substrate 30 is sequentially provided with metal conduction lines 31, data lines 34, common electrodes 35 and edge pixel electrodes 36b, And each edge pixel electrode 36 b is individually connected to one switching element 37 .

[0046] Specifically, combine Figure 13 , along the direction toward the second substrate 40, the first substrate 30 is sequentially provided with a metal conducting line 31, a gate insulating layer 306, a data line 34, a first insulating layer 303, a common electrode 35, and a second insulating layer 304 and edge pixel electrodes 36b. The scanning lines 33 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com