Optical lens back focus adjusting device

A technology of optical lens and adjustment device, which is applied in TV, color TV parts, electrical components, etc. It can solve the problems of blurred image, affecting imaging effect, unclear focus, etc., and achieve the effect of accurate focus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

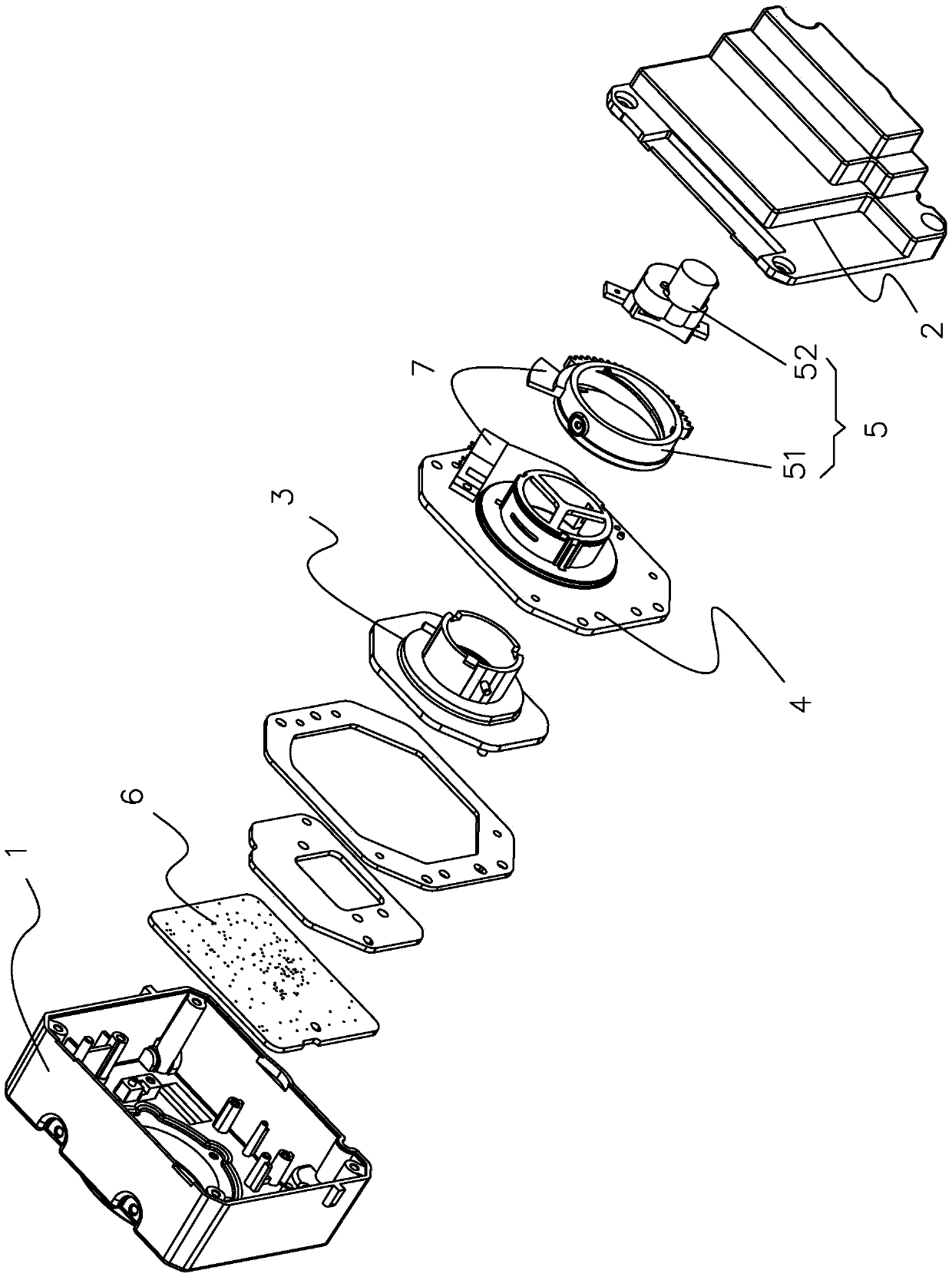

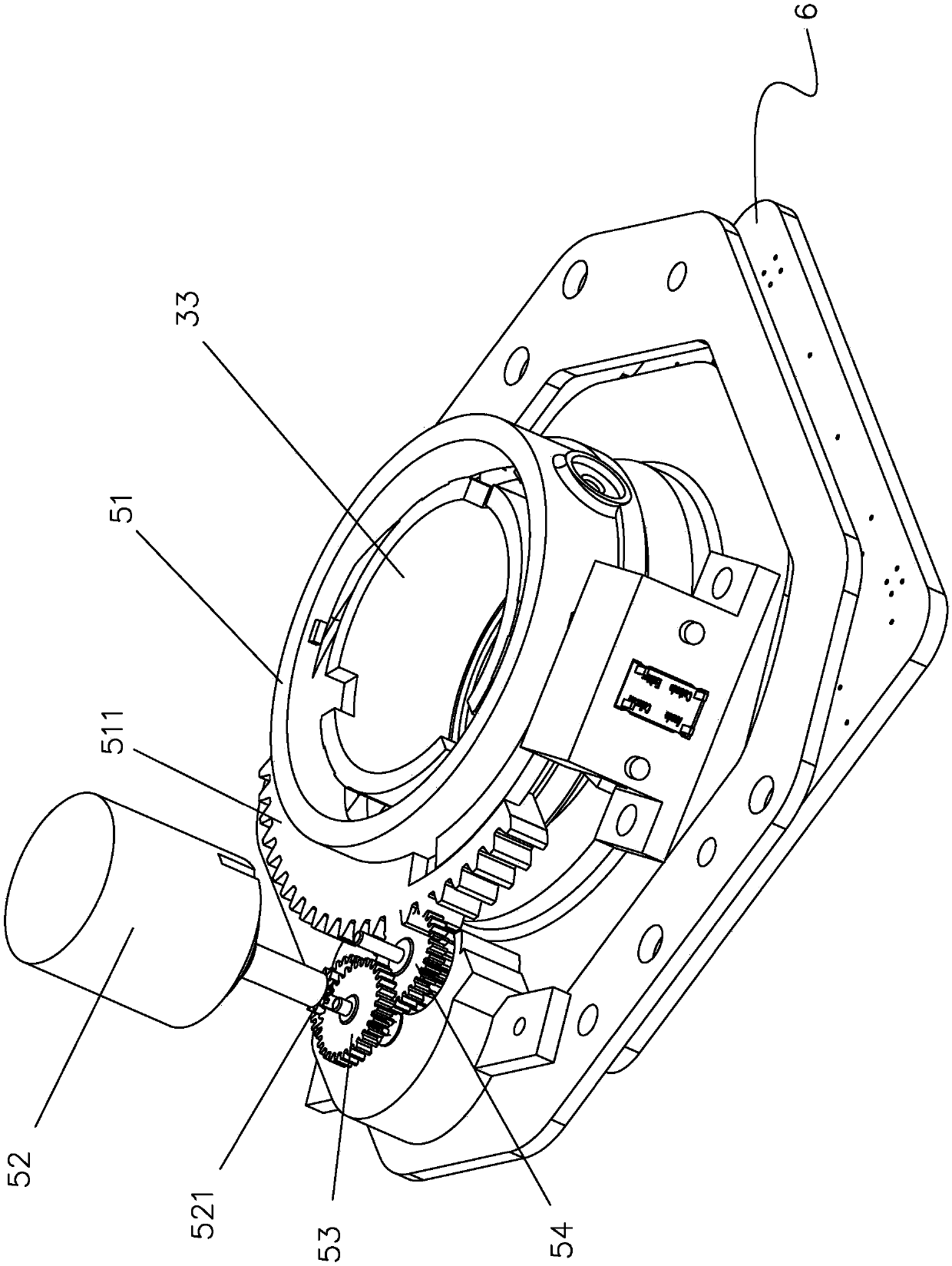

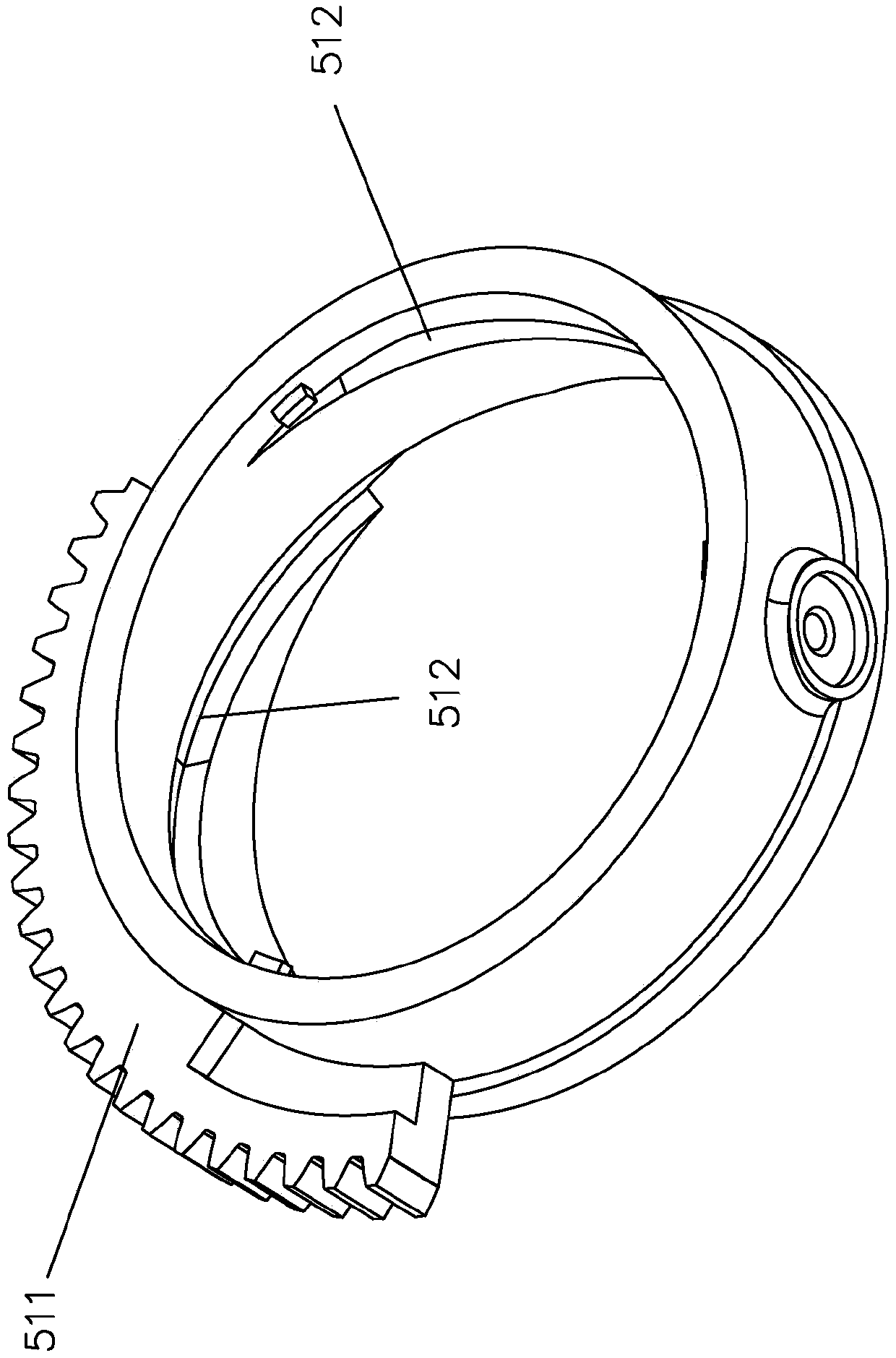

[0023] A kind of optical lens back focus adjustment device, comprises front cover 1, back cover 2 and is arranged in sequence from front to back between front cover 1 and back cover 2 moving part 3, guide cylinder 4 and driving device 5, front cover 1 The front portion is provided with a light-through hole 10, and the circumferential edge of the light-through hole 10 is provided with a mounting ring 11 that is socketed with the rear end of the optical lens, and the front end of the moving part 3 is provided with a CCD chip module 6 and the moving part 3 can The relative guide cylinder 4 moves forward and backward, and the driving device 5 includes a rotating sleeve 51 and a DC motor 52. The rotating sleeve 51 is sleeved on the guide cylinder 4 and is used to drive the rotating sleeve 51 of the moving part 3 to move back and forth. The output end of the DC motor 52 is provided with There is a gear 521 , and a rack 511 is provided on the circumferential outer side of the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com