Especially for actuating devices of friction clutches

A technology of manipulating devices and friction devices, applied in the direction of friction clutches, clutches, fluid-driven clutches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

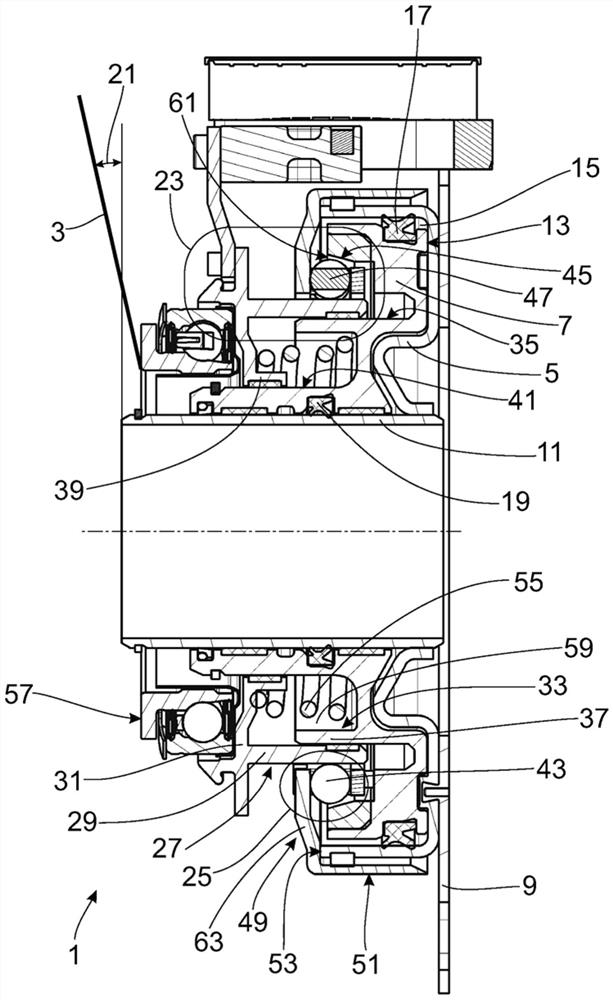

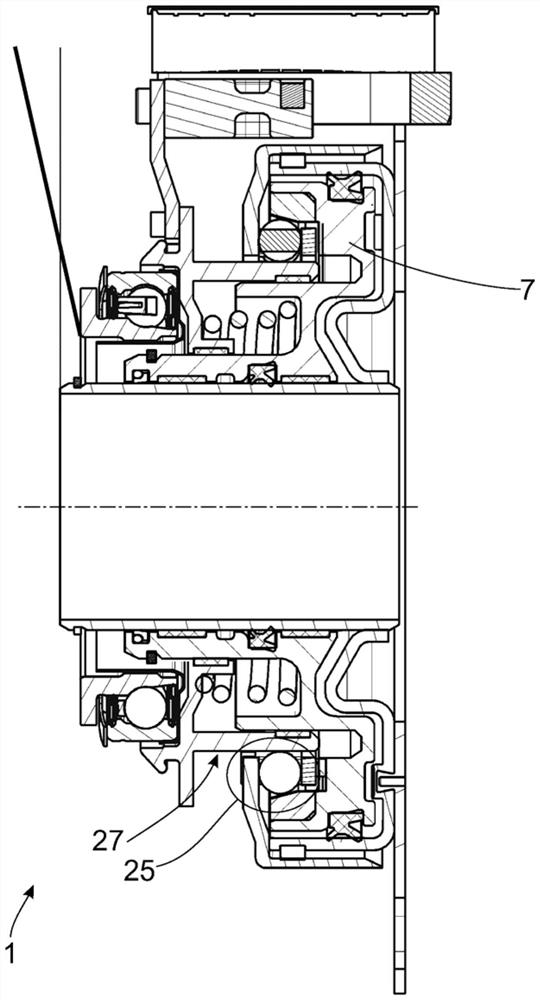

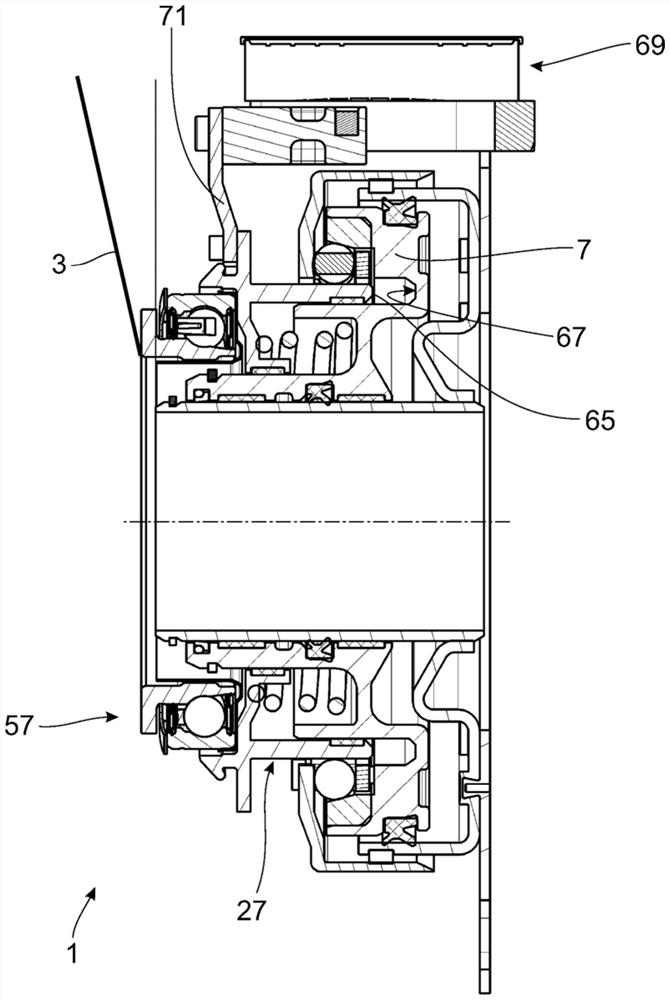

[0045] figure 1 The illustration is limited to an actuating device 1 for a friction clutch in a drive train. The specific structure of the friction clutch is not critical to the invention. For a friction clutch, an actuating lever 3 is shown symbolically, such as a reed like a diaphragm spring known per se.

[0046]The actuating device 1 comprises a working cylinder 5 in which a piston 7 is guided axially displaceably. The working cylinder 5 is secured in a positionally defined manner inside a clutch bell (not shown) via a preferably riveted support plate 9 . A bearing sleeve 11 on which the piston 7 slides is fastened coaxially with respect to the working cylinder 5 . The working cylinder 5 , the rear surface 13 of the piston 7 and the bearing sleeve 11 delimit a working chamber 15 which can optionally be filled with a gaseous or hydraulic pressure medium. Seals 17 , 19 prevent pressure medium from escaping at the inner and outer side surfaces of piston 7 . For the sake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com