Steam heater assembly

A technology of steam heaters and heaters, applied in the direction of steam/steam condensers, heat exchanger types, indirect heat exchangers, etc., can solve the problems of difficult detection of leaks, large number of straight pipes, and large dimensions, and achieve The effect of compact structure, saving steam, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

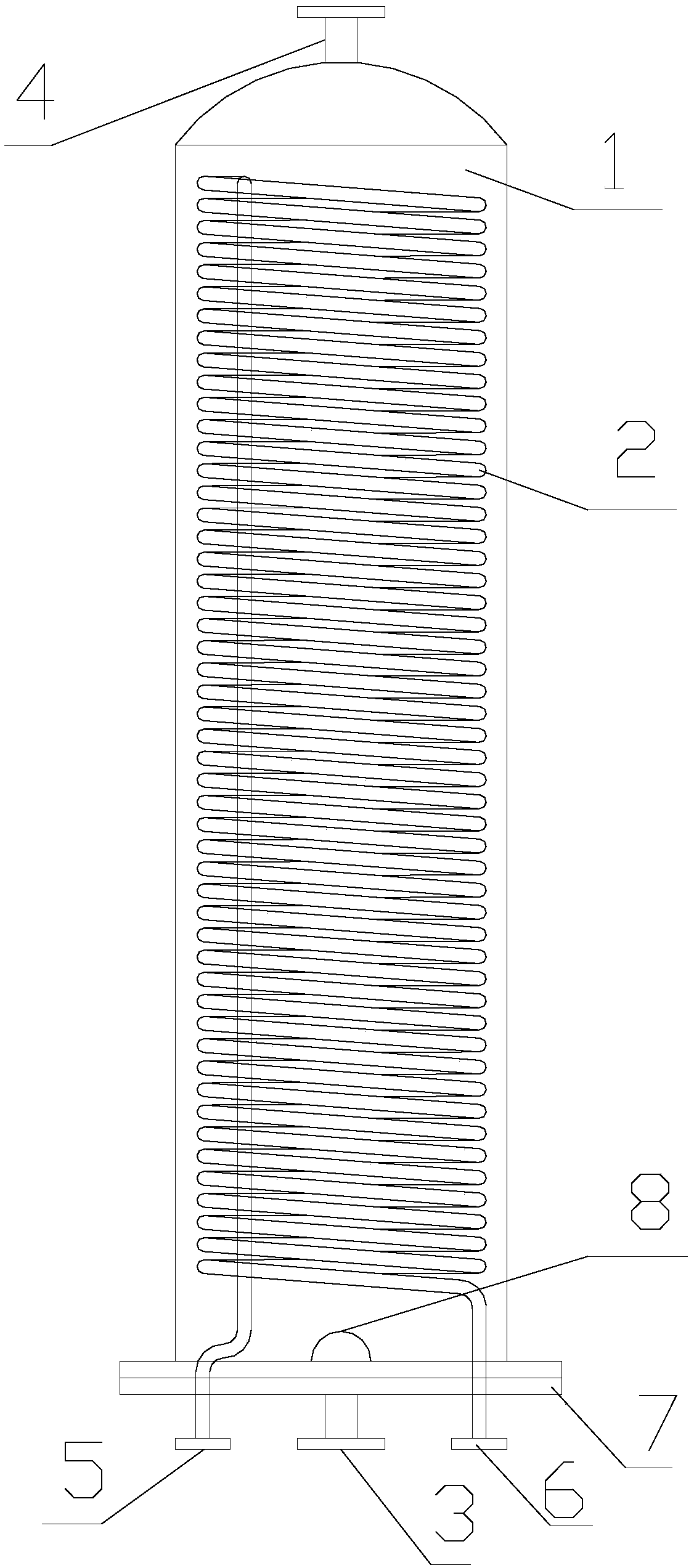

[0021] Such as figure 1 The shown steam heater assembly includes a stainless steel cylinder 1, and at least one set of heaters 2 are arranged inside the stainless steel cylinder 1, and the heater 2 is helical, and the cylinder 1 is provided with a A brine inlet 3 and a desalinated water outlet 4, the desalinated water inlet 3 is set at the bottom of the cylinder 1, and the desalinated water outlet 4 is set at the top of the cylinder 1. The heater 2 is provided with a steam inlet 5 and a steam outlet 6 , and the steam inlet 5 and the steam outlet 6 are arranged at the same end of the heater 2 . The top of the desalinated water inlet 3 is provided with a water diversion cover 8, and a number of through holes are evenly distributed on the water diversion cover 8 to prevent the generation of water columns when the desalinated water enters the water, which is not easy to distribute. By adding the water diversion cover 8, the water is dispersed Open, evenly distributed upstream.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com