Synchronizing ring for transmission with increased capacity and manufacturing method thereof

A technology of increasing capacity and synchronizing rings, which is applied to vehicle gearboxes, clutches, metal processing equipment, etc., can solve problems such as rising costs, unstable functions, and inconvenient manufacturing processes, so as to improve the sense of shifting, solve incongruous problems, The effect of large capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and an embodiment.

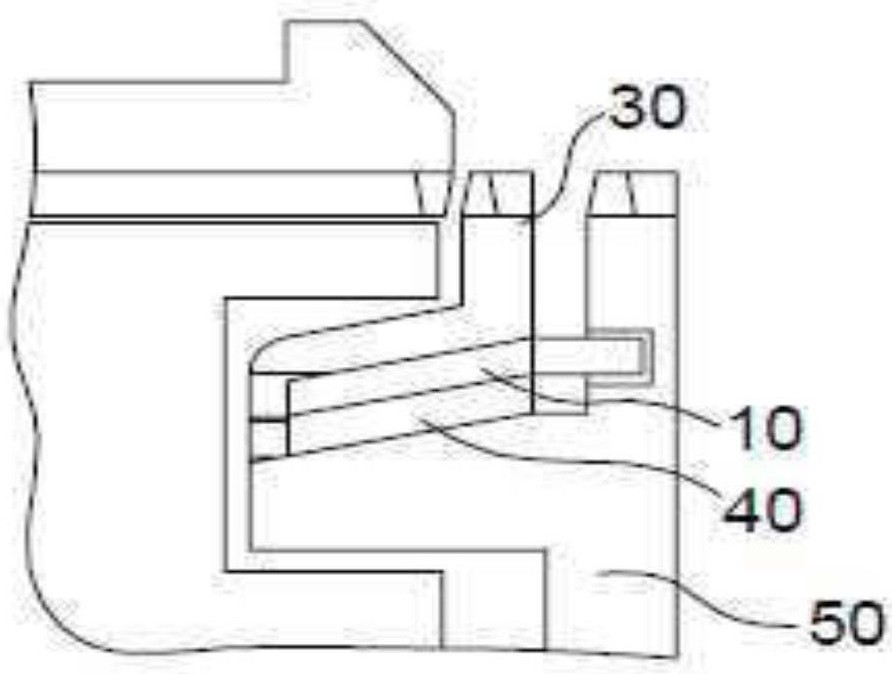

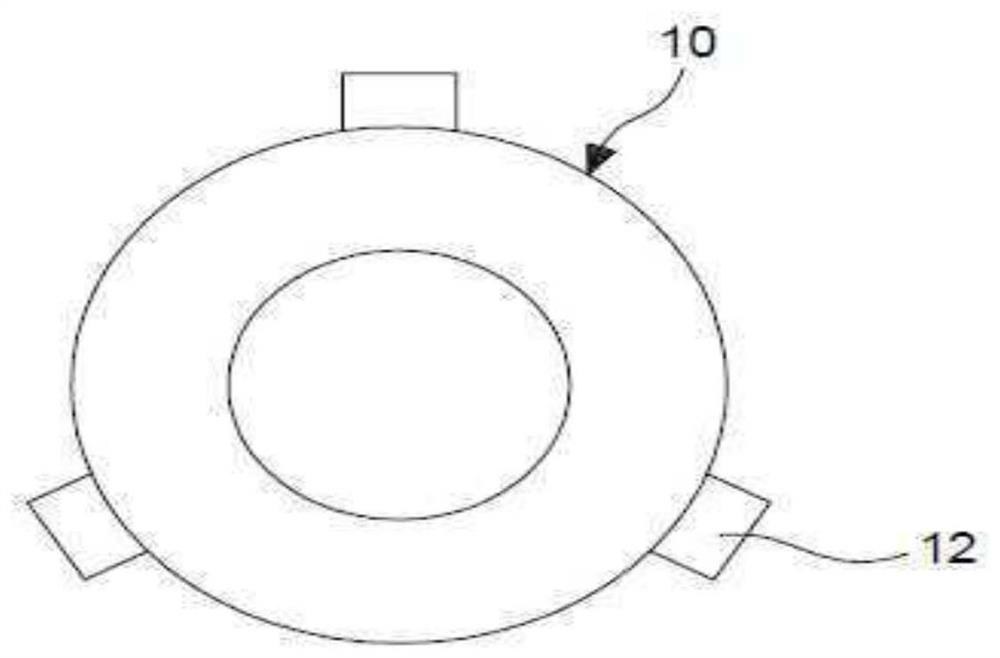

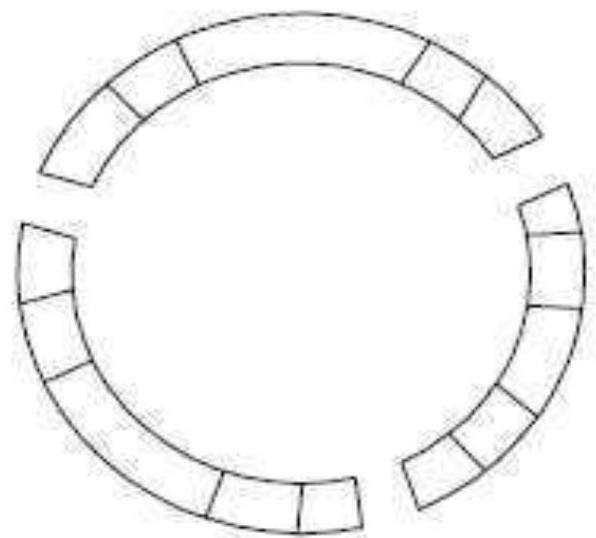

[0043] Such as Figure 5 to Figure 8 As shown, the structure of the present invention is that the synchronous ring 100 is formed in a single structure, and the outer side of the synchronous ring 100 is formed with a plurality of cutouts 110 and the inner side is formed with a plurality of protrusions 120 .

[0044] According to a preferred embodiment of the present invention, the synchronous ring 100 is formed by cutting and bending an iron plate having the same thickness. Therefore, the cutting ring 200 can be easily manufactured by bending the cutting ring 200 after simply manufacturing the ring by pressing an iron plate.

[0045] According to the present invention, the iron plate used to manufacture the cutting ring 200 has a thickness of 0.5 to 4 mm, more preferably, is made of an iron plate having a thickness of 1 to 2 mm.

[0046] According ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com