Friction element for transmission

A friction element and transmission technology, applied in the field of friction elements, can solve problems such as insufficient improvement of shifting feeling, and achieve the effect of improving shifting feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following description is merely exemplary in nature, and is not intended to limit the present invention, application, or use. It should be understood that throughout the specification and drawings, corresponding reference numerals indicate the same or corresponding parts and features.

[0025] In one form of the present invention, a friction element for a transmission may include a multi-disc disc pack 1 and a continuous fastening device.

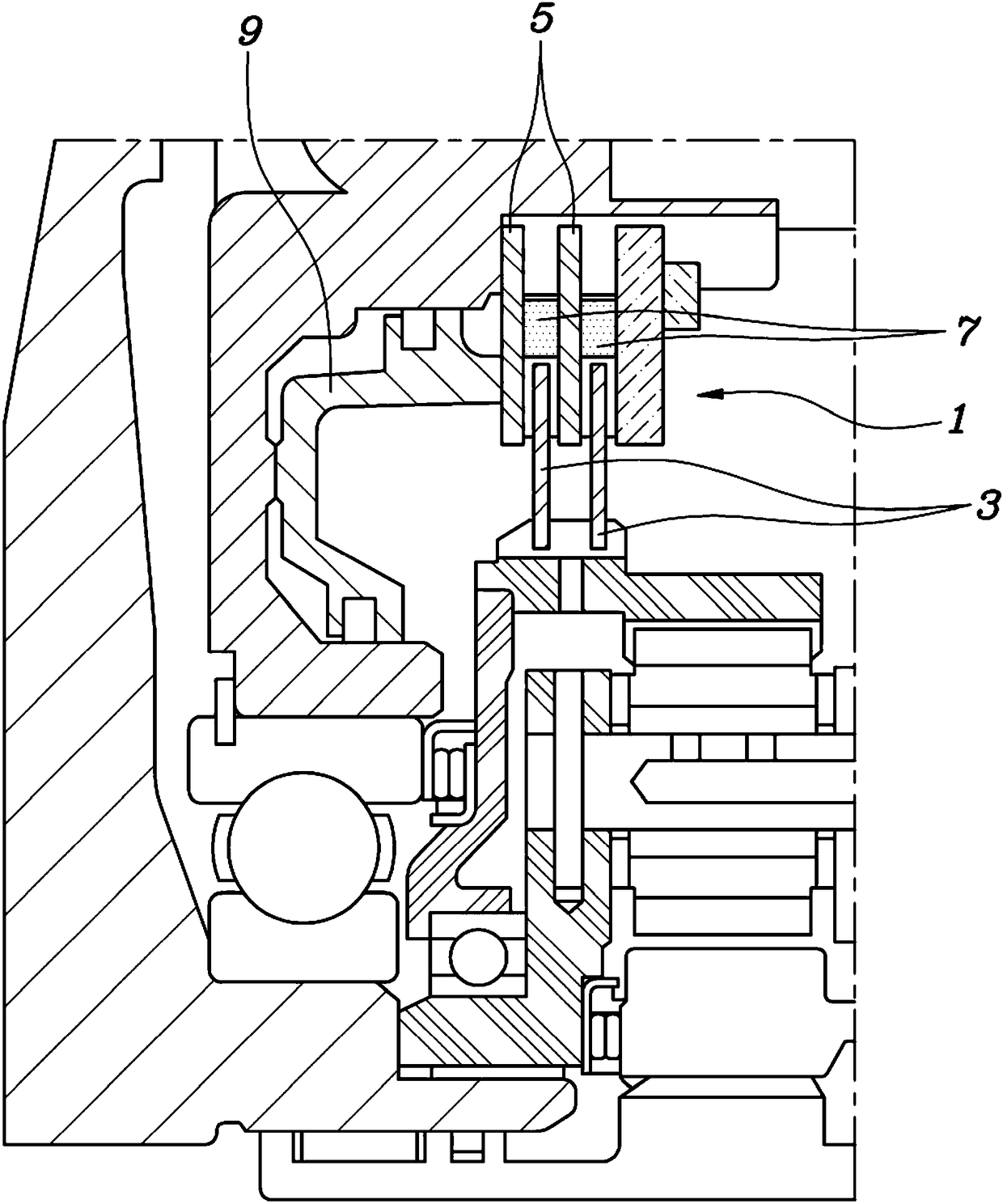

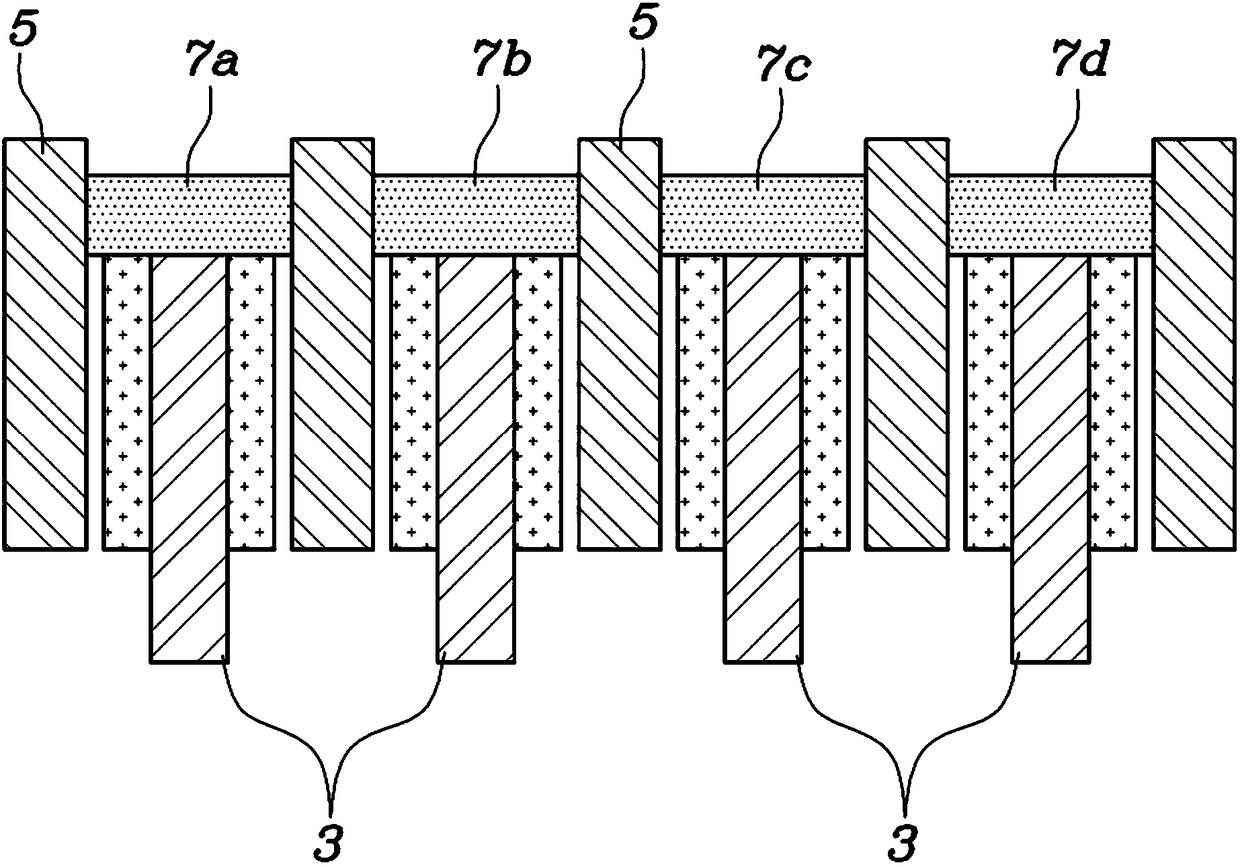

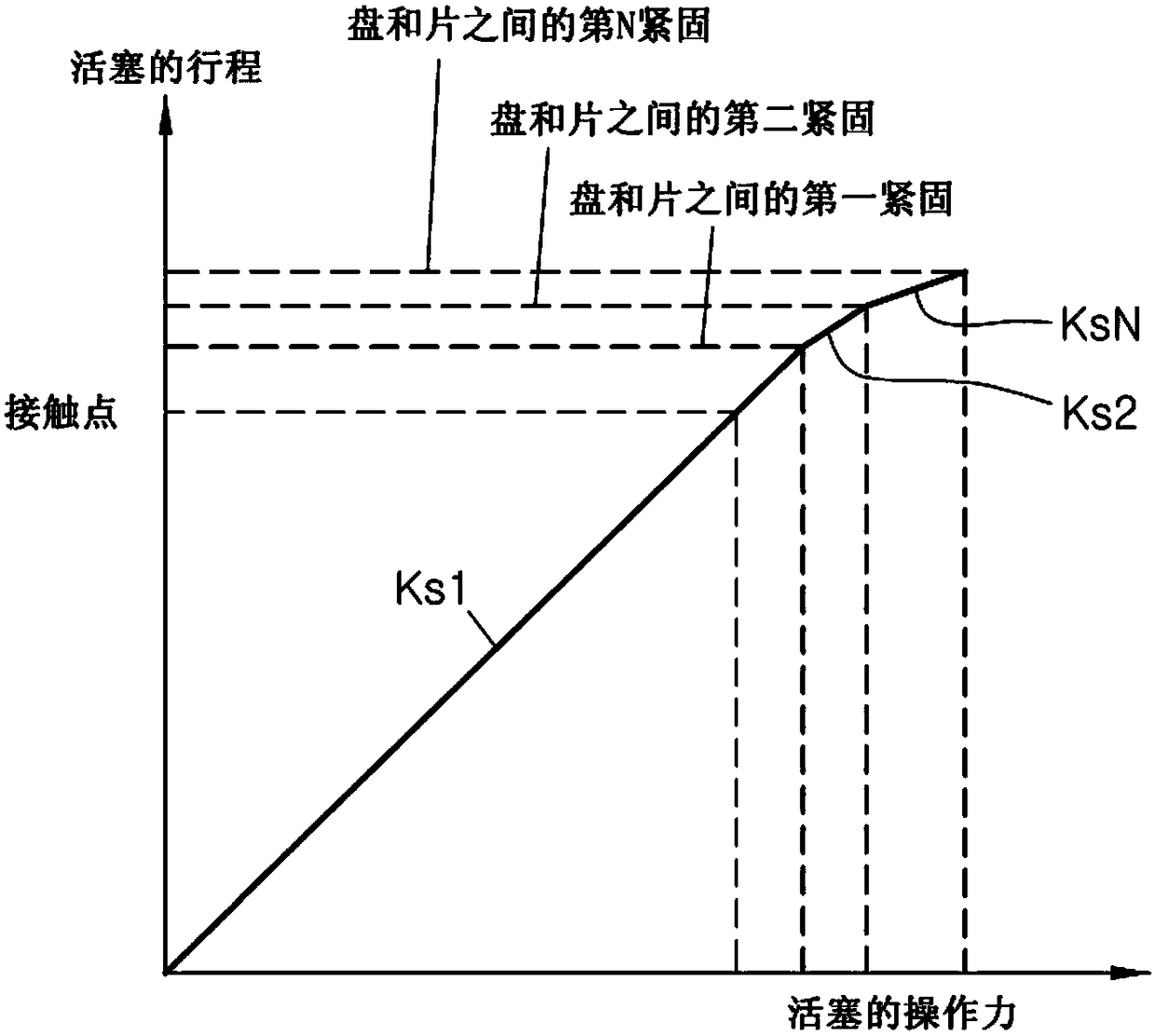

[0026] See figure 1 with figure 2 First, the multi-disc group 1 is formed to change the friction between the plurality of discs 3 and the plurality of discs 5 based on the operation of the piston 9. For example, the multi-disc group 1 may be a clutch or a brake provided as a friction element in an automatic transmission.

[0027] The continuous fastening device of the present invention may be configured to sequentially fasten the disc 3 and the sheet 5 according to the operation of the piston 9.

[0028] In one form, the continuous fas...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap